Page 4 Hydro Systems Co. 2019HYD10099044 Rev 1.4

WARNING • please use this equipment carefully and observe all warnings and cautions as detailed within

this manual before installation or operation of this equipment.

• all electrical work should be carried out by a qualified Electrician, in accordance with local

and national regulations.

• isolate power & water supply to this equipment before connection / disconnection of

water connections and / or maintenance on this unit and / or dispensers supplied by this

unit.

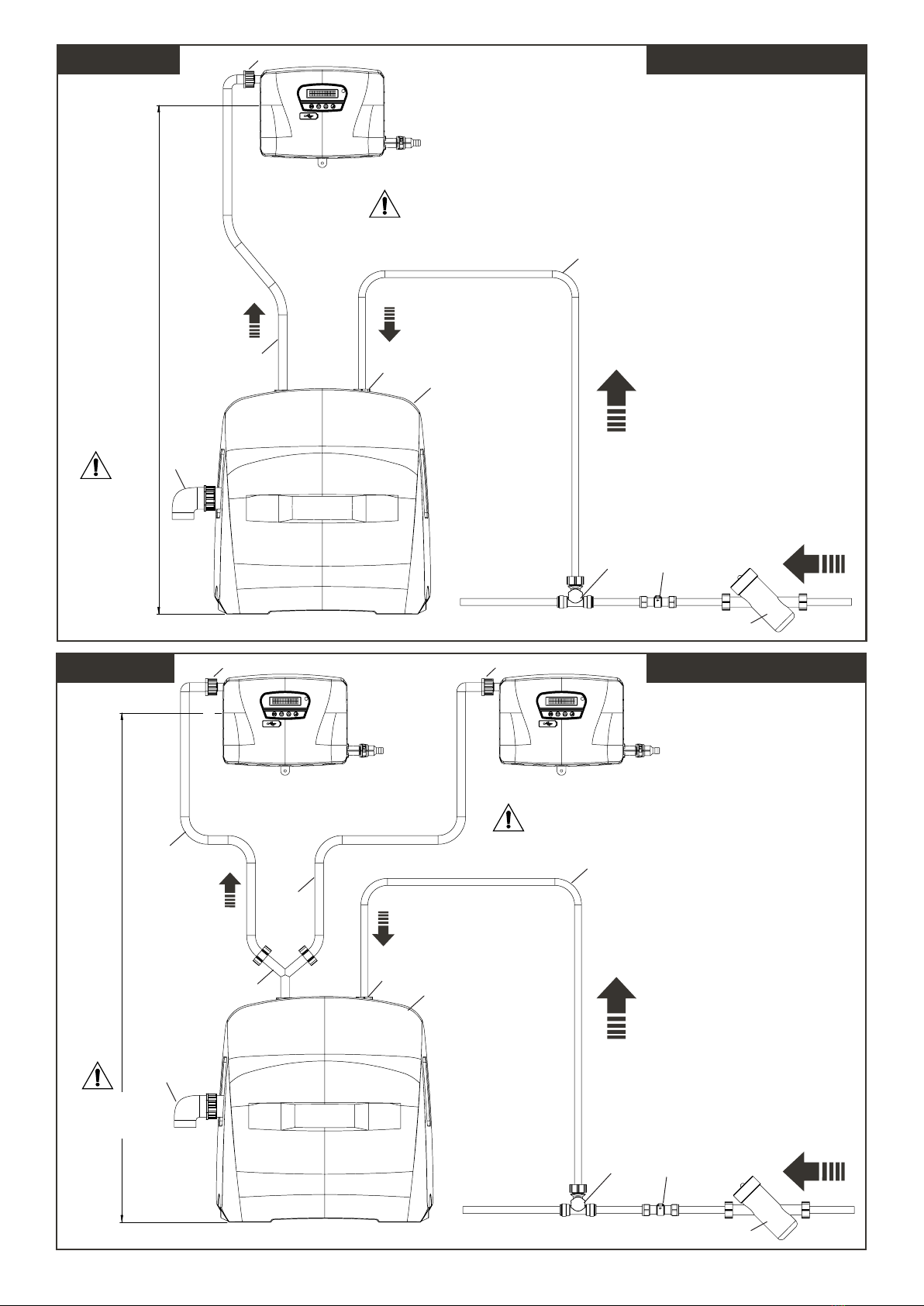

• ensure all plumbing is installed correctly before turning on power & water to the unit.

• to avoid damage to the unit, ensure dispensers connected to the EvoBoost are not used

whilst the water supply is isolated.

• the EvoBoost should be operated within the correct voltage range as listed in the Manual.

• the installer and user are responsible for ensuring the installation and operation of this unit

are in accordance with this Installation and User Manual and local and national regulations.

• the unit should only be used within the following temperature range: 5-40°C / 41-104°F.

• the unit is only to be installed and used indoors.

• means for connection of the appliance from the supply mains must be incorporated within

the fixed wiring in accordance with the wiring rules.

• if the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons to avoid a hazard.

• this unit is not to be used in an ATEX environment.

• ensure unit overflow is connected to a drain point

WEAR • the appropriate protective clothing and eye wear when installing and operating this

equipment or when handling or dispensing chemicals or other materials or when working in

the vicinity of all chemicals, filling or emptying equipment or changing metering tips.

ALWAYS • read and follow all safety instructions in safety data sheets (SDS) for all chemicals.

• observe safety and handling instructions of the chemical manufacturer.

• dilute and dispense chemicals in accordance with manufacturer’s instructions.

• direct discharge away from you or other persons and into approved containers.

• regularly inspect equipment and keep equipment clean and properly maintained.

NEVER • mix incompatible chemicals that pose hazards.

This unit is designed to be used with temperatures of 5-40°C / 41-104°F

Water pressures must be between 1 bar (14.5 psi) and 6 bar (87 psi)

1. safety

Safety Precautions

THANK YOU FOR YOUR INTEREST IN OUR PRODUCTS.

TO AVOID SERIOUS PERSONAL INJURY AND PROPERTY DAMAGE: