USER’S

GUIDE

7

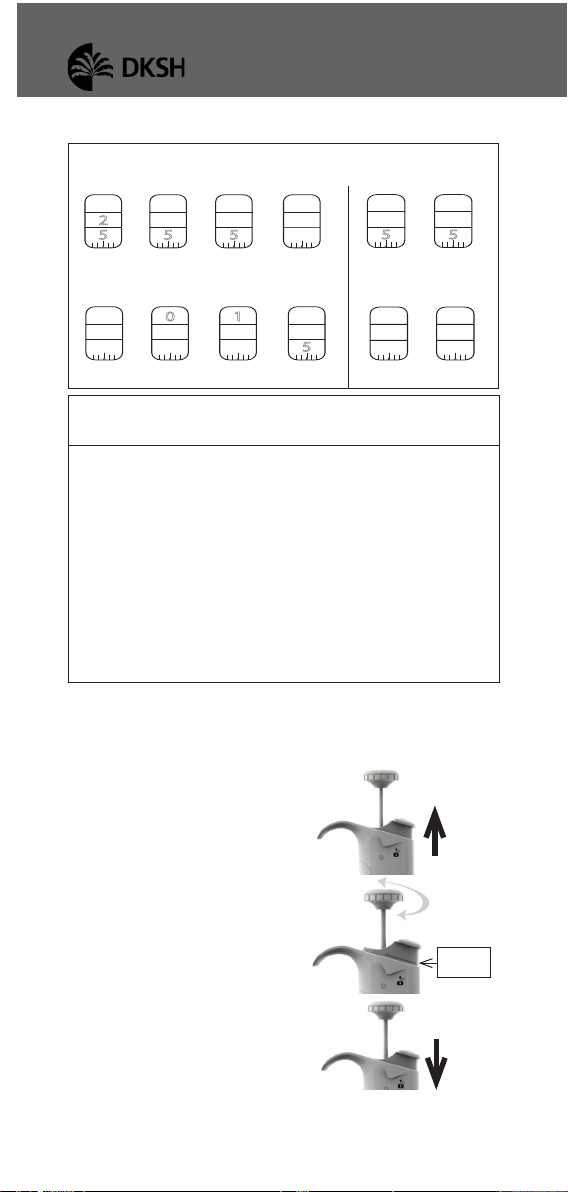

To adjust the volume setting:

Remove the push button.

Use the calibration key to take off the block cover.

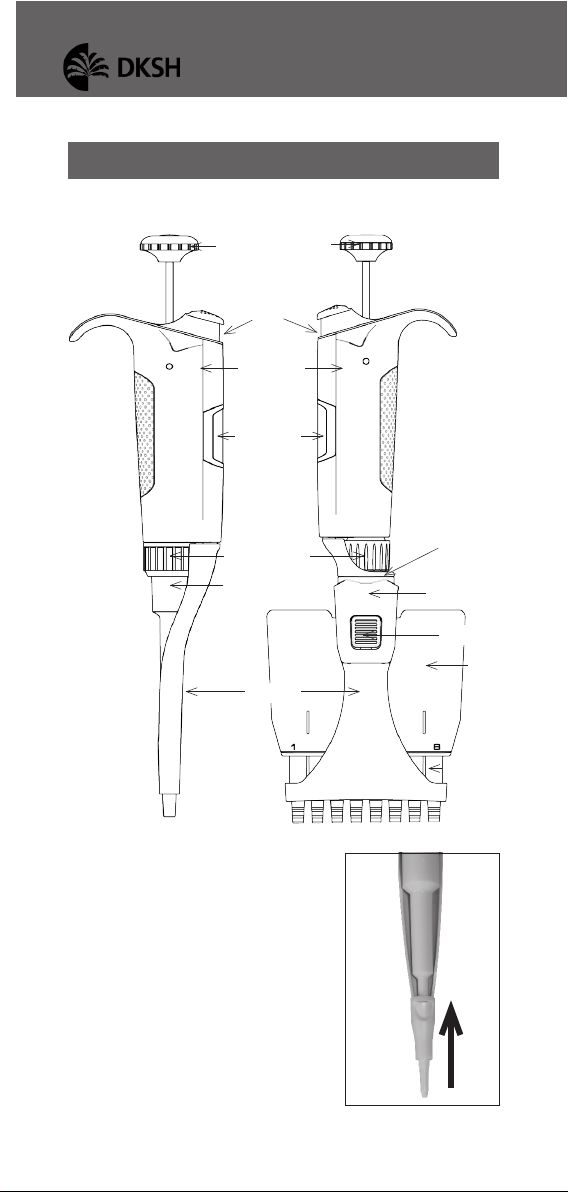

a.Insert the metal rod into the

calibration tool on the hexago-

nal side.

b.Engage the two rectangular

hooks of part 2 into the two

holes of the block cover. You

should feel them clipped on

firmly in the hidden part of the

pipette (see figure 5).

c. Make sure to hold the part 1 at the top cap, along

the part 2.

d.Turn the part 2 counterclock-

wise slowly to remove the block

cover (see figure 6).

Put the block cover apart.

To obtain maximum accuracy when setting the volume,

proceed as follows:

>when decreasing the volume setting, slowly reach the

required setting, making sure not to overshoot the mark.

>when increasing the volume setting, pass the required

value by 1/3 of a turn and then slowly decrease to reach

the volume, making sure not to overshoot the mark.

>To adjust perfectly the last digit, it is even more precise

to do so on the Lock position.

The calibration of the LabPRO Pipettes has been per-

formed with distilled water and very high precision

volumetric instruments. Adjusting the pipette can be

necessary for different solutions due to their density,

viscosity, surface tension and/or vapor pressure etc.

Calibration is sometimes recommended when it is used

in high altitudes or with special tips. It can also be reca-

librated when long pipette tips are used. Performance

testing should take place in a draught-free room at 15-

30°C, constant to ± 0.5°C and humidity above 50%.

FIGURE 5

FIGURE 6

Part 1

Part 2

5 - USER ADJUSTMENT

USER’S

GUIDE