2 Rotary Lobe Pumps - RZL-400 Series800.789.1718

Table of Contents

Safety ................................................................................................................................................................................................... 3

Care of Stainless Steel......................................................................................................................................................................... 4

Technical Specications....................................................................................................................................................................... 5

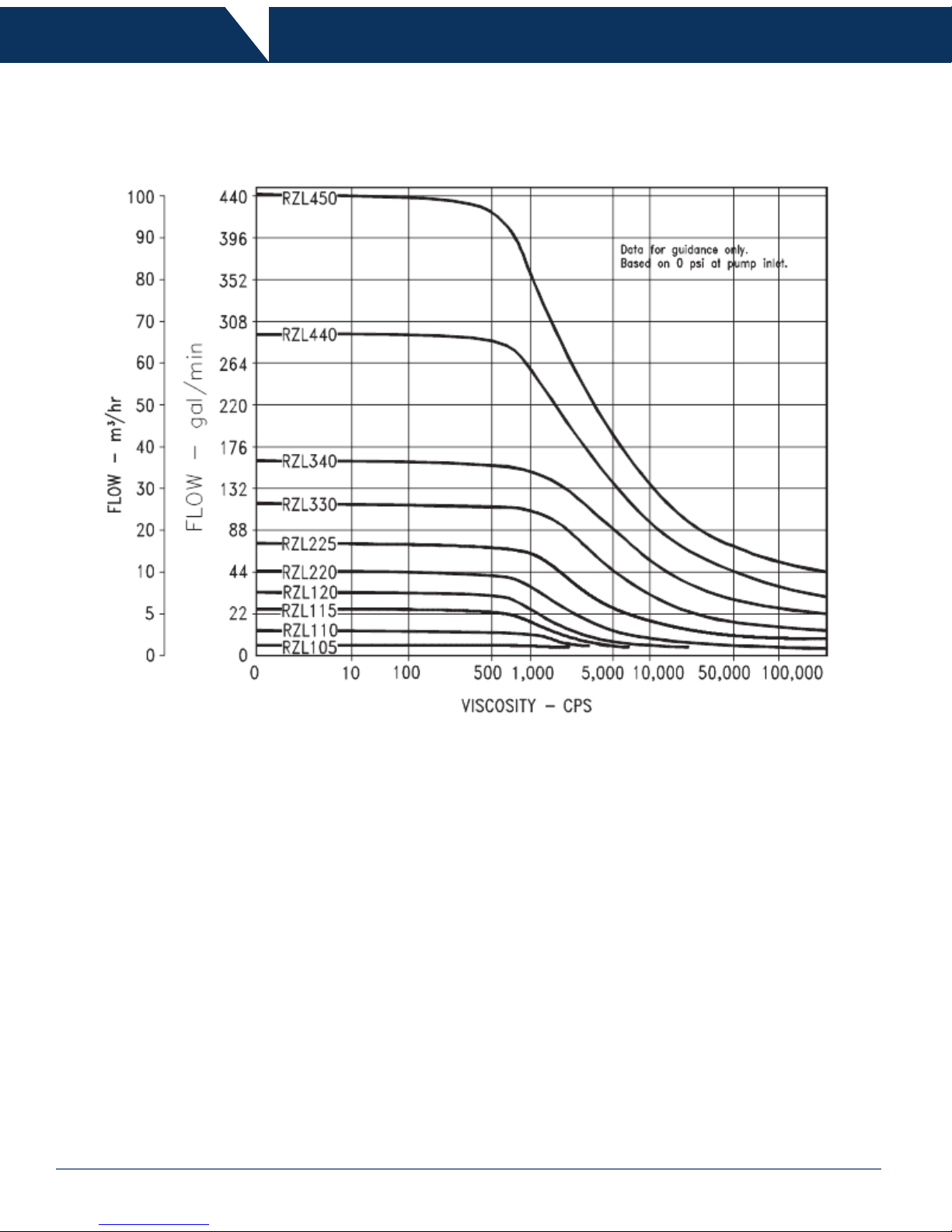

Family of curves ................................................................................................................................................................................... 6

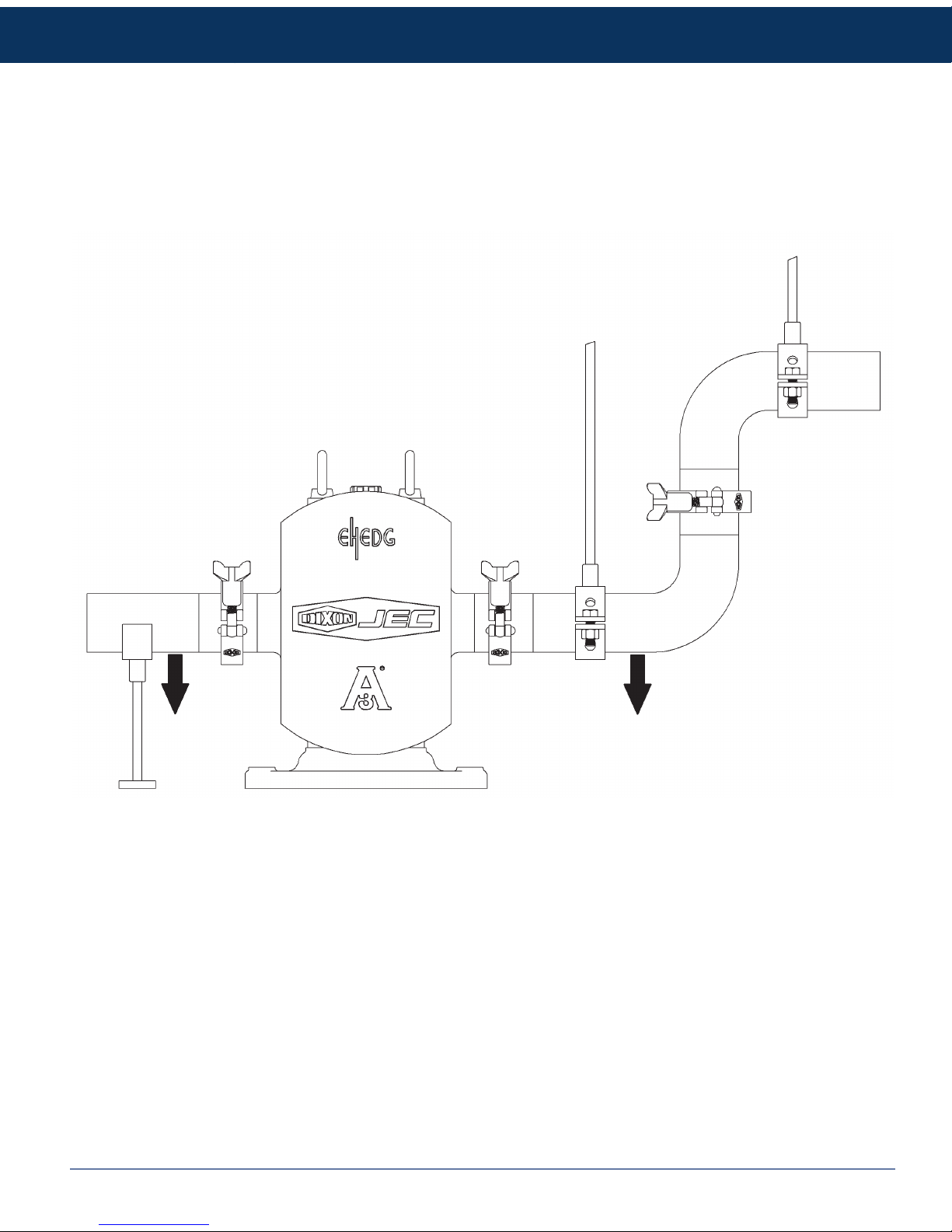

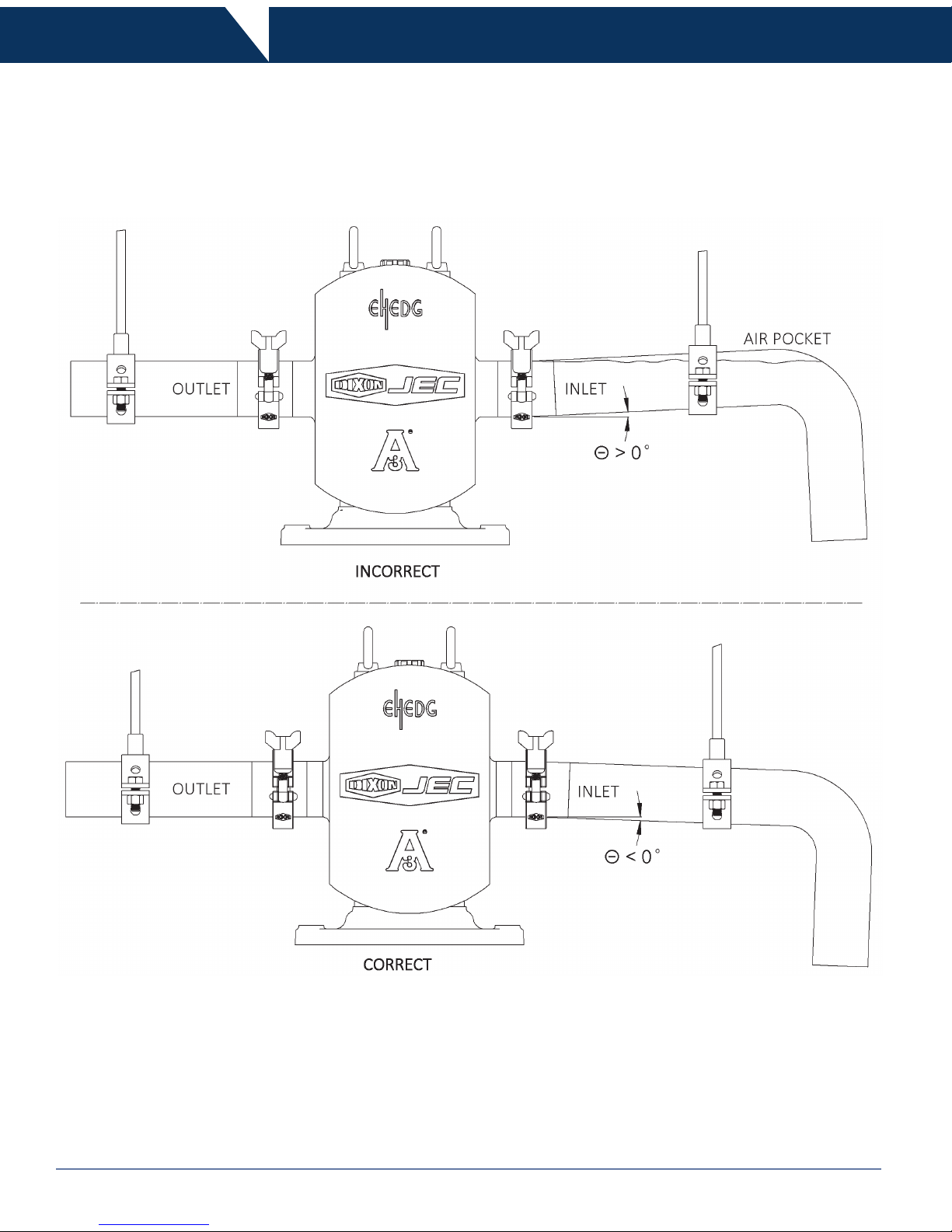

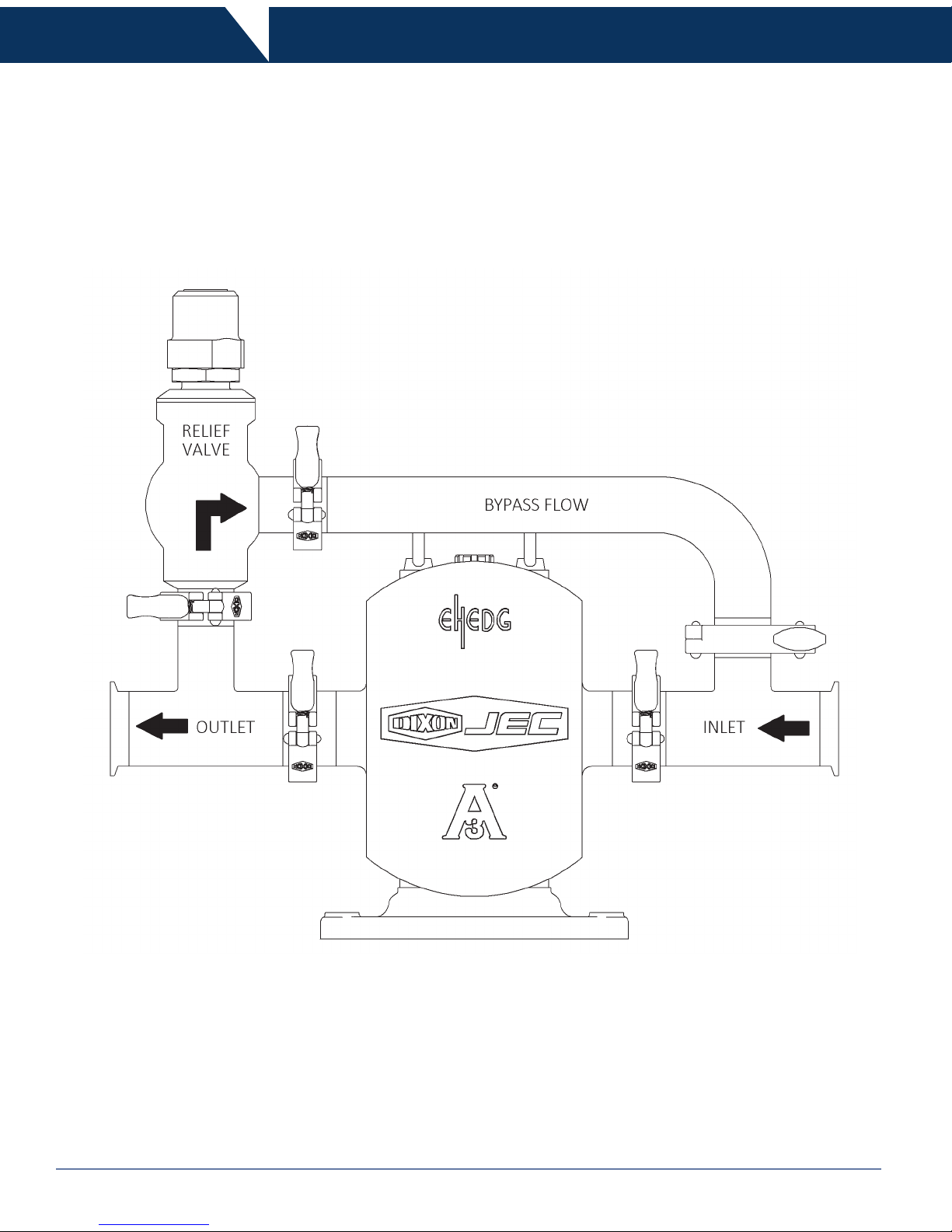

Unpacking Installation & Start Up.................................................................................................................................................... 7-16

Tools needed...................................................................................................................................................................................... 17

Maintenance.................................................................................................................................................................................. 17-55

Pump Housing Disassembly...................................................................................................................................................... 17-48

Single Mechanical Seal.......................................................................................................................................................... 17-25

Double Mechanical Seal......................................................................................................................................................... 26-35

Single O-ring Seal .................................................................................................................................................................. 36-41

Triple Lip Seal ........................................................................................................................................................................ 42-48

Inspection........................................................................................................................................................................................ 49

Pump Housing Assembly................................................................................................................................................................ 49

Rotor Clearance......................................................................................................................................................................... 50-52

Shimming .................................................................................................................................................................................... 52

Rotor Timing ................................................................................................................................................................................... 53

Gear Box Disassembly ................................................................................................................................................................... 54

Gear Box Assembly ........................................................................................................................................................................ 55

Scheduled Maintenance ................................................................................................................................................................. 55

Maximum RPM................................................................................................................................................................................... 56

Maximum Solids ................................................................................................................................................................................. 56

Dimensions......................................................................................................................................................................................... 57

Troubleshooting............................................................................................................................................................................. 58-60

BOM .............................................................................................................................................................................................. 61-73

Certicates..................................................................................................................................................................................... 74-75

Warranty............................................................................................................................................................................................. 76

Thank you for purchasing a Dixon Sanitary Product!

This manual contains installation, operation, disassembly and assembly instructions, maintenance procedures, troubleshooting and a

complete parts list for all RZL-Series positive displacement pumps.

READ THIS MANUAL carefully to learn how to service these pumps. Failure to do so could result in person injury or equipment

damage.