www.stonefloorpolisher.com

Dongguan Merrock Industry Co.,Ltd

Contactor: Lucy Luo Mobile:86-18929453650

E-Mail: dgmerroc @hotmail.com Web: www.stonefloorpolisher.com

Operation steps

Connect the wire to the outlet. The start switch use double side (left and right) control design, and for the

safety, it must coordinate with the safety switch when start the machine. Detail see picture as follows:

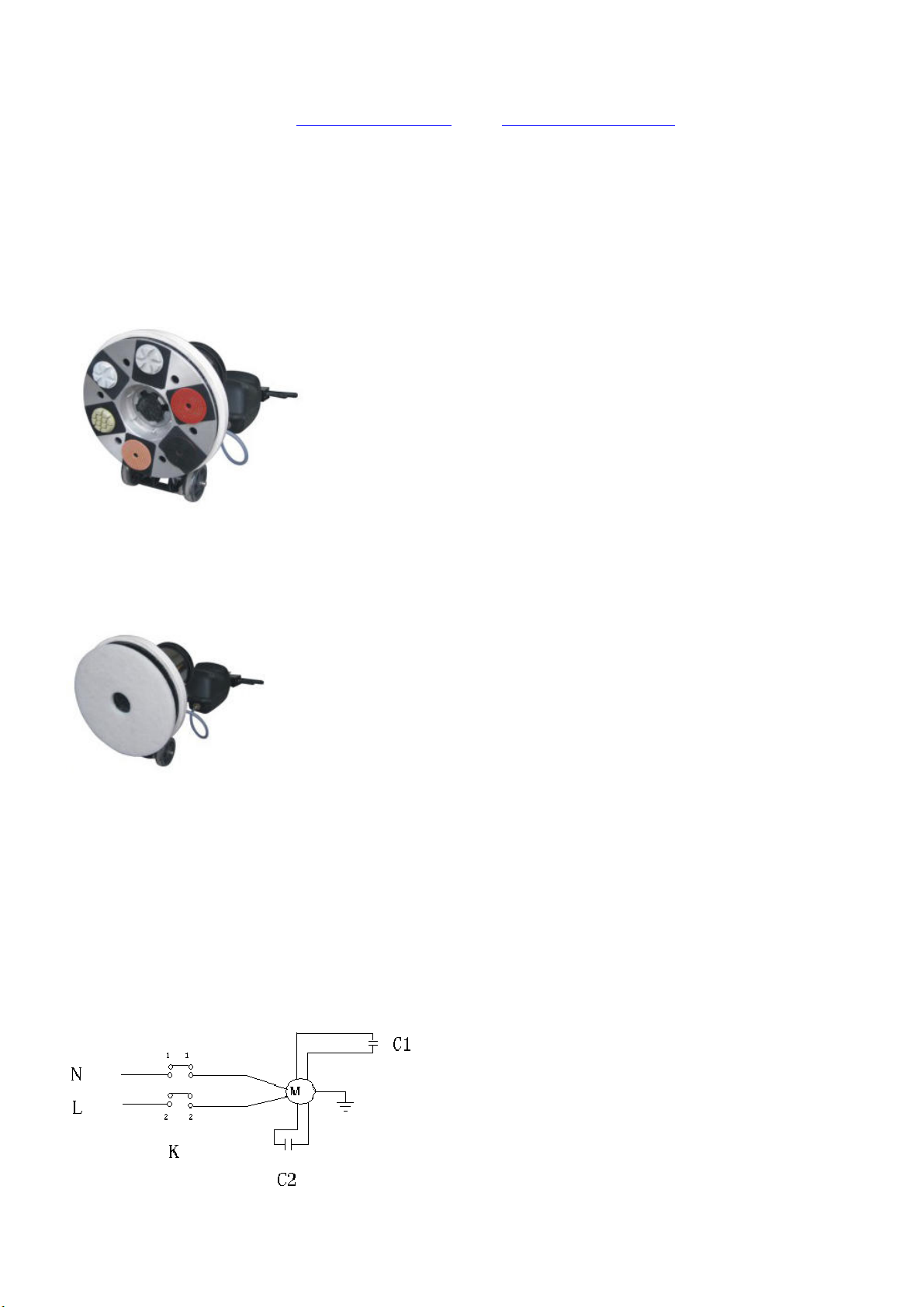

MRK-17/10 MRK-175

1.

The safety switch is on the front of the handle, after connecting power, please pull the safety switch, and

at the same time grasp the start handle firmly.

2.Loosen the start handle the machine will stop running.

3.After starting the machine, only control the handle up or down lightly, the machine will move toward

right or left automatically. hen press the handle down lightly, it adds the pressure on the back of pad

holder to make the machine move left. hen up the handle, it adds the pressure on the front of pad holder

to make the pad holder move right.

4.The picture show above on the left is for stairs, if change to 17" polishing machine, put the separated

disc on the stairs machine, lock by screws, then put the add length bar on the middle of the action bar and

lock by screws, at last fix the water tank.

5.Set action bar upright, upend the floor cleaning machine on the ground, after cover the pad holder

screwing in anticlockwise.

3

www.stonefloorpolisher.com