Instruction manual

Safety instructions

2

Markem-Imaje Ltd.

Nottingham Science Park

University Boulevard

Nottingham NG72QN United Kingdom

ensures that the new equipment

referenced below:

Markem-Imaje Ltd.

Nottingham Science Park

University Boulevard

Nottingham NG72QN United Kingdom

certifie que l’équipement neuf,

désigné ci-dessous:

Serial No:

is in accordance with the European directives

applicable to equipments that is to say:

• with the machinery directive 2006/42/EC

and the relevant European standards.

BS EN 60204-1:2006 +A1:2009

BS EN ISO 13849-1:2008

BS EN ISO 12100:2010

• with the electromagnetic compatibility

directive 2004/108/EC and the relevant

European standards.

EN61000-6-2:2005, EN 61000-6-4

• with the low voltage directive 2006/95/EC

and the relevant European standards.

BS EN 60950-1:2006+A12:2011

• The above referenced equipment bears the

CE marking.

Nottingham, 14th September 2011

Alan Beech

Engineering Manager

Directeur de technologie

Markem-Imaje Ltd. Nottingham Science Park, University

Boulevard, Nottingham, NG72QN, United Kingdom.

tel +44 (0) 115 9430055 fax +44 (0) 115 9430153

EC DECLARATION OF CONFORMITY

DECLARATION DE CONFORMITE CE

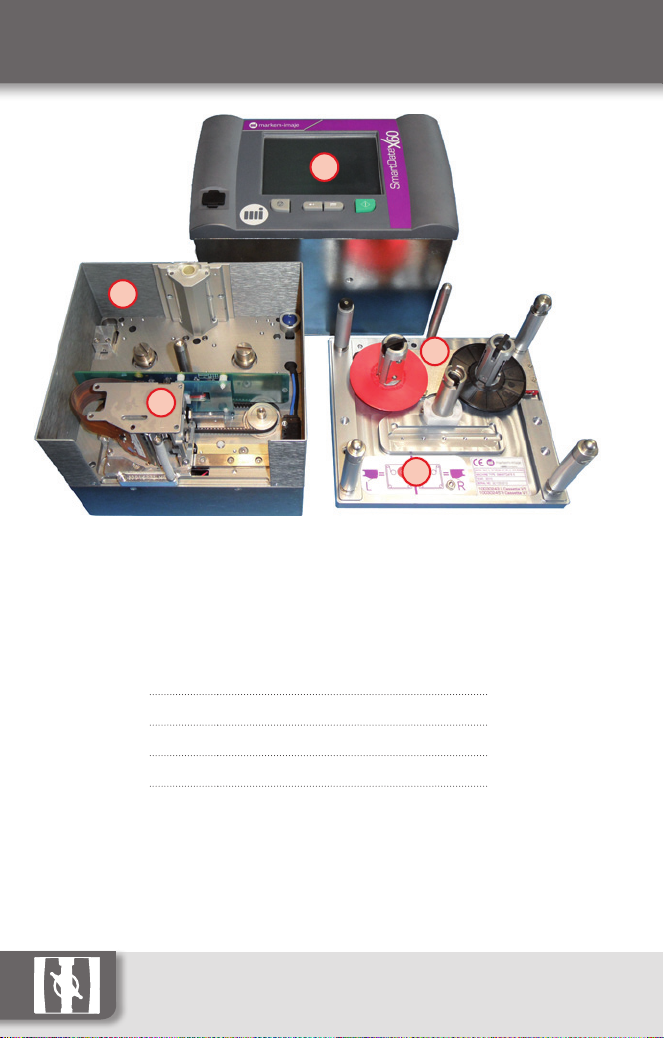

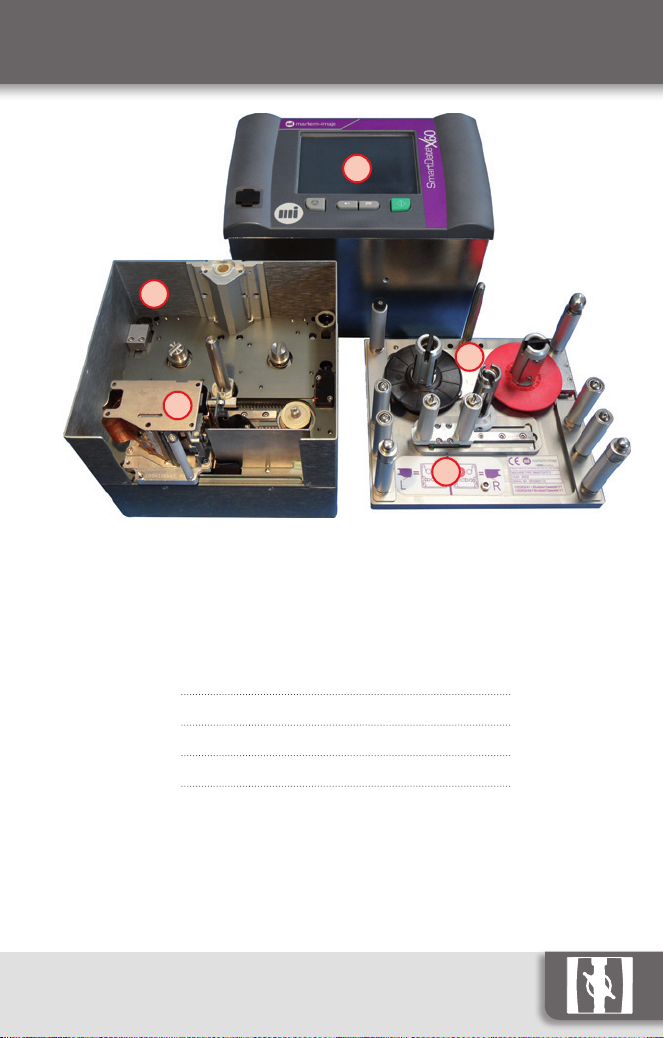

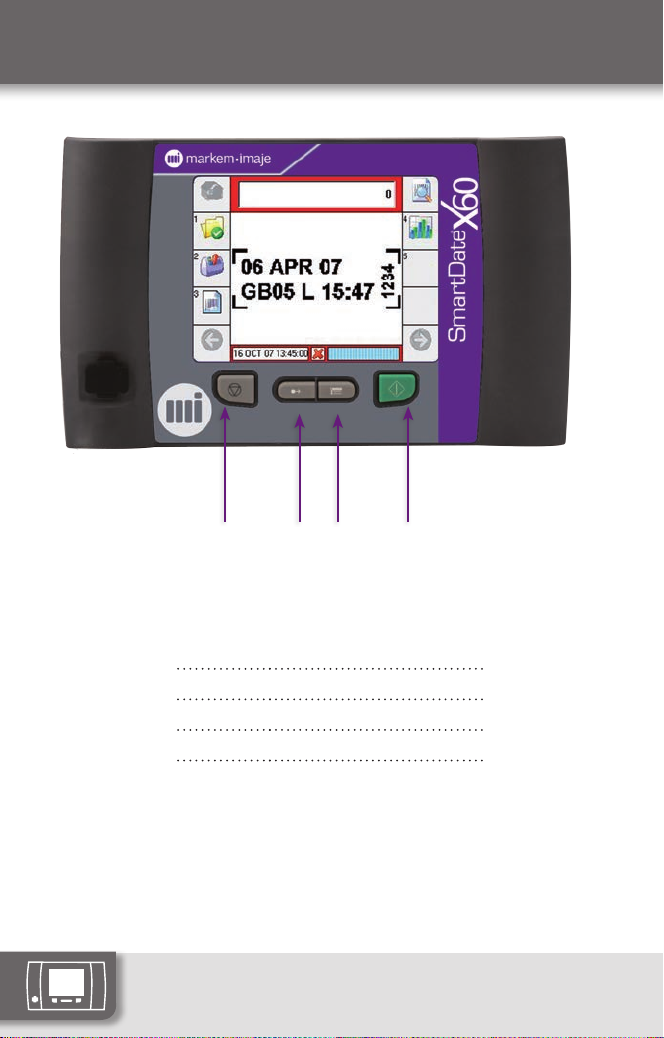

SmartDate X60

Thermal Transfer Printer

10059020-AB

est conforme aux directives européennes

applicables aux équipements, soit:

• à la directive sur les machines 2006/42/CE

et aux normes européennes correspondantes,

BS EN 60204-1:2006 +A1:2009

BS EN ISO 13849-1:2008

BS EN ISO 12100:2010

• à la directive sur la compatibilité

électromagnétique 2004/108/CE

et aux normes européennes correspondantes.

EN 61000-6-2:2005, EN 61000-6-4

• à la directive sur la basse tension

2006/95/CE et aux normes européennes

correspondantes.

BS EN 60950-1:2006+A12:2011

• L’équipement référencé ci-dessous peut

porter le marquage CE.

Nottingham, le 14 Septembre 2011

for parts & service call QLC (800) 837-1309