Doc. Nr.: DSDL_20013_A

[6]

5. WORKING PRINCIPLE

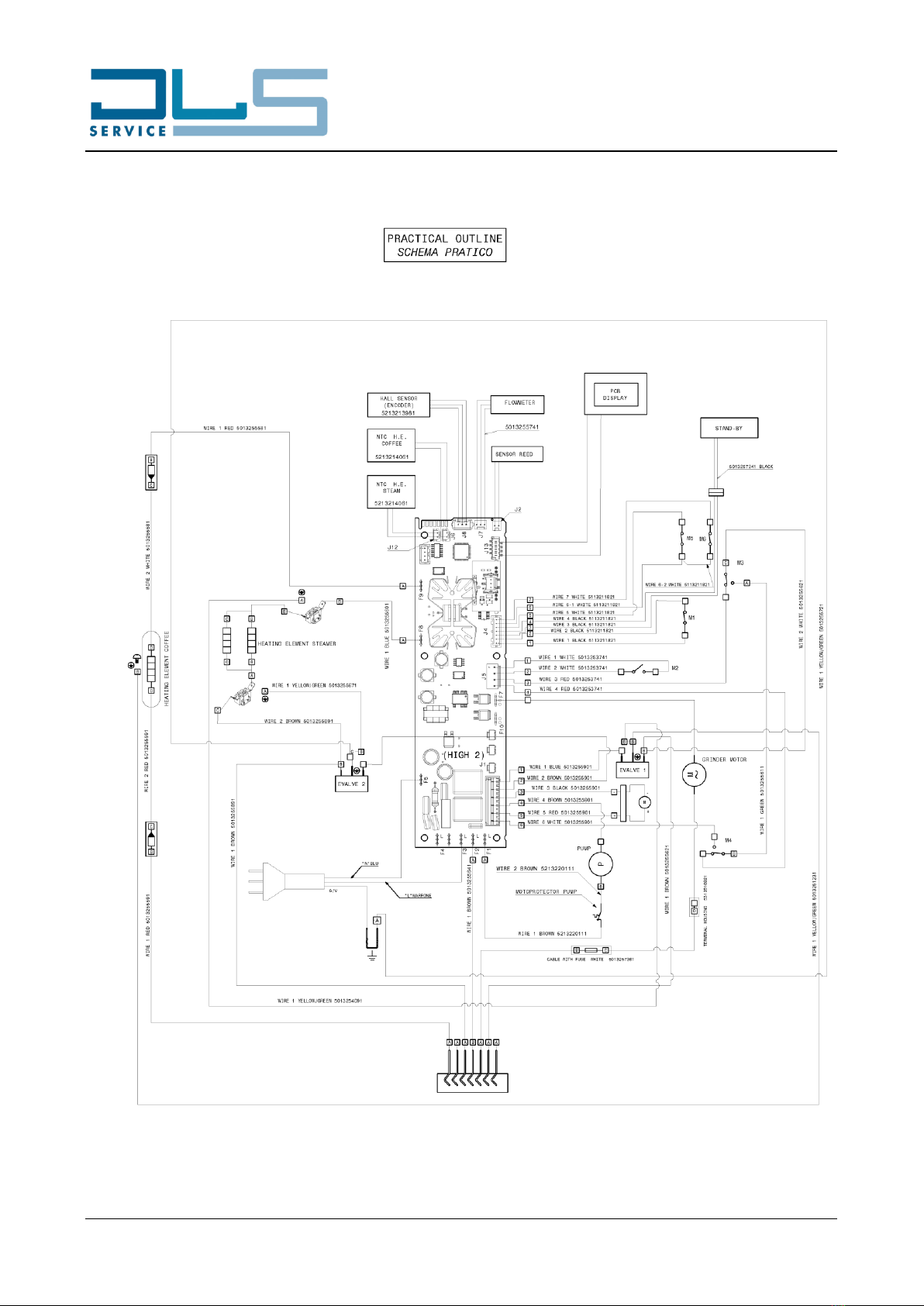

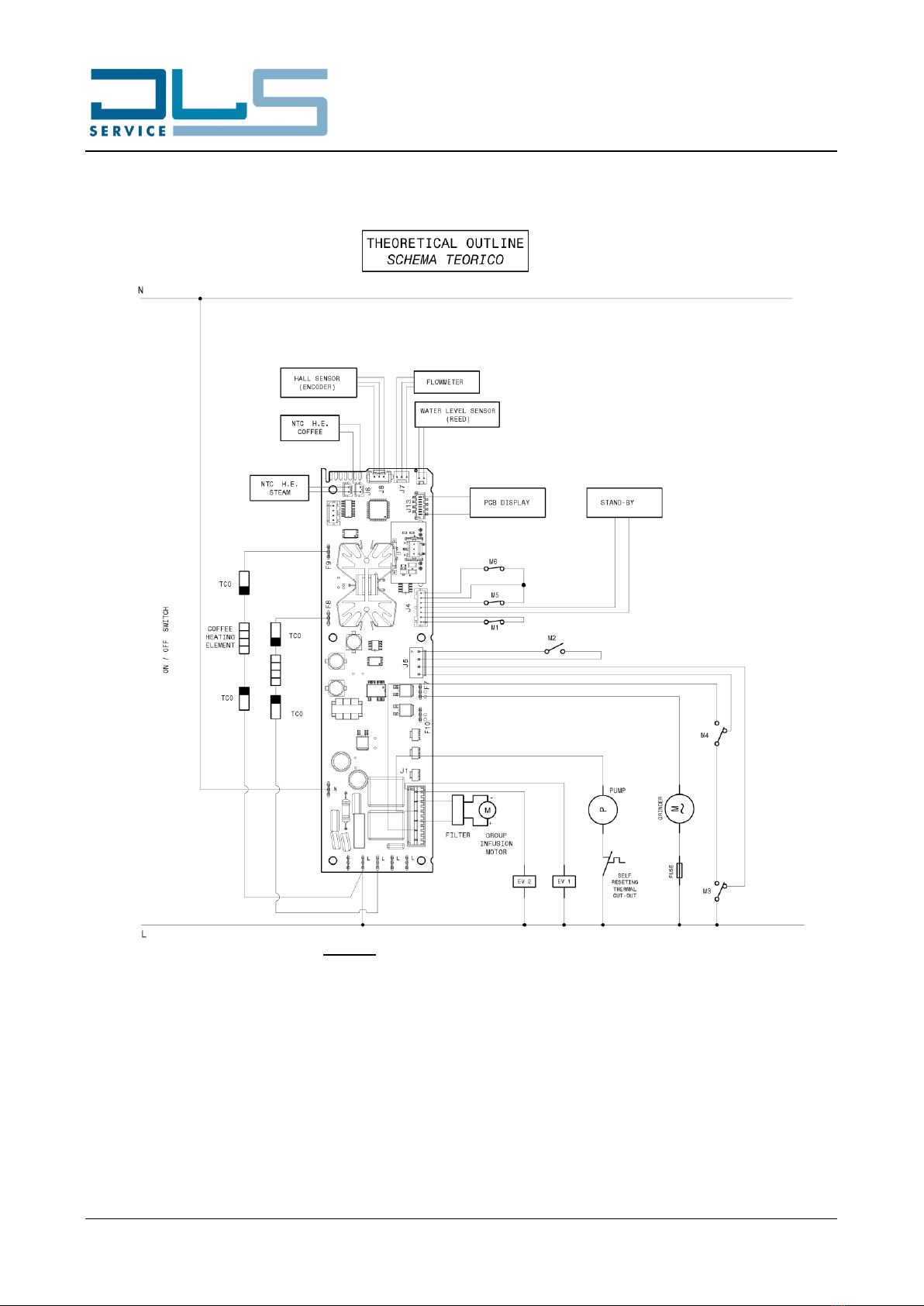

5.1. MICRO SWITCHES, SENSORS AND SOLENOID VALVES

Detects when the infuser is on top

position

“NC”, it opens when the infuser is in top

position

Detects when the infuser is on down

position

“NO”, it closes when the infuser is in down

position

Detects when the drip tray is in

correct position

3-pin micro switch. When the drip tray is

inserted:

- the contact for the drip tray

detection is OPEN;

- the contact for the transmission

motor power supply is CLOSED.

M4 = WATER TANK MICRO

SWITCH

Detects the presence of the water

tank

3-pin micro switch. When the water tank is

inserted:

- the contact for the water tank

detection is OPEN;

- the contact for the transmission

motor power supply is CLOSED.

Detects the presence of the milk jug

“NC”, it opens when the accessory is

present

M6 = HOT WATER SPOUT /

CLEAN MICRO SWITCH

Detects the presence of the hot

water spout or starts the CLEAN

function for the milk jug

“NC”, it opens when the hot water spout is

present or when the milk jug knob is in the

CLEAN position

Detects rotations of transmission

motor

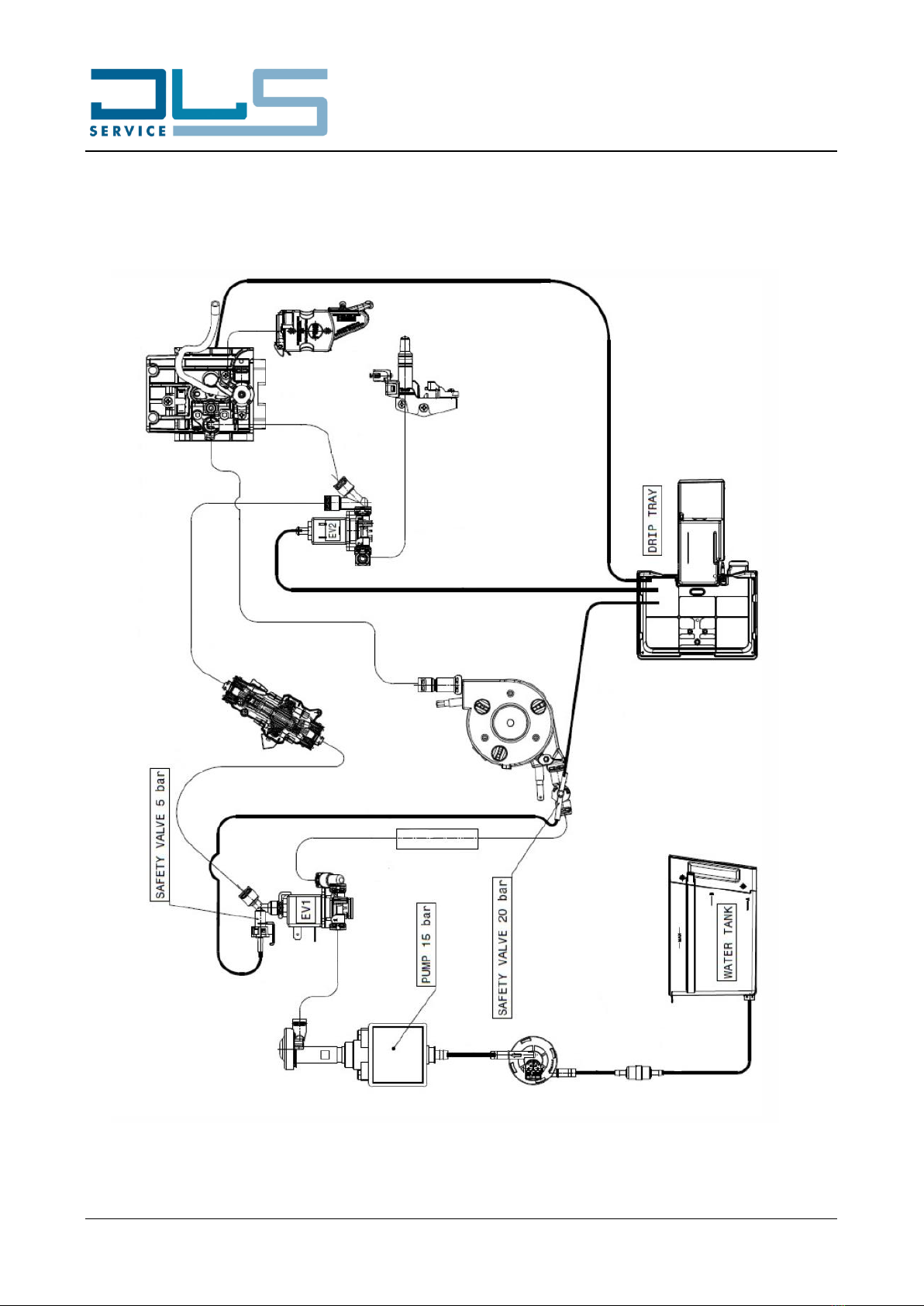

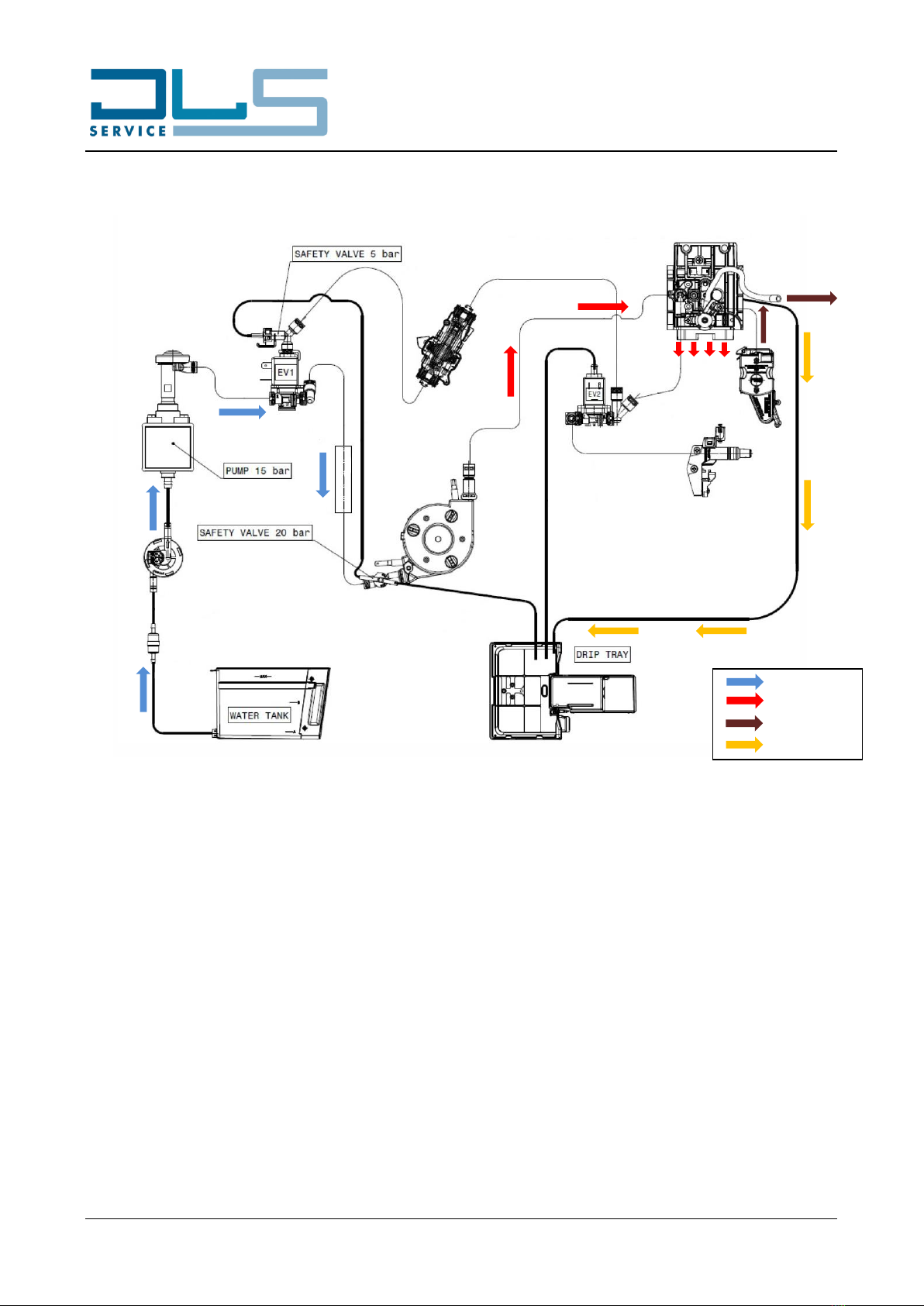

EV1 = 3-ways solenoid valve

Allows the water flow to go to the

Thermoblock

When activated, the water flow goes to the

Thermoblock.

When deactivated, the water flow goes to

the Steamer.

EV2 = 3-ways solenoid valve

Allows the hot water and the steam

to flow to the connection nozzle

When activated, the water/steam flow

goes to the connection nozzle