Contents-1

YK18-0012-AI-001-01

Table of Contents

Before Using the Machine........................................................................ i

About Safety Notation ............................................................................................................ii

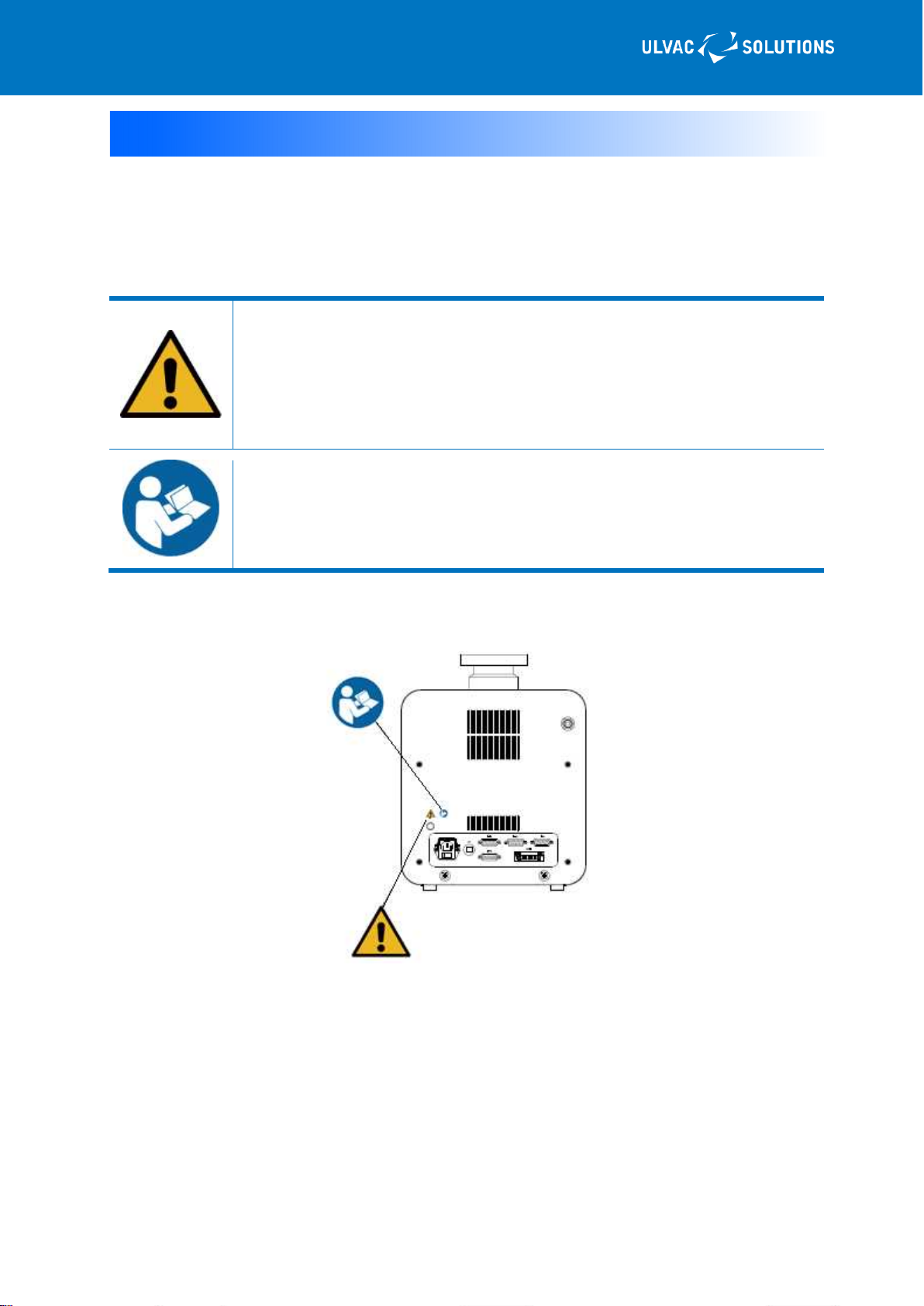

▶Meaning of signal words: ..........................................................................................ii

▶Meaning of symbol marks:........................................................................................ii

Types and display position on warning labels .......................................................................iii

▶Types and explanation on warning labels................................................................iii

Warranty Clause....................................................................................................................iv

▶Warranty Product .....................................................................................................iv

▶Warranty Period .......................................................................................................iv

▶Warranty Coverage..................................................................................................iv

▶How to Respond ......................................................................................................iv

▶Disclaimer .................................................................................................................v

▶Others(Warranty Clause).....................................................................................v

About this manual...................................................................................................................v

1. For safe use ........................................................................................1

1.1 Handling the machine...................................................................................................... 1

1.2 Acceptance /transport / storage ...................................................................................... 2

1.2.1 Acceptance............................................................................................................ 2

1.2.2 Transportation ....................................................................................................... 3

1.2.3 Storage.................................................................................................................. 3

1.3 Installation and operation ................................................................................................ 3

1.4 Disposal........................................................................................................................... 4

1.5 Protective equipment....................................................................................................... 4

1.6 Dangerousness inherent to the machine and safety measures...................................... 4

1.6.1 Intake and exhaust of dangerous gasses and substances................................... 4

1.6.2 Long-distance transportation ................................................................................ 5

1.6.3 Electric shock ........................................................................................................ 5

1.6.4 High temperature .................................................................................................. 5

1.6.5 Burst ...................................................................................................................... 6

2. Product Summary ...............................................................................7

2.1 Features .......................................................................................................................... 7

2.2 Use .................................................................................................................................. 7

2.3 Names and works on each section ................................................................................. 8

2.4 Explanation on touch panel operation screen ............................................................... 10

2.4.1 Initial screen ........................................................................................................ 10

2.4.2 Main screen......................................................................................................... 10

2.4.3 VAC screen ..........................................................................................................11

2.4.4 Menu screen ....................................................................................................... 12

2.4.5 Delay timer setting screen................................................................................... 12

2.4.6 P1 setting screen ................................................................................................ 13

2.4.7 P2 setting screen ................................................................................................ 13

2.4.8 etc.1/etc.2 screen ............................................................................................. 14

2.4.9 FIL screen ........................................................................................................... 16

2.4.10 DEG screen....................................................................................................... 16

Table of Contents