//

//

//

//

© 2021 DLX ENTERPRISES LLC. // VERSION 1.01 2

WARNING: READ CAREFULLY

!

RISK OF EXPLOSION OR FIRE

1. Do not store or use gasoline or other ammable vapors and liquids in the vicinity of

this or any other appliance.

2. Keep solid combustibles, such as building materials, paper, or cardboard a safe

distance away from the heater. As recommended by the instructions never use

the heater in spaces which do or may contain volatile or airborne combustibles,

or products such as gasoline, solvents, paint thinner, dust particles, or unknown

chemicals.

3. Service must be performed by a service agency.

RISK OF ELECTRICAL SHOCK

1. Check the heater and its electrical cords thoroughly for damage.

2. DO NOT operate if the heater or cords are damaged. Never service heater while

it is plugged in. Severe electrical shock can occur. Only plug unit into a properly

grounded, GFCI protected outlet.

3. Ensure power supply is adequate: 1 PH, 120v, 60 Hz, 3 A.

RISK OF CARBON MONOXIDE POISONING

1. Do not use a portable heater in an enclosed area. This can produce deadly levels

of carbon monoxide: an odorless, colorless gas.

2. Early signs of carbon monoxide poisoning resemble the u with headaches,

dizziness, or nausea. If you have these signs, the heater may not be working

properly. Get fresh air immediately.

3. Some people are more affected by carbon monoxide than others. These include

pregnant women, persons with heart or lung disease or anemia, those under the

inuence of alcohol, and those at high altitudes.

4. If carbon monoxide is detected, turn the heater OFF and have the unit serviced

immediately.

ADDITIONAL SAFETY INFORMATION

1. NEVER LEAVE THE HEATER UNATTENDED.

2. This unit is not for home or recreational vehicle use.

3. The packaging material is not a toy. Keep the plastic packaging out of the reach of

children, danger of suffocation!

4. Do not operate this unit when under the inuence of drugs or alcohol.

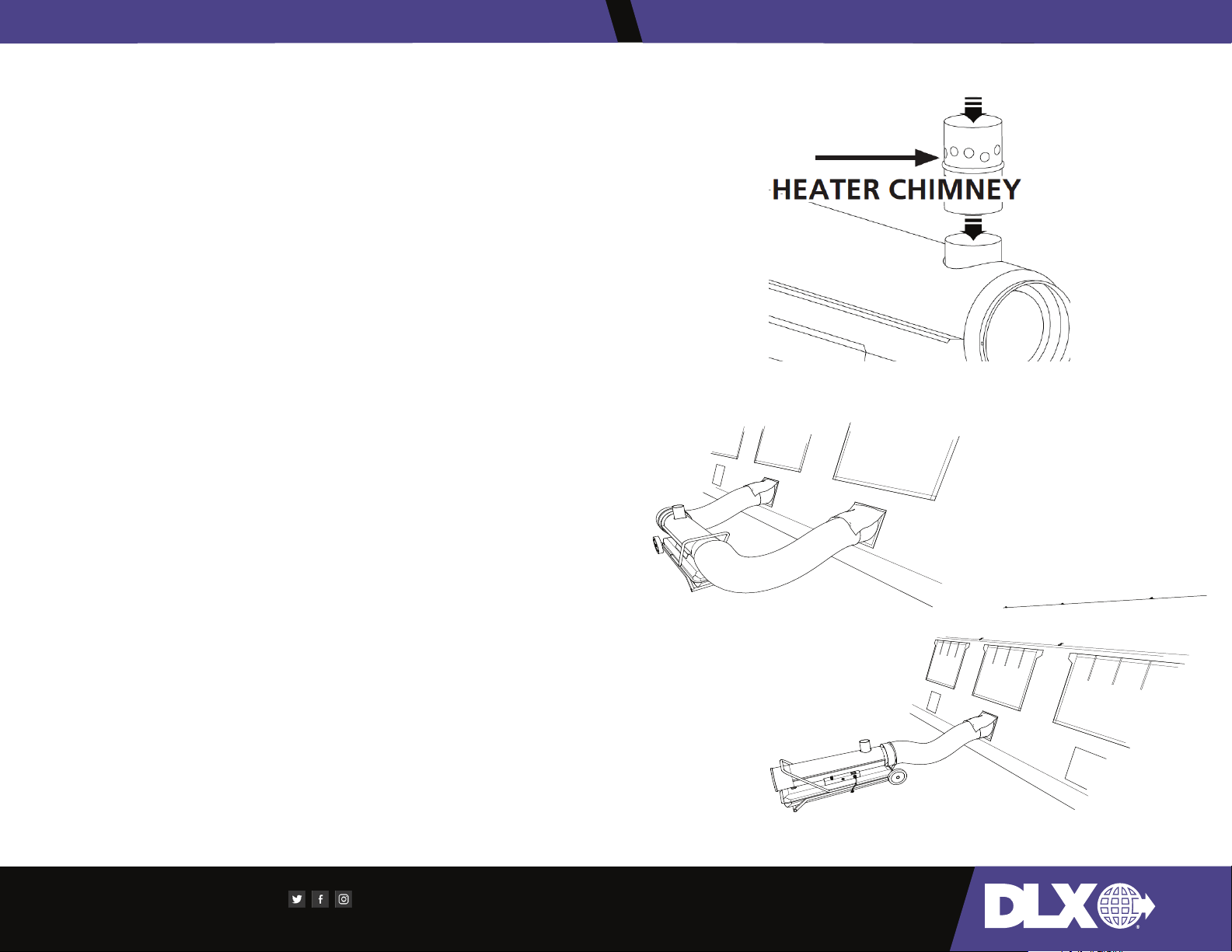

5. This is an indirect oil-red portable heater. It uses air (oxygen) from the area in

which it is used. Provisions for adequate combustion and ventilation air must be

provided.

6. Improper adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual for correct installation and operational

procedures.

7. Not suitable for operation with external tank.

8. The use of the unit shall be in accordance with the regulations and legislation of

authorities having jurisdiction.

9. Heaters used near tarps, curtains, or other similar covering materials must be kept

at a safe distance. It is advised to use re-proof covering material.

IMPORTANT: READ THIS OWNER’S MANUAL CAREFULLY AND COMPLETELY BEFORE TRYING TO ASSEMBLE, OPERATE, OR SERVICE

THIS HEATER. IMPROPER USE OF THIS HEATER CAN CAUSE SERIOUS INJURY OR DEATH FROM BURNS, FIRE, EXPLOSION, ELECTRICAL

SHOCK, AND/OR CARBON MONOXIDE POISONING.