9

The pump sends coded impulses to report failures.

Special modules can decode these impulses and can

specify the failures through failure lights or optical

contacts.

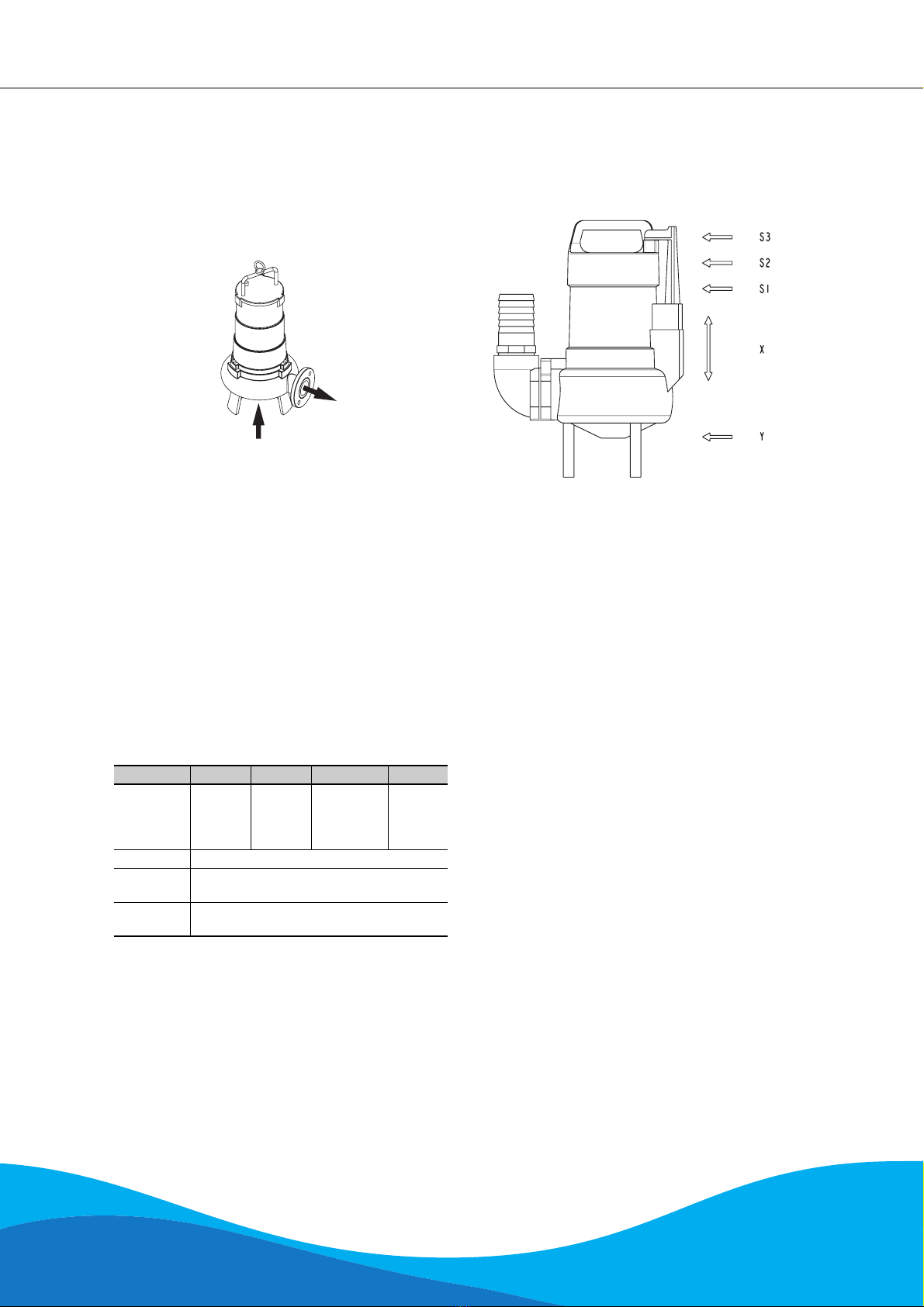

3.5.2 Two pump operation

The different operational phases of the pump are

combined through an algorithm in two pump

operation which enables the pumps to recognise

each other. The ratio of pumping times between

levels S3, S2, S1 and the lowest off switching level

are saved individually for each of the two pumps. The

pumping time that is calculated is assigned to the

following 7 pump cycles. Volume detection is

performed independently after every eighth pump

cycle.

The pumps can be operational simultaneously or in

sequence because the choice for starting one of the

pumps is random at level S2 or S3. When the water

level drops to below level S1 in relation to a pump that

is not operational, this pump will conclude that a

partner pump is available. The information about

there being a partner pump will be saved in the

memory of both pumps. The pump that has just been

operational, will save level S3 as the on switching

level. The pump that was not operational and which

detected the water level has dropped up to below

level S1, will now save level S2 as the on switching

level.

The two pumps will switch on in turns to on switching

level S2 when the water level drops to below level S1

of the pump that was currently not operational. When

the pumps have detected that there is a partner

pump, they will be switched on in turns when level S2

has been reached.

When sewage continues to flow into the pump sump,

the time is saved that is required to reach level S2

and level S1. The pumping time will be corrected

based on this. The same correction method can be

used for volume detection to compensate in changes

in the required pumping time when a partner pump is

available.

When one pump cannot supply sufficient pumping

capacity to drain away the incoming wastewater, the

second pump will be switched on when level S3 is

reached. You can determine when the pumps should

be switched off depending on the speed at which the

pump sump fills up and the time that is required for it

to be pumped and emptied. This can be determined

by both calculation and detection of the lowest off

switching level.

When one or both pumps have not been in operation

for a period of 24 hours, the pump or pumps will start

until the lowest off switching level has been detected.

The test run will be automatically activated after every

24 hour period when the water level has not

demanded a pump start.

3.5.3 Points of special interest

It is very important that the vent hole of the pump

housing is opened because the pump continues

running until the pump suctions air every eighth cycle.

ATTENTION

When installing a pump with an

automatic level regulation, the pump

must be at least 20 cm from the wall.

ATTENTION

The pump must be installed in such a

way that the inflow of the drain can

never reach the sensors for the level

regulation.

When a pump with automatic level regulation detects

that the water level is still above level S3 after 16

seconds, the pump will stop for a period of 3 seconds

will give a coded report for high water. A pump with

automatic level regulation must, therefore, only be

used in a drain.