TABLE OF CONTENTS

1INTRODUCTION.........................................................................................................................1

1.1 Safety Precautions..................................................................................................................1

1.2 Highway Transport.................................................................................................................2

1.2.1 Dimensions.....................................................................................................................2

1.2.2 Safety Chain & Jack.......................................................................................................3

1.2.3 Lights and Marking ........................................................................................................3

1.2.4 Rake Wheel Safety Locks ..............................................................................................3

1.2.5 Transport Safety Locks...................................................................................................4

1.2.6 Wheels & Caster Brakes.................................................................................................4

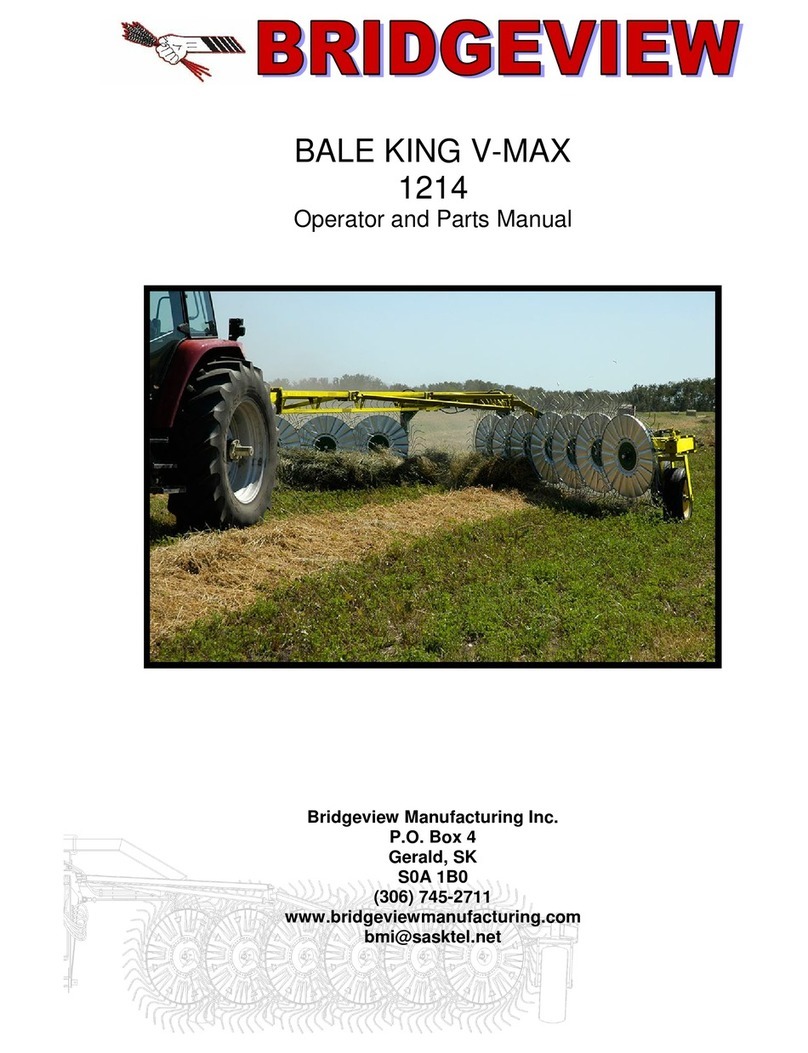

2FEATURES AND OPERATION..................................................................................................5

2.1 Hydraulics ..............................................................................................................................5

2.2 Field Operation.......................................................................................................................5

2.3 Adjustments............................................................................................................................6

2.3.1 Lift Cylinder Stoppers....................................................................................................6

2.3.2 Individual Spring Adjusters............................................................................................6

2.3.3 Windrow Width Adjustment ..........................................................................................7

2.3.4 Implement Tongue..........................................................................................................7

2.4 Optional Rubber Mounted Tine (RMT) Rake Wheel.............................................................8

2.5 Optional 14-Wheel Extension Kit..........................................................................................9

2.6 Optional Tire Kits...................................................................................................................9

2.7 Trouble-Shooting Guide.......................................................................................................10

2.8 Specifications .......................................................................................................................10

3MAINTENANCE & LUBRICATION........................................................................................11

3.1 Wheels and Tires..................................................................................................................11

3.2 Greasing................................................................................................................................12

3.3 Tine Replacement.................................................................................................................13

4PARTS BOOK ............................................................................................................................14

4.1 Gooseneck Assembly ...........................................................................................................15

4.1.1 Transport Lock .............................................................................................................17

4.2 Hitch Beam & Scissor Assembly.........................................................................................18

4.2.1 Scissor Components Front............................................................................................18

4.2.2 Scissor Components Rear VR581 ................................................................................20

4.2.3 Width Indicator.............................................................................................................22

4.3 Rear Frame Assembly ..........................................................................................................23

4.3.1 Rear Axle......................................................................................................................24

4.3.2 Slow Moving Vehicle (SMV) Sign Kit........................................................................25

4.4 Boom Arm Assembly...........................................................................................................26

4.4.1 Boom Arm Assembly...................................................................................................26

4.4.2 Lift Rod Details............................................................................................................28

4.4.3 Caster Wheel and Hub..................................................................................................29

4.5 Rake Wheel and Arm ...........................................................................................................30

4.5.1 Rake Wheel Assembly (Standard Tine) .......................................................................31

4.5.2 Rake Wheel Assembly (Rubber Mounted Tine) ..........................................................32

4.5.3 Spring Assembly ..........................................................................................................33

4.6 Decals...................................................................................................................................34

4.7 Hydraulic Components.........................................................................................................35

4.7.1 Diverter Valve Kit........................................................................................................37

4.8 Electrical Components .........................................................................................................38