9

Operation & Calibration Instructions

1. When starting up your applicator for the first time, you may notice that after 15-

20 minutes of run time, the volume may increase; this is normal. During the first

15-20 minutes, your pumping tube is being broke in. Your system does not

need to go through a break in period before use. If you notice the volume

increase, simply use the SP-2 Control to adjust back to the desired rate.

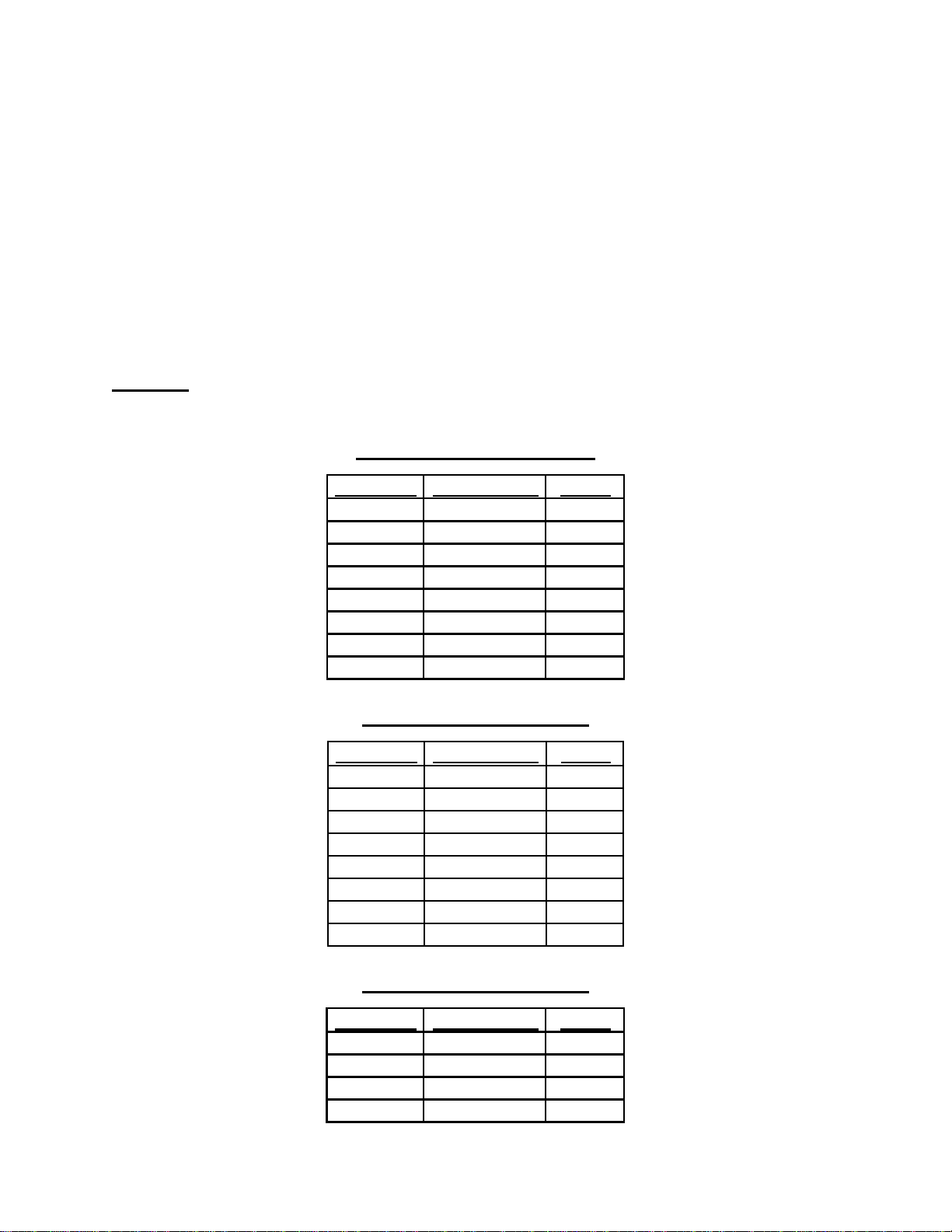

2. Calibrate your applicator against the charts found on pages 10 & 11. If you are

using your product mixed at the full concentrate rate of 100 tons per gallon,

simply float the ball on the line of the amount of tonnage you desire to treat per

minute. If you are using one of the other mix rates, refer to the chart on page 10

to find out the ounces per minute for your tonnage and float the ball on the line

for the desired ounces per minute found on the right side of the flowmeter.

3. Use the 2 quart mixing bottle for pre-mixing your product. Mix between 200-250

tons per mix. Mix the total amount of product you desire.

NOTE: The applicator is designed to mix up to 100 treatable ton of product per

gallon (see the calibration charts on the following page to find your desired

mixing rate based on your harvest rate).

Example 1: If you wish to mix for 400 treatable ton of product, you would mix 2

batches of 200 ton in the mixing jug. Then dump the solution into the tank. Fill

the tank up to 4 gallons. This mix will allow for an application rate of 1.28 oz/ton

(100 ton per gallon mix).

Example 2: If you wish to mix for 400 treatable ton of product, you would mix 2

batches of 200 ton in the mixing jug. Then dump the solution into the tank. Fill

the tank to 8 gallons. This mix will allow for an application rate of 2.56 oz/ton

(50 ton per gallon mix).

4. Add frozen plastic bottles (20 oz. soda bottle) of water to assist with providing a

cool environment for the product. At the days end, or during any prolonged

interruption of chopping (weather, breakdown, etc.), ice packs or frozen bottles

of water may be added to keep the product cool. (Ice packs or bottles not

included with the applicator.)

5. Your applicator should be flushed at the end of each day. To do this, turn the 3-

way valve handle up toward the flush bottle input. This will allow the pump to

draw clean water from the flush bottle and flush out the entire product line.

NOTE: 4 ft. of product line will contain enough product for 1 ton of forage. It is

recommended to flush out the product onto the last batch of forage harvested.

COLD WEATHER FLUSHING: During cold weather when there is a possibility

of the product lines freezing overnight, it is recommended to fill the flush bottle

with RV Waterline Antifreeze and flush the system. This will prevent the lines

and the flowmeter from freezing and cracking.

6. It is recommended to flush out the tank between batch mixes to remove any

product settlings. To do this, remove the tank and rotate the swivel connection

to expose the filter screen and rinse out with clean water. This will clean out the

tank and filter.