NT 1101-J00 08.10 A65 - AS65 e

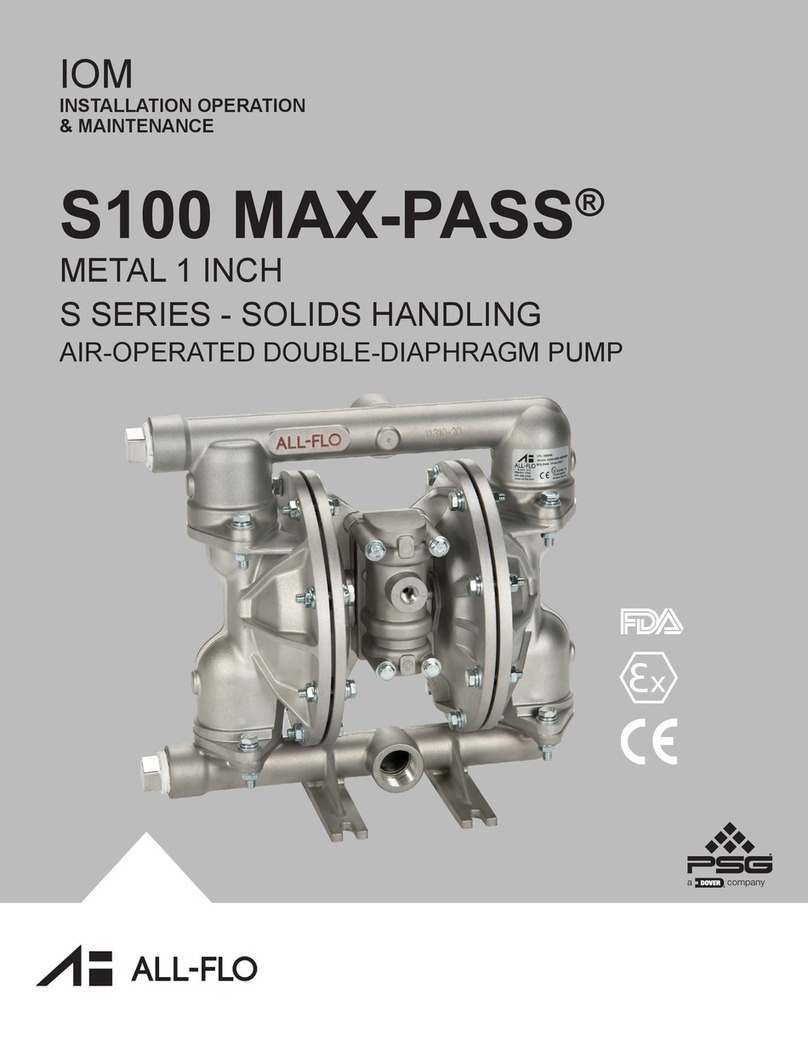

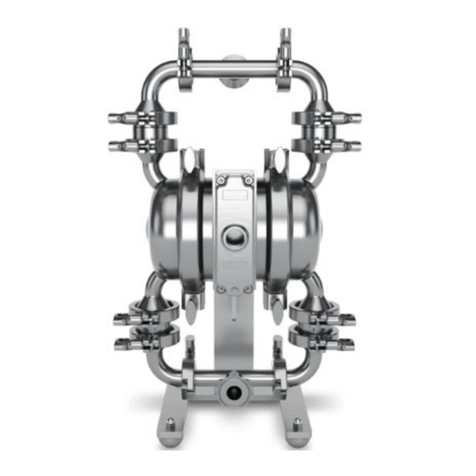

MOUVEX PERISTALTIC HOSE PUMP

SAFETY INSTRUCTIONS, STORAGE, INSTALLATION AND MAINTENANCE

MODELS : A65 -

AS65

TECHNICAL CHARACTERISTICS

• Maximum pump speed acceptable* :

• 60 tr/mn

(

rpm)

• Maximum running temperature * :

• NR hose . . . . . . . .70°C (158°F)

• NBR hose . . . . . .70°C (158°F)

• EPDM hose . . . . .80°C (176°F)

• Maximum discharge pressure acceptable*:

• 15 barg (217,5 psig)

• Minimum suction pressure acceptable :

• -0,9 barg (-13 psig)

• Cylinder capacity :

• 3,708 dm3 (0,980 gallon)

* CAUTION : Functional limitations indicated are strictly dependent on each

other, refer to TECHNICAL DATA § to define the limits of use for your

installation.

Pump n°:

Date of bringing into service :

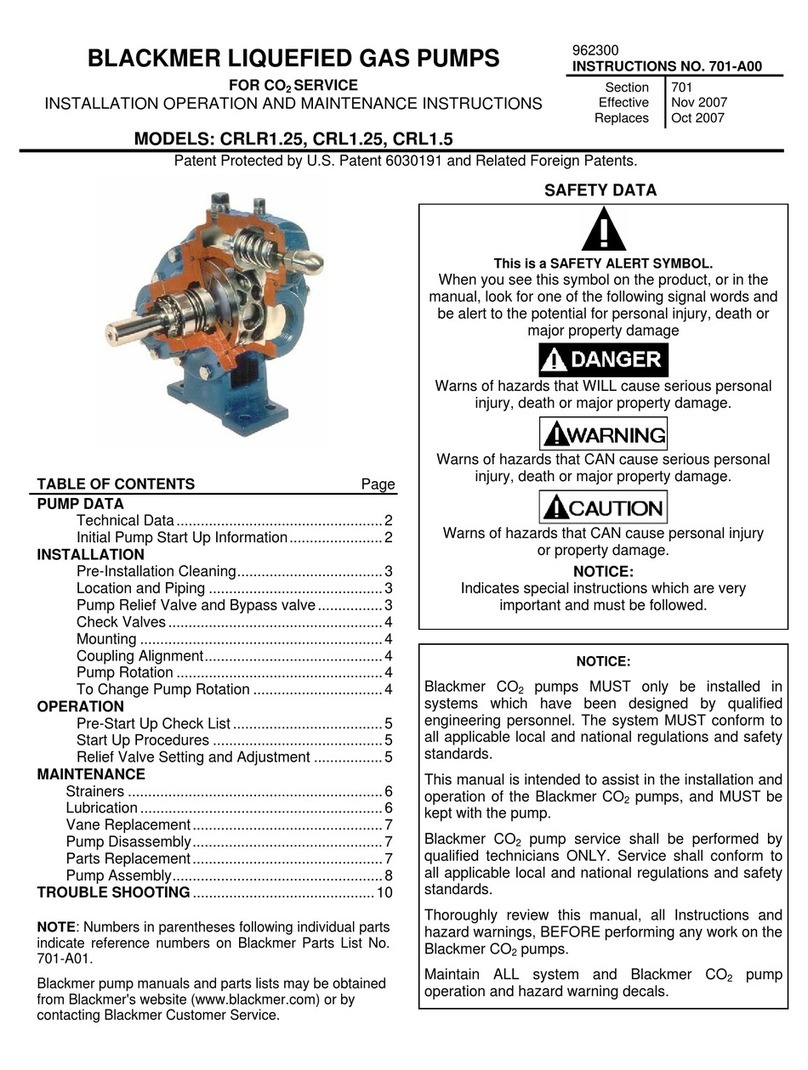

SAFETY INFORMA

TIONS

Thisisa

SAFETY

ALERT

SYMBOL

When you see this symbol on the product, or in the manual, look

for one of the following signal words and be alert to the potential

for

personalinjury,deathormajorpropertydamage.

DANGER

Warns of hazards that WILL cause serious personal injury,

death or major property damage

W

ARNING

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

CAUTION

Warns of hazards that CAN cause personal injury or property

damage.

TABLE OF CONTENTS Page

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 A65 model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.3

1.2 AS65 model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.4

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Operator principle . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.5

2.2 Hose compression . . . . . . . . . . . . . . . . . . . . . . . . . . .

.5

2.3 Pumped liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.5

2.4 Pipe diameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.5

2.5 Piping assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.5

2.6 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . .

.6

2.7 Liquids containing a high proportion of particles . . . .

.6

2.8 Working with vaccum on the suction side . . . . . . . . .

.6

2.9 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.6

2.10 Pump location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.6

2.11 Anchoring the pump units . . . . . . . . . . . . . . . . . . . . .

.7

2.12 Alignment of motor / pump and reduction gearbox /

pump shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.13 Electric motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.7

3. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Pump storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.8

3.2 Hose storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.8

3.3 Pumping hot products . . . . . . . . . . . . . . . . . . . . . . . . .

.8

3.4 Pump filled with product at shutdown . . . . . . . . . . . . .

.8

3.5 Starting-up the pump . . . . . . . . . . . . . . . . . . . . . . . . .

.8

3.6 Shutting down the pump . . . . . . . . . . . . . . . . . . . . . . .

.8

3.7 In the event of the hose breaking . . . . . . . . . . . . . . . .

.8

3.8 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.8

4. MAINTENANCE OPERATIONS . . . . . . . . . . . . . . . . . . . . .9

4.1 Replacing the hose . . . . . . . . . . . . . . . . . . . . . . . . . . .

.9

4.2 Re-assembling and disassembling the wheel . . . . . .12

4.3 Replacing the shoes . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4 Setting of pump at service pressure needed . . . . . . .13

5. TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . .15

5.1 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.2 Shimming the shoes . . . . . . . . . . . . . . . . . . . . . . . . . .16

6. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.1 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2 Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.3 Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . . .19

NOTES :

The MOUVEX peristaltic hose pumps MUST be installed on

systems specially designed by qualified staff. Installation

MUST comply with local standards, national rules and safety

regulations.

NOTICE

Indicates special instructions which are very important and

must be followed.

NOTES

The

numbers

writteninbold

charactersafter

part

namescorrespond

to reference numbers in the spare parts lists..

Photos and drawingsused in this IOM are not contractual.

This manual is designed for installation and start-up of the

peristaltic hose pumps. It MUST be supplied with the pump.

Maintenance of the peristaltic pumps must be carried out ONLY

by qualified personnel. This operation must comply with local

and national regulations as well as safety standards.

Read the whole manual and all the instructions and precau-

tions, BEFORE using any MOUVEX pumps.

Do not remove any warning and use stickers from the pumps.