Doc. Nr.: DSDL_22014_A

[9]

4. WORKING PRINCIPLE

4.1. MICROSWITCHES, SENSORS AND SOLENOID VALVES

Detects when the infuser is on top

position

“NC”, it opens when the infuser is in top

position

Detects when the infuser is on down

position

“NO”, it closes when the infuser is in down

position

Detects when the drip tray is in

correct position

Changeover micro switch. When the drip

tray is inserted:

- the contact for the drip tray

detection is OPEN;

- the contact for the transmission

motor power supply is CLOSED.

M4 = WATER TANK

MICROSWITCH

Detects the presence of the water

tank

Changeover micro switch. When the water

tank is inserted:

- the contact for the water tank

detection is OPEN;

- the contact for the transmission

motor power supply is CLOSED.

M5 = IFD CONNECTOR

MICROSWITCH

Detects when the IFD connector is

attached to the machine

“NO”, it closes when the IFD connector is

attached.

M6 = MILK JUG LID

MICROSWITCH

Detects when the milk jug lid is

attached to the machine

“NO”, it closes when the milk jug lid is

attached.

M7 = HOT WATER SPOUT

MICROSWITCH

Detects when the hot water spout is

attached to the machine

“NO”, it closes when the hot water spout is

attached.

REED SENSOR LOW WATER

TANK

Detects when the water level is at

minimum

Detects rotations of transmission

motor

MILK PRESENCE OPTICAL

SENSOR

Detects when the milk jug contains

milk and when it is empty

- When the jug is connected and

contains milk, the milk presence

blocks the

- infrared beam generated by the

sensor and the machine enables

the milk recipes preparation.

- When the jug is connected but it

is empty, the infrared beam

generated by the sensor is free to

pass and the machine disables

the milk recipes preparation. In

this case only the milk jug

cleaning function is active.

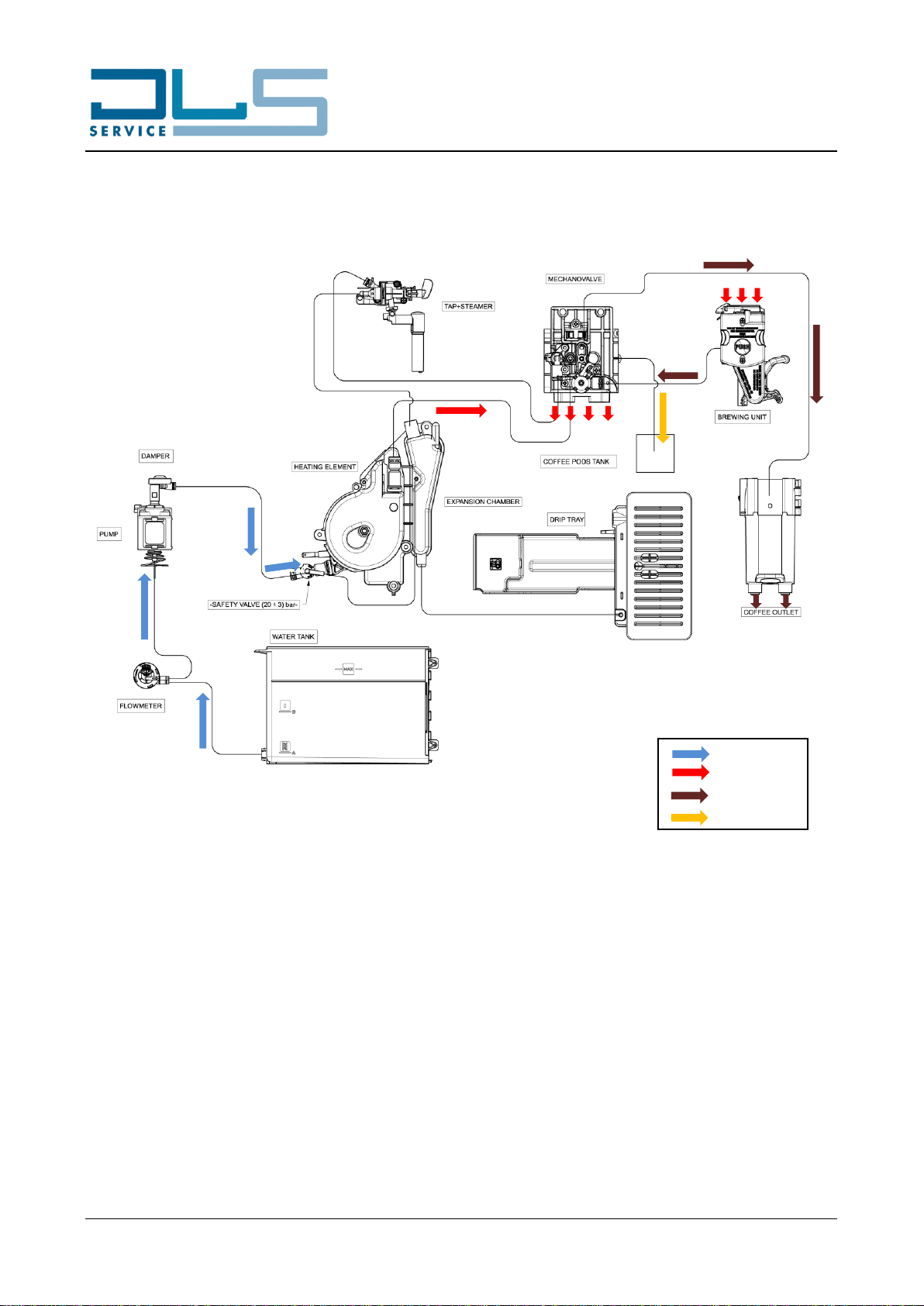

It opens to deliver hot water through the

hot water spout and steam to the milk jug

for milk frothing. When it closes, it allows

the discharge of the residual pressure to

the expansion chamber and drip tray.