RTU Modbus interface : MPNC006 Mect srl

1

ME7084_05 07/21

INDEX

INDEX...........................................................................................................................1

1Introduction ...........................................................................................................3

1.1 Staff qualification .............................................................................................3

1.2 Symbols.............................................................................................................3

1.3 Nomenclature....................................................................................................3

1.4 Security.............................................................................................................4

2Hardware Installation............................................................................................4

2.1 System description............................................................................................4

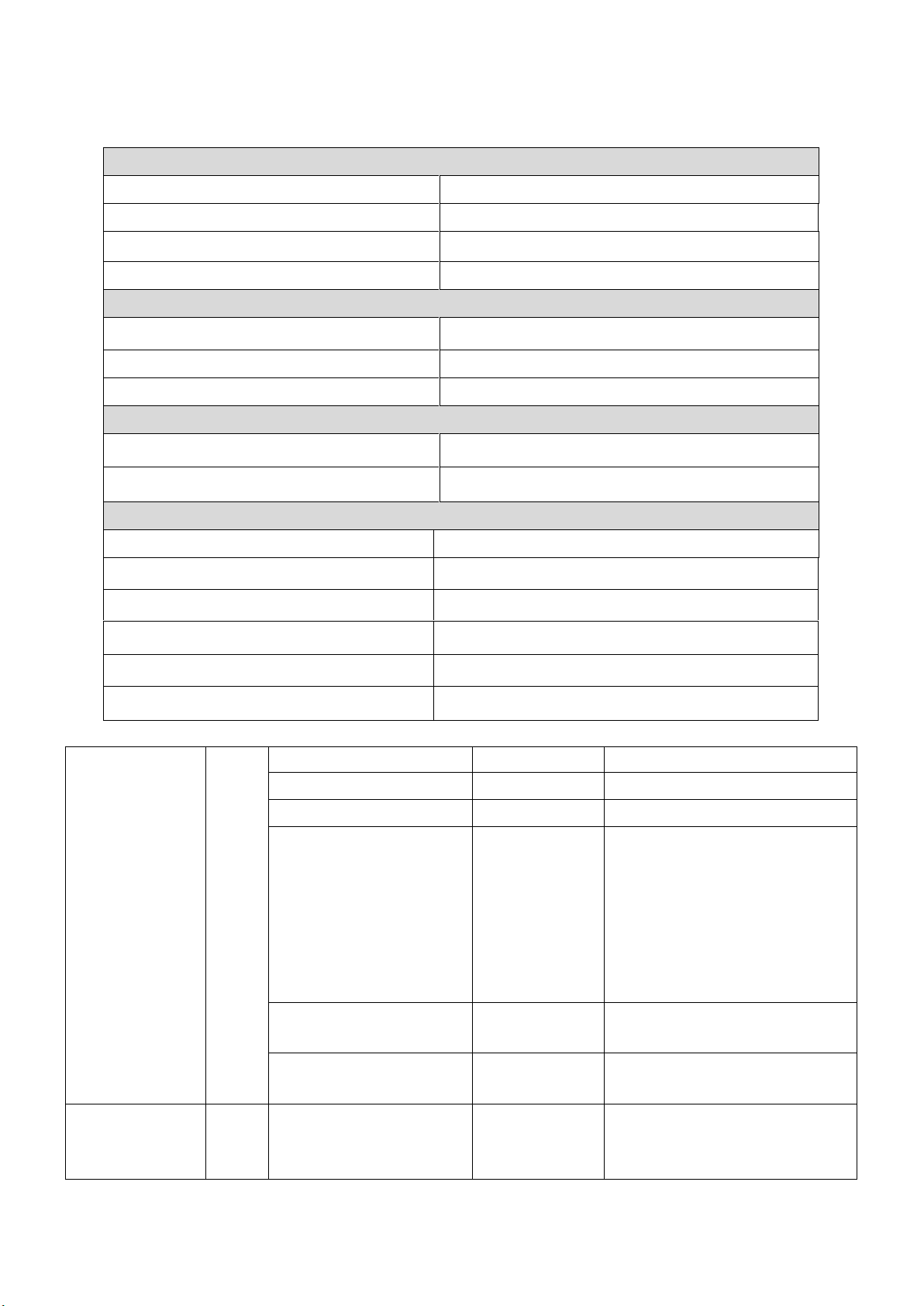

2.2 Features.............................................................................................................5

2.3 Installation ........................................................................................................7

2.3.1 Distances .................................................................................................7

2.3.2 Insertion and removal of components.....................................................7

2.3.3 Assembly sequence .................................................................................7

2.3.4 Proprieties of DIN rail and TBUS..........................................................8

3MPNC006 Wiring .................................................................................................9

3.1 Power supply.....................................................................................................9

3.1.1 Isolation...................................................................................................9

3.1.2 System power supply ..............................................................................9

3.1.3 Digital outputs power supply................................................................10

3.1.4 Fuses......................................................................................................10

3.1.5 Grounding..............................................................................................10

3.1.6 Cable screen ..........................................................................................10

3.2 The daisy chain...............................................................................................11

3.3 I/O Connection................................................................................................11

3.3.1 Analog input connection .......................................................................12

3.3.2 Digital inputs Connection.....................................................................12

3.3.3 Digital outputs connection ....................................................................13

3.4 Max Configuration..........................................................................................13

3.5 Modbus parameters configuration..................................................................14

3.5.1 Address (ID module).............................................................................14

3.5.2 Baud Rate settings.................................................................................15

3.5.3 Parity and stop bit configuration..........................................................16

3.5.4 Reset Configuration...............................................................................18