The Dolomite Centre Ltd.

3600051 - P-Pump API - programming instructions - v 1.3 Page 5 of 15

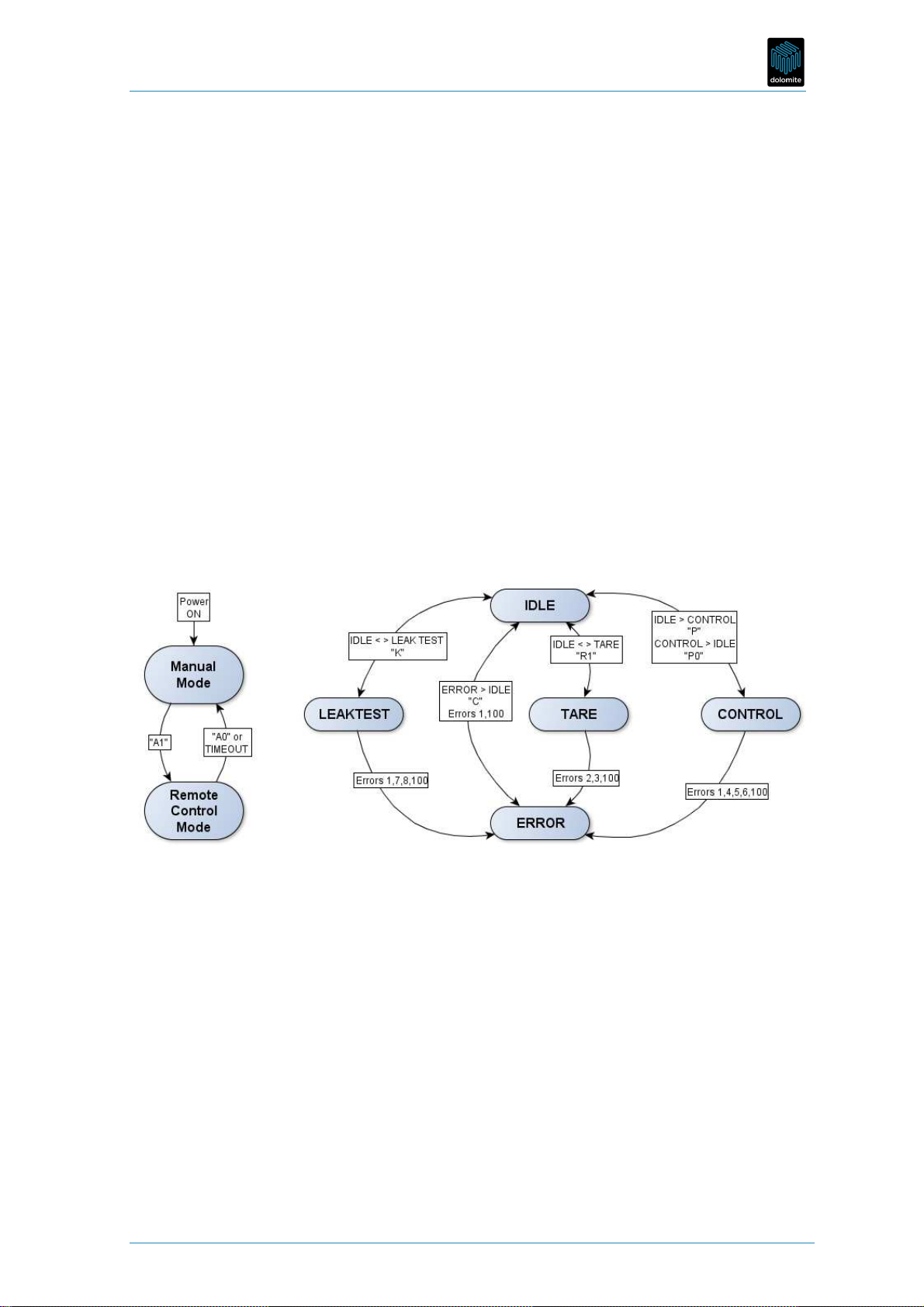

Issuing another control pressure command sets a new target but the pump stays in the CONTROL

state.

If your application issues a control pressure command when the pump is in any other state, the

command will be rejected and the pump will continue its current operation.

5.1.3 TARE (State: 2)

Your application should issue a “tare” command only when the status is IDLE. If the pump is in

any other state the command will be rejected. The pump automatically moves back to the IDLE

state when taring is complete.

During the tare operation, your application may see the TARE state, but that will depend on the

frequency of communication. Once the TARE is complete, any subsequent request for status

from the pump will only return IDLE or ERROR.

5.1.4 ERROR (State: 3)

The pump can get into the ERROR state from any other state if an error condition arises. The only

state to which the pump can move from ERROR is IDLE. To clear the ERROR state (move back to

IDLE the following conditions must be met:

•

The cause of an error must cease: you cannot clear the ERROR state unless the error

condition has been removed.

•

Your application must clear the ERROR state by explicitly sending a “C” command. This

ensures your application cannot "miss" any errors.

5.1.5 LEAKTEST (State: 4)

You can leak test the system by connecting a sealed chamber, a gas supply and setting the state

to LEAKTEST by issuing a “K” command. The test takes about 1 minute and performs a leak test at

two pressures - close to the supply and close to atmospheric pressure. The system is deemed

leak tight if neither test shows a change in pressure of more than ±5mbar/bar/minute. The test

assumes a system volume of about 30mls (the standard P-Pump chamber

1

.

When your application sees the status change back to IDLE, it can read the leak test result using

the “k” command. See command list below for details.

5.2 Control strategy

The pump only sends data in direct response to a command. As communication is asynchronous,

it is safest to write commands to the pump immediately following a completed response from the

pump to avoid collisions on the bus.

You can use the API to completely control the pump by setting the pump in full remote control

mode or leave the pump in manual mode and simply read pressure and state information back

from it when required. Full remote control mode has a timeout limit - you must send a

command to the pump at least once every 30 seconds or the pump will revert to manual mode

and IDLE. This acts as a safety watchdog in the event of PC, application or communications

failure.

The schematics below show a simple way of handling the data flow to and from the pump. There

are other methods that will work equally well or may be better or easier to implement in your

system. The system outlined has four main elements.

1. An interrupt driven timer

1

An acceptable leak rate of <±5mbar/bar/minute maximum is specified. Typical values are <±3mbar/bar/minute. The

apparent leak rate reported is inversely related to system volume – the specification assumes a standard 30ml volume

sealed system.