8.3

Each room airflow rate will need to be recorded on the Inspection

Checklist and Airflow Measurement Test Sheet. A completed copy must

accompany these instructions and be handed over to the dwelling’s

owner upon completion of the installation.

9.0 System Balancing

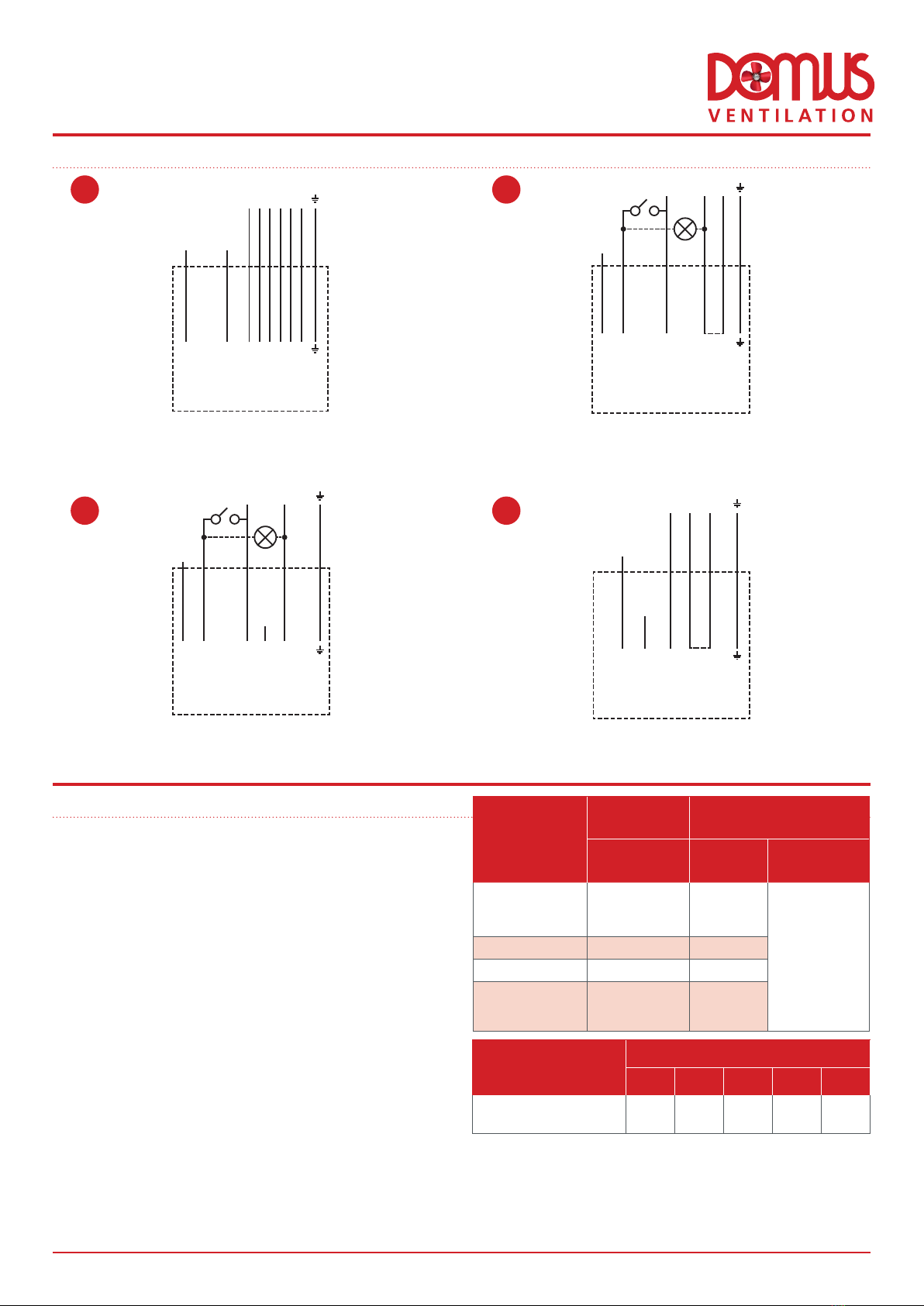

• Fully open all of the air valves (see figure 11).

• Switch the system to boost.

• Close all internal and external doors and windows.

• Measure the total air volume of the extract valves (wet rooms).

• To adjust the ‘boost’ control on the wiring centre in order to

achieve the whole dwelling extract ventilation rate, remove the rubber

tamper-deterrent cap and use Domus Ventilation commissioning

adjustment tool, SPR439.

• Adjust individual room air valves to achieve the individual room

boost extract rates.

• Switch the system to low.

• Measure the total air volume of the valves.

• To adjust the ‘trickle’ control on the wiring centre in order to

achieve the whole dwelling extract ventilation rate, remove the rubber

tamper-deterrent cap and use Domus Ventilation commissioning

adjustment tool, SPR439.

• To adjust the ‘remote humidity’ (%RH) sensor on the wiring centre,

remove the rubber tamper-deterrent cap and use Domus Ventilation

commissioning adjustment tool, SPR439.

• Using the lock nuts fitted to the air valves, lock in position (see

figure 11).

• Refit the rubber tamper deterrent caps to the lid of the wiring

centre.

10.0 Maintenance

The CMX-MULTI / CMX-MULTI-H appliance is essentially maintenance

free.

11.0 Warranty

The 2 year warranty starts from the day of delivery and includes first

year parts and labour, remaining year parts only. This warranty is void if

the equipment is modified without authorisation, is incorrectly applied,

misused, disassembled, or not installed, commissioned and maintained

in accordance with the details contained in this manual and general

good practice.

The product warranty applies to the UK mainland and in accordance

with Clause 14 of our Conditions of Sale. Customers purchasing from

outside of the UK should contact Domus Ventilation Sales office for

further details.

The above warranty does not apply to nor cover the repair of any

problem or fault with the product which arises as a result of: (a) failure

to install, operate, maintain and/or repair the product or any associated

parts and components (including any ducting) using reasonable skill

and care and in accordance with the instructions provided with it

(unless the original installation, maintenance or repair which gave rise

to the problem or fault was carried out by or on the behalf of Domus

Ventilation in which case this exclusion will not apply); (b) use of the

product for any purposes other than those for which it is designed;

(c) modifications made to the product by anyone other than Domus

Ventilation or its approved contractors; (d) deliberate damage; and/or (e)

damage caused by fire, flood or other water damage, explosions, rust or

corrosion.

12.0 TECHNICAL SUPPORT

For technical assistance or further product information, including spare

parts and replacement components, please contact Domus Ventilation

via below contact details.

Telephone 03443 715 523

11

V E N T I L A T I O N

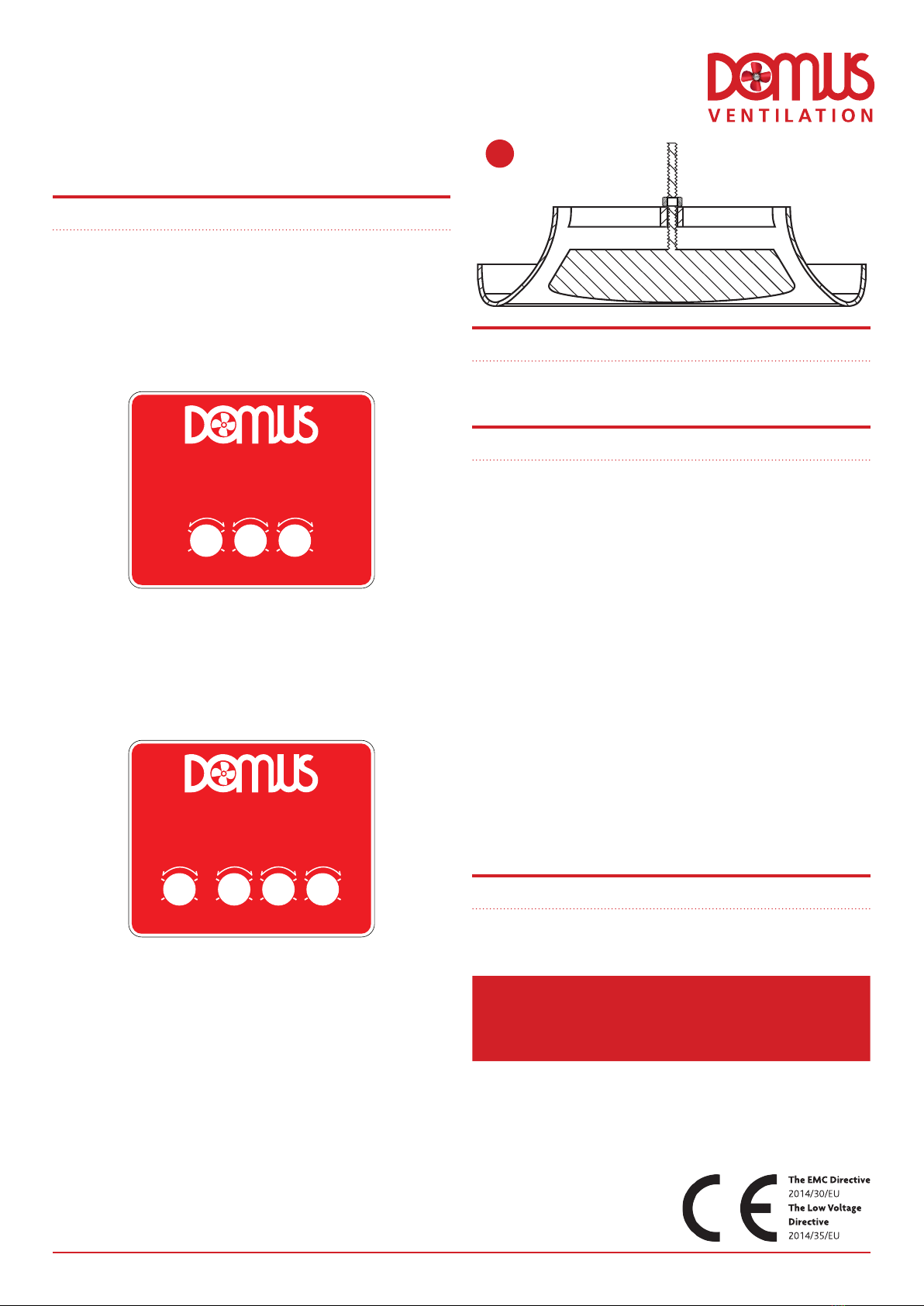

CMX-MULTI

www.domusventilation.co.uk

-

+

-

+

purge boost trickle

-

+

-

+

-

+

-

+

%RH purge boost trickle

-

+

V E N T I L A T I O N

CMX-MULTI

www.domusventilation.co.uk

Domus Ventilation

Block C, Van Court, Caerphilly CF83 3ED, United Kingdom

Tel: 03443 715 523

www.domusventilation.co.uk

Technical or commercial considerations may, from time to time, make it

necessary to alter the design, performance and dimensions of equipment

and the right is reserved to make such changes without prior notice.

LAB1356R | NOVEMBER 2018 PAGE 6