Donaldson Company, Inc.

4

Description

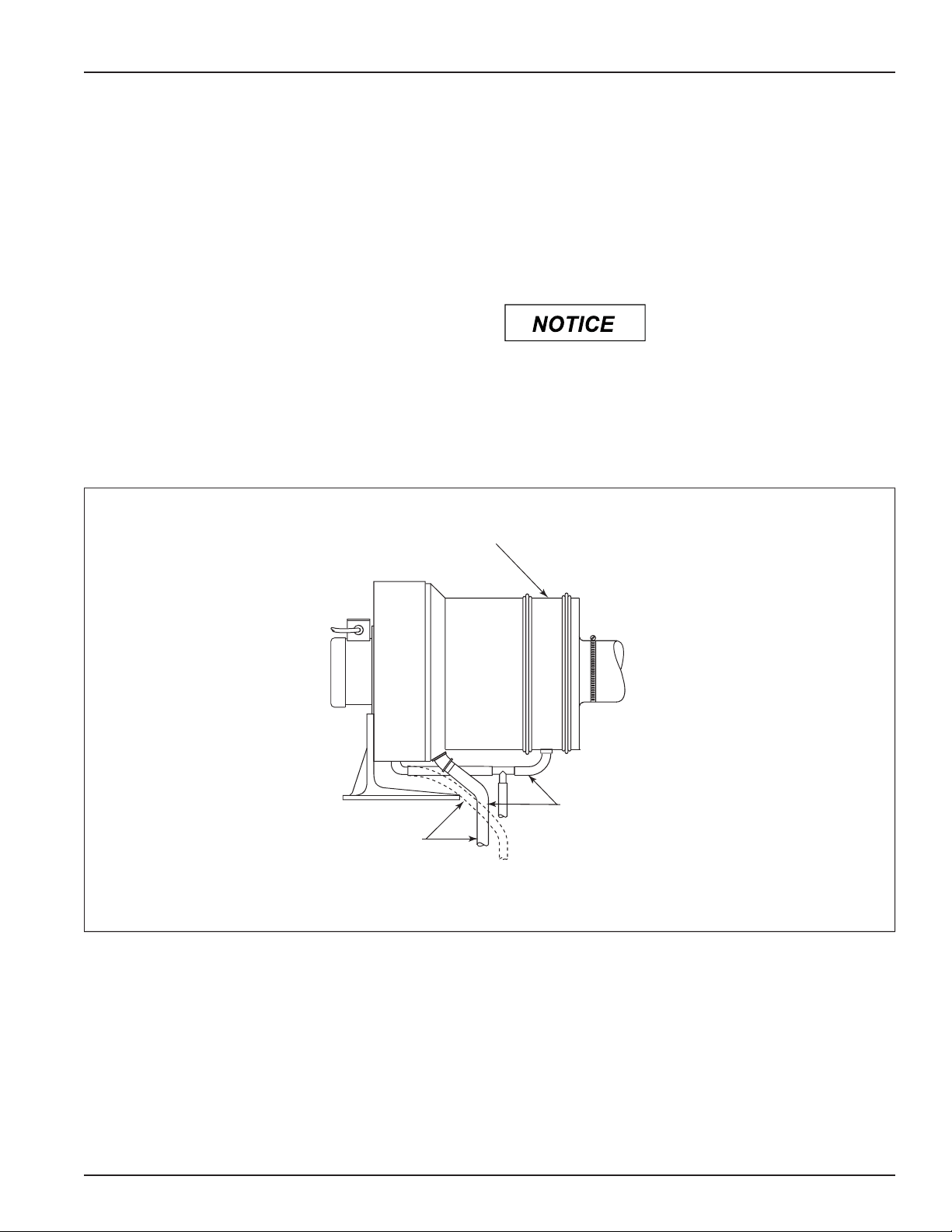

Centrifugal mist collectors are compact, high

efficiency, centrifugal mist collection systems

designed to collect, filter, and reclaim liquid mist

generated in machine tool or process operations.

The compact size allows direct machine mounting

which integrates the collection system directly to

the mist-generating machine or process. Four stages

of filtration provide effective indoor air pollution

control.

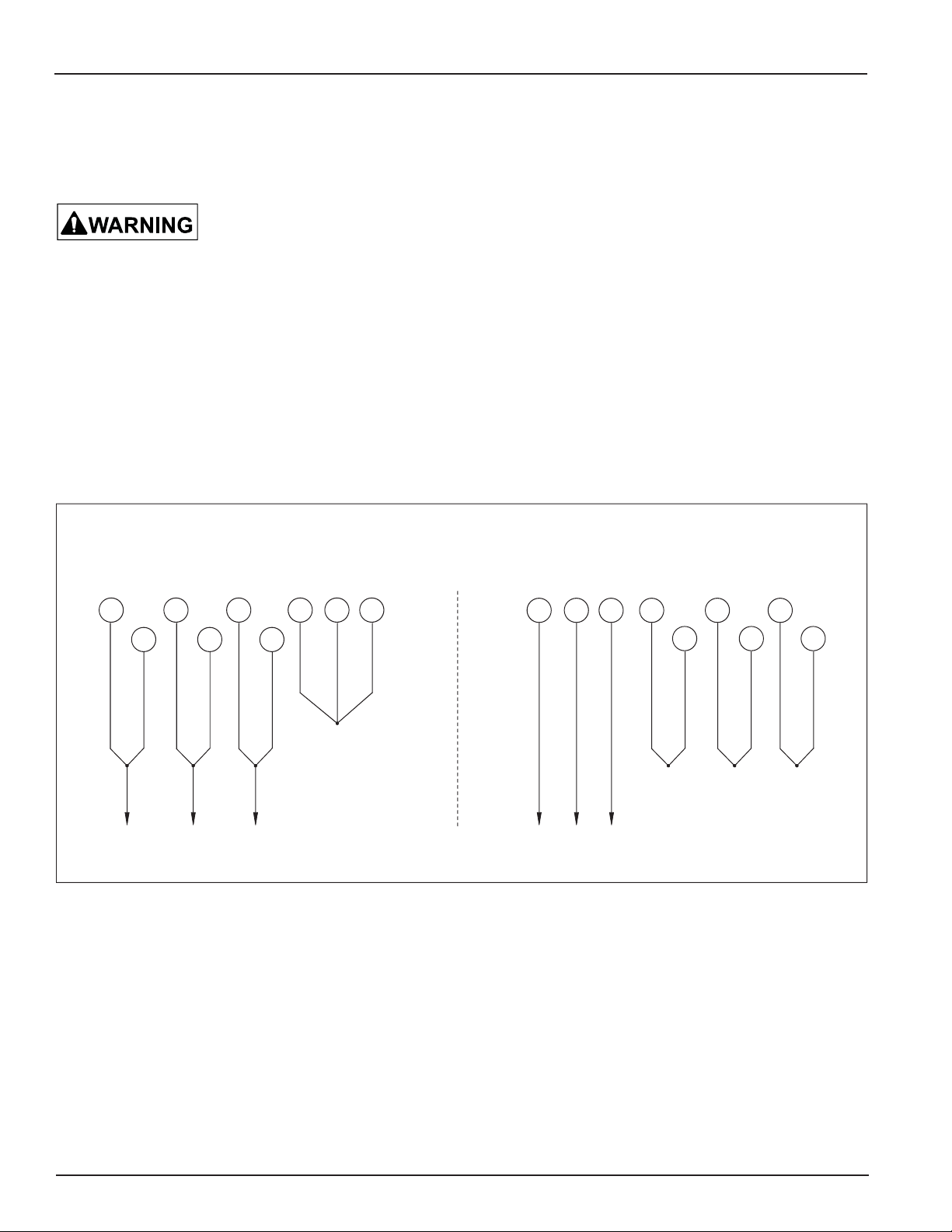

Optional prefilters, impingers, and afterfilters

provide additional filtration. Prefilters are used to

remove chips or solid particles before they enter

the rotating drum and impingers remove heavy

sprays of raw fluids. Optional HEPA afterfilters,

available in standard and high-capacity sizes, remove

smoke generated in a machine process while carbon

afterfilters remove gas vapor and odors.

Purpose and Intended Use

Misuse or modification of

this equipment may result in

personal injury.

Do not misuse or modify.

Centrifugal mist collectors are intended for

separation of various liquid particulates. It is not a

dust collector and should not be used to filter solid

particulate. The mist collector is designed to filter

mild amounts of smoke and only smoke of an oily

nature or mixed with oil mist. Typical applications

include chip-generating operations such as screw and

bar machines, CNC turning and milling machines,

and applications using straight oil coolants. Some

applications such as grinding, especially those with

heavy metal-removal rates, can cause a buildup of

grinding swarf or other solid particulate. Using a

prefilter trap is strongly recommended to extend

the maintenance cycle of the mist collector in these

operations.

The collector must be sized to the application or

filtration will not be effective. Too little airflow will

not draw the contaminant into the filter and too

much airflow may result in the unit picking up large

or heavy solid particles increasing the frequency of

maintenance or filter replacement.

Combustible materials such as buffing lint, paper, wood, metal dusts, weld fume, or

flammable coolants or solvents represent potential fire and/or explosion hazards. Use

special care when selecting, installing, and operating all dust, fume, or mist collection equipment

when such combustible materials may be present in order to protect workers and property from

serious injury or damage due to a fire and/or explosion.

Consult and comply with all National and Local Codes related to fire and/or explosion properties

of combustible materials when determining the location and operation of all dust, fume, or mist

collection equipment.

Standard Donaldson Torit equipment is not equipped with fire extinguishing or explosion protection

systems.