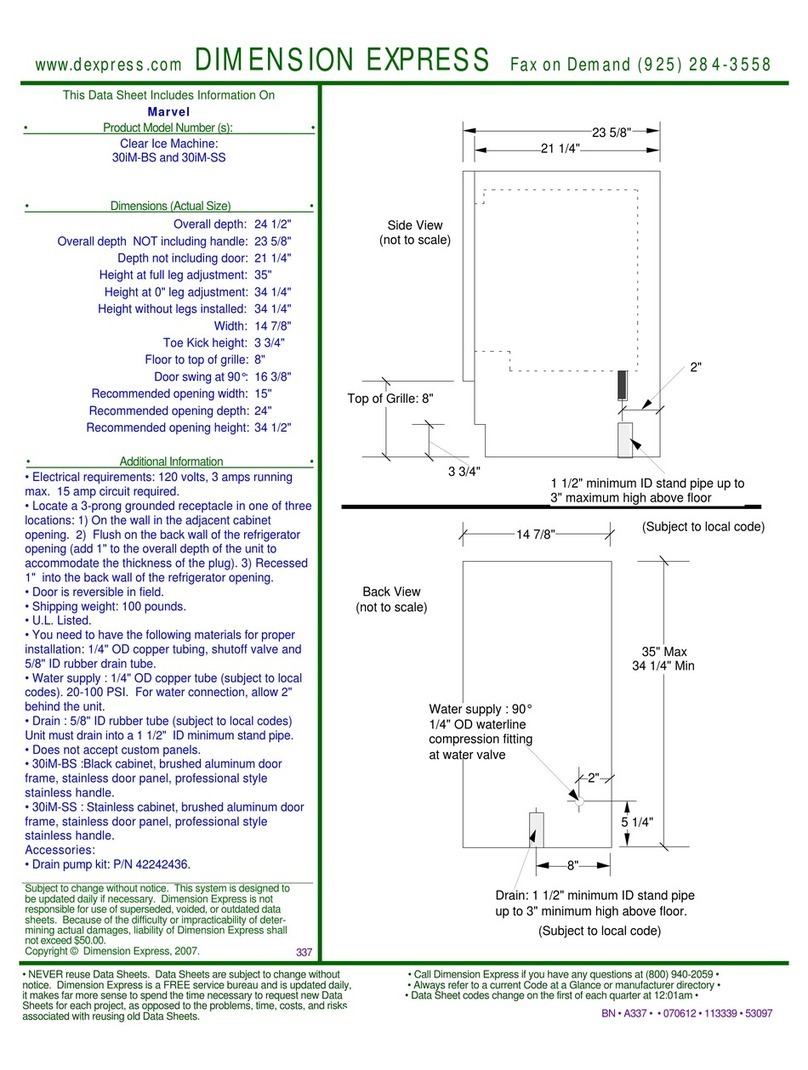

The Marvel Drain Pump is designed to remove drain water

from ice machines installed in areas without direct drain-

age access. The sealed reservoir pump collects the melted

ice water and pumps it to a maximum lift of eight (8) feet

through 3/8” I.D. vinyl tubing to a drain.

This pump has been evaluated for use with water

only.

NOTE: Despite the ease of installation, reasonable care

and safe methods should be practiced. Do NOT work

with energized electrical equipment in a wet area. Read

and follow the installation instructions listed in this

manual.

Risk of electric shock - This pump is supplied with a

grounding conductor and grounding-type attachment

plug. To reduce the risk of electric shock, be certain that

it is connected only to properly grounded, grounding-

type receptacle.

Materials Supplied

1- Marvel 115VAC/60Hz Drain Pump

1- 20 ft. x 3/8 in. I.D. Discharge Tubing

1- 18 in. x 3/8 in. I.D. Vent Tubing

1- Installation Kit (contents below)

1- 1-3/4 in. x 5/8 in. I.D. Inlet Tubing

1- 8 in. x 5/8 in. I.D. Inlet Tubing

2- Tubing Clips (secures vent tubing to back of ice

machine)

2- Small Tubing Clamps (secures vent and discharge

tubing)

2- Large Tubing Clamps (secures inlet tubing)

2- #8 x 3/8” Screws

Tools Required

Pliers

Phillips Screwdriver

Flat Blade Screwdriver

5/16” Hex Head Driver

Maintenance

The following items require review on a regular basis.

Check that the inlet tubing from the ice machine1.

drain to the drain pump is open and is free of foreign

material. Inspect the screen at the top of the inlet tube

to ensure there is nothing blocking water flow to the

pump.

Check that the vent line is open, free of kinks/sharp2.

bends, so that air flows freely from the pump reservoir.

Check that the discharge tubing is free of foreign ma-3.

terial (algae, etc.) and kinks/bends. Confirm that the

check valve is operational by observing that the water

flow is evident in one (1) direction only - out of the

pump. Remove and clean as required.

Troubleshooting

NOTICE: If the drain pump reservoir (not the ice machine

bin) reaches overfill condition, the power to the ice ma-

chine will be shut off.

If the ice machine is not working, check the following:

Make sure there is power at the receptacle.•

Make sure the ice machine is turned on.•

Make sure the ice bin is not full.•

Then check the drain pump:

The pump does not run:

Make sure the pump is plugged in and there is power•

to the receptacle.

Check the inlet screen for debris and clean as needed.•

Make certain the vent line is free of kinks/sharp bends•

or restrictions.

Make certain there is enough water to activate the•

drain pump. It will take at least one (1) quart of water

to activate the drain pump.

The pump runs, but no water is pumped out:

Check that the vent is clear and free of restrictions.•

Check the discharge line to make certain there are no•

restrictions.

Make sure that the discharge tubing has not exceeded•

the maximum lift of eight (8) feet and the horizontal

run is not greater than twenty (20) feet.

The pump runs and then quickly turns off repeatedly:

Check to make certain the drain pump is level.•

Check that the vent is clear and free of restrictions.•

OPTIONAL DRAIN PUMP INSTALLATION

5