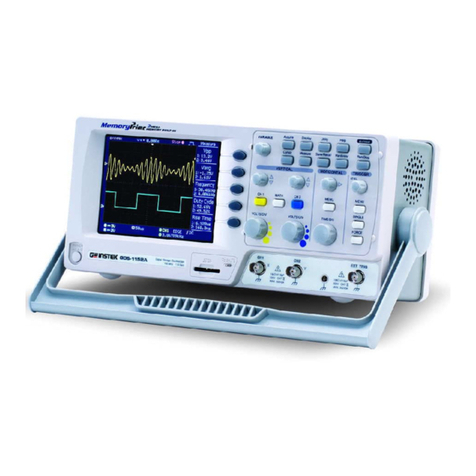

③

INSTALLATION

1. Turn the both fixing handles of BNC terminals from LCR-05A test fixture

toward left side until the gap of BCN external sleeve faces upward.

2. Align the gap with the salient point of BNC terminal from LCR test

instrument and insert it firmly into place. Turn the both fixing handles of

BNC terminals from LCR-05A

test fixture toward right side until the external

sleeve of BCN is fixed stably into place.

Note: When the L-shape bracket is employed, take off the nut from the

ground terminal prior to test fixture installation. Follow the steps

above for proper installation followed by fastening the nut so that the

test fixture can be held tightly when DUT is inserted.

Note: Refer to the pictures below for details of L-shape bracket installation.

Test Fixture Installation

L-shape Installation

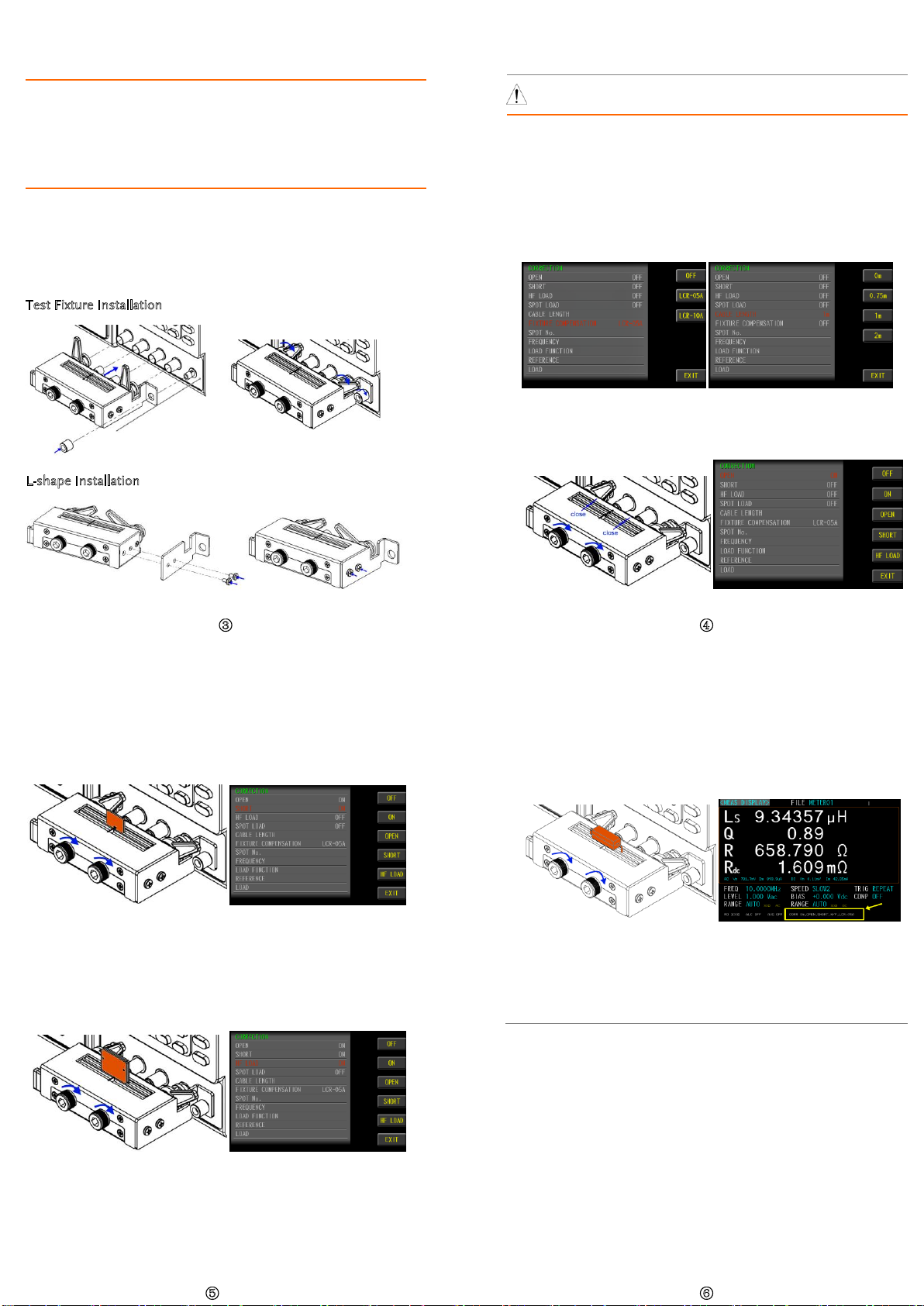

④

MEASUREMENT

WARNING Before measurement, be sure to read the operating

instructions to avoid danger.

1. Set measuring conditions with parameters, and install LCR-05A test fixture.

2. Execute the CORRECTION mode. Set LCR-05A for the FIXTURE

COMPENSATION item in order to execute LCR-05A parameter

compensation, by which the CABLE LENGTH item will be unavailable.

On the other hand, when extension cable is wired with LCR-05A for

measurement, it is required to disable the FIXTURE COMPENSATION

item (OFF) and instead select an appropriate option for CABLE LENGTH

corresponding to the employed cable.

3. Fasten the adjusting screws clockwise to make the Electrodes tightly

close. Execute the OPEN CORRECTION and the OPEN item will change

from OFF to ON.

⑤

4. Loosen the adjusting screws counter-clockwise to make the Electrodes

open. Insert the short-circuit jumper into the Electrodes followed by

fastening the screws. Subtly adjust the Electrodes to clamp the short-

circuit jumper tightly. Execute the SHORT CORRECTION and the SHORT

item will change from OFF to ON.

5. It is suggested to execute HF LOAD calibration when test frequency is

greater than 3MHz. Loosen the adjusting screws counter-clockwise to

make the Electrodes open. Insert the STD-LOAD into the Electrodes

followed by fastening the screws. Subtly adjust the Electrodes to clamp

the STD-LOAD tightly. Execute the HF LOAD CORRECTION and the HF

LOAD item will change from OFF to ON.

⑥

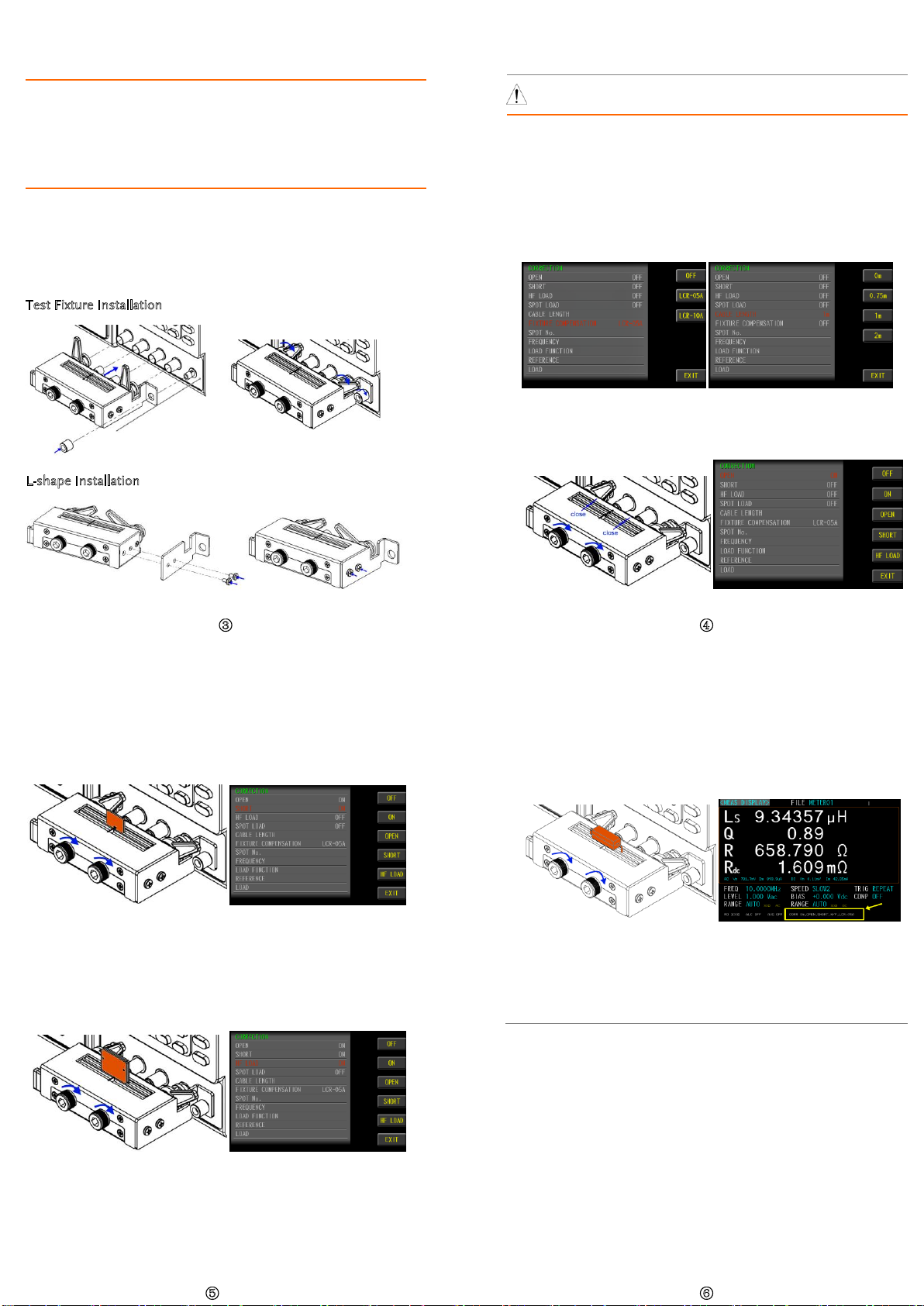

6. Loosen the adjusting screws counter-clockwise to make the Electrodes

open. Insert the DUT into the Electrodes followed by fastening the screws.

Subtly adjust the Electrodes to clamp the DUT tightly and it is now ready

for measurement. The latest calibration status will be shown in the

bottom of the LCD display (item and measuring cable length or test

fixture model).

7.

Remove the component from the test fixture.

Note: It is required to place DUT into the test fixture in exactly vertical way

without any tilt, skew or wobble. Do Not fasten the adjusting screws

overly in case of thread stripped

and over compression on DUT. Also, do

Not overly loosen the screws in case of accidental drop out of screws.