-1-

DPX300 R20151015

Digital Pressure Switch

CAUTIONS

1. This product may cause an electric shock in handling. Please do not attempt to open it with power turned on.

2. This product should be installed in a place fixed secured by a rack or panel.

3.This product can be used under the following environmental condition.

① Indoor ②Pollution Degree 2 ③At an altitude of 2000m or below

4. Power input must be within the designated ranges.

5. To turn on or turn off power supply for this product, please the circuit breaker or switch of a standard product of IEC

60947-1 or IEC 60947-3 product and install it within a close distance allowing convenient operation by user.

6. Please be understood that if this product is dismantled or modified discretionary, after sales service will not

be able to be provided.

7. An output wire to be used for this product should be inflammable grade FV1 (V-1 grade or above), the thickness

of the wire should be AWG No. 20 or above(0.50mm

2

).

8. In order to prevent it from an inductive noise, please maintain the high-voltage wire and power wire separated.

9. Please avoid installing the product in a place where a strong magnetism, noise, severe vibration and impact exist.

10. When extending the sensor wire, use a shield wire and do not extend it unnecessary long.

11. The sensor wire and signal wire should be away from the power and load wires using conduits separately installed.

12. Please avoid using the product near a device generating strong high frequency noise (high-frequency welding machine,

high-frequency sewing machine, high-frequency radiotelegraph, high capacity SCR controller)

13. Product’s damages other than those decribed in the guarantee conditions provided by the manufacturer shall not be

respoinsible by us.

14. If this unit is used to control machineries (Medical equipment, vehicle, train, airplane, combustion apparatus,

entertainment, processing and transportation equipment, elevator and various safety device etc.) enabling to effect

on human or property, it is required to install fail-safe device.

※ The Aforementioned precautions must be observed, and if you fail to do so, it may cause a product’s breakdown

.

※ The specifications, dimensions, and etc. are subject to change for enhancement without a prior notice.

DPX300

User Manual

DOTECH INC.

6F, JOONGANG-ILBO B/D, 30, Dongsan-ro, Danwon-gu,

Ansan-si, Gyeonggi-do, KOREA

TEL: +82-31-495-3767 FAX: +82-31-495-3917

www.dotech21.com

1. OVERVIEW

※ FEATURES

- High pressure protection, Low pressure protection, Oil pressure protection,

an integrated high pressure fan control

- Automatic / Manual reset, Selectionof various refrigerants

- Precise pressure control, Sensor offset, Sensor error detection

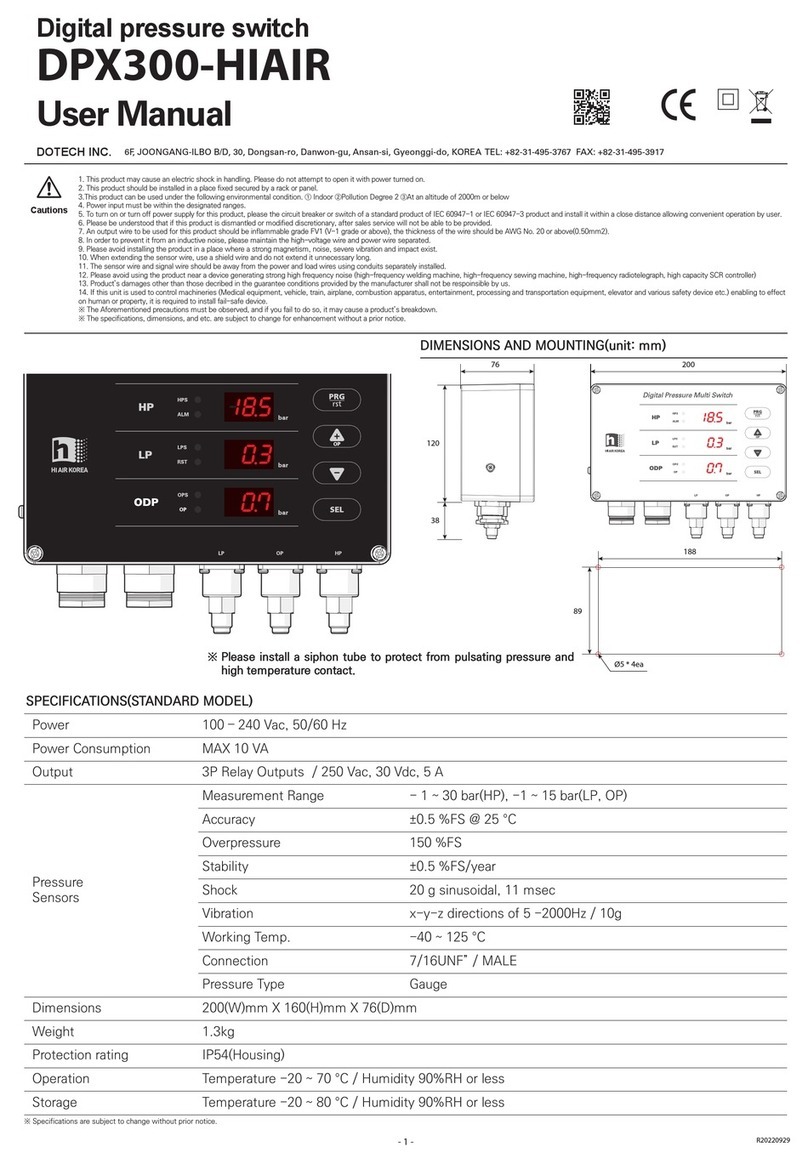

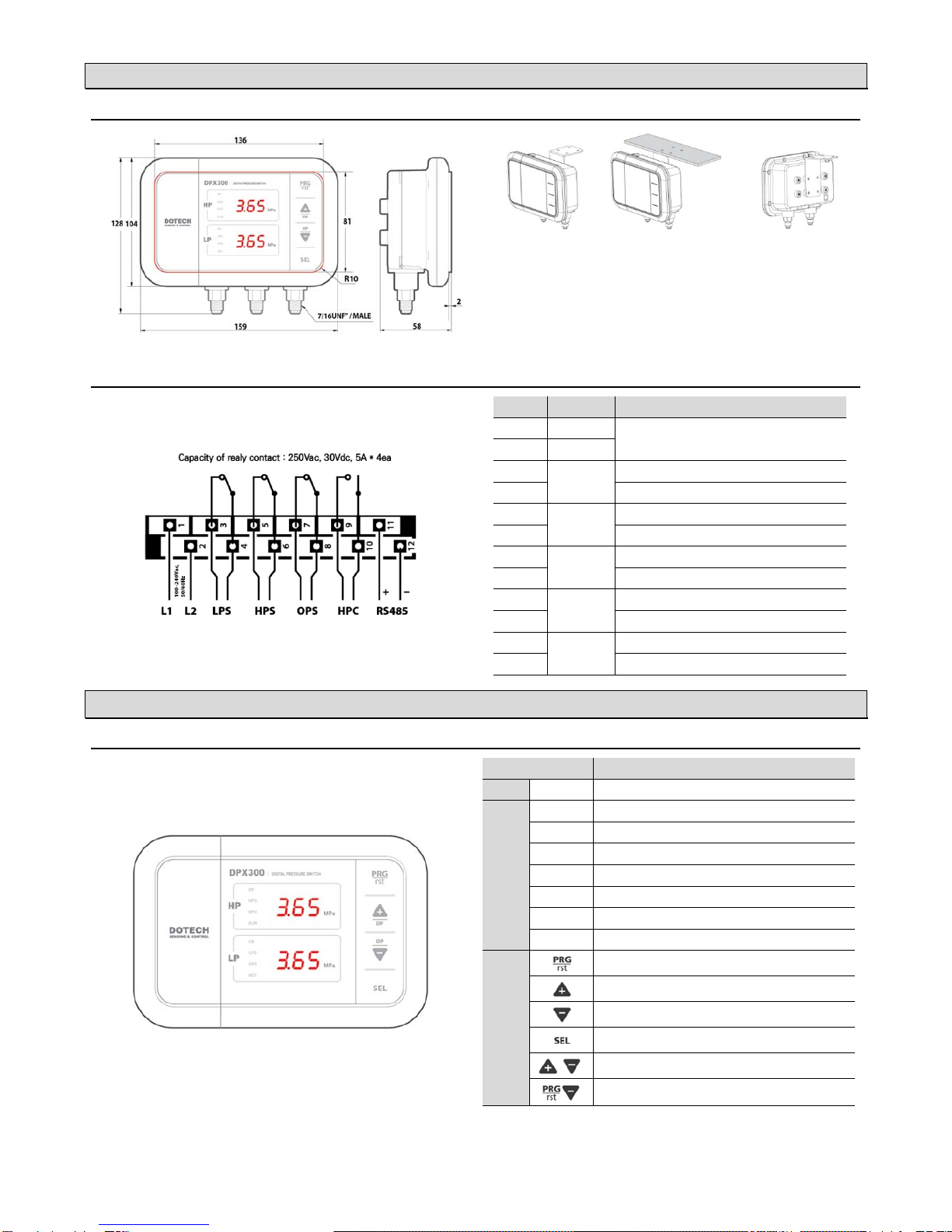

: SPECIFICATIONS(STANDARD MODEL)

Description

Power 100 – 240 Vac, 50/60 Hz

Power Consumption MAX 10 VA

Output 4P Relay Outputs / 250Vac, 30Vdc, 5 A

Pressure

Sensors

Measurement

Range -0.10 ~ 5.00 MPa

Accuracy ±1.0 %FS

Overpressure 150 %FS

Stability ±0.5 %FS/year

Shock 20 g sinusoidal, 11 msec

Vibration x-y-z directions of 5 -2000Hz / 10g

Working Temp. -40 ~ 120 °C

Connection 7/16UNF” / MALE

PressureType Gauge

Dimensions 159(W)mm X 128(H)mm X 58(D)mm

Operation Temperature -10~50 °C / Humidity 90%RH or less

Storage Temperature -20~60 °C / Humidity 90%RH or less

: SELECTION GUIDE

Model Description

DPX300-HLO-00-MPA Digital Pressure Switch Standard(PressureUnit: MPa )

DPX300-HLO-R4-MPA Digital Pressure Switch for Communication(RS485 Modbus )

DPX300-HLO-00-KGF Digital Pressure Switch Standard(Pressure Unit: kgf/cm2)

DPX300-HLO-R4-KGF Digital Pressure Switch for Communication(RS485 Modbus )

DPX300-HLO-00-BAR Digital Pressure Switch Standard(Pressure Unit: bar )

DPX300-HLO-R4-BAR Digital Pressure Switch for Communication(RS485 Modbus )

DPX300-HLO-00-PSI Digital Pressure Switch Standard(Pressure Unit: psi )

DPX300-HLO-R4-PSI Digital Pressure Switch for Communication(RS485 Modbus )

※Communication is not supported in standard models.

※Specify the pressure unit when ordering.

: Supplied Contents

Bracket 1ea User Manual

※This item is provided for securing the bracket tightening all bolts please.