Paqes

Accessories

.........

...............•..•·· ....

..

22

How to Use ····:.···············

···

•··

··

·

23

Hemmers •···········

···

··················

24

Seam

Gauge

or

Cloth

Guide

···

···

25

Quilting

Guide

25

Adjusting

and

Chanqinq "V" Belt

28

Attachments.....•...............•..............

33

Adjustable

Cord

and

Zipper Foot

40

Attachment Foot···

···················

··

34

Binder·

••••

••··••••·····•··•·••·····

···

••

·•·•

36

·Edgestitcher •········•••··••··•···········

34

Hemmers ···········

··

····

··

··

···

·········

'57

Ruffler •··············

•·

····•

··

•········ 41-42

Blind Hem.........••••••••

..

..

.......

....

•...•••

16

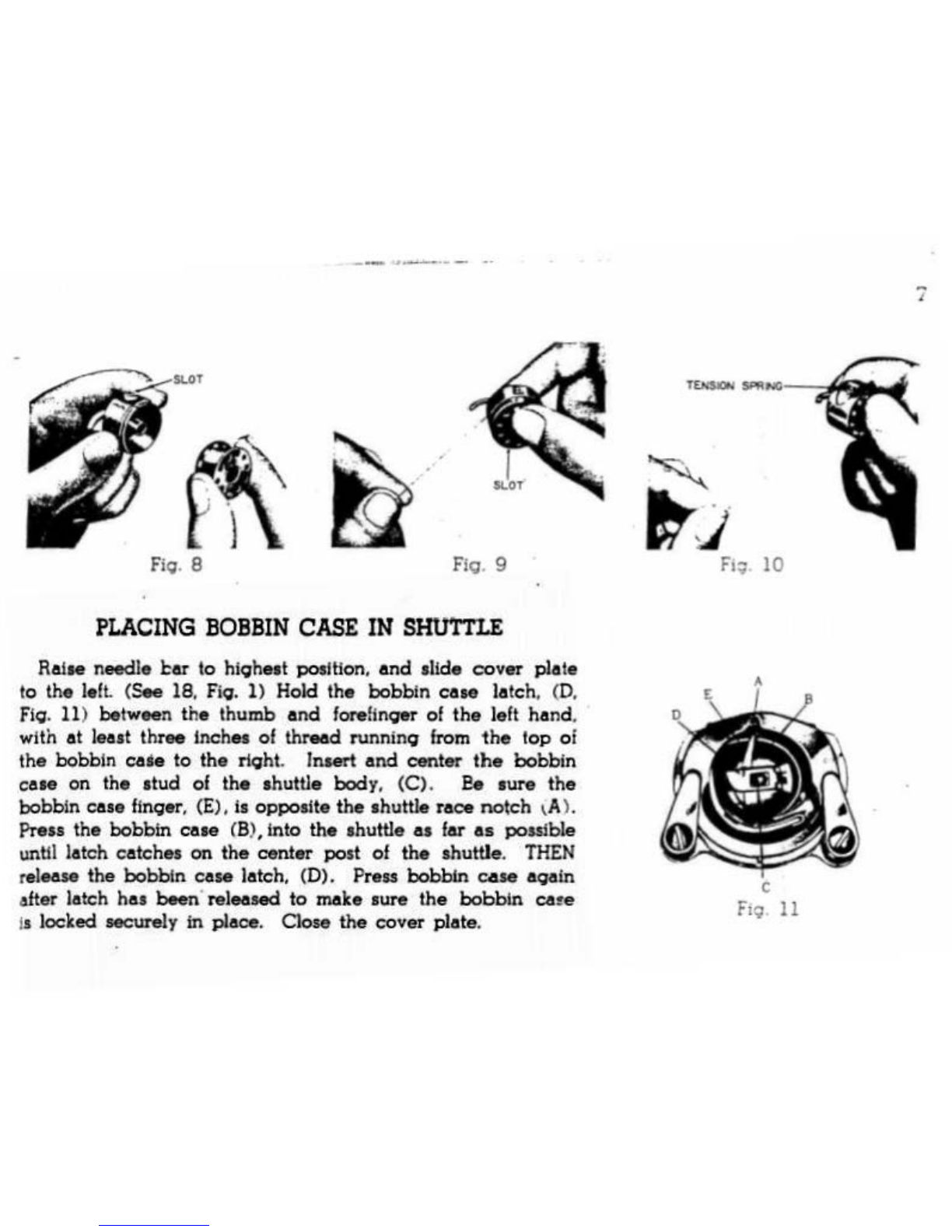

Bobbin

Placing in Shuttl

e·

·····•················· 7

Threading ··········••········· ············ 6

Winding ········· ···············

·········

·

··

5

Buttonholes •

•·

··•·········•················ 19-20

Bound ···

··

··································

46

Buttons Sew

-On·

·····························

21

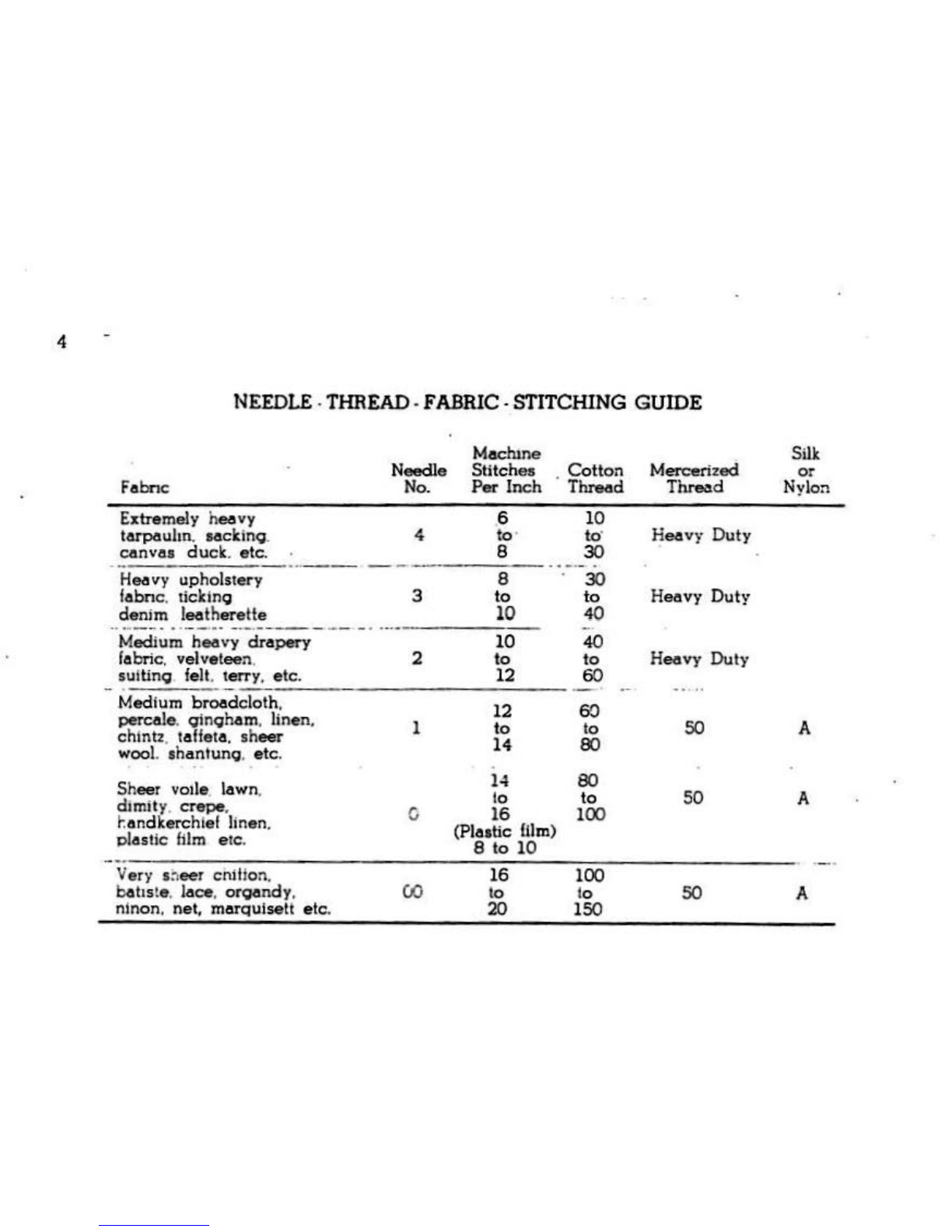

Charts

Needle•Thread.Fabric-Stitching••···· 4

Stitch Length···········

······

············· 9

Trouble •······

··

···

···

············

29

.30.31

INDEX

Pages

Darning

and

Mending--···

··

·

·····

···

·····

11

· Embroidery

Creati

ve •····· ·················· •··

···

···

17

Hoop

···

········•··•················•·......

18

Features

and

Parts (Front View) ..:... 2

(Back View)········· 3

Installation• Head

in

Cabinet•···········

49

He

ad

in

Portable

case

··•

48

Maintenance

and

Care

······ ······ ······

26

Cleaning

and

Oiling

the

Shuttle

27

Needle Setting ········

..

·················..···· 6

Pressure

and

Feeding of Fabric ······ 11

Thin

and

Light weight

Fabr

ics•·· 11

Reverse Sewing································· 9

Sewing Preparation ··•

•·

•··················

12

Sewing Tips ························ ··· ·

...

,•

43

Straight Stitching ·······················•···

13

Tension Adjustment ·······••

00

•···

·

·····

···

10

Thread

ing-Upper ......•··......

......

•......•• 8

1