Dodge ACR User manual

Owner’s Manual

This booklet is a supplement to your Viper SRT10 Owner’s Manual.

Please review the Owner’s Manual in addition to this booklet.

1.0 Overview

The Viper ACR is the literal fusion of Street and Racing Technology. It takes

the awe inspiring performance capabilities of the Dodge Viper SRT10 to the

next level.

The Viper ACR is not certified as a race car and it is not equipped with a

racing safety cage, racing restraints or other racing safety equipment.

Throughout this manual there are notes of WARNING and CAUTION. Review

each of them before driving this car.

WARNING: It is recommended that all customers complete a high-per-

formance driving school prior to operating this vehicle. Speeds at the

handling limits of this car are much higher than with other sports cars.

Competitive driving and track outings can cause serious injury or death.

Drive safely.

Splitters are potent aerodynamic elements usually only found

on purpose built racing cars. The Viper ACR front splitter has

been specially adapted for street use with the addition of several

new features.

•Theleadingedgehasbeenscallopedbacktoreducefront

overhang for day to day driving

•Toughenedpolymerrubstripshavebeenaddedtoreducewear

and abrasion on the splitter panel

•Tensioncablessupportthefrontedgetoallowsomeupward

deflection in minor impacts with ramped surfaces

In spite of these enhancements, the splitter remains highly vulnerable

to impact because of its position on the car.

The front splitter will not flex or compress against impacts from the

front. If an impact does occur, have the splitter inspected. A cracked

or delaminated splitter should be replaced.

The Viper ACR aerodynamics are capable of high levels of downforce

which will noticeably affect the grip and handling of the vehicle at speeds

as low as 50 mph.

Regularly inspect all of the aerodynamic components and attachments for

damage or wear.

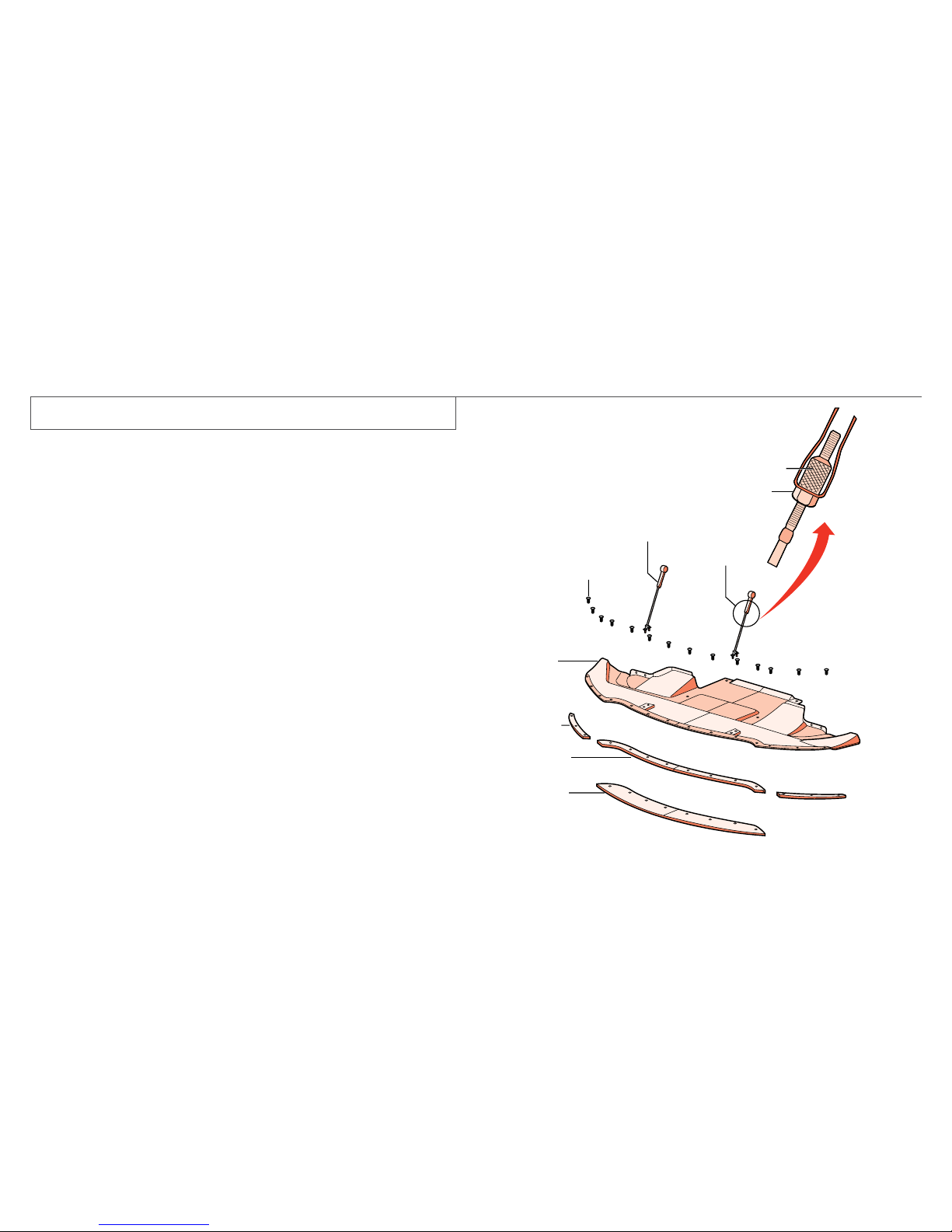

2.1 Front Splitter

2.0 Aerodynamics

Always leave ample room and be sure to educate

anyone you allow to operate the vehicle.

CAUTION: Use care when approaching parking blocks,

tall speed bumps and garage curbs. These surfaces

can severely damage your splitter.

Use care when driving up to sloped surfaces or over

speed bumps. Approaching a speed bump or a slope

at a slight angle may improve your clearance.

CAUTION: Hard contact with steep ramps may cause

damage to your splitter.

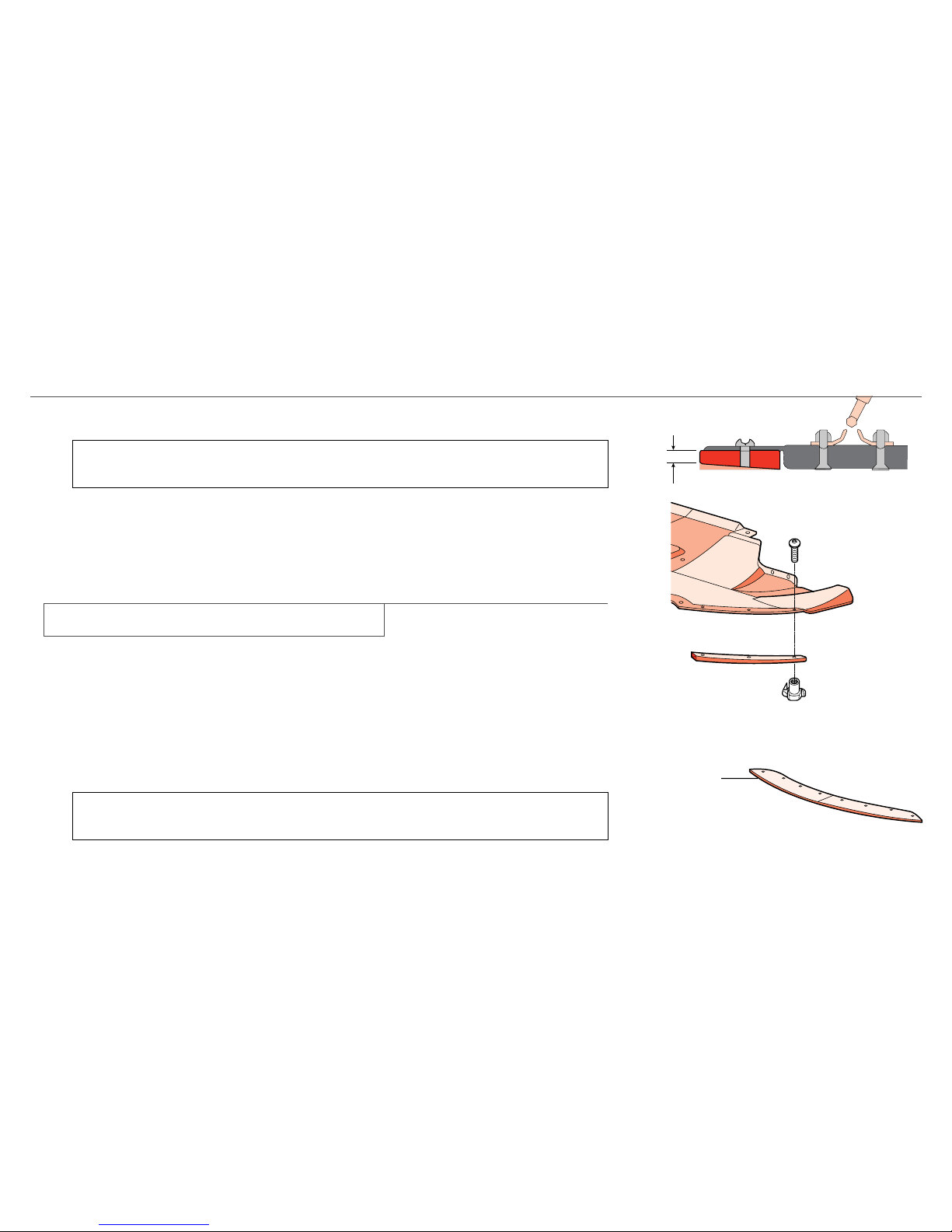

The front of the ACR splitter is supported by two stainless

steel cables. These cables and their attachments should be

regularly inspected.

The splitter cables have an adjustment capability, however it

is recommended to leave the splitter at the factory delivered

settings. The splitter cables may have some slack while the

vehicle is at rest. When the splitter is loaded, and the cables

are under tension, the panel should be approximately parallel

to the bottom of frame.

Solid polymer rub strips are attached to the leading edge of

the splitter panel. Regularly inspect these rub strips to avoid

damage to the carbon fiber splitter panel.

2.2 Splitter Components

Lock Nut

Length

Adjustment

Adjustment Nut

Splitter Panel

Center Rub Strip

Side Rub Strip

Track Extension

Splitter Cable

Screws

3/8” (10 mm)

CAUTION: Replace rub strips when they are worn down to 3/8 in. (10 mm) on the front

edge. This will avoid damage to the carbon fiber panel.

Regularly inspect the outboard knock-in threaded insert to avoid premature splitter wear

(right and left side). Replace these fasteners as needed in order to protect the carbon

fiber splitter panel.

A splitter track extension is included in the trunk of every Viper ACR. The track extension

is mounted in the same location as the center rub strip. The on-track aerodynamic

balance was optimized with the track extension in place.

To install the track extension, remove the eight (8) screws of the center rub strip and

install the extension in the same mounting locations.

Tighten fasteners to 70 in-lbs (7.9 N·m).

CAUTION: The track extension should only be used during closed circuit track events. The

track extension can cause premature damage to your vehicle if used on public roads.

2.3 Track Extension

Lock Nut

Length

Adjustment

Adjustment Nut

Splitter Panel

Center Rub Strip

Side Rub Strip

Track Extension

Splitter Cable

Screws

The ACR rear wing generates most of the car’s aerodynamic downforce.

The wing is a powerful element that will affect the handling of the car

at speeds greater than 50 mph. Extreme caution should be given to any

modifications to the factory settings.

WARNING: Do not operate the vehicle with the rear wing removed.

The aerodynamic balance of this setup is unstable and can cause

the loss of control.

Regularly inspect the wing panel and attachment points for damage

or looseness.

The Viper ACR on-track aerodynamics have been tuned and balanced

for the vehicle with the track extension installed.

Wing Stanchions

The wing stanchions are designed with adjustment capability but they

are delivered locked with tamper resistant fasteners.

The wing is delivered from the factory in hole position 2.

2.4 Rear Wing

Wing setting as delivered

Wing Adjustment

It is possible to adjust the wing using the hole pattern at the top front of

the stanchion.

Note: Adjustment to the wing setting is not recommended.

The wing is attached to the lower stanchions with thread locker and tamper

resistant fasteners. The warranty does not cover any modifications or

removal of these wing fasteners.

In general, moving the wing up (e.g. Hole 2 to Hole 1) will decrease

rear down force and decrease overall understeer. Moving the wing down

(e.g. Hole 2 to Hole 3) will increase understeer.

Each successive hole increases the wing angle of attack by 1.5 degrees.

Adjustment

hole numbering

Example: Hole 4

The ACR aerodynamic components are made from prepreg autoclaved

carbon fiber. Both woven and unidirectional materials are used.

The clear coated carbon fiber panels will have some variation and minor

waviness in the woven pattern. This is inherent to the process and a sign

of its authenticity.

All carbon fiber materials are susceptible to UV degradation during long

exposure to the sun. The ACR woven carbon components use the latest

technology for both the resin system and the clear coat. As with any

automotive coating, storing your vehicle in a covered location will guarantee

a long lasting finish.

The rear wing on the non two-tone ACR is molded completely with

unidirectional carbon fiber and painted in body color. Some patterned or

linear conditions may be visible in the painted carbon fiber surfaces. This

is also a normal result of the carbon fiber process.

2.5 Carbon Fiber

This manual suits for next models

1

Table of contents

Other Dodge Automobile Accessories manuals