DIWELL Electronics Co., Ltd.

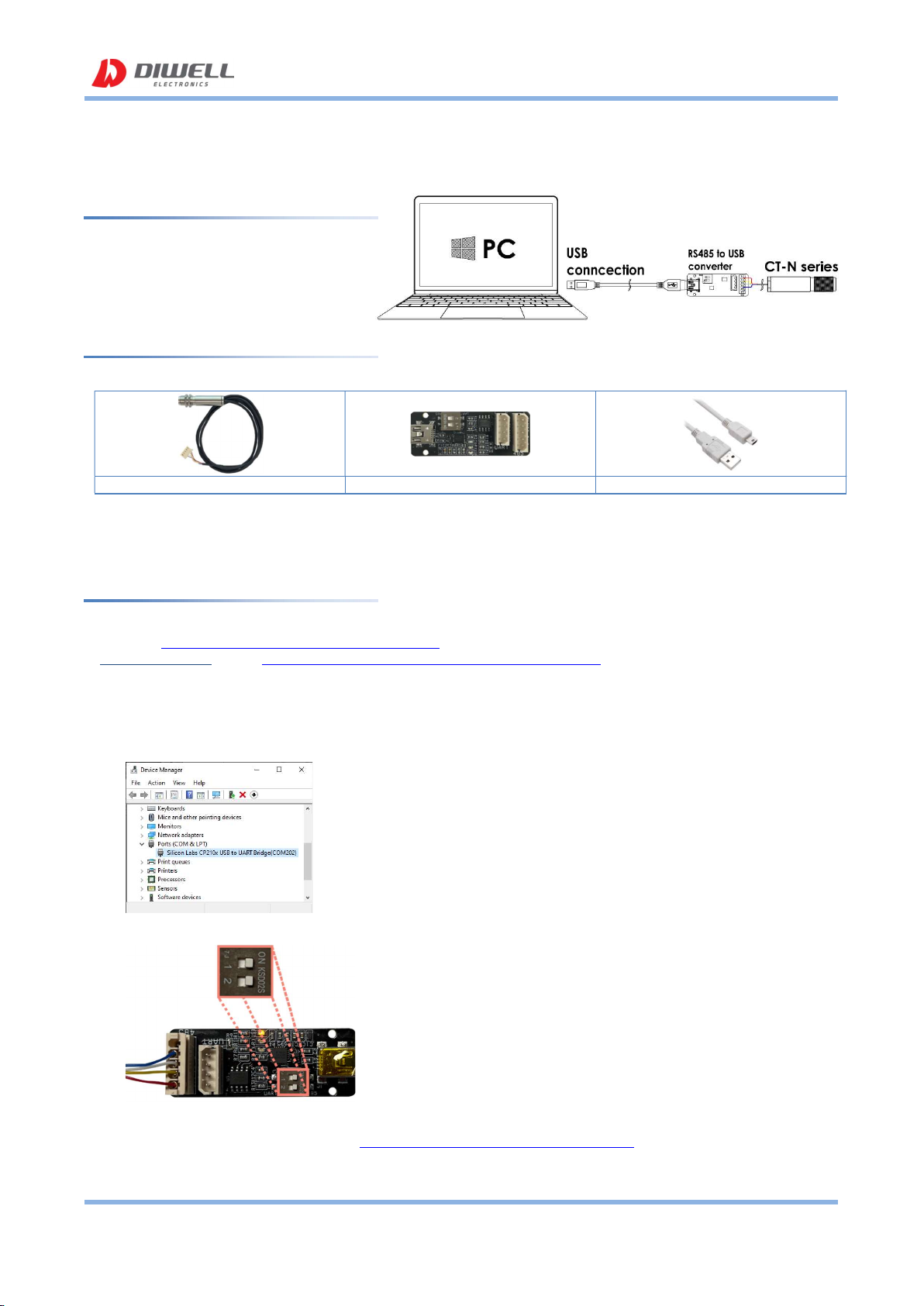

CT-N Series Test board Manual

2 / 3 V.1.0.0

User interface

- Temperature tab

◇ Open COM port: Select the COM number (see previous page step3) and press the “Connect” button.

Note. The port connection status does not mean that the test board connection is successful. It's just that the port is open state.

◇ Read temperature: Click the play button. (▶)

◇ Stop reading: Click the stop button. (■)

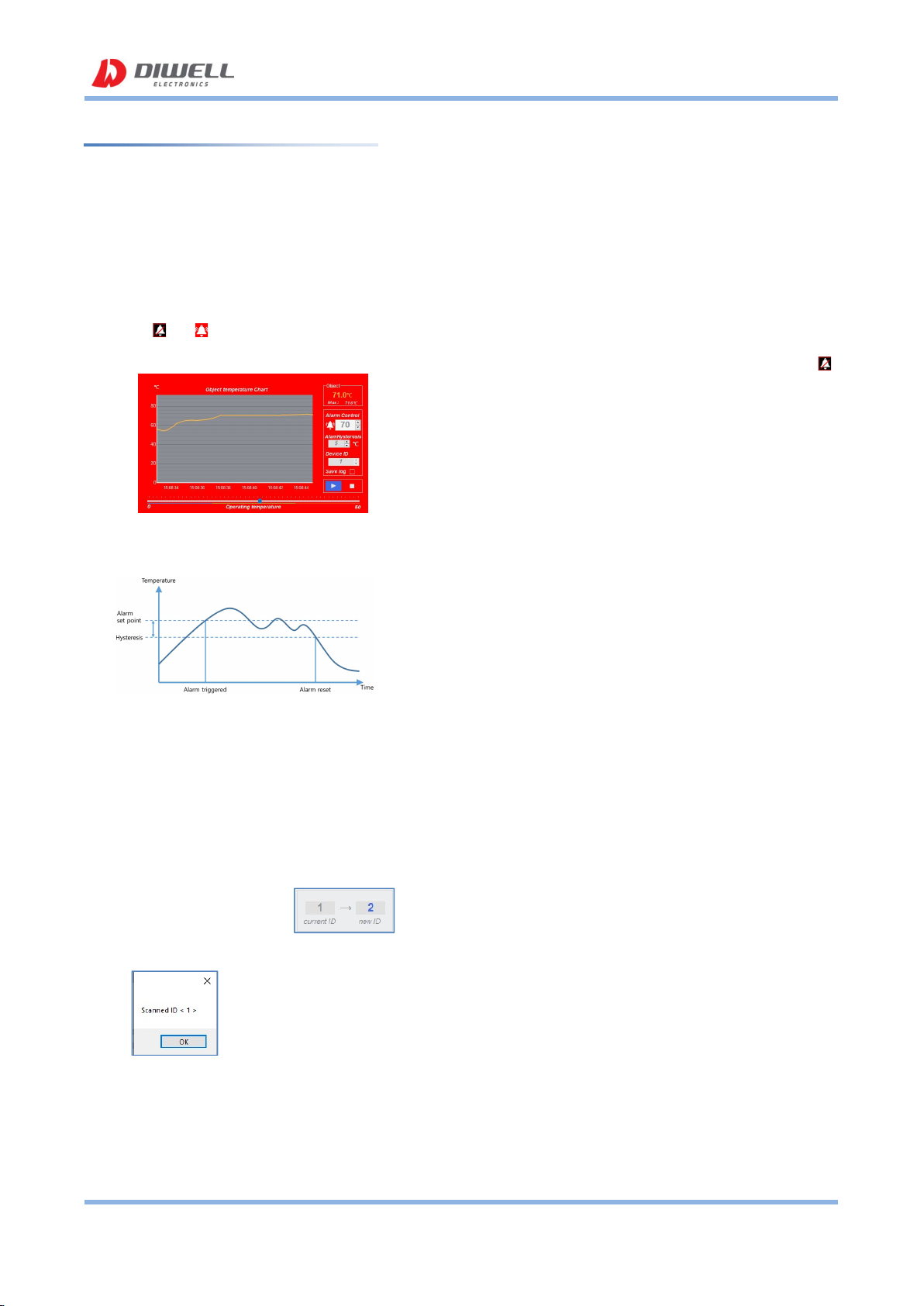

◇ Alarm Control: Configure the settings for alarm.

- Alarm Off: , On: (Click the alarm icon, default: Off)

- Alarm Set Point: The temperature at which the alarm is triggered. Minimum: 30°C. Maximum: 1000°C.

An alarm sound will be played. And the background of the Temperature View will stay red, until the alarm is reset. It can turn off the alarm manually.

- Hysteresis: The temperature difference between the Alarm Set Point and the reset temperature. Please see the diagrams below for more information.

Minimum: 1°C, Maximum: 20°C.

- Alarm Type: High, (The alarm is triggered when the temperature rises above the Alarm Set Point.)

- Alarm reset: The alarm is acknowledged and reset automatically when the temperature reaches the reset temperature.

- Q. Set Point: 70℃, Hysteresis: 5℃. What is the temperature at which the alarm automatically stops? A. less than 65℃

◇ Device ID: Modbus ID (factory default: 1)

◇ Data Logging: All data is saved as a text file in a subfolder “TEMPLOG”. Logging can be started and stopped manually.

If the temperature exceeds the set point during data logging, an "A" character is added to the end of the data line.

- Setting tab

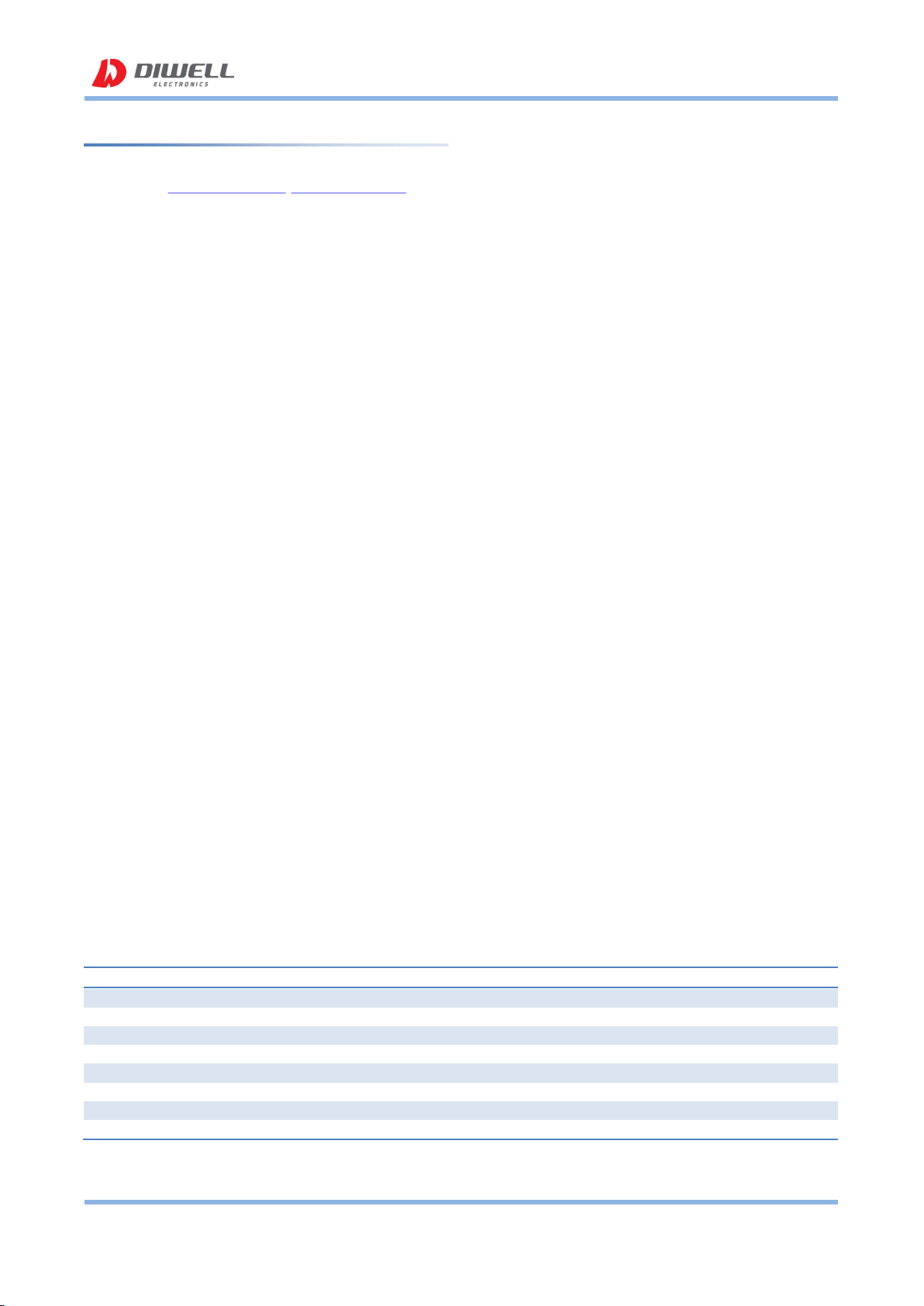

◇ ID setup: Enter a new Modbus ID, then click Apply button to save it to the sensor. Minimum: 1, Maximum: 200

Example of changing ID from 1 to 2

◇ ID scan: It can be easily find ID by scanning.

◇ Emissivity: The CT-N is calibrated for an object emissivity of 0.97. It can be customized by the customer for any other emissivity in the range 0.1…1.0.

The emissivity value in the program is multiplied by 100. i.e. 97 means 0.97, 100 means 1.0, 10 means 0.1

※ When measuring metallic luster materials such as aluminum and copper, it is recommended to apply a black spray or a blackbody tape to the surface of the object.

◇ Average Filter: Number of average filter array elements. Affected by noise reduction of Object temperature and peak temperature measurement time.

minimum: 1(no averaging), maximum: 10