Ditch Witch SK5TR User manual

SK5TR

Attachment Operator’s Manual

Publication number: 054-096; page 1 of 9

Foreword

Read and understand this manual and the power unit operator’s

manual before using your attachment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch®

dealer. Visit our website at www.ditchwitch.com or write to the

following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject

to change without notice. The Charles Machine Works, Inc.

reserves the right to improve equipment. Some product

improvements may have taken place after this manual was

published. For the latest information on Ditch Witch equipment,

see your Ditch Witch dealer.

SK5TR Trencher Attachment

Operator’s Manual

Issue number 4.0/OM-2/19

Part number 054-096

Copyright 2003, 2004, 2005, 2007, 2019

by The Charles Machine Works, Inc.

Ditch Witch is a registered trademark of The

Charles Machine Works, Inc.

Equipment Modification

This equipment was designed and built in accordance with

applicable standards and regulations. Modification of

equipment could mean that it will no longer meet regulations

and may not function properly or in accordance with the

operating instructions. Modification of equipment should only be

made by competent personnel possessing knowledge of

applicable standards, regulations, equipment design

functionality/requirements and any required specialized testing.

Intended Use

The SK5TR trencher attachment is designed for digging

trenches up to 6” (152 mm) wide and 38” (965 mm) deep.

Safety

• Complete proper training and read operator’s manual before using

equipment.

• Contact your local One-Call (811 in USA) or the One-Call referral

number (888-258-0808 in USA and Canada) to have underground

utilities located before digging. Also contact any utilities that do not

participate in the One-Call service. Mark proposed path with white

paint prior to contacting One-Call or utilities.

• Classify jobsite based on its hazards and use correct tools and

machinery, safety equipment, and work methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and

individual responsibilities with all personnel before work begins.

Safety videos are available from your Ditch Witch®dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate anything

that does not look or feel right.

• Do not operate unit where flammable gas may be present.

• Contact your Ditch Witch dealer if you have any question about

operation, maintenance, or equipment use.

Safety Alert Classifications

These classifications and the icons work together to alert you to

situations which could be harmful to you, jobsite bystanders or your

equipment. When you see these words and icons in the book or on the

machine, carefully read and follow all instructions. YOUR SAFETY IS

AT STAKE.

indicates a hazardous situation that, if not avoided, will

result in death or serious injury. This signal word is to be limited to the

most extreme situations.

indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

indicates a hazardous situation that, if not avoided, could

result in minor or moderate injury.

NOTICE indicates information considered important, but not hazard-

related (e.g., messages relating to property damage). IMPORTANT can

help you do a better job or make your job easier in some way.

SK5TR

Attachment Operator’s Manual

Publication number: 054-096; page 2 of 9

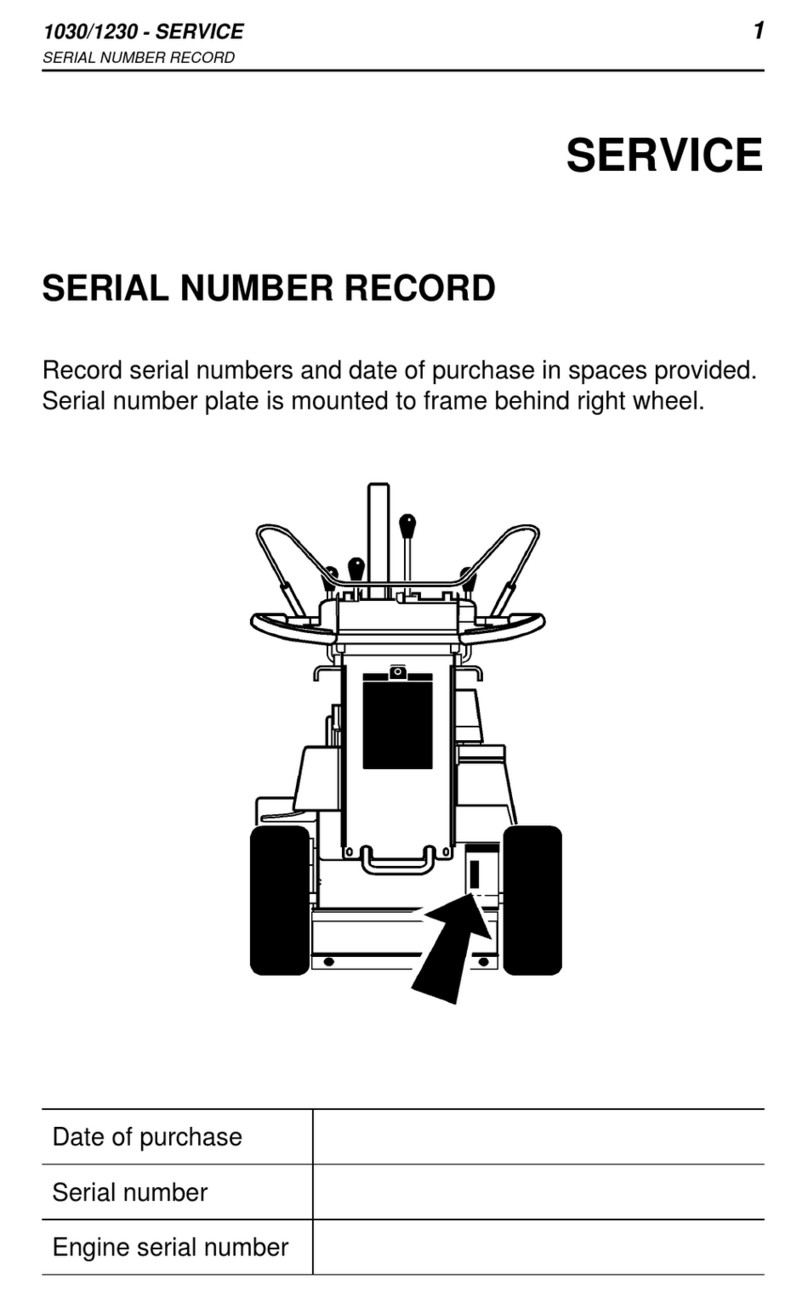

Safety Alerts Connect Attachment

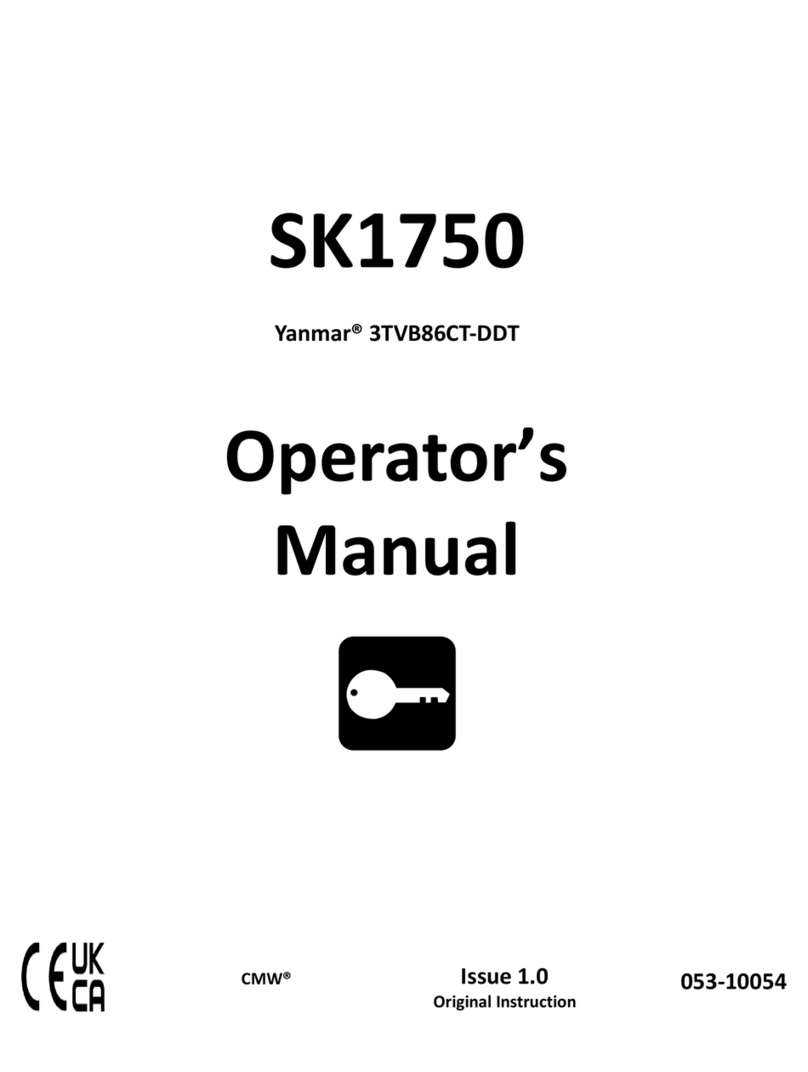

1. Position attachment

on level surface with

enough space

behind it to

accommodate unit.

2. Start engine.

3. Tilt mount plate (2)

forward.

4. Position mount plate

in the upper lip of the

receiver plate (1) on

attachment.

5. Raise lift arms while

tilting back mount

plate.

6. Pins will

automatically

engage.

7. Ensure lock pins are

engaged by rotating

attachment down.

Verifythatbottomsof

lock pins are visible

under attachment

plate.

1

DANGER decal. See

Parts Manual for

replacement part

numbers.

2

DANGER stripe decal.

See Parts Manual for

replacement part

numbers.

3

Lift point.

4

Tiedown location. See

Transport chapter for

more information.

274-318

5

Moving

digging teeth. Contact will

cause death or serious

injury. Stay at least 6’ (2m)

away.

6ft/2m

IMPORTANT: Before connecting attachment to unit,

ensure that mount and receiver plates are free of dirt

and debris and that latch handles are down.

IMPORTANT: Attachment should be raised enough to

clear the ground. Mount plate should be tilted back fully.

t43om006w.eps

t05om026c.eps

12

t43om007w.eps

SK5TR

Attachment Operator’s Manual

Publication number: 054-096; page 3 of 9

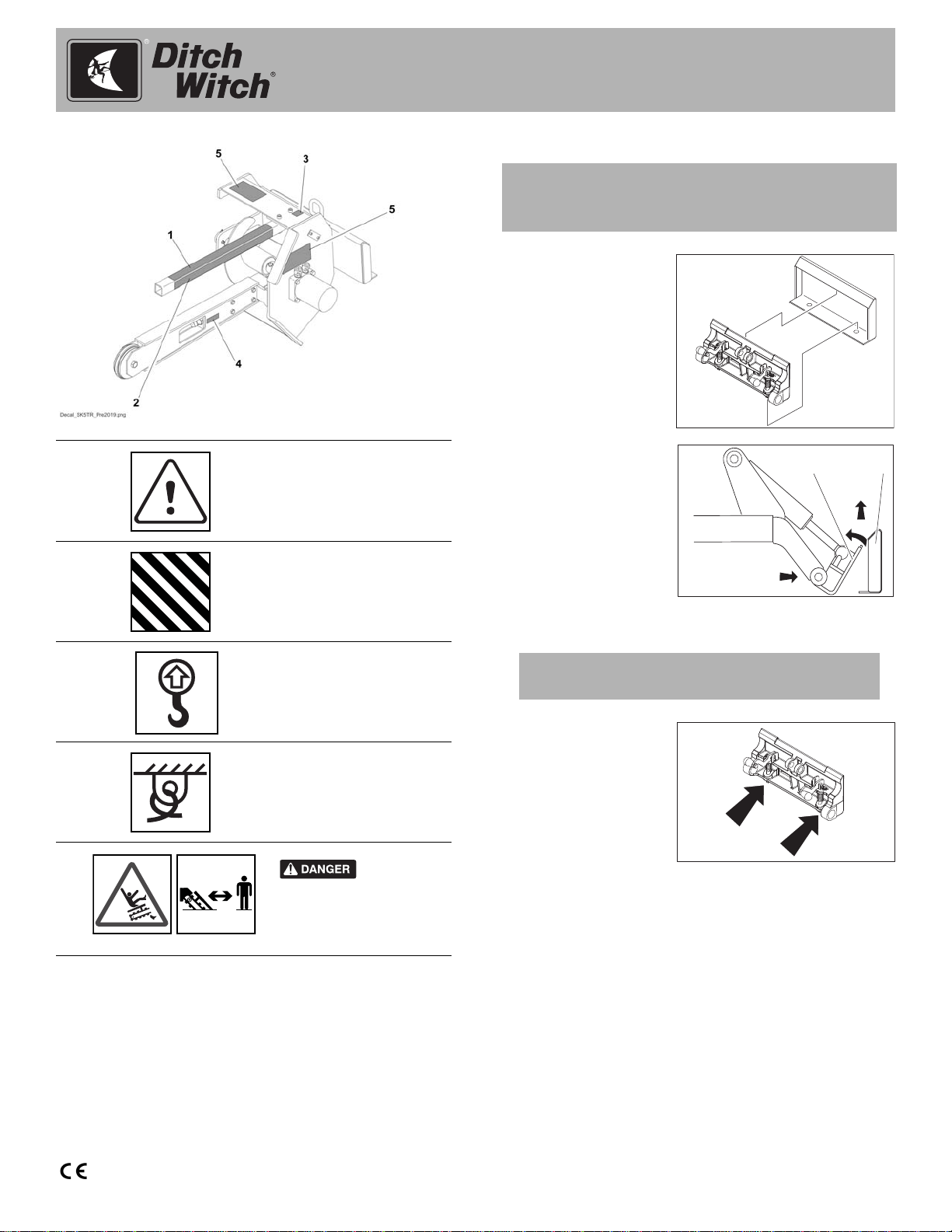

Hydraulic Hoses

Connect hydraulic hoses.

1. Remove dirt and

debris from

hydrauliccouplers.

2. Connect male

coupler on

attachment to

female coupler (3)

on unit.

3. Connect female

coupler on attachment to male coupler (1) on unit.

4. Ensure that connections are secure by pulling on

hoses.

Function Overview

Pressurized fluid or air

could pierce skin and cause injury

or death. Stay away.

To help avoid injury:

• Use a piece of cardboard or wood, rather than

hands, to search for leaks.

• Wear protective clothing, including gloves and eye

protection.

• Before disconnecting a hydraulic line, turn engine

off and operate all controls to relieve pressure.

• Lower, block, or support any raised component

with a hoist.

• Cover connection with heavy cloth and loosen

connector nut slightly to relieve residual pressure.

Catch all fluid in a container.

• Before using system, check that all connections

are tight and all lines are undamaged.

• If you are injured, seek immediate medical

attention from a doctor familiar with this type of

injury.

Hot parts may cause

burns. Do not touch until cool or

wear gloves.

To help avoid injury: Wear gloves when connecting

and disconnecting hydraulic hoses and wait until unit

has cooled before touching hydraulic components.

Attachment Function

To raise trencher, raise lift (loader)

arms.

To lower trencher, lower lift (loader)

arms.

To curl trencher up/tilt trencher up, tilt

mount plate up.

To curl trencher down/tilt trencher down,

tilt mount plate down.

To start digging chain, engage

attachment drive (auxiliary) control in

forward.

To reverse digging chain, engage

attachment drive (auxiliary) control in

reverse.

c00ic015c.eps

c00ic016c.eps

c00ic018c.eps

c00ic017c.eps

c00ic019c.eps

c00ic020c.eps

SK5TR

Attachment Operator’s Manual

Publication number: 054-096; page 4 of 9

Operate Attachment

1. Move unit to starting point of trench.

2. Move track drive controls to neutral.

3. Move throttle to half open.

4. Use lift (loader) arm control to lower trencher to 1" (25 mm)

above ground surface.

5. Use attachment drive (auxiliary) control to start forward

digging chain rotation. DIGGING CHAIN WILL MOVE.

6. Increase engine speed to full throttle.

7. Use lift (loader) arm control to slowly curl digging boom

down to digging depth.

8. Move track drive controls to begin trenching. UNIT WILL

MOVE.

9. When trench is complete, move track drive controls to

neutral.

10. Move throttle to half open.

11. Use lift (loader) arm control to curl boom up to top of

trench.

12. Use attachment drive (auxiliary) control to stop digging

chain rotation.

13. Use lift (loader) arm control to raise trencher.

14. Use track drive controls to drive unit away from trench.

15. Lower attachment to ground surface.

16. Idle engine a few moments to stabilize engine temperature.

17. Stop engine.

For Proper Operation

• Avoid using badly worn teeth. When replacing teeth,

maintain original pattern. Use Ditch Witch®

replacement teeth.

• Use correct length boom. See your Ditch Witch

dealer for more information.

• Do not make sharp turns. For easier turning, lower

boom to full depth.

• If an object becomes lodged in chain, move digging

chain control to neutral and raise boom slightly.

Reverse chain direction. If object must be removed

manually, turn engine off.

• When beginning trench near a wall or fence, allow

enough distance between boom and footings, drains,

and cables.

• When cutting across asphalt roads, start trench in

soil at edge of road and dig with shortest possible

boom at full digging depth.

• When straight trenching across a slope, it can be

helpful to stake a wooden beam parallel to intended

course and just far enough from trench to guide

downslope track.

• Keep bystanders clear of work area.

• Do not walk or work under raised attachments unless

lift (loader) arms are securely supported.

• Avoid sudden starts and stops.

Storage

Store attachment upright in a clean, dry place. Cover

attachment to keep it clean.

Moving digging teeth.

Contact will cause death or serious

injury. Stay at least 6’ (2m) away.

To help avoid injury: Machine might jerk when digging

starts. Allow 3’ (1 m) between digging teeth and obstacle.

EMERGENCY SHUTDOWN: Turn ignition switch to STOP.

IMPORTANT: Trenching movement is toward you.

6ft/2m

SK5TR

Attachment Operator’s Manual

Publication number: 054-096; page 5 of 9

Service

Each Use

Check Bit Rotation

Bits must rotate freely in bit holders. Clean chain and

check bits for free rotation after each use. If any bit does

not rotate, it will quickly wear unevenly. If using rock

chain bits, replace bit when tungsten cap or insert is worn

or adapter can be damaged.

10-Hour

Check Hydraulic Hoses and Fittings

Check hydraulic hoses for leaks every 10 hours.

Check and Adjust Digging Chain

Check digging chain

tension every 10

hours. Clearance

between chain and

boom (4) should be

approximately 1" (25

mm).

To adjust chain with

roller boom:

1. Lower boom to

ground and stop engine.

2. Loosen four trencher boom clamp bolts (3), if

equipped.

3. Loosen jam nut (2) and turn adjusting screw (1)

clockwise to increase and counterclockwise to

decrease chain tension.

4. Tighten jam nut.

5. Tighten trencher boom clamp bolts to 78 ft•lb

(106 N•m).

To adjust chain with

sprocket boom:

1. Lower boom to

ground and stop

engine.

2. Adjust chain

tension by

tightening or loosening adjustment screw (2) and jam

nut (1). Digging chain tension is correct when 1-1.5"

(25-40 mm) of slide and stop is exposed (3).

3. Tighten jam nut.

To help avoid injury: Unless otherwise noted, all

service should be performed with the engine off.

Pressurized fluid or air

could pierce skin and cause severe

injury. Stay away.

To help avoid injury:

• Use a piece of cardboard or wood, rather than

hands, to search for leaks.

• Wear protective clothing, including gloves and eye

protection.

• Before using system, check that all connections

are tight and all lines are undamaged.

• If you are injured, seek immediate medical

attention from a doctor familiar with this type of

injury.

Hot parts may cause

burns. Do not touch until cool or

wear gloves.

To help avoid injury: Wear gloves when connecting

and disconnecting hydraulic hoses and wait until unit

has cooled before touching hydraulic components.

t05om053c.eps

123

4

t05om056c.eps

123

Table of contents

Other Ditch Witch Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions