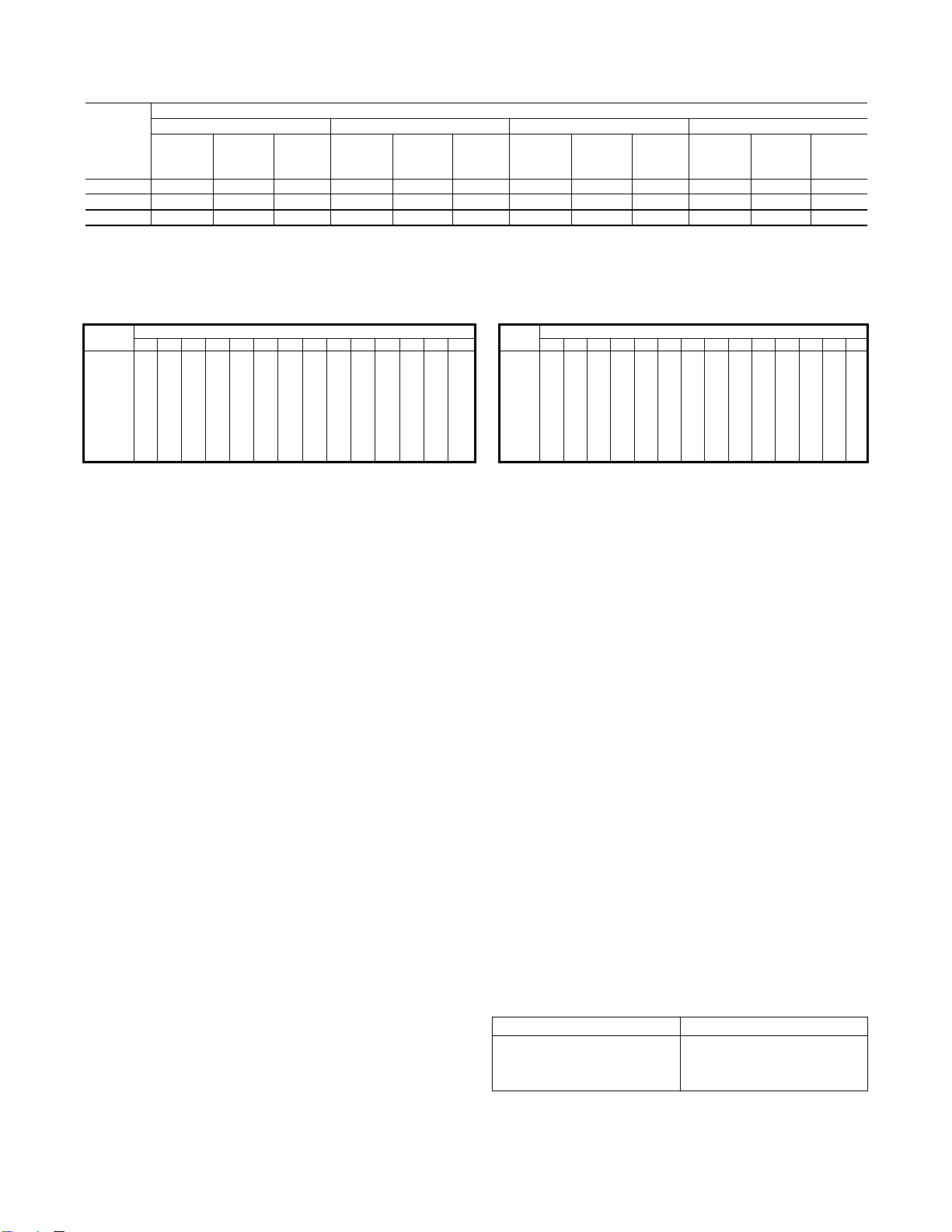

6

Refer-

ence Name of Part No.

Req’d. HXT305A

Part No. HXT405A

Part No. HXT505A

Part No.

12 Backstop Assembly 1 243102 244148 245154

HOUSING 1 253165 254218 255216

Air Vent 1 241237 241237 245237

16 Housing Bolt 6 411440 411442 411464

18 Adapter Housing Bolt 2 411442 411444 411466

19 Washer 4 419094 419094 419096

20 Lockwasher 6 419012 419012 419013

22 Hex Nut 8 407089 407089 407091

24 Dowel Pin 2 420055 420055 420110

Pipe Plug 2 430031 430031 430033

Magnetic Plug 1 430060 430060 430062

30* Input Shaft Bearing Shim Pack 2‡ 389723 389724 389725

.002" Thick † 427853 254226 427833

.005" Thick † 427854 254227 427834

.010" Thick † 427855 254228 427835

.025" Thick † 427856 254229 427836

32 Carrier and Cover Screws 10 411390 411407 411407

33 Lockwasher 10 419010 419011 419011

34 Backstop Cover 1 253175 254223 255019

38 Backstop Cover Screw 6 416524 411035 411406

39 Lockwasher 6 419007 419009 419009

40* Input Shaft with Pinion 1 253141 254141 255161

44* Input Shaft Brg. Cone 1 402190 402179 402270

45* (Input Side) Cup 1 403132 403006 403026

46* Input Shaft Brg. Cone 1 402271 402285 402266

47* (Backstop Side) Cup 1 403101 403125 403073

OUTPUT HUB

ASSEMBLYTaper Bushed 1 389703 389710 389717

60* cOutput

Hub Taper Bushed 1 243556 244588 245590

62* cOutput Gear 1 243570 244188 245186

64* cOutput Gear Key 2 243216 244217 355064

72 Bushing Back-up Plate 2 243308 244099 245114

74 Retaining Ring 2 421109 421108 421107

76 Output Hub Seal Carrier (Input

Side) 1 243547 244591 245592

77 Roll Pin 1 409022 409022 409022

80* Output Hub Cone 2 402272 402268 402193

81* Bearing Cup 2 403127 403163 403016

82* Output Hub Bearing Shim Pack 2‡ 389706 389713 389719

.002" Thick † 427849 244616 427825

.005" Thick † 427850 244617 427826

.010" Thick † 427851 244618 427827

.025" Thick † 427852 244619 427828

SEAL KIT* 1 389726 389727 389728

36* cBackstop Cover Gasket 1 253176 254221 255020

42* cInput Shaft Seal 1 351123 355011 245546

78* cOutput Hub Seal 2 243578 244673 245545

RTV Sealant, Tube 1 465044 465044 465044

Includes parts listed immediately below marked “c.” HXT505A housing

assembly also includes a two-piece housing. Bushing assemblies include 2

bushings.

cParts marked “c” make up the assemblies under which they are listed.

Not shown on drawing.

‡One set consists of one each of the shims listed immediately below marked “†.”

†See last paragraph under “ORDERING PARTS.”

Refer-

ence Name of Part No.

Req’d. HXT305

Part No. HXT405

Part No. HXT505

Part No.

1

5/16" Bore 1 243282 ...... ......

1

3/8" Bore 1 243284 ...... ......

1

7/16" Bore 1 243260 244079 ......

1½" Bore 1 243262 244081 ......

1

5/8" Bore 1 243264 244083 ......

1

11/16" Bore 1 243268 244085 ......

1¾" Bore 1 243266 244087 ......

1

7/8" Bore 1 243270 244089 245084

84 BUSHING 115/16" Bore 1 243272 244093 245086

ASSEMBLY 2" Bore 1 243274 244095 245088

2

1/8" Bore 1 ...... 244109 ......

2

3/16" Bore 1 243276 244111 245090

2¼" Bore 1 ...... 244113 245092

2

7/16" Bore 1 ...... 244115 245094

2½" Bore 1 ...... ...... 245099

2

11/16" Bore 1 ...... ...... 245110

2

15/16" Bore 1 ...... ...... 245112

86 cBushing Screw 6 411407 411408 411435

88 cLockwasher 6 419011 419011 419012

1

5/16" Bore 1 443264 ...... ......

1

3/8" Bore 1 443264 ...... ......

1

7/16" Bore 1 443265 443254 ......

1½" Bore 1 443265 443254 ......

1

5/8" Bore 1 443265 443254 ......

1

11/16" Bore 1 443266 443254 ......

1¾" Bore 1 443266 443254 ......

90 cKey, Bushing 17/8" Bore 1 443267 443255 443251

to Shaft 115/16" Bore 1 443269 443255 443251

2" Bore 1 443268 443255 443251

2

1/8" Bore 1 ...... 443258 ......

2

3/16" Bore 1 443270 443259 443251

2¼" Bore 1 ...... 443260 443251

2

7/16" Bore 1 ...... 443261 443243

2½" Bore 1 ...... ...... 443244

2

11/16" Bore 1 ...... ...... 443245

2

15/16" Bore 1 ...... ...... 443250

cKey, Bushing to Output Hub 1ß 443262 443257 443202

cKey, Bushing to Output Hub 1λ...... 443256 ......

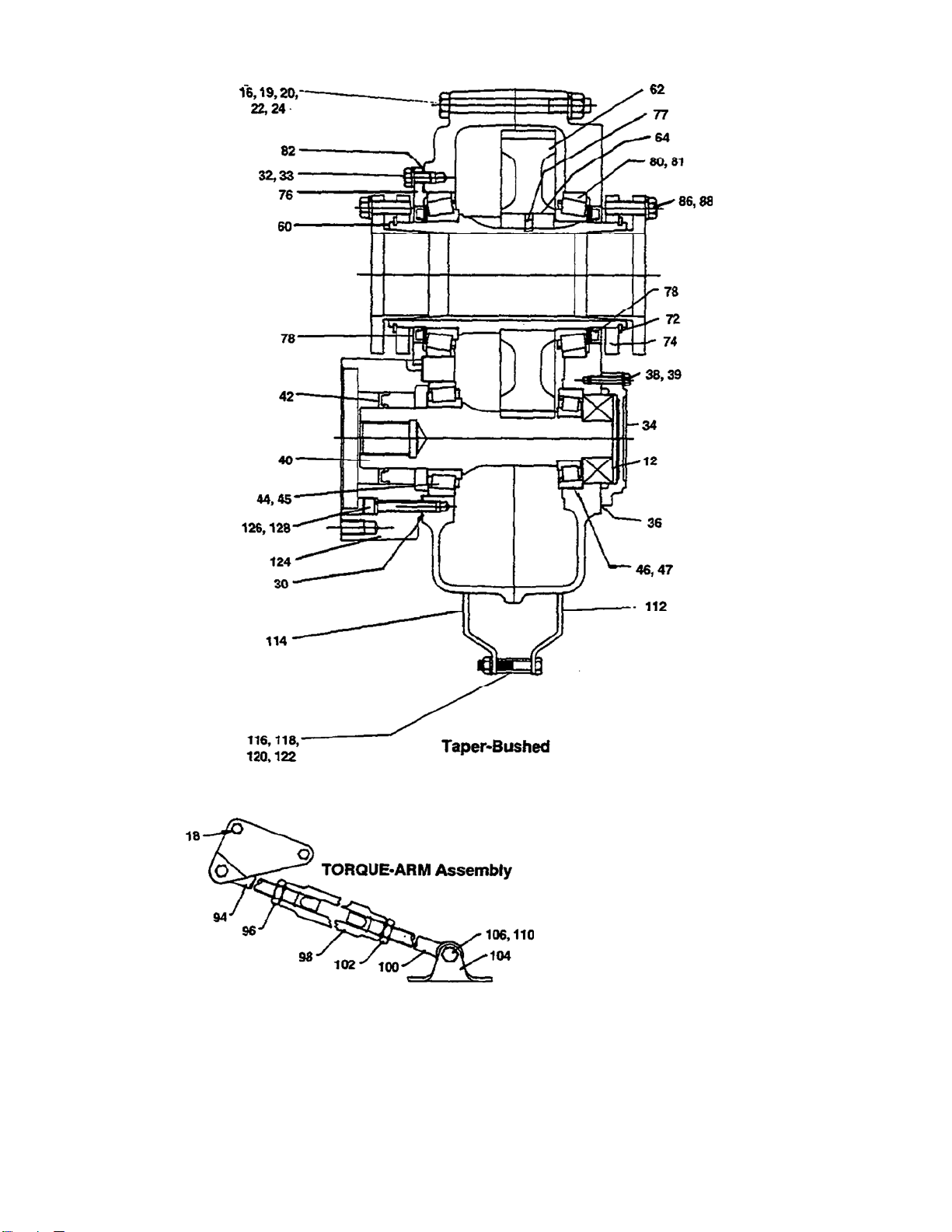

TORQUE-ARM ASSEMBLY1 243097 245097 245097

94 cRod End 1 243245 245245 245245

96 cHex Nut 1 407095 407097 407097

98 cTumbuckle 1 243246 245246 245246

100 cExtension 1 243247 245247 245247

102 cL.H. Hex Nut 1 407244 407246 407246

104 cFulcrum 1 243249 246249 246249

106 cFulcrum Screw 1 411484 411484 411484

110 cHex Nut 1 407093 407093 407093

ADAPTER ASSEMBLY1 259153 259154 259155

112 cR.H. Adapter Plate 1 243242 244244 245242

114 cL.H. Adapter Plate 1 243241 244243 245241

116 cAdapter Bushing 1 243243 245243 245243

118 cAdapter Bolt 1 411437 411460 411460

120 cLockwasher 1 419012 419013 419013

122 cHex Nut 1 407089 407091 407091

124 Motor Adapter 1 253142 254142 255162

126 Adapter Screw 4417081 417108 417108

128 Lockwasher 4419046 419047 419047

*Recommended spare parts

ßOn size HXT305A for 15/16" thru 1¾" bores; HXT405A for 17/18" thru

17/8" bores; HXT505A for 17/8" thru 2¼" bores.

λOne size — HXT405A for 115/16" bores and 2" bores.

Requires 5 bolts.

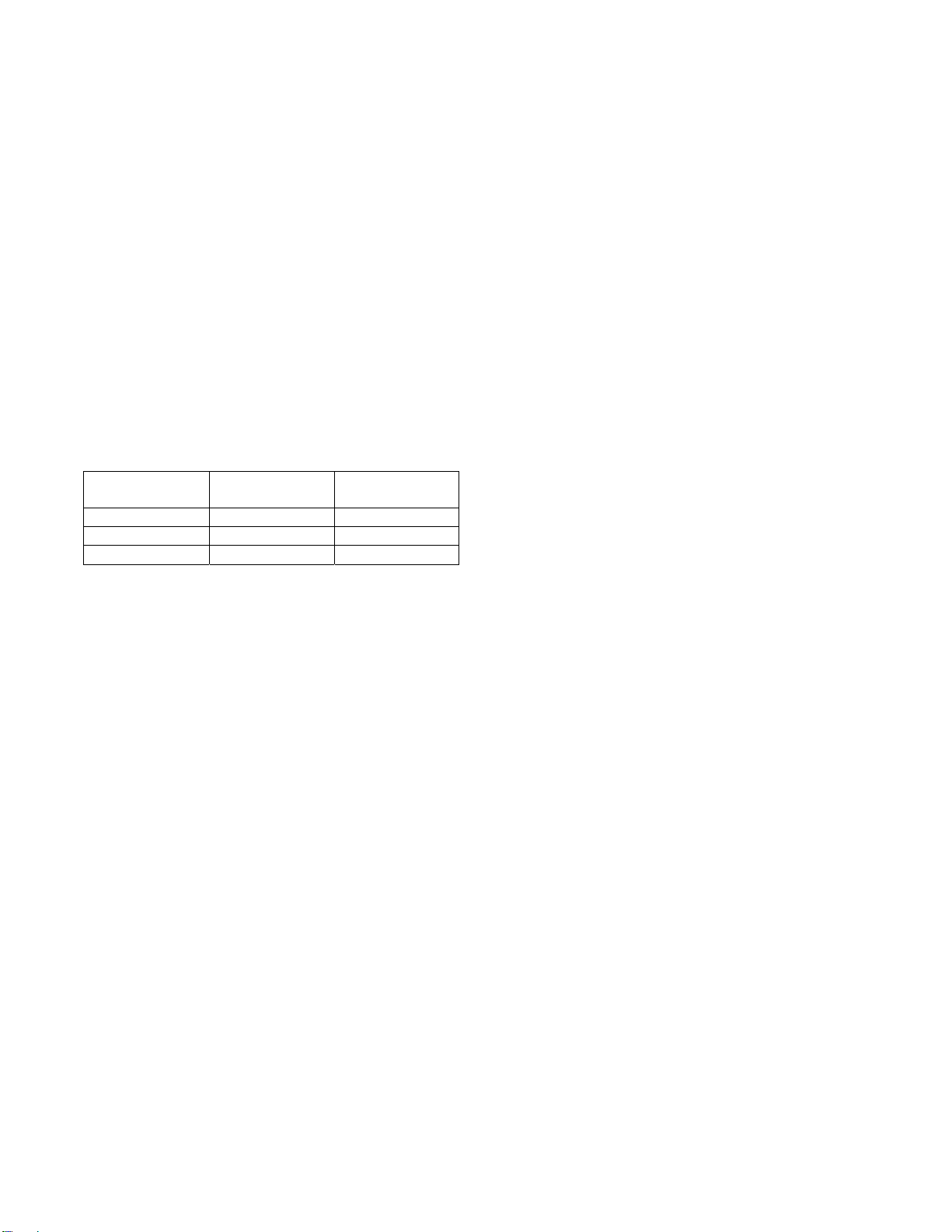

Table 5 — Manufacturers’ Part Numbers

For Replacement Output Hub Bearings

Output Hub BearingTORQUE-ARM Reducer

Drive

Size DODGE

Part Number Timken

Part Number

402272 LM814849

HXT305A 403127 LM814810

402268 498

HXT405A 403163 492A

402193 42381

HXT505A 403016 42584

Table 6 — Manufacturers’ Part Numbers

For Replacement Input Shaft Bearings

TORQUE-ARM

Reducer Input Bearing Input Side Input Bearing Adapter Side

Size DODGE Part

No. Timken Part

No. DODGE Part

No. Timken Part

No.

402190 LM603048 402271 02872

HXT305A 403132 LM603011 403101 02820

402179 368 402285 339

HXT405A 403006 362A 403125 332

402270 45289 402266 350A

HXT505A 403026 45220 403073 352