Assembly

Housing

Maintenance

nClearing a clogged ferrule assembly

If fiber happens to break off inside the ferrule assembly,

Clean-Out Wire

and a

Clean-Out Wire Guide

is supplied to

assist in removing any debris. Disconnect the patch cable

from the Divot® Module by rotating the LiteLOCK® dial

slightly to the left and pull the connector out from the

interface. Remove the end cap, OCC cartridge and sleeve.

Pull the ferrule assembly out of the bulkhead housing.

Push the ferrule assembly into the 2.5mm interface of the

Clean-out Wire Guide. Insert a piece of clean-out wire into

the small hole on the end of the Clean-out Wire Guide and

slowly push forward to clean out any broken fiber or debris.

Reassemble the Divot® Module and insert the connector

with the red boot or red band from the patch cable into the

Universal Bulkhead Housing and secure by rotating the

LiteLOCK® dial to the right. Do not overtighten.

nCartridge Replacement

The OCC cartridge is filled with optical coupling compound and under normal use will typically

produce a minimum of 500 insertions. The cartridge needs to be replaced when you start to

experience inconsistent launches. In some cases, especially over prolong use, debris can build

up in the cavity on the tip of the Ferrule Assembly which will cause inconsistency in the

connection. Before replacing the cartridge, clean out the ferrule assembly. Please refer to page

2 for instructions on how to replace (load) the Optical Compound Cartridge.

Insert

Clean-out Wire

nConnecting and Disconnecting the patch cable for cleaning

Occasionally you may have to clean the connector on the patch cable (identified with a red boot

or band below the boot) and/or both ends of the ferrule assembly inside the Divot® Module. The

ferrule assembly can be removed from the bulkhead housing and cleaned or immersed in

alcohol. To remove the Divot® Module from the Patch Cable simply loosen the LiteLOCK® dial

by rotating it slightly to the left and pull the connector out from the interface. To reconnect the

patch cable, insert the connector marked with a red boot or red band below the connector boot

into the Universal Bulkhead Housing. Push the ferrule of the connector into the 2.5mm interface

and secure by rotating the LiteLOCK® dial to the right. Do not overtighten. The LiteLOCK® dial

can also be unscrewed from the bulkhead housing in order to clean or replace the zirconia

sleeve. Over time, especially if inserting non-cleaved fiber, the patch cable mated to the Divot®

module will wear and may need to be replaced. Additional cables are available as accessories.

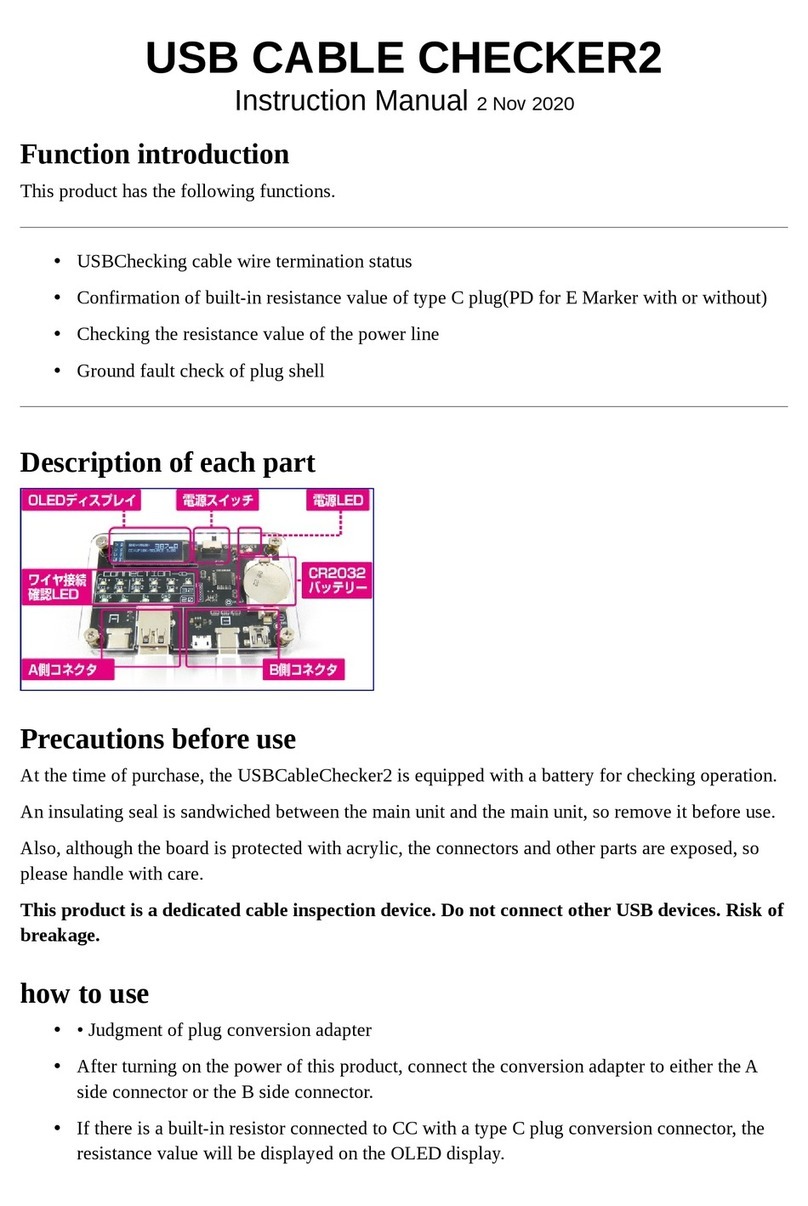

Ferrule

Assembly

Phos. Bronze

Sleeve

OCC

Cartridge End Cap

Universal

LiteLOCK® Dial

Zirconia

Sleeve

Specifications & Accessories

nSpecifications

Fiber type: Singlemode 9/125µm, Multimode 62.5/125µm or Multimode 50/125µm

Cable length: 1 meter

Number of insertions (Typical): 3000 min. (500 min. per cartridge, 6 cartridges included)

Insertion loss (Typical): < 0.5 dB (uncleaved fiber < 0.8dB)

Back Reflection (Typical): < 45 dB

Operating temp.: -10° C to +40° C

nAccessories

DVT-RC3 Divot® Replacement OCC Cartridges (3 pack)

DVT-RC12 Divot® Replacement OCC Cartridges (12 pack)

COKS-40 40 pc. Vial of Clean-Out Wire

DVT-RP4000 Divot® Replacement Sleeve Set (1 Zirconia, 1 Phos. Bronz)

DVT-RP4100 Divot® Replacement Ferrule Assembly

--------- Divot® Replacement Patch Cable Assembly

--------- Dead Zone Eliminator® Launch Box (Fiber Spool) for use with OTDR’s

3