Ditch Witch JT920 User manual

JT920/JT920L - SERVICE 1

SERIAL NUMBER

JT920/JT920L - SERVICE 1

SERIAL NUMBER

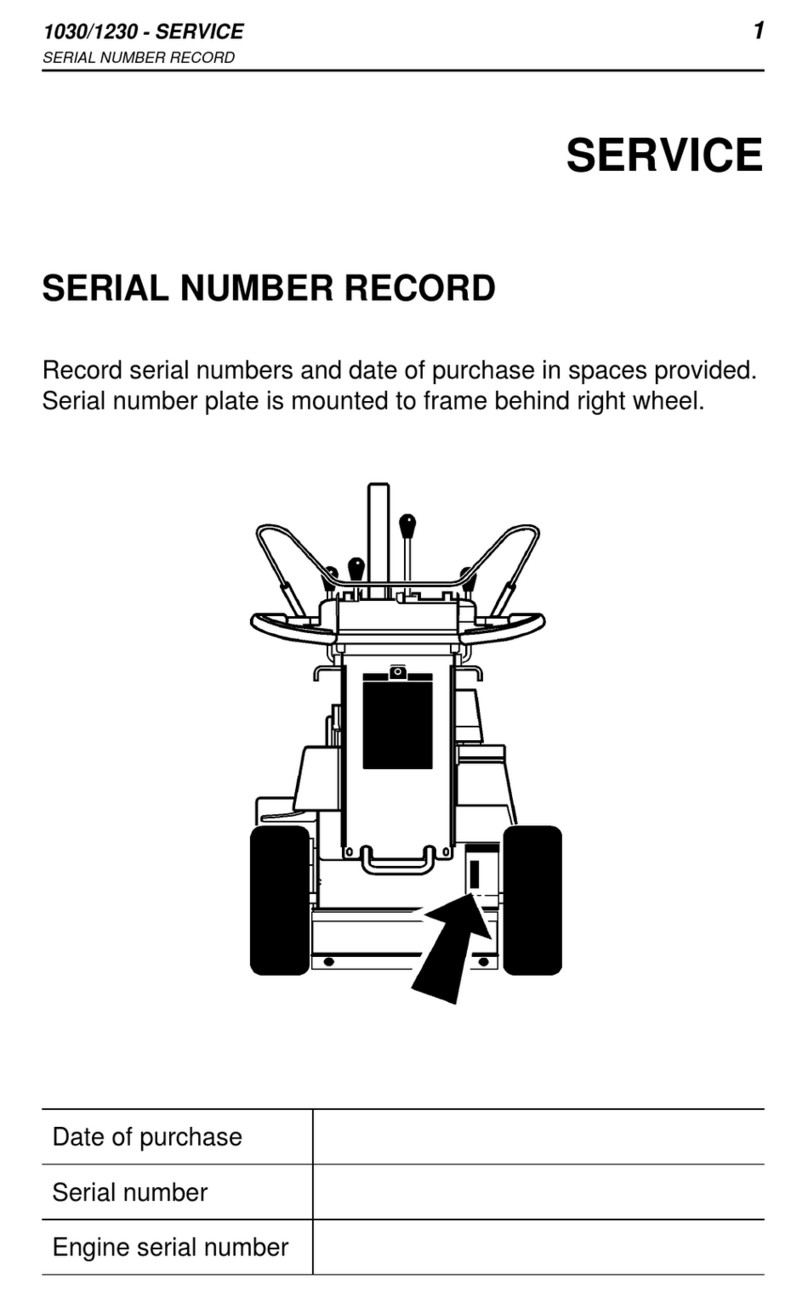

SERVICE

SERIAL NUMBER

Record the serial numbers and date of

purchase of your equipment in the

spaces below.

Date of Manufacture:

Date of Purchase:

Drilling Unit Serial Number:

om0115c.eps

SERVICE

SERIAL NUMBER

Record the serial numbers and date of

purchase of your equipment in the

spaces below.

Date of Manufacture:

Date of Purchase:

Drilling Unit Serial Number:

om0115c.eps

2JT920/JT920L - SERVICE

SUPPORT PROCEDURE 2JT920/JT920L - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of your

equipment purchase. This information should be recorded and

placed on file by the owner at the time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration if in warranty time frame.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty consideration.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications and videos

covering safety, operation, service, and repair of your equipment.

Ditch Witch Training Center

For information about on-site, individualized training, contact your

Ditch Witch dealer.

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of your

equipment purchase. This information should be recorded and

placed on file by the owner at the time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration if in warranty time frame.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty consideration.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications and videos

covering safety, operation, service, and repair of your equipment.

Ditch Witch Training Center

For information about on-site, individualized training, contact your

Ditch Witch dealer.

JT920/JT920L - FOREWORD 3

JT920/JT920L - FOREWORD 3

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have

taken place after this manual was published. For the latest

information on Ditch Witch equipment, see your Ditch Witch

dealer.

Thank you for buying and using Ditch Witch equipment.

FOREWORD

This manual is an important part of your equipment. It provides

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have

taken place after this manual was published. For the latest

information on Ditch Witch equipment, see your Ditch Witch

dealer.

Thank you for buying and using Ditch Witch equipment.

4JT920/JT920L - FOREWORD 4JT920/JT920L - FOREWORD

Operator's Manual

JT920/JT920L

Issue No.6.0/OP-4/11

Part Number 054-509

Copyright 1996, 1997, 1998, 2001, 2002, 2004

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, CMW, AutoCrowd,

Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, Perma-

Soil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The

Underground, and The Underground Authority Worldwide are

registered trademarks of The Charles Machine Works, Inc.

This product is covered by one or more of the following patents:

U.S. B1 4,858,704; 4,953,638; 5,148,880; 5,242,026; 5,341,887; 5,490,569;

5,544,712; 5,546,833; 5,682,956; 5,684,466; 5,713,423; 5,794,719; 5,880,680;

5,941,322; 6,085,852; 6,109,371; 6,179,065; 6,216,803; 6,250,403; 6,250,404;

6,290,606; 6,311,790; 6,411,094; 6,543,551; 6,550,547; RE37,450; RE37,450;

RE37,923; RE37,975; Germany 694 17 019; 695 26 634; France 683,845;

674,093; Australia 684,595; 689,533; 718,034; 706,544; 755,862; UK 2,309,239;

2,312,006; EP683,845; EP674,093 ; other U.S. and foreign patents pending.

Operator's Manual

JT920/JT920L

Issue No.6.0/OP-4/11

Part Number 054-509

Copyright 1996, 1997, 1998, 2001, 2002, 2004

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, CMW, AutoCrowd,

Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, Perma-

Soil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The

Underground, and The Underground Authority Worldwide are

registered trademarks of The Charles Machine Works, Inc.

This product is covered by one or more of the following patents:

U.S. B1 4,858,704; 4,953,638; 5,148,880; 5,242,026; 5,341,887; 5,490,569;

5,544,712; 5,546,833; 5,682,956; 5,684,466; 5,713,423; 5,794,719; 5,880,680;

5,941,322; 6,085,852; 6,109,371; 6,179,065; 6,216,803; 6,250,403; 6,250,404;

6,290,606; 6,311,790; 6,411,094; 6,543,551; 6,550,547; RE37,450; RE37,450;

RE37,923; RE37,975; Germany 694 17 019; 695 26 634; France 683,845;

674,093; Australia 684,595; 689,533; 718,034; 706,544; 755,862; UK 2,309,239;

2,312,006; EP683,845; EP674,093 ; other U.S. and foreign patents pending.

JT920/JT920L - CONTENTS 5

JT920/JT920L - CONTENTS 5

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Setup Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Gauges and Indicators . . . . . . . . . . . . . . . . . . . . . . . .22

Anchoring System Console . . . . . . . . . . . . . . . . . . . .26

ESID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Subsite 950 Display . . . . . . . . . . . . . . . . . . . . . . . . . .32

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Underground Hazards . . . . . . . . . . . . . . . . . . . . . . . .40

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . .41

Jobsite Classification . . . . . . . . . . . . . . . . . . . . . . . . .44

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . .48

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setup Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gauges and Indicators . . . . . . . . . . . . . . . . . . . . . . . . 22

Anchoring System Console . . . . . . . . . . . . . . . . . . . . 26

ESID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Subsite 950 Display . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Underground Hazards . . . . . . . . . . . . . . . . . . . . . . . . 40

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . . 41

Jobsite Classification . . . . . . . . . . . . . . . . . . . . . . . . . 44

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . 48

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6JT920/JT920L - CONTENTS 6JT920/JT920L - CONTENTS

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Inspect Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Plan Bore Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Check Supplies and Prepare Equipment . . . . . . . . . . 64

Prepare Jobsite. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Record Bore Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tiedown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Tow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Assemble Electric Strike System . . . . . . . . . . . . . . . . 78

Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Assemble Drill String . . . . . . . . . . . . . . . . . . . . . . . . . 81

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Gather Information . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Inspect Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Plan Bore Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Check Supplies and Prepare Equipment . . . . . . . . . 64

Prepare Jobsite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Record Bore Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tiedown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Tow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Assemble Electric Strike System . . . . . . . . . . . . . . . . 78

Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Assemble Drill String . . . . . . . . . . . . . . . . . . . . . . . . . 81

JT920/JT920L - CONTENTS 7

JT920/JT920L - CONTENTS 7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Operate Thrust/rotation Control . . . . . . . . . . . . . . . . .88

Drill First Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Add Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Remove/Add Pipe Box . . . . . . . . . . . . . . . . . . . . . . . .96

Correct Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Surface Drill Head. . . . . . . . . . . . . . . . . . . . . . . . . . .100

Assemble Backream String . . . . . . . . . . . . . . . . . . .101

Remove Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Remove Pullback Device . . . . . . . . . . . . . . . . . . . . .114

Troubleshoot Automation . . . . . . . . . . . . . . . . . . . . .115

BREAKDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Remove Anchors. . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Rinse Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Stow Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Drilling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Drilling Fluid Pump . . . . . . . . . . . . . . . . . . . . . . . . . .127

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Operate Thrust/rotation Control . . . . . . . . . . . . . . . . . 88

Drill First Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Add Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Remove/Add Pipe Box . . . . . . . . . . . . . . . . . . . . . . . . 96

Correct Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Surface Drill Head . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Assemble Backream String . . . . . . . . . . . . . . . . . . . 101

Remove Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Remove Pullback Device . . . . . . . . . . . . . . . . . . . . . 114

Troubleshoot Automation . . . . . . . . . . . . . . . . . . . . 115

BREAKDOWN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Remove Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Rinse Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Stow Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Drilling Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Drilling Fluid Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8JT920/JT920L - CONTENTS 8JT920/JT920L - CONTENTS

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

General Components . . . . . . . . . . . . . . . . . . . . . . . . 130

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Power Components . . . . . . . . . . . . . . . . . . . . . . . . . 136

Pipeloader Automation . . . . . . . . . . . . . . . . . . . . . . . 138

Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Troubleshoot Strike System . . . . . . . . . . . . . . . . . . . 141

Use Electric Strike Simulator . . . . . . . . . . . . . . . . . . 143

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

JT920 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

JT920L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

A. Bend Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B. Entry Pitch, Setback, and Depth . . . . . . . . . . . . . 158

C. Drilling Fluid Requirements . . . . . . . . . . . . . . . . . 156

D. Nozzle Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

General Components. . . . . . . . . . . . . . . . . . . . . . . . 130

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Power Components . . . . . . . . . . . . . . . . . . . . . . . . . 136

Pipeloader Automation. . . . . . . . . . . . . . . . . . . . . . . 138

Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Troubleshoot Strike System. . . . . . . . . . . . . . . . . . . 141

Use Electric Strike Simulator . . . . . . . . . . . . . . . . . . 143

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

JT920 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

JT920L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

A. Bend Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

B. Entry Pitch, Setback, and Depth . . . . . . . . . . . . . 158

C. Drilling Fluid Requirements . . . . . . . . . . . . . . . . . 156

D. Nozzle Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

JT920/JT920L - OVERVIEW 9

JT920/JT920L - OVERVIEW 9

OVERVIEW

The JT920 directional drilling unit can be connected to a fluid unit

by only one electric line and one fluid hose, or it can have an

optional drilling fluid tank mounted directly on the drilling unit.

The JT920 features rubber tracks, simple, precise controls and

gauges, and an onboard drilling fluid system. Options include

fluid tank, anchoring systems, and remote fluid systems.

Although the JT920 directional drilling unit was designed to

provide one-unit drilling, it is compatible with Ditch Witch drilling

fluid units. Downhole tools are compatible with Subsite beacons.

1. Operator station 7. Rear stabilizer

2. Spindle 8. Tracks

3. Carriage 9. Frame

4. Drilling fluid tank 10. Drill pipe box

5. Set-up/drive controls 11. Front wrench

6. Drilling fluid pump 12. Stake mount plate

12345

678910

1112

om2098a.eps

OVERVIEW

The JT920 directional drilling unit can be connected to a fluid unit

by only one electric line and one fluid hose, or it can have an

optional drilling fluid tank mounted directly on the drilling unit.

The JT920 features rubber tracks, simple, precise controls and

gauges, and an onboard drilling fluid system. Options include

fluid tank, anchoring systems, and remote fluid systems.

Although the JT920 directional drilling unit was designed to

provide one-unit drilling, it is compatible with Ditch Witch drilling

fluid units. Downhole tools are compatible with Subsite beacons.

1. Operator station 7. Rear stabilizer

2. Spindle 8. Tracks

3. Carriage 9. Frame

4. Drilling fluid tank 10. Drill pipe box

5. Set-up/drive controls 11. Front wrench

6. Drilling fluid pump 12. Stake mount plate

12345

678910

1112

om2098a.eps

10 JT920/JT920L - OVERVIEW 10 JT920/JT920L - OVERVIEW

The JT920L directional drilling unit is a self-contained unit that

can be connected to a fluid unit with only one electric line and one

fluid hose.

The JT920L features rubber tracks, genuine Ditch Witch pipe, a

pipe loader and pipe box, onboard anchoring system, onboard

fluid system, cold start kit, and simple, precise controls. Optional

equipment includes a Subsite 750 Display that can be mounted

beside the control console.

The JT920L directional drilling unit can be used with Ditch Witch

drilling fluid units and Subsite locating equipment.

1. Operator station 8. Tracks

2. Spindle 9. Frame

3. Carriage 10. Drill pipe box

4. Water tank 11. Front wrench

5. Set-up/drive controls 12. Anchoring system

6. Drilling fluid pump 13. Anchoring controls

7. Rear stabilizer

1

345

6789101112

13

2

om0109c.eps

The JT920L directional drilling unit is a self-contained unit that

can be connected to a fluid unit with only one electric line and one

fluid hose.

The JT920L features rubber tracks, genuine Ditch Witch pipe, a

pipe loader and pipe box, onboard anchoring system, onboard

fluid system, cold start kit, and simple, precise controls. Optional

equipment includes a Subsite 750 Display that can be mounted

beside the control console.

The JT920L directional drilling unit can be used with Ditch Witch

drilling fluid units and Subsite locating equipment.

1. Operator station 8. Tracks

2. Spindle 9. Frame

3. Carriage 10. Drill pipe box

4. Water tank 11. Front wrench

5. Set-up/drive controls 12. Anchoring system

6. Drilling fluid pump 13. Anchoring controls

7. Rear stabilizer

1

345

6789101112

13

2

om0109c.eps

JT920/JT920L - CONTROLS 11

SETUP CONSOLE OVERVIEW

JT920/JT920L - CONTROLS 11

SETUP CONSOLE OVERVIEW

CONTROLS

SETUP CONSOLE OVERVIEW

1. Throttle switch

2. Track width control (JT920 only)

3. Stabilizer lift control

4. Frame tilt control

5. Left track control

6. Right track control

7. Autobore select switch

8. Ignition switch

9. Cold start switch

om2094a.eps

CONTROLS

SETUP CONSOLE OVERVIEW

1. Throttle switch

2. Track width control (JT920 only)

3. Stabilizer lift control

4. Frame tilt control

5. Left track control

6. Right track control

7. Autobore select switch

8. Ignition switch

9. Cold start switch

om2094a.eps

12 JT920/JT920L - CONTROLS

SETUP CONSOLE OVERVIEW 12 JT920/JT920L - CONTROLS

SETUP CONSOLE OVERVIEW

SETUP CONSOLE DESCRIPTIONS

Throttle Switch

This switch controls engine speed

during drilling and backreaming.

• Press top to increase speed.

• Press bottom to decrease

speed.

• Return switch to center position

to maintain selected speed.

Track Width Control

(JT920 only)

This lever controls track width by

moving left track toward or away

from right track.

IMPORTANT: Lower drill frame

and rear stabilizer to raise tracks

off ground before adjusting track.

• Push to move left track out.

• Pull to move left track in.

Stabilizer Lift Control

This lever controls rear stabilizer.

• Push to lower.

• Pull to raise.

ic0136h.eps

ic1064x.eps

ic0054c.eps

SETUP CONSOLE DESCRIPTIONS

Throttle Switch

This switch controls engine speed

during drilling and backreaming.

• Press top to increase speed.

• Press bottom to decrease

speed.

• Return switch to center position

to maintain selected speed.

Track Width Control

(JT920 only)

This lever controls track width by

moving left track toward or away

from right track.

IMPORTANT: Lower drill frame

and rear stabilizer to raise tracks

off ground before adjusting track.

• Push to move left track out.

• Pull to move left track in.

Stabilizer Lift Control

This lever controls rear stabilizer.

• Push to lower.

• Pull to raise.

ic0136h.eps

ic1064x.eps

ic0054c.eps

JT920/JT920L - CONTROLS 13

SETUP CONSOLE OVERVIEW

JT920/JT920L - CONTROLS 13

SETUP CONSOLE OVERVIEW

Frame Tilt Control

This lever raises or lowers drill

frame.

• Push to lower.

• Pull to raise.

Left Track Control

This lever controls speed and

direction of left track.

• Push to move forward.

• Pull to move backward.

• Move to center to stop.

Right Track Control

This lever controls speed and

direction of right track.

• Push to move forward.

• Pull to move backward.

• Move to center to stop.

ic0056c.eps

ic0143h.eps

ic0142h.eps

Frame Tilt Control

This lever raises or lowers drill

frame.

• Push to lower.

• Pull to raise.

Left Track Control

This lever controls speed and

direction of left track.

• Push to move forward.

• Pull to move backward.

• Move to center to stop.

Right Track Control

This lever controls speed and

direction of right track.

• Push to move forward.

• Pull to move backward.

• Move to center to stop.

ic0056c.eps

ic0143h.eps

ic0142h.eps

14 JT920/JT920L - CONTROLS

SETUP CONSOLE OVERVIEW 14 JT920/JT920L - CONTROLS

SETUP CONSOLE OVERVIEW

Autobore Select Switch

This switch selects between

autobore and manual modes.

• Press top for autobore control.

• Press bottom for manual

control.

Ignition Switch

This switch has three positions.

• Insert key and turn all the way

clockwise to start engine.

• Release when engine starts.

• Key will return to on position.

Cold Start Switch

This optional switch helps start

cold engine.

• Turn key to on position.

• Press top of switch for 10-20

seconds.

• Start engine.

Autobore Select Switch

This switch selects between

autobore and manual modes.

• Press top for autobore control.

• Press bottom for manual

control.

Ignition Switch

This switch has three positions.

• Insert key and turn all the way

clockwise to start engine.

• Release when engine starts.

• Key will return to on position.

Cold Start Switch

This optional switch helps start

cold engine.

• Turn key to on position.

• Press top of switch for 10-20

seconds.

• Start engine.

JT920/JT920L - CONTROLS 15

DRILL OVERVIEW

JT920/JT920L - CONTROLS 15

DRILL OVERVIEW

DRILL OVERVIEW

1. Fluid pump switch

2. Spindle control

3. Pipe lift switch (JT920L only)

4. Pipe shuttle switch (JT920L only)

5. Pipe autoload selector (JT920L only)

6. Auxiliary wrench switch

7. Fluid source selector switch

8. Remote start switch

9. Throttle switch

10. Wrench control

11. Remote throttle switch

12. Remote engine stop switch

13. Fluid flow control

14. ESID *

15. Remote display mounting bracket

* called out later in chapter

13245678

10

9

11

12

131415

om0111c.eps

DRILL OVERVIEW

1. Fluid pump switch

2. Spindle control

3. Pipe lift switch (JT920L only)

4. Pipe shuttle switch (JT920L only)

5. Pipe autoload selector (JT920L only)

6. Auxiliary wrench switch

7. Fluid source selector switch

8. Remote start switch

9. Throttle switch

10. Wrench control

11. Remote throttle switch

12. Remote engine stop switch

13. Fluid flow control

14. ESID *

15. Remote display mounting bracket

* called out later in chapter

13245678

10

9

11

12

131415

om0111c.eps

16 JT920/JT920L - CONTROLS

DRILL OVERVIEW 16 JT920/JT920L - CONTROLS

DRILL OVERVIEW

DRILL DESCRIPTIONS

Fluid Pump Switch

This switch controls fluid pump.

• Press left to turn on.

• Move to center position to turn

off.

• Pressright for fullpumpflow to

fill pipe with fluid. Switch will

return to center when

released.

Spindle Control

This lever controls thrust direction

and rotation.

Pull or push to control thrust

direction.

• Pull to move backward.

• Push to move forward.

Move to right or left to control

rotation.

• Move right to rotate counterclockwise (breakout).

• Move left to rotate (makeup).

ic0059c.eps

DRILL DESCRIPTIONS

Fluid Pump Switch

This switch controls fluid pump.

• Press left to turn on.

• Move to center position to turn

off.

• Pressright for fullpumpflow to

fill pipe with fluid. Switch will

return to center when

released.

Spindle Control

This lever controls thrust direction

and rotation.

Pull or push to control thrust

direction.

• Pull to move backward.

• Push to move forward.

Move to right or left to control

rotation.

• Move right to rotate counterclockwise (breakout).

• Move left to rotate (makeup).

ic0059c.eps

JT920/JT920L - CONTROLS 17

DRILL OVERVIEW

JT920/JT920L - CONTROLS 17

DRILL OVERVIEW

Pipe Lift Switch

(JT920L only)

This switch raises and lowers all

rows in pipe box.

• Press top to lower.

• Press bottom to raise.

Pipe Shuttle Switch

(JT920L only)

This switch moves shuttle to and

from pipe box.

• Press top to move toward pipe

box.

• Press bottom to move away

from pipe box.

Pipe Autoload Selector

(JT920L only)

This switch selects pipe autoload

function.

• Press top when drilling.

• Press center to use manual

pipe loader controls.

• Press bottom when

backreaming.

ic1280a.eps

ic1328a.eps

Pipe Lift Switch

(JT920L only)

This switch raises and lowers all

rows in pipe box.

• Press top to lower.

• Press bottom to raise.

Pipe Shuttle Switch

(JT920L only)

This switch moves shuttle to and

from pipe box.

• Press top to move toward pipe

box.

• Press bottom to move away

from pipe box.

Pipe Autoload Selector

(JT920L only)

This switch selects pipe autoload

function.

• Press top when drilling.

• Press center to use manual

pipe loader controls.

• Press bottom when

backreaming.

ic1280a.eps

ic1328a.eps

18 JT920/JT920L - CONTROLS

DRILL OVERVIEW 18 JT920/JT920L - CONTROLS

DRILL OVERVIEW

Auxiliary Wrench Switch

This switch controls auxiliary

(back-up) breakout wrench.

• Press top to lock wrench onto

pipe flats.

• Press bottom to release pipe.

Fluid Source Selector Switch

This switch selects fluid source.

• Press top to use remote fluid

system.

• Press bottom to use on-board

fluid system.

Remote Start Switch

This button starts remote fluid unit

from drilling unit.

• Push switch.

• Release when engine starts.

This button only works when

ignition switch on fluid unit is on.

ic1327a.eps

ic0048c.eps

ic1272a.eps

Auxiliary Wrench Switch

This switch controls auxiliary

(back-up) breakout wrench.

• Press top to lock wrench onto

pipe flats.

• Press bottom to release pipe.

Fluid Source Selector Switch

This switch selects fluid source.

• Press top to use remote fluid

system.

• Press bottom to use on-board

fluid system.

Remote Start Switch

This button starts remote fluid unit

from drilling unit.

• Push switch.

• Release when engine starts.

This button only works when

ignition switch on fluid unit is on.

ic1327a.eps

ic0048c.eps

ic1272a.eps

JT920/JT920L - CONTROLS 19

DRILL OVERVIEW

JT920/JT920L - CONTROLS 19

DRILL OVERVIEW

Throttle Switch

This switch controls remote fluid

unit engine speed.

• Press top to run engine at

maximum speed.

• Press bottom to run engine at

idle speed.

This switch only works when fluid

unit throttle switch is in idle

position.

Wrench Control

This lever controls front wrench

(near pipe guide) and back wrench

(at spindle).

Pull or push lever to control back

wrench.

• Pull to release pipe.

• Push to lock onto pipe flats.

Move lever to right or left to control

front wrench.

• Move right to lock onto pipe flats.

• Move left to release pipe.

ic0050c.eps

ic1057c.eps

Throttle Switch

This switch controls remote fluid

unit engine speed.

• Press top to run engine at

maximum speed.

• Press bottom to run engine at

idle speed.

This switch only works when fluid

unit throttle switch is in idle

position.

Wrench Control

This lever controls front wrench

(near pipe guide) and back wrench

(at spindle).

Pull or push lever to control back

wrench.

• Pull to release pipe.

• Push to lock onto pipe flats.

Move lever to right or left to control

front wrench.

• Move right to lock onto pipe flats.

• Move left to release pipe.

ic0050c.eps

ic1057c.eps

20 JT920/JT920L - CONTROLS

DRILL OVERVIEW 20 JT920/JT920L - CONTROLS

DRILL OVERVIEW

Remote Throttle Switch

This switch controls engine speed

during drilling and backreaming.

• Press top to increase speed.

• Press bottom to decrease

speed.

This switch only works if throttle

switch is in neutral position.

Remote Engine Stop Switch

This button stops drilling unit and

remote fluid unit (if used) engines

from operator station.

• Press red button on operator’s

station to stop engine(s).

• Use ignition or remote restart

switch(es) to restart engine(s).

ic0136h.eps

ic1273a.eps

Remote Throttle Switch

This switch controls engine speed

during drilling and backreaming.

• Press top to increase speed.

• Press bottom to decrease

speed.

This switch only works if throttle

switch is in neutral position.

Remote Engine Stop Switch

This button stops drilling unit and

remote fluid unit (if used) engines

from operator station.

• Press red button on operator’s

station to stop engine(s).

• Use ignition or remote restart

switch(es) to restart engine(s).

ic0136h.eps

ic1273a.eps

This manual suits for next models

1

Table of contents

Other Ditch Witch Farm Equipment manuals

Popular Farm Equipment manuals by other brands

GREAT PLAINS

GREAT PLAINS HT1110-6.0M Assembly manual

Rosensteiner

Rosensteiner VET PRO STATIONARY Operating, and servicing instructions

Farm King

Farm King 1370 Operator and parts manual

GREAT PLAINS

GREAT PLAINS NTA607HD Operator's manual

ABSCO SHEDS

ABSCO SHEDS A15081FKFD manual

Landoll

Landoll Brillion WL360 Operator's manual