6MN16042

GUIDELINES FOR (H)SCXT REDUCER

LONG-TERM STORAGE

During periods of long storage, or when waiting for delivery or

installation of other equipment, special care should be taken to

protect a gear reducer to have it ready to be in the best condition

when placed into service.

By taking special precautions, problems such as seal leakage

and reducer failure due to lack of lubrication, improper lubrication

quantity, or contamination can be avoided. The following

precautions will protect gear reducers during periods of extended

storage:

Preparation

1. Drain oil from the unit. Add a vapor phase corrosion inhibiting

oil (VCI-105 oil by Daubert Chemical Co.) in accordance with

Table 3.

2. Seal the unit airtight. Replace the vent plug with a standard

pipe plug and wire the vent to the unit.

3. Cover all unpainted exterior parts with a waxy rust

preventative compound that will keep oxygen away from the

bare metal (Non-Rust X-110 by Daubert Chemical Co. or

equivalent).

4. The instruction manuals and lubrication tags are paper and

must be kept dry. Either remove these documents and store

them inside, or cover the unit with a durable waterproof cover

which can keep moisture away.

5. Protect reducer from dust, moisture, and other contaminants

by storing the unit in a dry area.

6. In damp environments, the reducer should be packed inside

a moisture-proof container or an envelope of polyethylene

containing a desiccant material. If the reducer is to be stored

outdoors, cover the entire exterior with a rust preventative.

When Placing the Reducer into Service

1. Fill the unit to the proper oil level using a recommended

lubricant. The VCI oil will not aect the new lubricant.

2. Clean the shaft extensions with petroleum solvents.

3. Assemble the vent plug into the proper hole.

Follow the installation instructions provided in this manual.

Table 3 – Quantities of VCI #105 Oil

Reducer Size Quantity (Ounces / Milliliter)

(H)SCXT305E 1 / 30

(H)SCXT405E 1 / 30

(H)SCXT505E 1 / 30

SCXT605E 2 / 59

SCXT705E 2 / 59

REPLACEMENT OF PARTS

IMPORTANT: Using tools normally found in a maintenance

department, a Dodge (H)SCXT speed reducer can be

disassembled and reassembled by careful attention to the

instructions following.

Cleanliness is very important to prevent the introduction of dirt

into the bearings and other parts of the reducer. A tank of clean

solvent, an arbor press, and equipment for heating bearings and

gears (for shrinking these parts on shafts) should be available.

The oil seals are contact lip seals. Considerable care should be

used during disassembly and reassembly to avoid damage to the

surface on which the seals rub.

The keyseat in the input shaft, as well as any sharp edges on

the output hub should be covered with tape or paper before

disassembly or reassembly. Also, be careful to remove any

burrs or nicks on surfaces of the input shaft or output hub before

disassembly or reassembly.

Ordering Parts: When ordering parts for reducer, specify

reducer size number, reducer model number, part name, part

number, and quantity.

It is strongly recommended that, when a pinion or gear is

replaced, the mating pinion or gear is replaced as well. If the large

gear on the output hub must be replaced, it is recommended

that an output hub assembly consisting of a gear assembled

on a hub be ordered to ensure undamaged surfaces on the

output hub where the output seals rub. However, if it is desired

to use the old output hub, press the gear and bearing o and

examine the rubbing surface under the oil seal carefully for

possible scratching or other damage resulting from the pressing

operation. To prevent oil leakage at the shaft oil seals, the smooth

surface of the output hub must not be damaged.

If any parts must be pressed from a shaft or from the output hub,

this should be done before ordering parts to make sure that none

of the bearings or other parts are damaged in removal. Do not

press against rollers or cage of any bearing.

Because old shaft oil seals may be damaged in disassembly, it is

advisable to order replacements for these parts.

Removing Screw Conveyor Drive from Trough End

Disconnect an electrical power to the drive. Drain lubricant from

reducer. Uncouple drive shaft and screw. Remove nuts from

trough end studs. Support drive by means of hoist and carefully

pull unit away from trough end to slide drive shaft out of screw.

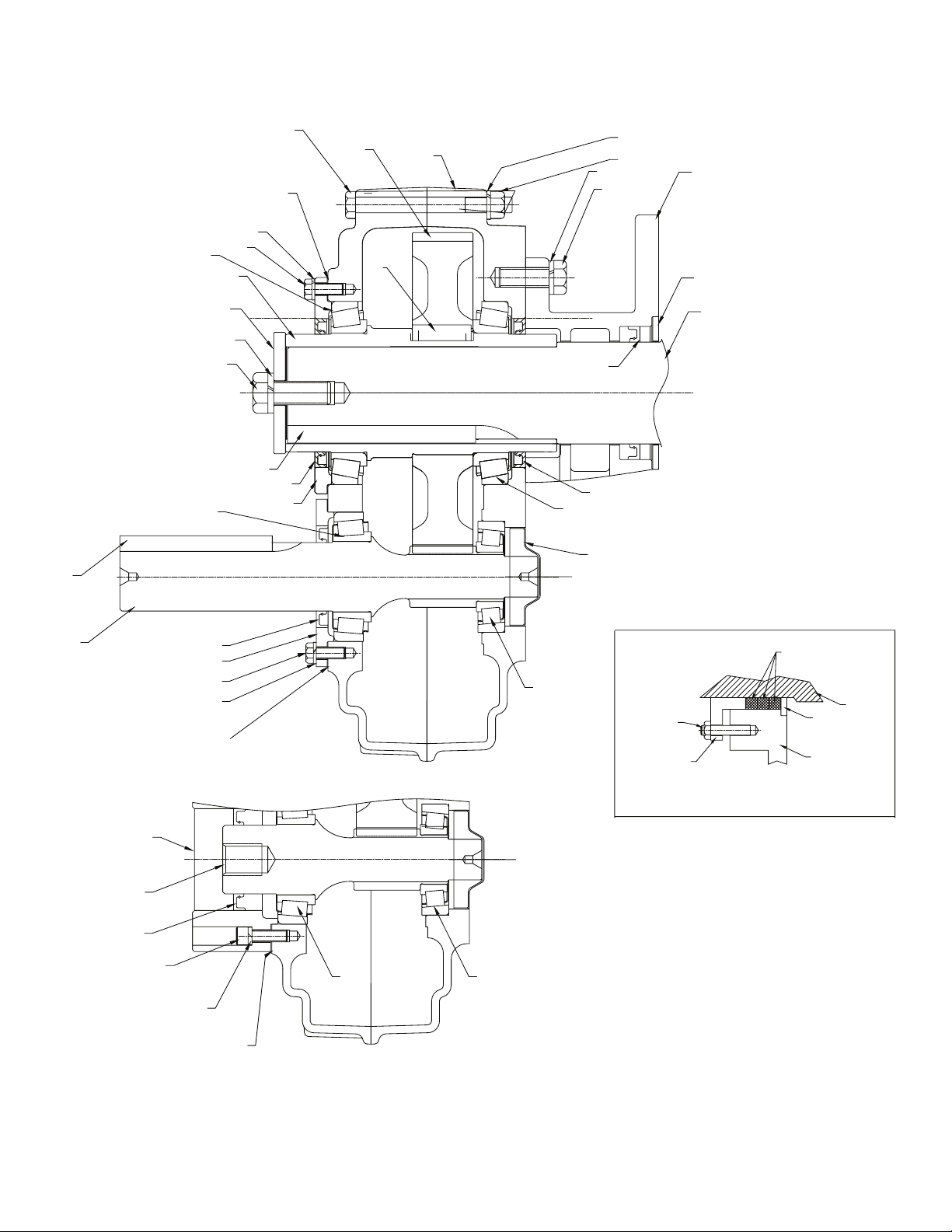

Disassembly

1. Remove retainer bolt, lockwasher, and shaft retainer from

drive shaft. Pull drive shaft out of reducer from adapter side.

Remove adapter.

2. Position the reducer on its side and remove all housing

bolts. Drive dowel pins from housing. Using the three pry

slots around the periphery of the ange, gently separate the

housing halves. Open housing evenly to prevent damage to

the parts inside.

3. Lift input shaft, all gear assemblies, and bearing assemblies

from housing.

4. Remove seals from housing.

5. Remove bearings from shafts and hubs. Be careful not to

scratch or damage any assembly or seal area during bearing

removal. The hub assembly can be disassembled for gear

replacement but if scratching or grooving occurs on the hub,

seal leakage will occur and the hub will need to be replaced.

Reassembly

1. Output Hub Assembly: Heat gear to 325°F to 350°F to

shrink onto hub. Heat bearings to 270°F to 290°F to shrink

onto hub. Any damage to the hub surfaces where the oil seals

rub will cause leakage, making it necessary to replace the

hub.

2. Input Shaft Assembly: Heat bearings 270°F to 290°F to

shrink onto shaft. Press bearings on shaft.

3. Drive the two dowel pins into place in the right-hand housing

half (backstop side).

4. Place right-hand housing half on blocks to allow for protruding

end of output hub.

5. Install all bearing cups in right-hand housing half, making sure

they are properly seated.

6. Mesh the output hub gear and input shaft assembly together

and set in place in housing. Make sure bearing rollers (cones)