Doc. Nr.: DSDL_22007_C

[2]

1 Summary

2TECHNICAL DATA................................................................................................................................3

3HYDRAULIC DIAGRAM........................................................................................................................4

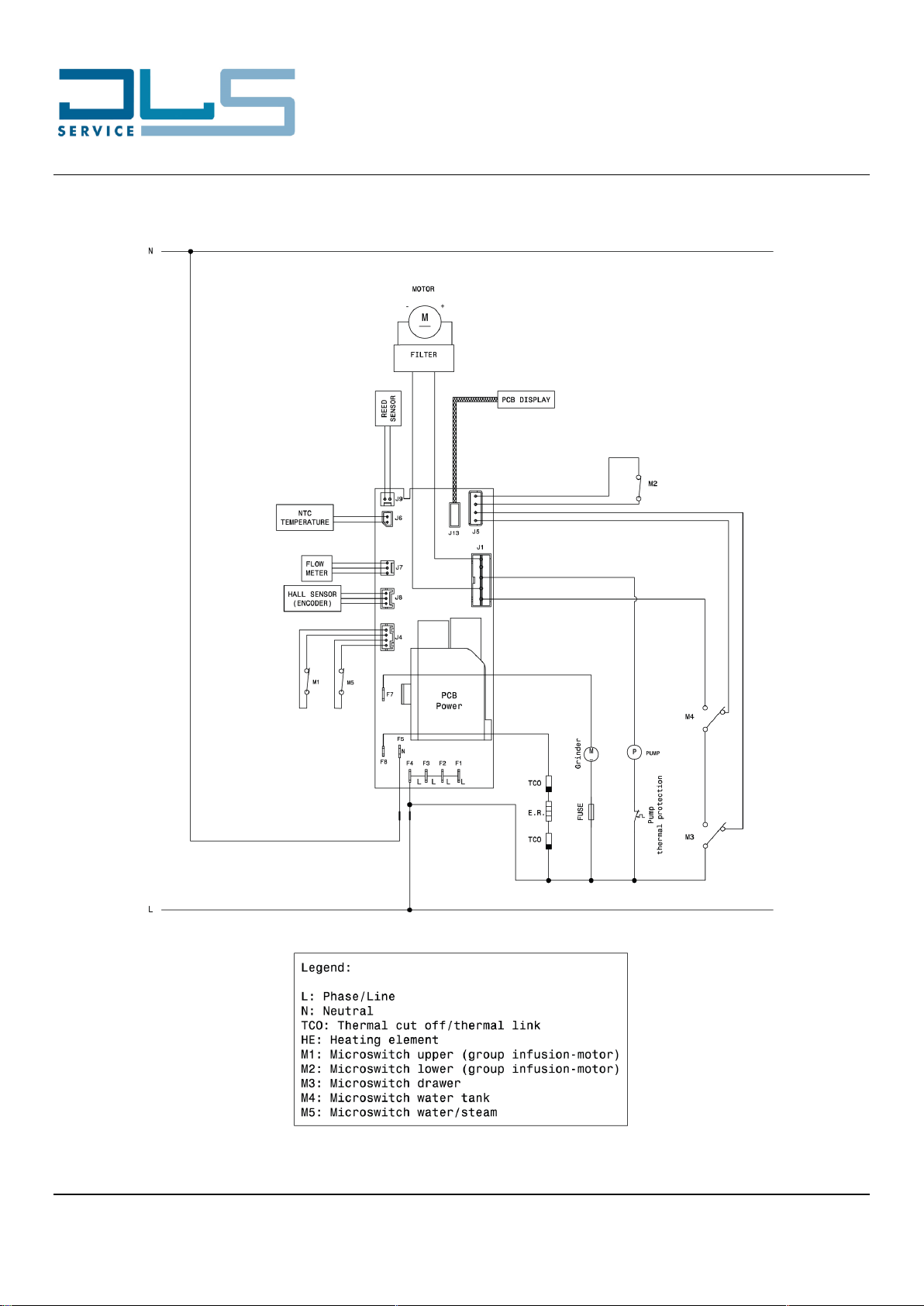

4WIRING DIAGRAM ...............................................................................................................................5

4.1 Practical Outline.............................................................................................................................5

4.2 Theorical Outline............................................................................................................................6

5WORKING PRINCIPLE.........................................................................................................................7

5.1 MICROSWITCHES, SENSORS AND SOLENOID VALVES...........................................................7

6TEST MODE .........................................................................................................................................8

6.1 LOAD TEST MODE........................................................................................................................8

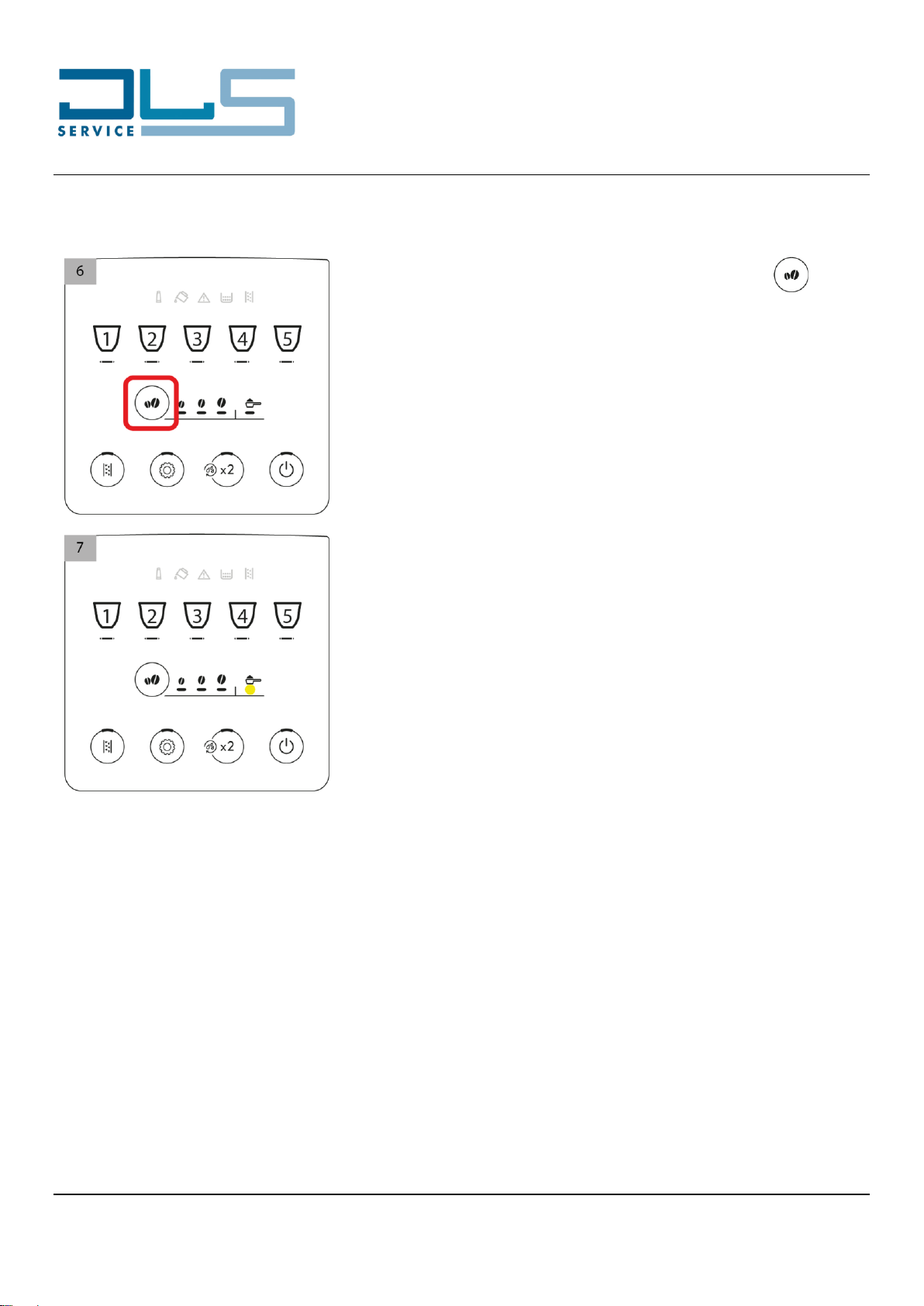

6.2 DISPLAY TEST MODE ..................................................................................................................9

6.3 RESET ENCODER ......................................................................................................................10

7STATISTICS MODE............................................................................................................................11

8A. HEATING ELEMENTS RESISTANCE CHECK...............................................................................13

9COFFEE TEMPERATURE TEST........................................................................................................14