PAGE 2 OF 3 0714 IH-1993

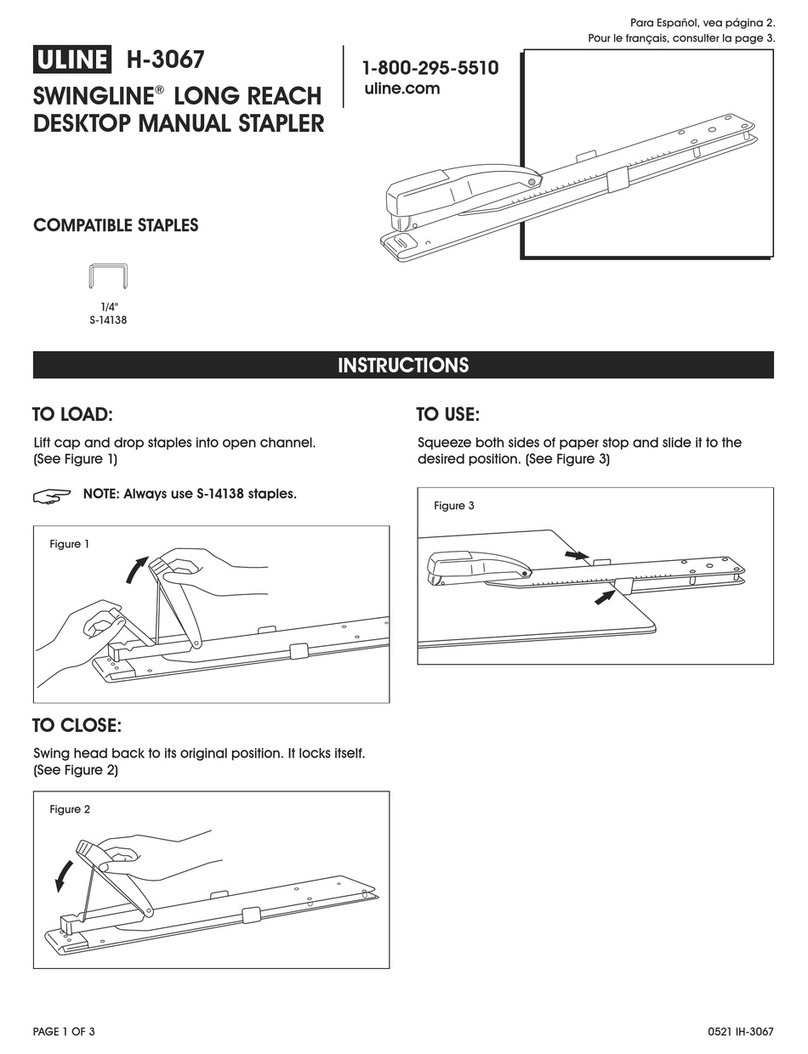

LOADING THE STAPLER

NOTE: Always use Josef Kihlberg original

staples – S-10720 (5/8") or S-10721 (3/4").

The correct type of staple is marked on the left hand

side of the magazine. Be sure to use the correct staple

length for your application and that ensure the stapler is

adjusted for this length.

1. Pull the pusher all the way

out. (See Figure 5)

2. Place three staple strips

into the magazine from

the top. (See Figure 6)

3. Lift the pusher to release.

Carefully move the pusher

forward until it reaches the

staples. (See Figure 7)

LOADING CONTINUED

OPERATION

MAINTENANCE

OPERATING THE STAPLER

WARNING! Always place yourself in a firmly

balanced position when using or handling

the stapler.

• Press the stapler against the cardboard.

• Pull the handle firmly.

• Move the stapler and repeat until you have

finished stapling.

• Control the clinch regularly. Adjust when necessary.

WARNING! Before stapling, ensure that your

hand or any other part of your body is not

underneath the staple discharge area.

Staple Strip

Figure 6

Pusher

Figure 5

Pusher

Figure 7

CLEANING THE STAPLER

This stapler does not require special servicing. It

only needs regular cleaning with a non-aggressive

(non-corrosive) cleaning agent.

NOTE: Do not remove any parts for cleaning

purposes.

NOTE: Check the proper functioning of all

safety devices daily. Make sure that all screws

and nuts are securely tightened.

REMOVING JAMMED STAPLES

To remove a jammed staple:

1. Unscrew 6 screws at the rear body. (See Figure 8)

2. Remove rear body and the defective staple.

(See Figure 9)

3. Assemble by reattaching the rear body with

6 screws. (See Figure 8)

Allen

Wrench

Figure 8 Figure 9