CONTENTS

SAFETY INSTRUCTIONS...................................................................................................................................................... 1

WARNING................................................................................................................................................................................1

PROVISION FOR LIFTING AND CARRYING.....................................................................................................................2

OPERATING ENVIRONMENT.............................................................................................................................................. 2

CLIMATIC ENVIRONMENT................................................................................................................................................. 2

i) temp 5-55 deg celcius......................................................................................................................................................... 2

ii) humidity 30-95% RH............................................................................................................................................................2

iii) Altitude 2000m above sea level...........................................................................................................................................2

ELECTRICAL INFORMATION..............................................................................................................................................2

INSTALLATION CATEGORY AND POLLUTION DEGREE............................................................................................. 3

ELECTRICAL SUPPLY...........................................................................................................................................................3

SECTION 1 INTRODUCTION................................................................................................................................................ 4

1.1 The SBT401.........................................................................................................................................................................4

1.2 Features of the SBT401....................................................................................................................................................... 4

SECTION 2 SPECIFICATIONS AND INSTALLATION.......................................................................................................4

2.1 Machine Settings - ABRASION......................................................................................................................................... 4

2.2 Machine Settings - Pilling................................................................................................................................................... 4

2.3 Machine Settings at subsequent calibrations.......................................................................................................................5

NOTE 1............................................................................................................................................................................5

NOTE 2............................................................................................................................................................................5

2.4 Calibration Checks.............................................................................................................................................................. 5

SECTION 3 INSTALLATION AND ASSEMBLY................................................................................................................. 6

3.1 Assembly for Abrasion Testing...........................................................................................................................................6

3.2 Assembly for Pilling Testing...............................................................................................................................................7

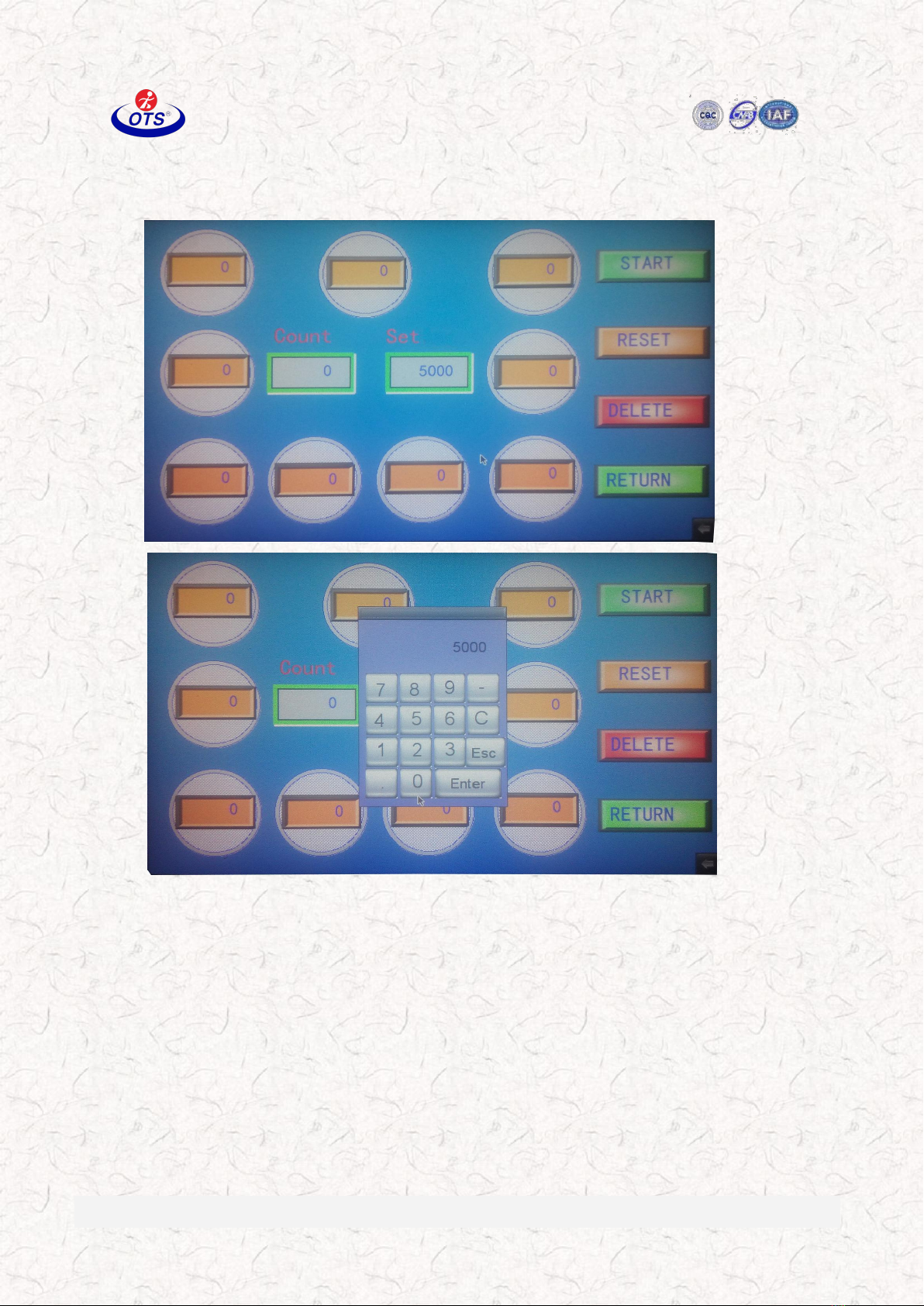

SECTION 4 OPERATING INSTRUCTIONS FOR THE SBT401..........................................................................................7

4.3.1 preparation of apparatus................................................................................................................................................. 10

4.3.2 Conditioning................................................................................................................................................................... 10

SECTION 5 TESTING PROCEDURES.................................................................................................................................10

5.1 Sample preparation - Abrasion..........................................................................................................................................10

5.2 Sample preparation - Pilling..............................................................................................................................................11

5.3 Test Procedure - Abrasion................................................................................................................................................. 12

1. Determination of specimen breakdown..................................................................................................................... 12

2. Determination of Mass Loss...................................................................................................................................... 12

5.4 Test Procedure –Pilling................................................................................................................................................ 13

SECTION 6 CALIBRATION AND MAINTENANCE......................................................................................................... 14

6.1 Calibration......................................................................................................................................................................... 14

6.2 Maintenance...................................................................................................................................................................... 14