DIZHUO DB Series Instruction Manual

《DB Series self-contaienr ice machine installation maintenance manual》

This manual contains the following ice machine

DB75A/W DB95A/W DB125A/W DB175A/W DB215A/W

DB320A/W DB430A/W DB510A/W DB710A/W

DB1050A/W DB1500A/W DB1950A/W DB2200A/W

WARNING

IMPORTANT:

Safety Warning

When you operate and maintain DIZHUO ice machine , be sure

to pay attention to safety warning . If ignore these warning could

result in personal injury or damage to the ice machine

In this manual, you will see the following forms of safety warning:

The potential personal injury, if you not according to the manual installation

, use , or use the machine which make an unauthorized change may cause

personal injury.

NOTICE:

Correct installation , use and maintenance of ice machine , it is very important

to keep the ice machine production capacity and reduce the failure rate . Please

read and understand this manual, it contains valuable information about installation

,use and maintenance. If you encounter issues not covered in this manual, please

contact our company or the company maintenance agent at any time.

The content involved in this manual of adjustment、maintenance and cleaning

does not belong to the warranty scope.

Note: Please Keep This Manual properly

The manual is an important part of product, the user must be properly kept.

Please read carefully the guidelines and the cautions described in this manual , because these

guidelines and cautions provides the necessary information about the correct installation, safely

use and maintenance of this product to installation personnel/user.

Please keep this manual for reference when necessary.

Contents

2.1

1

2

3-4

3-4

5

5

5

5

5

6

9

9

9

10-11

6-7

6

6-7

7-8

2.1.1

2.1.2

2.2

4.1

3.1

Installation instructions

Ice Maker Overview

Ice Machine Appearance

Ice Machine Size

Ice Machine Key Parameters

Unpacking

The Ice Maker Level Adjustment

Power Supply

Water Supply / Drainage

Check after Installation

Ice Machine Running

Main screen

Main Menu and Sub-menu

WIFI Ice Machine Running Processes Instructions

Maintenance

Cleanning

Condenser Cleaning

The machine stop/winterizing

WIFI Cloud-Service Ice Machine Touch Screen Operation Instructions

3.2

3.3

Servicing

Servicing

1.2

1.1

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

Choose installation location

1.1 Ice Maker Overview

②Due to ventilation air in and out all from front, so no space requirement on the left and right

side of ice machine.

1.2 The shape of integrated ice machine

1

DB Series Internet Of Things ice Machine

①DB series ice machine is a new generation Of Things Internet of ice machine that use of a

numberof patented technology, key components use international famous brand parts, apply

to work under high ambient temperature, making ice with high efficiency, stable and reliable

work.

④ Removable water tank design, make cleaning and maintenance easier.

Plastice door

Air inlet

Adjustable foot

Service label

Touch screen

Auxiliary Air outlet

Air outlet

Water output

Water input

Power line

③Ice machine can connecr to internet through WI-FI, customer can check and control

icemachine with iphone The ice machine work data upload to cloud server continuously.

The data helps service personnel to monitor machine work stat and find some unstable

situation. The unstable situation can transfer to customer or service agent for further

processing

The shape of split ice machine shape

Touch screen

Touch screen

Plastice door

Plastice door

Air outlet

Auxiliary Air outlet

Adjustable foot

Power line

Water input

Water output

2

DB Series Internet Of Things ice Machine

1.3The size of ice machine

The key parameters of integrated ice machine

**

Power Supply A B B BCCCDE

max max

min min

DB95W

DB125W

DB175W

DB215W

DB255W

75

75

97

97

97

14

14

14

14

14

16

16

16

16

16

1

1

1

1

1

90

90

111

111

111

92

92

113

113

113

53

53

68

68

68

62

62

67

67

67

76

76

Power Supply

Model

Power(W)

Current(A)

Refrigerator

Liquid

amount(g)

Ice Output(kg)

Ice Storage(kg)

Unit: kg/24h; Text Environment: Ambient temperature 21℃,water temperature 10℃.

Unit:kwh/100P(45kg) Unit:L/100P(45kg)

***

*

Unit:Centimeter

bar bar

3

DB Series Internet Of Things ice Machine

R404a R404a R404a R404a R404a R404a

38 45

40 40 40

60 80 100 115

DB75A DB95A DB125A DB175A DB215A DB255A

220VAC/50Hz/1ph

291 380 420 550 630 750

2.3 2.7 3.6 4.7 4.7 5.2

180 310 290 380 435 380

20 25 25

1.4The size of ice machine

The key parameters of split ice machine

型号 ABCDEFGH

DB320A/W

DB430A/W

DB510A/W

DB710A/W

DB1050A/W

DB1500A/W

DB1950A/W

DB2200A/W

AC

B

DE

F

G

H

164.7

175.5 105.5

105.5

105.5

110.0

110.0

110.0

184.5

195.5

198.0 125.5

125.5

125.5

205.0

205.0

92.2

56.7 66.1 83.8

83.8

87.0

87.0

87.0

89.0

89.0

89.0

10.5

10.5

10.5

10.5

10.5

10.5

10.5

10.5

66.1

67.5

67.5

78.5

74.5

74.5

74.5

56.7

76.7

76.7

76.7

92.2

62.0

62.0

59.5

68.5

79.5

77.5

84.5

84.5

154.2

154.2

165.0

174.0

185.0

187.5

194.5

194.5

164.7

**

Unit: kg/24h; Text Environment: Ambient temperature 21℃,water temperature 12℃.

Unit:kwh/100p(45kg) Unit:L/100P(45kg)

***

*

Unit:Centimeter

4

DB Series Internet Of Things ice Machine

Power Supply

Model

Power(W)

Current(A)

Refrigerator

Refrigerating

Capacity(g)

Ice Output(kg)

Ice Storage(kg)

R404a R404a R404a R404a R404a

140 180

240 240

250 300 450

DB320A DB430A DB510A DB710A DB1050A

220V AC/50Hz/1ph

800 900 1000 1350 2350

4.8 4.7 4.7 7.1 7.3

650 750 1100 1350 1950

160 160 240

③Remove the protective film on the shell.

Remove the attachment and check the

type and quantity

5

1.5Unpacking

①Before unpacking, check whether the outer packing

machine is well and the machine model is consistent

with you purchased.

②Remove the shipping tape on the door and evaporator

(ice tray)

Plastic adjustment foot 4 pieces(DB75A/W, DB95A/W,

DB125A/W plus 4 counter installation foot)

Plastic ice scraper

Inlet pipe

Drain pipe

Drain pipe clamp

Specification

Warranty card 1

1

1

1

1

1

The ice maker is not suitable for outdoor use , don't

get close to the location of the source of heat or direct

sunlight.

Working environment temperature should be5 ℃ ~ 38

℃,the normal work of the water temperature should be

5 ℃ ~ 35 ℃ . If the ice machine long time work beyond

the normal working temperature range , may affect ice

-making capacity.

Ice machine should be installed in a solid, flat ground.

Don't put any items in front of the ice machine ventilation

window.

Ice machine can not work in sub-zero temperatures. To

prevent water supply line fault , when air temperature

is below freezing , please drain the water in the ice

machine (see "preparations for long-term storage of

ice machine").

1.7The ice maker level adjustment

Adjust the four foot adjustable part twist in the end,

andthen adjust the foot twist into ice machine bottom

corresponding installation hole.

Move the ice machine to install location.

Use spirit level to maker ice machine keep horizontality.

Notice

Using counter board foot, ice machine level adjustment

do not use the method of adjustment level in the bottom

of foot pad hard objects. To ensure the four foot of ice

machine touches the ground steady, to prevent vibration

when machine is running.

1.8 Power supply

warning

Wiring used in power supply must be reliable grounding, The

wiring use must accord with the local countries and regions

laws and regulations.

Ice machine starting, allows the voltage fluctuation

range is + / - 10% of rated voltage.

The ice maker must have a separate fuse/circuit

breakers.

The maximum capacity of this series machine we

recommended fuse is 15 A.

1.9Water supply/drainage

The water supply

According to the local water supply condition, to

determinewhether to need to install the watertreatment

system, used to prevent formation sediment, and filter

out the impurities, removethe smell of bleach.

warning

Ice machine must be connected to a drinkable water.

Please follow the following guide to install water supply

pipe:

Don't put ice machine connected with hot water .

If the water pressure over the allowed maximum

feed waterp ressure of (5 bar), pls buy a water

pressu re regulator.

Ice machine must be installed water valve in front

of all theinlet pipe.

Drainage

When installing a drain, should prevent water poured into

the ice machine or the ice storage bin , please observe the

following guidelines:

Main drain should be thick enough, to be able to

dischargeall the water in the drain pipe.

Ice storage bin and water-cooling condenser pipes

should be separated, and coated heat preservation

material, in order to prevent condensation.

Every one metre long drainage pipe must have a drop

of 2.5 cm. And there can not be bended.

Good

Downward sloping

Effect is bad

Effect is bad

Upward sloping

DB Series Internet Of Things ice Machine

1.6 Choose installation location

a). The device information:

b). The user setting:

Ice thickness setting: through "+" and "-" keys the

users themselves can adjust the thickness of the ice.

Ice making mode: can choose the way of ice making,

Such as on/off mode means ice machine will stop when

ice storage bin was full; 2/2 mode means ice machine

stop 2 hours work for 2 hours, so it can let users according

to the need to make ice, energy saving, no old ice, more

health.

Energy saving mode: timing ice making, ice making

machine can be set the starting and stopping time,

Drainage time adjustment, can adjust the length of

the drainage time of ice machine, achieve the goal

of saving water and energy saving.

Maintenance information: Setting the ice machinesystem

for how many times of ice making or howlong ice machine

operation , ice machine need toclean and maintain, the

water filter cartridge needsto be replaced.

c). Advanced Settings:

Making ice/ receiving ice setting: setting the longest making

ice time and the longest closed time of ice maker;

Water inlet/drainage setting: setting the longest water

inlet time and the longest water drainage time;

Temperature setting: setting the temperature of the

condenser and evaporator of ice machine, used for

auxiliary ice and fault alarm;

Screen Settings: setting the activation of screen

brightness, dormancy brightness and no operation

delay time to sleep

6

1.10Check after installation

Ice machine after installation, you need to checkthe

following content before running machine.

The ice maker keep steady?

All of the inner packing dismantled?

All of the water, electricity connection?

Power supply voltage is accord with rated voltageof

the nameplate?

The ice machine grounding right?

Ahead of ice maker have adequate space to makethe

air flow ?

Ice making machine in the ambient temperature between

5 ° ~ 38 ° C?

Ice machine inlet water temperature of the installationpoints

remain between 5 ° ~ 32 ° C?

Ice machine and ice storage bin already clean?

Ice machine running

2.1WIFI cloud service ice machine touch

screen operation instructions:

2.1.1 Main screen

Ice making button: press ice making buttons, ice machine

for making ice state, then press again, turn off the machine.

Clean button: press clean button, the ice machine for

automatic cleaning state, then press again, downtime.

Menu button: click the menu button, ice machineinto

the menu bar, press the return key, ice machine return

to the main screen.

2.1.2Main menu has the following

secondary menu:

Level 1 menu contains:

Equipment information: recording related informationof

equipment . Including the model, number , has the number

of ice , cleaning , production date and other information.

User setting: user can set the ice thickness of the ice maker

, ice making mode, the energy saving mode, maintenance due

to remind.

A d v a n c e d S e t t i n g s : p a s s w o r d p r o t e c t i o n , f o r

e n g i n e e r s a n d e q u i p m e n t s e r v i c e p e r s o n n e l t o

p r o v i d e i c e m a c h i n e p a r a m e t e r S e t t i n g s .

Default mode: a key recovery factory set state,it is

available for you when you set the parameter error.

Services: including fault records, input check, outputcheck

, manually collecting ice.

Network Settings: set up to find the WIFI network.

Language Settings: can offer Chinese, English and

other languages.

Password Settings: provides the password protectionfor the

ice maker, prevent outsiders change ice machineparameters.

The secondary menu contains

view the ice maker general information and use

information

Ice machine model

Ice machine number

The date of production

Number of ice making

Number of cleaning machine

DB Series Internet Of Things ice Machine

d). Default mode::

e). services

1)Fault record: ice machine fails, first to stop,and

record fault in computer board, the fault information

is displayed on the screen at the same time, and it

will send the fault informationto the cloud server ;

Cloud server receives a fault information forwarded

to the computer server and mobile phone APP, so that

customers and factory at the same time will receive the

fault information of machine.

Fault information code and meaning:

2)input check

Check the condition and quality of magnetic

switch, high voltage switch, water level probe,

ice receiving probe, T1 & T2 temperature probe.

3)output check

Check the state and the quality of the compressor

, fan, water pump, inlet valve, drain valve, thermal

valve.

4)manual charge ice receiving

Used for maintenance, let the ice melted on the ice tray.

f). Network Settings:

Set up to find WIFI network。

g). Language:

Can offer Chinese, English and other languages.

h). Password Settings:

Provides the password protection for the ice maker

, prevent outsiders to change the ice machine

parameters.

2.2. WIFI ice machine running

processes instructions:

Turn on the power supply--the screen display

on standby

Start--press the ice making buttons on the

screen - device self-checking.。

Determine whether high voltage protection and

magnetic switch is closed. Open circuit equipment

not start, screen display high voltage protection

or magnetic switch open circuit fault.

Melting ice - hot air valve, water inlet valve,

compressor, water pump, drain valve.

Inlet valve open, hot air valve open, compressor starting

after 10 s, water inlet 30 s or the water full then the water

inlet valve will close; Pump starting after 30 s, then after

20 s, drain valve open; After 20 s, hot air valve, water

pump and drain valve closed.

Precooling---water inlet valve, compressor

, cooling fan.。

Precooling time 40 s. Cooling fan starting, water inlet

valve is opened, water level detection probe detect the

water full then the water inlet valve closed. If 40s finish

into the water, and the water levels fall after water pump

start, then the inlet valve filling water immediately and

stop when water is full; If after 40 s, the pump is still not

filled with water, so the water valve open until filled withwater.

7

Ice thickness adjustment: 0

Ice making mode On/off

The longest ice making time 40 minutes

The longest ice receiving time 4 minutes

The longest water inlet time 5.5 minutes

Drainage time about 15 seconds

language: Chinese

Ice making temperature of evaporation: - 5 degrees

Ice recerving temperature of evaporation : 0 degrees

Maintain notice no

Water saving model turn off

Timeing switch machine turn off

The screen to activate the brightness in 160 seconds

Dormancy brightness in 80 seconds

No operation dormancy for 10 seconds

Condenser cleaning for 9000 hours

Filter replacement of 9000 hours

Condensation temperature 55 degrees

E1, ice making time is long.

E2, ice receiving time is long.

E3, water shortage protection.

E4, refrigeration system failure.

E5, ice receiving system failure.

E6, high voltage protection.

E7, high temperature protection.

E8, T1 evaporator temperature sensor short-circuit.

E9, T1 evaporator temperature sensor circuit.

E10, T2 condenser temperature probe short-circuit.

E11, T2 condenser temperature sensor circuit.

E12 , magnetic switch failure.

E13, ice receiving probe failure.

DB Series Internet Of Things ice Machine

Freezing - compressor, cooling fan,

water pump, the water inlet valve。Running check

Notice

Confirm the water faucet open, ice machine has been

switched on.

The pipe inspection. Check all the pipes and pipe joint

, and to ensure no leakage.

The thickness of the ice bridge inspection. The thickness

of the ice bridge set up in 3 mm from factory, if you need

to adjust, pls click touch screenSettings button then it will

have user Settings menu.

8

Energy storage---compressor, water pump.

Closed cooling fans ahead of time, accelerate the

speed of ice receiving, improve the efficiency of the

ice maker.Condenser temperature probe by detecting

condensation temperature, determine the length of

the storage time, storage time means fan shut early

time is 0-60 s.

Ice receiving --- compressor, hot air valve,

drain valve, water pump, water inlet valve.

Hot air valve is opened, the ice dish began to let the bottom

of the ice to melt, on the effect of gravity then loss. Inspect

the condition of the magnetic switch when ice receiving,

magnetic switch is closed----to disconnect, ice receiving

finish, closed once agian within 30 s , return to the precooling

stage , ice making again ;After 30 s closed magnetic switch is

not closed, downtime, screen shows filled with ice. If the

magnetic switch is open, the ice magnetic switch is closed

whithin 4 minutes after ice receiving, then return to the

precooling stage, ice making again, magnetic switch is still

open after 4 minutes then machine will be stop , the screen

shows magnetic switch failure. When ice machine into the

ice receiving process 2 minutes, the evaporator temperature

below zero degrees , downtime . drainage after 30s ice

receiving , drainage time 0---30 s adjustable,end of the ice

receiving, drainage time is over, even if there still have

drainage time.

Before shipment ice machine has been running

and debugging in factory. In general, the new

machine without any debugging. In order to en

sure the ice machine normal operation, in the

following cases, need to be run to check:

•First start,

•Restart after long downtime

•After cleaning and disinfection

The thickness of the ice bridge inspection. The thickness

of the ice bridge set up in 3 mm from factory , if you need

to adjust, pls click touch screen Settingsbutton then it will

have user Settings menu.

Water pump start, ice machine starting into freezing cycle. In the

freezing process, if ice receiving detection probe can not detect

water, screen display ice receiving detection probe failure and

machine stop. Water levels fall in the process of ice making, when

the water level probe detect the water was fullthen the water valve

opens, the second filling water, water level detection probe after

the expiration of the water inlet valve closing (similarly can set

multiple moisturizing). In the freezing period of 6 minutes, testing t

he temperature of the evaporator and condenser probe, if evaporator

temperature higher than0 ℃, report downtime, screen displayed

refrigeration system failure; If the temperature of the condenser is

higher than 55℃, alarm warining, screen displayed radiator is dirty

, if higher than 65 ℃, report downtime, screen displayed high

temperature protection. Condenser temperature probr by detecting

condensation temperature,then determine the length of the storage

time; When ice probe does not come into contact with water, delay

set time, into the process of energy storage.

DB Series Internet Of Things ice Machine

Ice bridge thickness: 3mm

Maintenance

Notice

1) remove the air filter.

2) please use the vacuum cleaner or soft brush to clean

the air filter. If the air filter serious blocked, please clean

with warm water and neutral detergent.

3) please rinse air filter thoroughly with water and

make it completely dry, then put back in place.

3.2Condenser cleaning

warning

Clean the condenser, must be cut off the ice maker

power supply . Condenser fin edge sharp, be careful

to clean.

If the condenser is dirty, can block the air circulation,

causing ice machine operating temperature is too high

, reduce the amount of ice, shorten the service life of

parts. At least every six months to clean condenser,

according to the following steps.

Using a soft brush or a vacuum cleaner with brushto clean

the outside of the condenser, cleaning order

is from top to bottom, not from one side to the other

side. Be careful not to bend the fin condenser.

Use flashlight irradiate condenser fin, and check

whether there is a dirt between fin. If there have

dirt, so indicates theat the internal along the finned

blow compressed air from the condenser. Be careful

not to deform the fan blade.

Using commercial coil (air conditioning) cleaner. When

used to follow the instructions and noticeof the coil

cleaner.

3.3The machine stop/winterzing

If the ice machine is stopped for a long time, or exposure

to 0 ° C or below, need to take special protective measures.

Notice

In below 0 ° C environment, if there have water stay

inside the machine , may cause severe damage to

machine parts . The causes of failure is beyond the

scope of the warranty.

For air-cooled ice machine, please follow these steps:

9

3.1Cleanning

It is forbidden to use water jet flushing the ice

machine.

Shall not use any alcoholic liquids to clean or

disinfect ice machine, otherwise may cause

crack of plastic parts.

Please do not remove the roof and ventilation

window, but need to professional maintenance

personnel to remove it.

Please do not put plastic parts in more than 40

℃ temperature of the water or in the dishwasher

cleaning, in order to avoid damage to the parts.

Before cleaning or maintenance operations,

please put power plug of ice machine out from

supply network.

Environmental cleaning: clean regularly around the ice

machine, in order to keep clean, make the equipment

run efficiently.

The shell cleaning: sponge dip in neutral soap water

to clean the ice maker, and to wipe them with a clean

soft cloth. When necessary, can use stainless steel

cleaner/polishes.

Air filter cleaning: plastic mesh air filter can filter out the

dirt and dust in the air, prevent condenser blocked

. If the filter blockage, the performance of the ice machine

will drop. Please remove and clean air filters for at least

twice a month:

Tease bended condenser fin with fin comb.

5. Make sure there is no water left in the inlet pipe

, drainage pipe, water pipe.

1. Disconnect the power supply of the ice machine.

2. Disconnect the water supply of the ice machine.

3. Drain the water in the sink.

4. Unplug the inlet pipe at the back of the ice machine

, make the water inlet pipe emptying.

DB Series Internet Of Things ice Machine

4.1Maintenance

10

Maintenance

1. Before the repair, please consider the following aspects, in order to quickly to

find questions, provide the efficiency of the machine to return to work.

a). Whether the water supply is normal? including whether to open the faucet,

whether the inlet valve mouth is blockage and the water pressure is too low or

too high?

b). The power supply is normal? including whether the voltage is too low, the

switch is turned on, the fuse is burnt and whether the plug is out?

c). Whether the environment temperature is too high or too low (ice machine

working environment temperature range 5 ~ 38 degrees), whether the water

temperature is too high or too low (water temperature range 5 ~ 32 degrees)

2. Write down the serial number of the machine and computer board, andcall

free telephone on the service label

3. The circuit diagram.

d). I s t h e refr i ger a tor st o rage i s f u ll? ca n cle a n u p a fte r w o rk? D ) . I s the

ref r ige r a tor s t o rag e i s f ull ? c a n clea n u p a fte r w o rk?

Power Section

Microprocessor part WIFI part

L

N

High

Pressure

Evaporation

Temperature

Condensation

Temperature

Cleaning

Operation

Ground

Connection

Display

Screens

AC220V

WIFI Antennas

T

T

Connect the

Dispaly Screens

Ice Receiving Probe

Water Level Probe

Compressor Fan Water Pump

Water Inlet

Valve Drain Valve

Hot Air

Valve

DB Series Internet Of Things ice Machine

Water baffle

plate switch

Wiring diagram of DB series all-in-one machine

11

DB Series Internet Of Things ice Machine

S

Rocker

Switch

AC220V

~

KM

KM

Compressor Fan Water Pump

Water Inlet

Valve Drain Valve

Hot Air

Valve

Ice Receiving Probe

Water Level Probe

WIFI part

WIFI

Antennas

Water baffle

plate switch

High

Pressure

Evaporation

Temperature

Condensation

Temperature

Cleaning

Operation

Microprocessor part

Connect the

Dispaly Screens

Ground

Connection

Display

Screens

Power Section

Wiring diagram of DB series split nachine

This manual suits for next models

13

Table of contents

Popular Ice Maker manuals by other brands

KitchenAid

KitchenAid KUIS155HBL4 parts list

Nostalgia Electrics

Nostalgia Electrics Coca-Cola CKICEBSC26CR Instructions & recipes

Xxxlutz

Xxxlutz IMB1000-GS manual

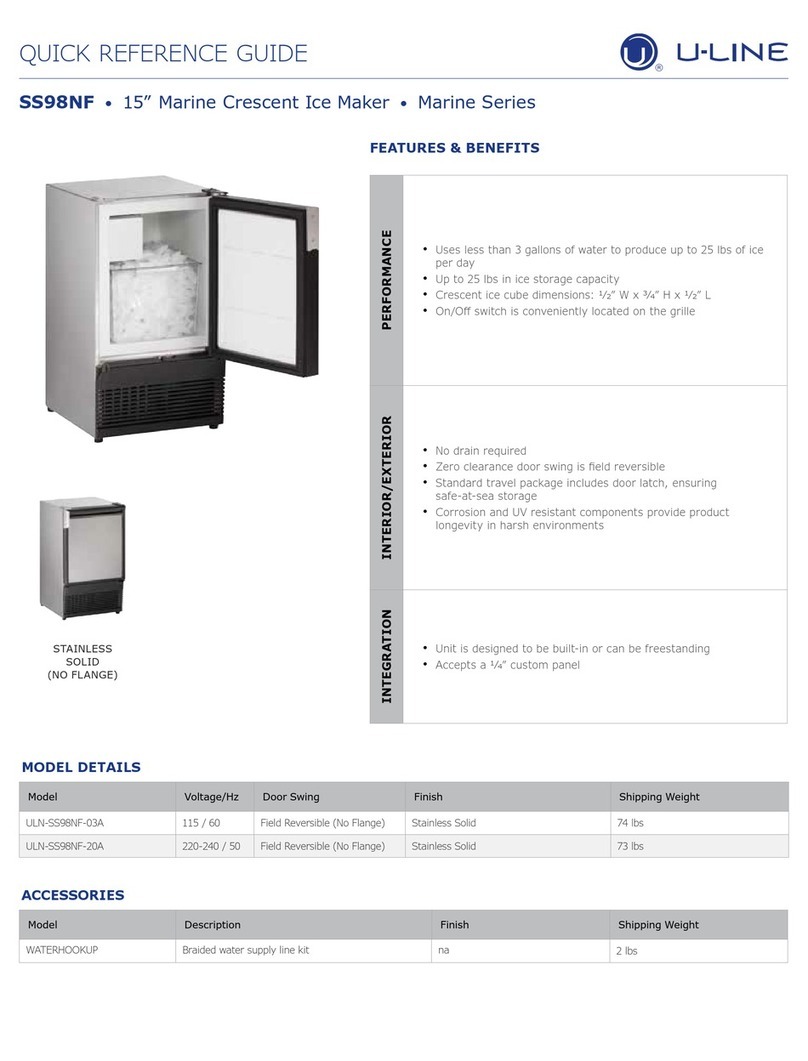

U-Line

U-Line SS98NF Quick reference guide

icetro

icetro IM Series Technician's handbook

Marvel

Marvel 30iMT Installation, operation and maintenance instructions