DMC HX33 User manual

Pneumatic Crimp Machine

Version HX33 –02/16 –Rev. A

HX33

Operating Instructions

HX33-DS Rev. A Page 2 / 23

Producer

WEZAG GmbH

Werkzeugfabrik

Wittigstr. 8

35260 Stadtallendorf

Germany

Sale

DMC

Daniels Manufacturing Corporation

526 Thorpe Road

Orlando, FL 32824-8133

USA

Telephone: 001 407 855 6161

www.dmctools.com

Date Version

02.24.2016 REV. A

© by WEZAG

Reproduction of these instructions or parts of them in whatever form is not permitted without

express written permission from the publisher.

We reserve the right to make technical changes necessary to improve the machine that could

diverge from figures and information in these instructions.

HX33-DS Rev. A Page 3 / 23

Table of Contents

1Introduction...............................................................................................................................................4

1.1 Product Specification.........................................................................................................................4

1.2 Conformity .........................................................................................................................................4

1.3 Dealing with the Operating Instruction...............................................................................................4

2Safety .......................................................................................................................................................5

2.1 Warning & Safety Precautions in this Operating Instruction .............................................................5

2.2 Safety Precautions ............................................................................................................................5

2.3 Responsibilities..................................................................................................................................7

2.4 Designed Use....................................................................................................................................7

2.5 Predictable Misuse ............................................................................................................................7

2.6 Hazardous Areas...............................................................................................................................8

3Shipment ..................................................................................................................................................8

3.1 Packing..............................................................................................................................................8

3.2 Packing Contents...............................................................................................................................8

4Technical Description...............................................................................................................................9

4.1 Operators Guide................................................................................................................................9

4.2 Machine Identification..................................................................................................................... 10

4.3 Technical Data................................................................................................................................ 10

4.4 Safety Guard................................................................................................................................... 10

4.5 Release Button............................................................................................................................... 11

5Transport and Installation.......................................................................................................................11

5.1 Transport ........................................................................................................................................ 11

5.2 Installation....................................................................................................................................... 11

6Commissioning / Connecting to Compressed Air Supply ......................................................................12

7Tooling....................................................................................................................................................14

8Normal Operation / Production Cycle.....................................................................................................15

9Maintenance...........................................................................................................................................16

9.1 Maintenance Plan........................................................................................................................... 16

9.1.1 Daily..................................................................................................................................... 16

10 Problem Handling and Fault Diagnostics...............................................................................................17

11 Removal from Service, Demounting, Disassembly,...............................................................................18

12 Storage...................................................................................................................................................18

13 Disposal..................................................................................................................................................18

14 Exploded View Drawing, Spare Part List ...............................................................................................19

14.1 Exploded View Drawing.............................................................................................................. 19

14.2 Parts List Exploded View Drawing.............................................................................................. 20

14.3 Pneumatic Diagram .................................................................................................................... 22

14.4 Parts List Pneumatic................................................................................................................... 22

14.5 Accessories overview for re-orders ............................................................................................ 23

14.6Additional Information / Limitation of Liability / Limited Warranty............................................... 23

HX33-DS Rev. A Page 4 / 23

1 Introduction

1.1 Product Specification

The DMC HX33 is a bench top pneumatic crimp machine that is compatible with M22520/5

military and many DMC "Y-die" series crimp dies. The die sets are interchangeable and can

be easily installed and removed from the HX33 pneumatic crimp tool.

Utilizing the enclosed foot pedal, the crimping cycle of the HX33 is activated and allows the

operator to have both hands free to insert the crimped item and wire. All HX33 crimp tools are

equipped with a positive closing mechanism to ensure consistent crimp quality.

The HX33 has an emergency release button that will open the crimping jaws in the event of

blocked jaws caused by operation or handling errors or wrongly placed terminals.

All other applications of the HX33 are only permitted with a written permission of the

manufacturer. For all unauthorised applications of the HX33 the manufacturer cannot be held

liable for any resultant damage or injury.

1.2 Conformity

The machine may only be used for the purpose specified in the operating instruction. The

manufacturer and supplier will not be liable for any damages which may result due to the

machine being used for a purpose other than that for which it was intended. This is done

entirely at the user’s own risk.

RoHS Information

The pneumatic crimp machine HX33 complies with the EU-Guideline 2011/65/EU(RoHS2).

CE

The pneumatic crimp machine HX33 is CE compliant.

The original declaration of conformity was supplied together with the invoice of the

machine.

1.3 Dealing with the Operating Instruction

The operating instruction manual contains all information concerning operating elements,

operation, commissioning, and maintenance work as well as technical data.

The operating instruction must be constantly within reach of the HX33 pneumatic crimp

machine. Every machine operator must read and understand the operating instruction in order

to ensure safe and efficient production with this piece of equipment.

DMC declines to accept any liability for damages that are incurred due to the fact that the

instructions on the machine or in the operation instruction have been disregarded.

The user is responsible for supplementing the operation instruction with any instructions

resulting from current national regulations for accident prevention and protection of the

environment.

This operating instruction has to be guarded for later use.

The German original version of the operating instruction is legally binding.

HX33-DS Rev. A Page 5 / 23

2 Safety

2.1 Warning & Safety Precautions in this Operating Instruction

The following warnings and safety related cautionary notices in the individual chapters alert

you to various levels of danger:

DANGER

+Identifies an imminent, serious danger, which, if it is not avoided, will lead to serious

injuries or even to death.

CAUTION

+Identifies a possible danger, which, if it is not avoided, will lead to serious injuries or even

to death.

ATTENTION

+Identifies a potential dangerous situation, which, if it is not avoided, can lead to medium

or minor injuries or material damages.

INFORMATION

+If this information is not followed, it can lead to a deterioration of the operating procedure.

2.2 Safety Precautions

The HX33 pneumatic crimp machine has been constructed according to state-of-the-art

technology and the acknowledged technical safety regulations.

When carrying out jobs such as installation, putting the machine into operation or setting it up,

operation, changing the conditions of use and the mode of operation or carrying out

maintenance and service jobs, it is important to observe the procedures for switching off the

machine described in the operation instruction.

Please observe the national regulations according to the minimum age of the personnel

operating the HX33 pneumatic crimp machine. Allowing younger persons access to the

machine is strictly prohibited.

+Do not operate the HX33 pneumatic crimp machine until you have studied and fully

understood all the instructions described in this operating instruction.

+Operate the HX33 pneumatic crimp machine in a dry and dust free environment only. The

crimp machine is only allowed to be used when it is in complete functional condition.

+Do not modify the HX33 pneumatic crimp machine nor use it for any purpose for which it

was not intended.

+The use a chain hoist or lifting device is recommended for transporting the crimping

machine.

+Wear suitable safety shoes when transporting the machine.

+Prior to starting up the HX33 pneumatic crimp machine, make sure it is firmly positioned on

a sturdy stand or bench to prevent it from tipping over. Ensure that the table or bench is

stable enough to support the machine in normal use.

+Assure an appropriate table height. The table height is dependent on the position of the

operator, (work in sitting or standing position) according to prEN 894-4:2004, Table A.1

+Assure appropriate illumination of the working place. (EN 1837:1999 –chapter 4.2: “The

general value of illumination has to be 500 lx […]”).

+Connect compressed air supply only with the supplied compressed air hose.

HX33-DS Rev. A Page 6 / 23

+Place the pneumatic tubes on the floor or out of the way so that they do not cause a trip

hazard.

+Pneumatic tubes must not be damaged.

+Place the foot pedal on the floor. No other place is allowed. The foot pedal must be

movable, so that the operator has the possibility to change his position for ergonomic and

production needs.

+Do not lay the foot pedal in aisles or walkways.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+Before starting maintenance, disassembly or repair work, the crimp machine must be

disconnected from air supply.

+Maintenance work may be performed only by authorized and properly trained personnel.

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

+Before commissioning the machine, it is always important to check whether all safety

devices, especially the safety guard and the die set, are installed and are functioning

correctly.

+Check the release button before starting the work on the crimp machine. In the case of

imminent danger immediately press the release button. The release button must be within

the direct reach of the operator. It must not be covered.

+Exercise caution at all times when the HX33 pneumatic crimp machine is switched on.

+The HX33 pneumatic crimp machine is not allowed to be used without a installed die set

and safety guard.

+The HX33 pneumatic crimp machine may only be set up and operated in perfect technical

condition, observing all the safety regulations and considering any possible dangers.

+The crimp machine is only allowed to be used when it is in a completely functional

condition.

+If you suspect that the machine cannot be operated safely, it must be switched off and

secured against anyone accidentally switching it on.

+In cases of a machine malfunction, production must be stopped and the malfunction must

be fixed before continuing work with the machine.

+Work with caution.

+Only one person is allowed to work on or with the machine at a time.

+Only trained personal are allowed to work on or with the machine.

+It is only allowed to work with the specified air pressure.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Disconnect the HX33 pneumatic crimp machine from the air supply before attempting any

maintenance work. Due to the risk of hand or finger injury, never try to reach into the

machine before having assured that the machine is disconnected from the air supply.

+The machine can only be depressurized by disconnecting the machine from the main air

supply.

HX33-DS Rev. A Page 7 / 23

2.3 Responsibilities

The HX33 pneumatic crimp machine may only be operated by suitably trained and authorized

personnel. The user must clearly define and observe the responsibilities of the personnel for

operation, set-up, maintenance, and service. It is particularly important to define who is

responsible for work on the pneumatic equipment. Such work should only be carried out by

specially trained staff.

Should the user make any changes to the machine without consulting the manufacturers or

the suppliers, the latter will not be liable for any damage that may result.

The user of the HX33 pneumatic crimp machine is responsible for making sure that all persons

involved in any way, either in the installation or in maintenance of the machine, have been

thoroughly trained on the system using this operating instruction.

The user is also responsible for the training of operators and the instruction must include the

following aspects:

+Purpose of the machine

+Hazard zones

+Safety rules and regulations

+Functionality of the various components of the machine

+Proper operation of the machine

To assure full familiarization with the system, the training must be conducted in the native

language of the operators involved.

Staff qualifications required in conjunction with the use of the pneumatic crimp

machine HX33:

Installation

Set-up

Instruction

Technical personnel with language proficiency in either English or

German, in addition to the native language of the operator.

Operation

Through qualified personnel trained as indicated above.

Maintenance

Service

Technical personnel with proficiency in English or German.

The safety instructions, warnings, and precautions contained in the individual chapters must

be strictly observed by all users and operators.

2.4 Designed Use

+Realization of crimp connections up to a wire size of 10AWG (5.3mm2) depending on the

terminal design.

The HX33 pneumatic crimp machine is designed for the use of the DMC “Y-die” series dies.

The HX33 pneumatic crimp machine should only be used with the dies specified by DMC. It is

only allowed to use the pneumatic crimp machine HX33 together with the DMC die sets for the

preparation of crimp connections!

2.5 Predictable Misuse

+Every application which is not mentioned in chapter 2.4 “Designed Use“.

HX33-DS Rev. A Page 8 / 23

2.6 Hazardous Areas

1. Hazardous Area: Area of interchangeable crimping dies

Person at risk: Operator

Type of Hazard: Hand Injuries

2. Hazardous Area: Opened machine

Person at risk: Installation Engineer

Type of Hazard: Direct or indirect contact with movable parts of the machine,

Hand injuries (cuts from sharp edges)

Hand injuries (risk of crushing)

3 Shipment

3.1 Packing

Upon receipt, unpack the HX33 pneumatic

crimp machine carefully and check that you

have received all components against the

packing slip, declaration of conformity, and

operating instructions. We recommend that

you retain the packing for further dispatch

and for storage.

Dimension (Carton 1/machine and black box):

Length: 15” (380 mm)

Width: 13.4” (340 mm)

Height: 15.4” (390 mm)

Gross-Weight: 34.61 lbs (15,7 kg)

Dimension (Carton 2/Foot pedal):

Length: 11.4” (290 mm)

Width: 7.5” (190 mm)

Height: 5.5” (140 mm)

Gross-Weight: 2.64 lbs (1,2 kg)

DANGER

+Use a chain hoist or lifting device to transport the crimping machine.

3.2 Packing Contents

1 pc

Pneumatic crimp machine HX33

with operating instruction (German original version and English translation)

(without die set)

1 pc

Safety guard

1 pc

Pneumatic foot pedal with cover

1 pc

Hexagon wrench key SW 2,0

1 pc

Air hose set

Carton 1: Machine

and black box

Carton 2: Foot pedal

Fig. 3.1

HX33-DS Rev. A Page 9 / 23

4 Technical Description

4.1 Operators Guide

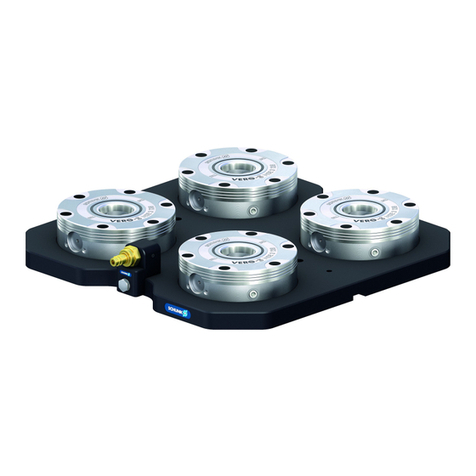

Item

Description

01

Pneumatic crimp machine HX33

02

Release Button

03

Safety guard

04

Die Set

05

A =control pressure (foot pedal)

06

P1 = compressed air (foot pedal)

07

P = compressed air

08

Label with serial number

09

Pneumatic foot pedal

10

Safety cover for foot pedal

10

10

11

01

02

03

04

05

06

07

08

Fig. 4.1

HX33-DS Rev. A Page 10 / 23

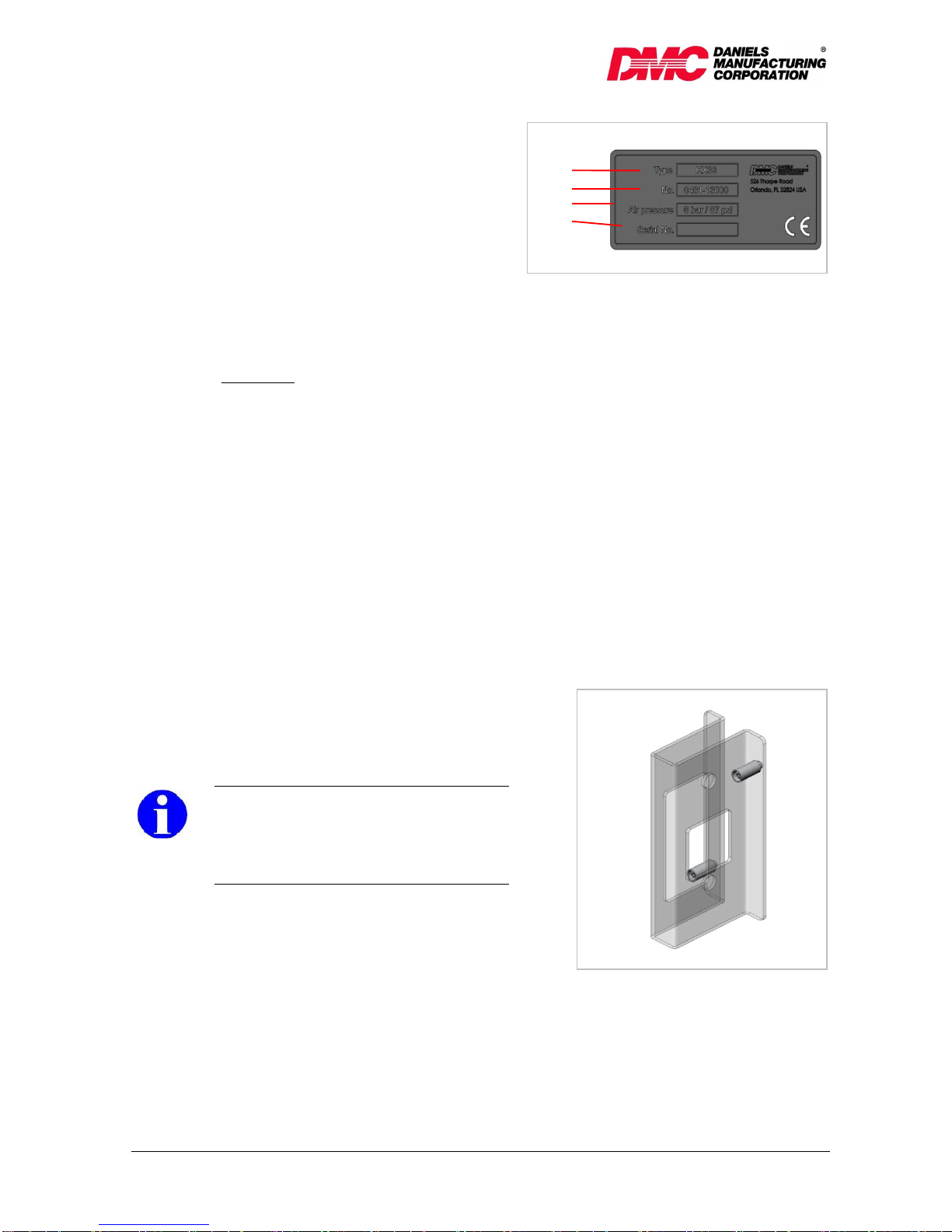

4.2 Machine Identification

Item

Description

1

Machine Type

3

Article Number

4

Air Pressure

2

Serial Number

4.3 Technical Data

Dimension:

Length overall:

11.8” (300 mm)

Width:

4.9” (125 mm)

Height:

10.2” (260 mm)

Weight with foot pedal:

32 lbs (14,5 kg)

Air pressure:

max. 87-116 psi / 6-8 bar

Air consumption per stroke:

5.2 l

crimp force at 87psi/6 bar:

3147lbf /14 kN

crimp force at 116psi/8 bar

3597 lbf / 16 KN

Noise level:

73 dB (A)

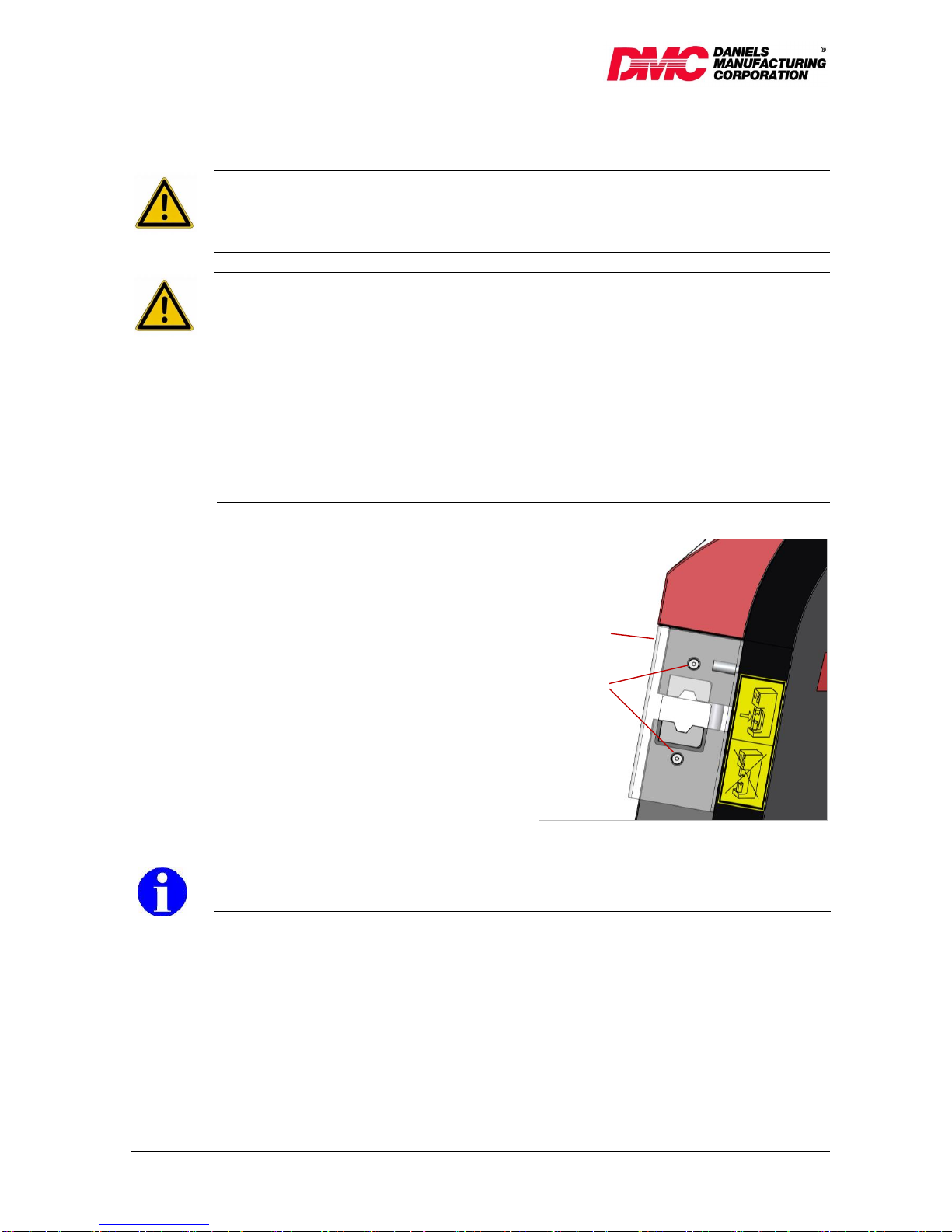

4.4 Safety Guard

The HX33 pneumatic crimp machine has a

special safety guard (in the scope of the

delivery).

INFORMATION

+In case of an accident, because of

mishandling or manipulation of the safety

guard, the manufacturer cannot be held

liable for any resultant damage or injury.

Fig. 4.2

Fig. 4.3

1

2

3

4

HX33-DS Rev. A Page 11 / 23

4.5 Release Button

In case of jammed jaws caused by operation

or handling errors or wrongly placed

terminals the jaws can be opened as follows:

+Press release button.

5 Transport and Installation

5.1 Transport

The weight of the pneumatic crimp machine HX33 is approx. 32 lbs / 14 kg.

CAUTION

+During transport and installation of the machine, wear suitable safety shoes.

ATTENTION

+Pneumatic tubes must not be damaged.

5.2 Installation

ATTENTION

+Position the HX33 pneumatic crimp machine on a flat surface and assure the stability of the

machine. Ensure that the table or bench is stable enough to support the machine in normal

use.

+Assure an appropriate table height. The table height is dependent on the position of the

operator, (work in sitting or standing position) according to prEN 894-4:2004, Table A.1.

+Assure appropriate illumination of the working place. (EN 1837:1999 –chapter 4.2: “The

general value of illumination has to be 500 lx [...]").

INFORMATION

+To reduce production noise or vibration, the machine can be placed on an insulating rubber

mat.

Place the foot pedal on the floor. No other place is allowed!

Fig. 4.4

Fig. 4.5

HX33-DS Rev. A Page 12 / 23

ATTENTION

+Place the pneumatic tubes on the floor so that they do not cause a trip hazard.

+Do not lay the foot pedal in aisles or walkways.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+During transport and installation of the machine, wear suitable safety shoes.

INFORMATION

+To ensure fatigue-proof use, the user has to take a working position where the machine is

in a right height position and an acceptable usage of the foot pedal is possible. The foot

pedal has to be installed in a stable position. The position of the foot pedal should be

chosen in that way, that free access will be possible.

6 Commissioning / Connecting to Compressed Air Supply

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+The HX33 pneumatic crimp machine may only be set up and operated in perfect technical

condition, observing all the safety regulations and considering any possible dangers.

+The crimp machine is only allowed to be used with mounted dies and safety guard.

+The crimp machine is only allowed to be used when it is in complete functional condition.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Work with caution.

+In cases of a machine malfunction, production must be stopped and the malfunction must

be fixed before continuing work with the machine.

+Only one person is allowed to work on or with the machine at a time.

+Only trained personal are allowed to work on or with the machine.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+It is only allowed to work with the specified air pressure.

HX33-DS Rev. A Page 13 / 23

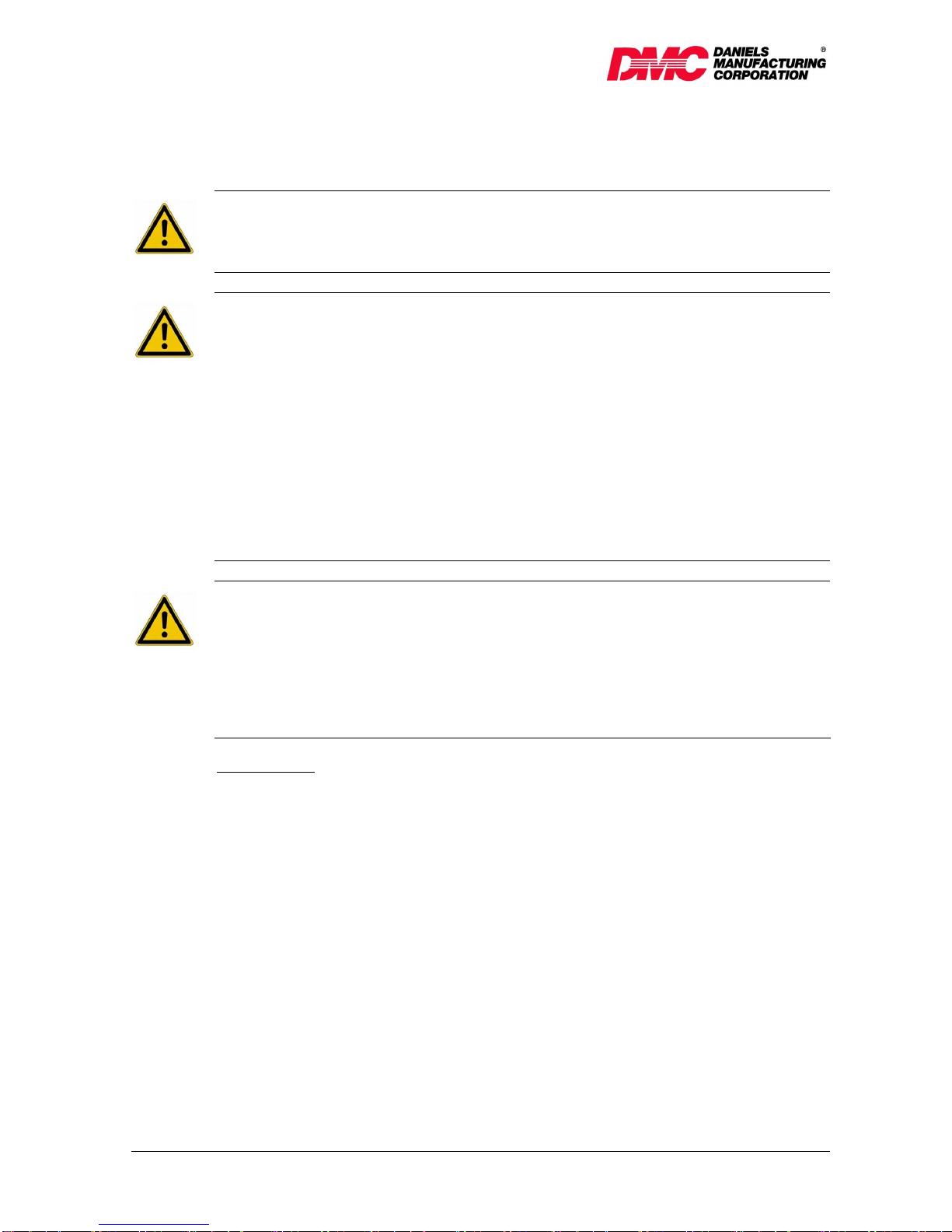

Connect the pneumatic foot pedal

connection 1with connection P1 on the

machine (PU air hose Ø 6 / 4 mm).

Install control cable of the pneumatic foot

pedal 4on connection Aof the machine (PU

air hose Ø 4 / 2,5 mm).

Use the HX33 pneumatic crimp machine

only with conditioned air (lubricated and

filtered). Standard Filter: 30 µm.

Connect connection Pof the machine with

air hose Ø 8 / 6 mm to the compressed air

supply.

Air pressure: 87-116psi / 6 - 8 bar

CAUTION

+Connect compressed air supply only with the supplied compressed air hose.

+The machine can only be depressurized by disconnecting the machine from the main air

supply.

INFORMATION

+Use only lubricated and filtered compressed air.

1

A

P1

P

4

Fig. 6.1

HX33-DS Rev. A Page 14 / 23

7 Tooling

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+The pneumatic crimp machine HX33 may only be set up and operated in perfect technical

condition, observing all the safety regulations and considering any possible dangers.

+The crimp machine is only allowed to be used with mounted dies and safety guard.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Work with caution.

+Only one person is allowed to work on or with the machine at a time.

+Only trained personal are allowed to work on or with the machine.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+It is only allowed to work with the specified air pressure.

1. Disconnect pneumatic supply.

2. Remove the safety guard 1.

3. Remove special screws of die set 2.

4. Slide the upper and lower die in the

adapter and tighten the screws.

5. Install the safety guard 1and tighten the

screws.

INFORMATION

+Control the right position of the die halves! The size of the profile should be in line!

2

1

Fig. 7.1

HX33-DS Rev. A Page 15 / 23

8 Normal Operation / Production Cycle

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+The HX33 pneumatic crimp machine may only be set up and operated in perfect technical

condition, observing all the safety regulations and considering any possible dangers.

+The crimp machine is only allowed to be used with mounted dies and safety guard.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Work with caution.

+In cases of a machine malfunction, production must be stopped and the malfunction must

be fixed before continuing work with the machine.

+Only one person is allowed to work on or with the machine at a time.

+Only trained personal are allowed to work on or with the machine.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+It is only allowed to work with the specified air pressure.

ATTENTION

+Position the HX33 pneumatic crimp machine on a flat surface and assure the stability of the

machine. Ensure that the table or bench is stable enough to support the machine in normal

use. During the utilization, the machine has to be placed on a table or a similar flat surface.

+Place the foot pedal on the floor. No other place is allowed. The foot pedal must be

movable, so that the operator has the possibility to change his position for ergonomic and

production needs. Do not lay the foot pedal in aisles or walkways.

+Place the pneumatic tubes on the floor so that they do not cause a trip hazard.

Crimp process:

1. Insert the crimp contact in the die profile. Please pay attention to the correct profile

assignment and to the correct positioning within the crimp profile!

2. Insert the wire/cable which is stripped acc. to the specification and position it for crimping.

3. Press the foot pedal to start the crimp process.

4. Keep the foot pedal pressed until the crimp cycle is finished.

5. Remove crimped contact.

HX33-DS Rev. A Page 16 / 23

9 Maintenance

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+Connect compressed air supply only with the supplied compressed air hose.

+Before starting maintenance, disassembly or repair work, the crimp machine must be

disconnected from air supply.

+Maintenance work may be performed only by authorized and properly trained staff. The

housing and the covers in particular may only be removed by specially trained staff.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+The crimp machine is only allowed to be used when it is in complete functional condition.

+The crimp machine is only allowed to be used with mounted dies and safety guard.

+Work with caution.

+Only one person is allowed to work on or with the machine at a time.

+Assure free access to the operating elements of the machine, especially the foot pedal.

+It is only allowed to work with the specified air pressure.

9.1 Maintenance Plan

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+Before starting maintenance, disassembly or repair work, the crimp machine must be

disconnected from air supply.

+Maintenance work may be performed only by authorized and properly trained staff. The

housing and the covers in particular may only be removed by specially trained staff.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Work with caution.

Regular maintenance and cleaning of the parts which can be reached without opening the

machine will prolong the life of the machine. Do not use rough materials to clean the machine

such as steel wool. The machine and or machine part should not be cleaned with compressed

air. The crimping machine as well as the machine parts must not be cleaned with hard objects

like scrapers, steel wool or similar. Vacuum heavily soiled parts and wear.

9.1.1 Daily

+Visual inspection of the HX33 pneumatic crimp machine.

+Check air pressure (87-116psi / 6-8 bar) of the house installation (manometer not in the

scope of the delivery).

+Check oil-level of service unit of the house air supply (not in the scope of the delivery).

HX33-DS Rev. A Page 17 / 23

10 Problem Handling and Fault Diagnostics

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+Before starting maintenance, disassembly or repair work, the crimping machine must be

disconnected from air supply.

+Maintenance work may be performed only by authorized and properly trained staff. The

housing and the covers in particular may only be removed by specially trained staff.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Work with caution.

+Before commissioning the machine, it is always important to check whether all safety

devices, especially the safety guard and the die set, are installed and are functioning

correctly.

In the event of a problem, our customer service personnel will be able to help you.

Service address:

DMC

Daniels Manufacturing Corporation

526 Thorpe Road

Orlando, FL 32824-8133

USA

Telephone: 001 407 855 6161

www.dmctools.com

Please have the following information ready when you contact service:

+Machine Type/Part Number

+Machine Serial Number

HX33-DS Rev. A Page 18 / 23

11 Removal from Service, Demounting, Disassembly,

DANGER

+Due to the risk of hand or finger injury, never try to reach into the machine before having

assured that the machine is disconnected from the air supply. Disconnect the air supply

before changing the safety guard and the dies.

CAUTION

+Before starting maintenance, disassembly or repair work, the crimping machine must be

disconnected from air supply.

+Maintenance work may be performed only by authorized and properly trained staff. The

housing and the covers in particular may only be removed by specially trained staff.

+When working with the HX33 pneumatic crimp machine, do not wear loose clothing,

jewellery or long, loose hair that can get caught in the HX33 pneumatic crimp machine.

+Only one person is allowed to work on or with the machine at a time!

+Work with caution.

+The machine can only be depressurized by disconnecting the machine from the main air

supply.

12 Storage

Store the machine in the original carton at room temperature.

13 Disposal

For the disposal of the pneumatic crimp machine HX33, send it back to DMC.

HX33-DS Rev. A Page 19 / 23

14 Exploded View Drawing, Spare Part List

14.1 Exploded View Drawing

Fig. 14.1

HX33-DS Rev. A Page 20 / 23

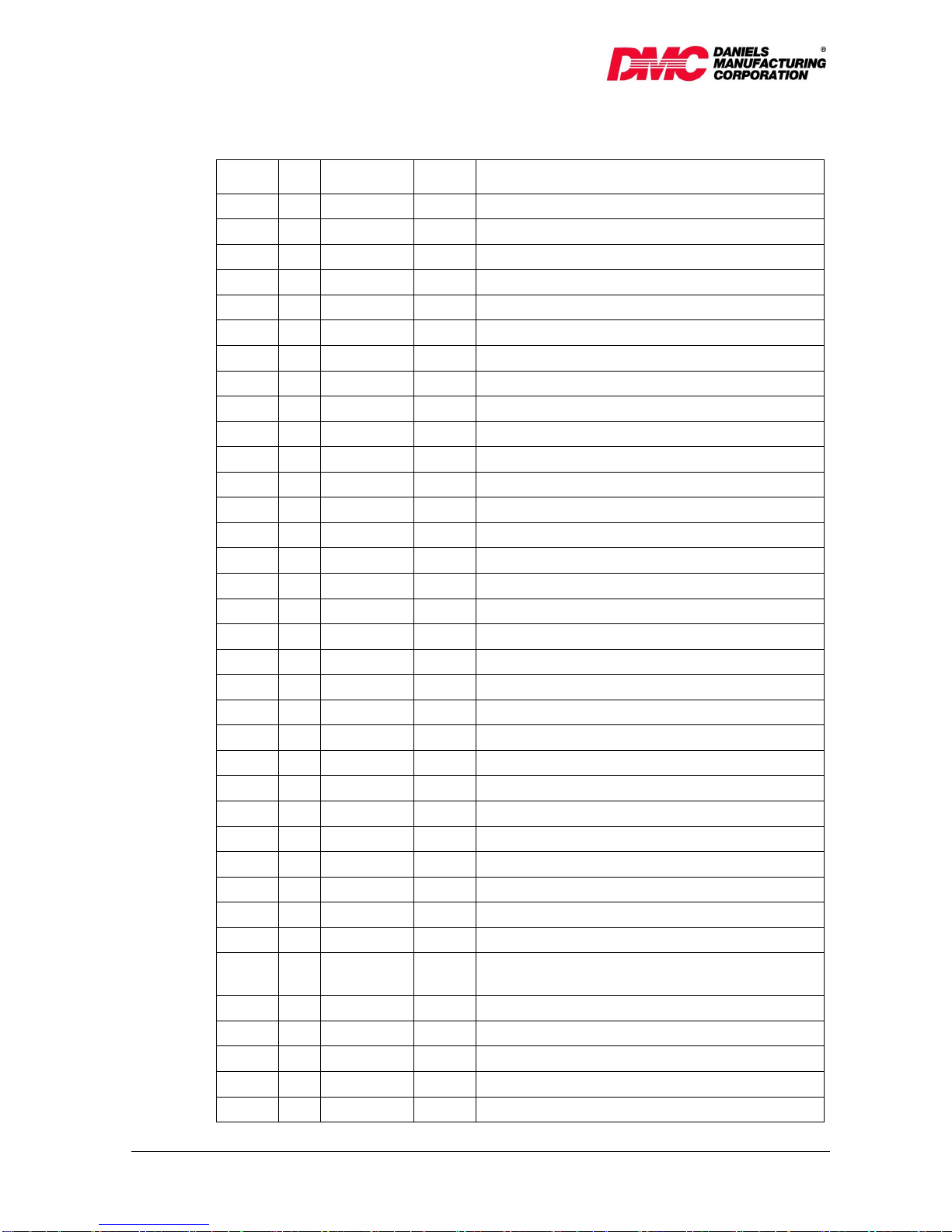

14.2 Parts List Exploded View Drawing

Item

No.

Pcs

P/N

Spare

Part

Description

1

1

2481-01001

Bottom plate

2

2

8480-84001

O-Ring Ø100x2 DIN 3771

3

1

2480-82016

Cylinder Housing

4

1

2480-84012

Piston

5

1

2480-84015

Piston guide band

6

1

8480-84007

O-Ring Ø92x4 DIN 3771

7

1

8480-84002

O-Ring Ø22x2 DIN 3771

8

1

2481-01019

Distance plate

9

1

2481-01020

Damping disc Ø30/12x2,5

10

1

2481-01007

Piston rod

11

1

8480-88011

Hex. socket screw M8x40 DIN912

12

1

8480-84003

O-Ring Ø25x3 DIN 3771

13

1

2481-01008

Cylinder Liner

14

1

2481-13012

Cover Plate

15

4

8480-99129

Hex. socket screw M6x110 DIN912

16

2

8480-88008

Hex. socket screw M8x60 DIN912

17

1

2481-13001

Plate, right

18

1

2481-13002

Plate, left

19

4

8480-99137

Hex. socket screw M8x25 DIN912

20

2

8481-01001

Hex. socket screw M8x45 DIN912

21

2

8480-99109

Cylinder bolt 6h6x50 DIN6325

22

2

8481-01509

Cylinder liner Ø16/12 x20

23

1

2481-13005

Lever

24

1

8480-89037

Cylinder liner Ø16/12 x12

25

1

2480-89024

Drive shaft-1296-18

26

2

8480-99161

Locking ring DIN 471-12x1

27

2

2481-13011

Bolt

28

2

8481-13002

Plain bearing XSM-1214-12 (Igus)

29

2

2481-13007

Roll

30

1

8481-13013

Cylinder bolt 8m6x100 DIN6325

31

1

8481-13003

Pressure Spring D-180D L0 41, Ln 21,82, Lndyn

23,11

32

2

8183-79006

Hexagon socket set screw M3x8 DIN913

33

1

8332-12003

Hexagon socket set screw M3x10 DIN913

34

2

8480-99055

Adjusting washer Ø6/12 x 0,2 DIN 988

35

1

2481-13003

Lower die plate

36

1

2481-13004

Upper die plate

Table of contents

Other DMC Power Tools manuals

Popular Power Tools manuals by other brands

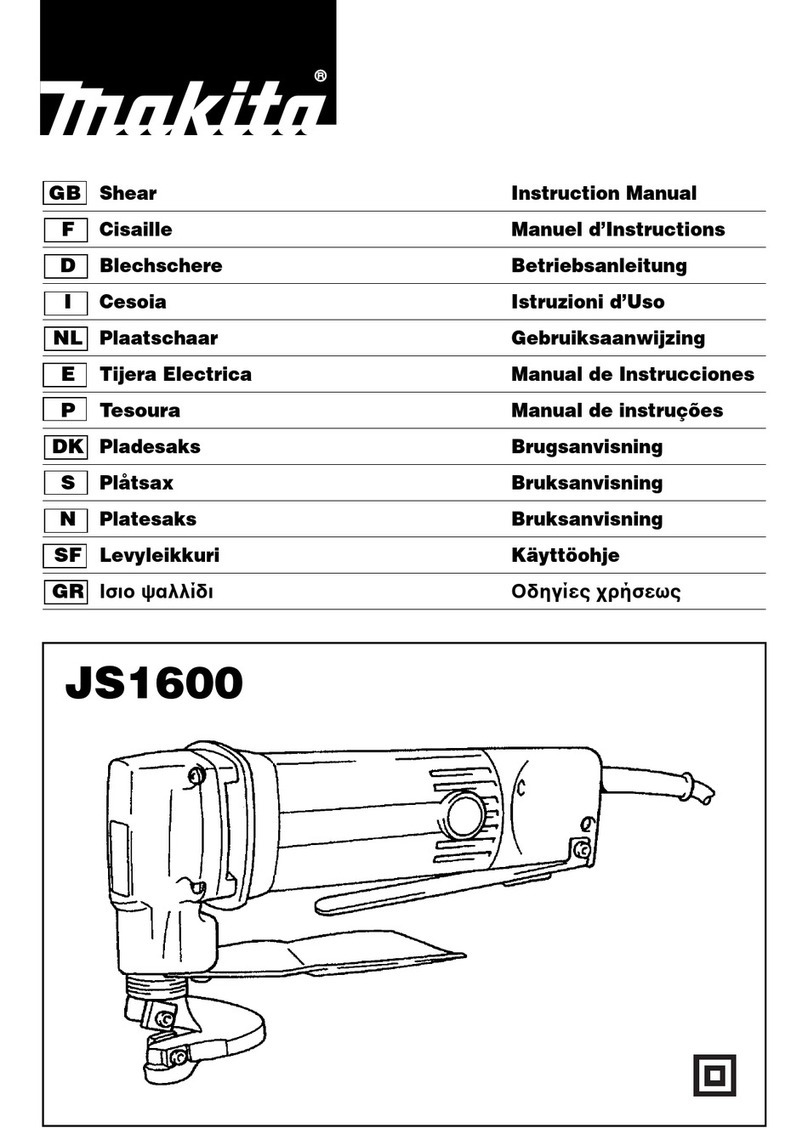

Makita

Makita JS1600 instruction manual

Parkside

Parkside PKGA 20-Li C2 Translation of the original instructions

Bosch

Bosch 1500C Operating/safety instructions

Black & Decker

Black & Decker KS501 manual

Makita

Makita 4351T instruction manual

RAMSET

RAMSET MD380 Operator's safety & operating instruction manual