Manual Supplement 5320A Users

6 2/16

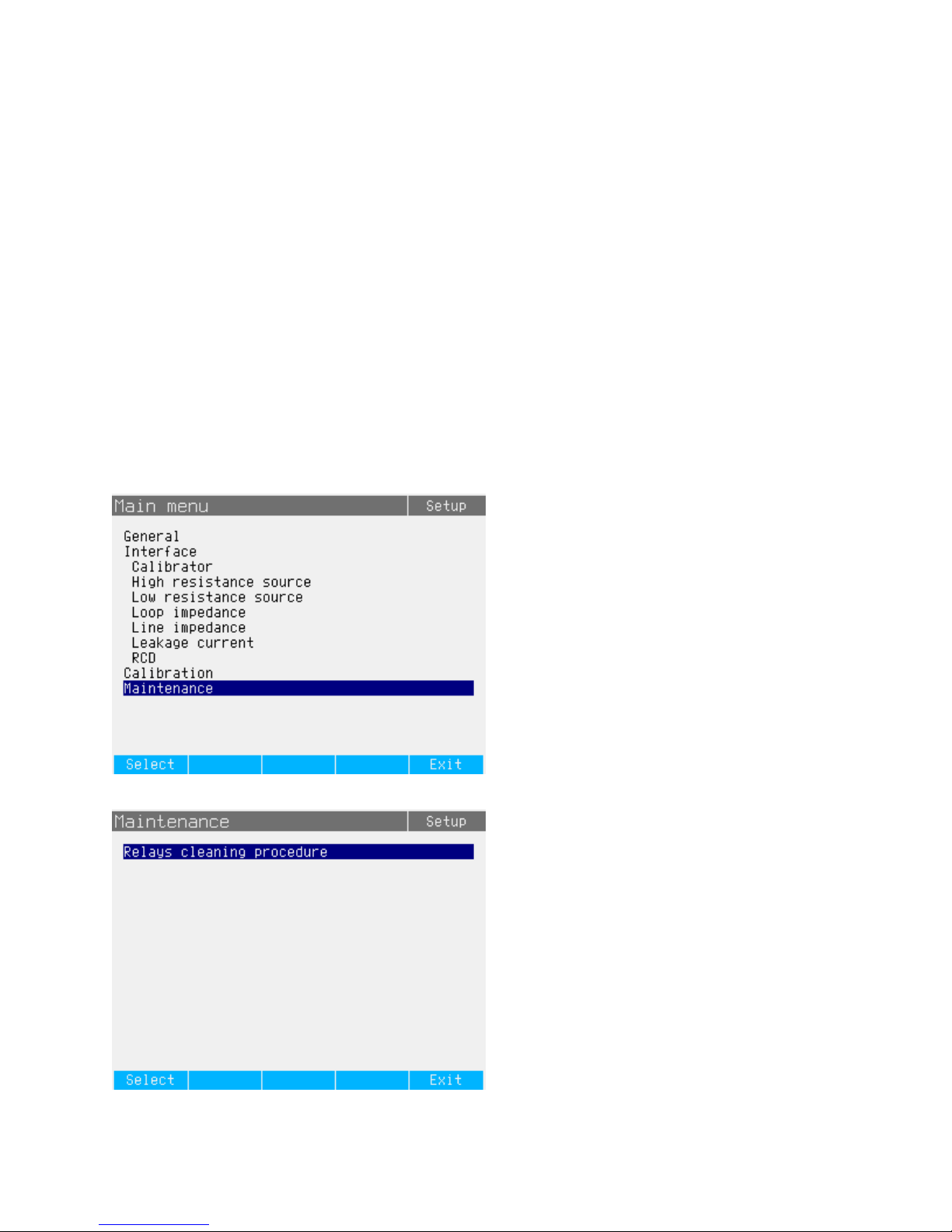

Note

For units with serial number lower than xx548xxxx, do not run the cleaning procedure

without connecting the external power supply. When the cleaning procedure is performed

without connecting the external power supply, the relay contact resistance may become

even worse. Changing the polarity of the dc supply source is recommended from cleaning

to cleaning to avoid one-way transport of contact material from one side of the contacts

to the other.

Change #9, 449

On page 1-7, add the following to the Symbols table:

ÃConforms to relevant South Korean EMC

Standards.

On page 1-9, add the following to the General Specifications:

Electromagnetic Compatibility (EMC)

International......................................IEC 61326-1: Basic Electromagnetic Environment

CISPR 11: Group 1, Class A

Group 1: Equipment has intentionally generated and/or uses conductively-coupled

radio frequency energy that is necessary for the internal function of the equipment

itself.

Class A: Equipment is suitable for use in all establishments other than domestic and

those directly connected to a low-voltage power supply network that supplies

buildings used for domestic purposes. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted and radiated

disturbances.

Emissions that exceed the levels required by CISPR 11 can occur when the

equipment is connected to a test object.

Korea (KCC).....................................Class A Equipment (Industrial Broadcasting & Communication Equipment)

Class A: Equipment meets requirements for industrial electromagnetic wave

equipment and the seller or user should take notice of it. This equipment is intended

for use in business environments and not to be used in homes.

USA (FCC) .......................................47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103.

Change #10, 255, 468

On page 1-9, under WFuse Protection, replace the existing content with:

RCD input.........................................3.15 A, 250 V, Fast (F3.15H250V – 5 mm x 20 mm)

Meter amps (A) input........................20 A, 500 V, Fast (T20H500 V – 6.3 mm x 32 mm)

Loop/Line impedance input...............4 A, 500 V, Time delay (T4H500 V – 6.3 mm x 32 mm)

On page 4-6, following Table 4-2, replace the sentence with:

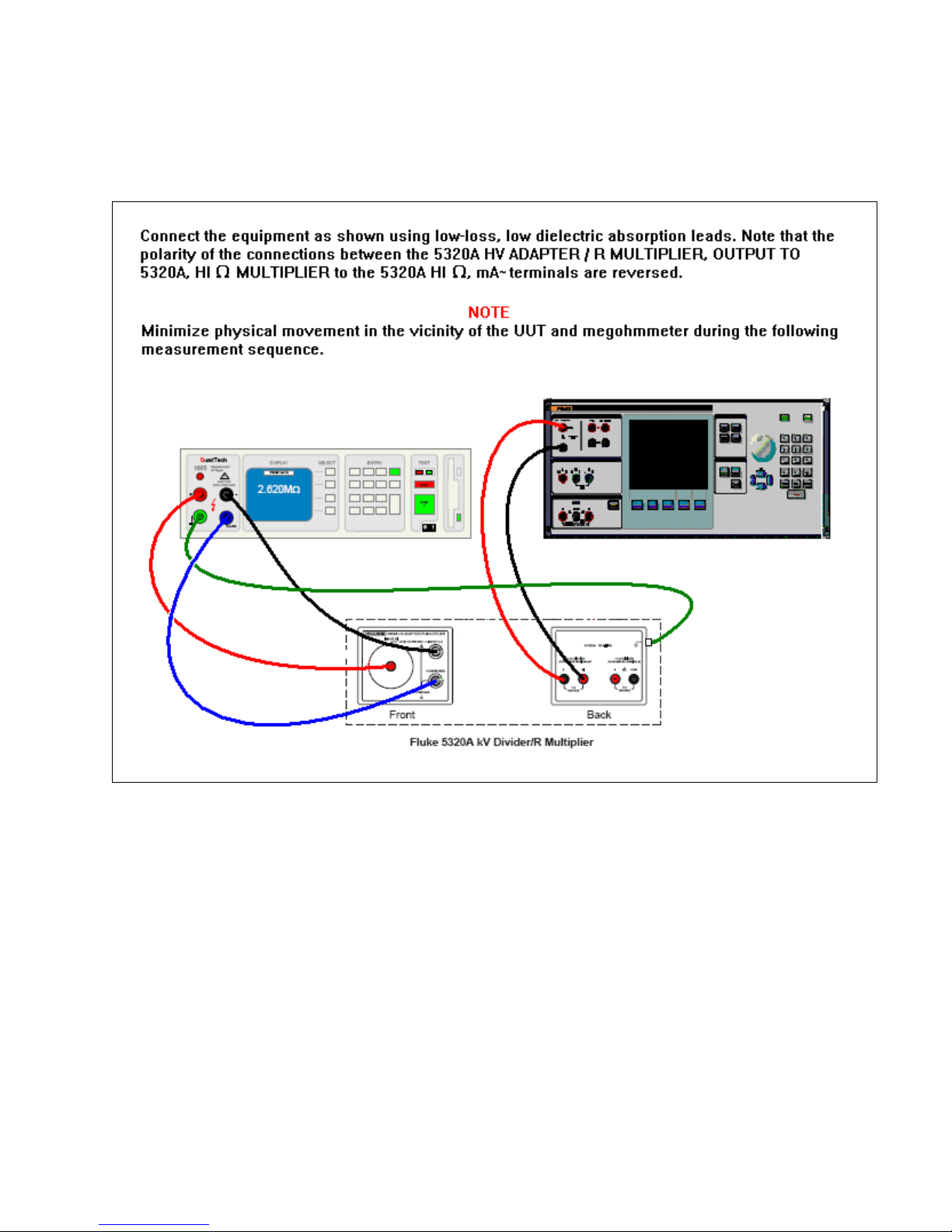

An optional resistance multiplier is offered to increase the range of high resistances from 350 MΩto

10 TΩand applicable dc test voltage to 5 KV. Resistance multiplier is based on a passive T-type

resistance network. Nominal value of multiplication is 1000. Exact value depends on resistance

multiplier calibration data. Input resistance of the multiplier is approximately-300 MΩ. Resistance

multiplier can be applied for calibration of such UUTs which use virtual ground (current to voltage

converter) as current sense terminal with input resistance. For UUTs with finite input resistance and

non-virtual ground on sense terminal, the input resistance must be taken into consideration. For this

purpose, the Calibrator is equipped with a parameter “R multiplier input”. Input resistance of sense

terminal of UUT should be written here to perform calibration correctly.

Note

Input resistance of the sense terminal is different for different models of megohmmeter.

Do not to set the parameter to the correct value. For megohmmeters with virtual ground,

0 Ωmust be written and saved here before calibration.