PAS:MAC 1000 - 4 - OCTOBER 2010

4.0 OPERATING INSTRUCTIONS

4.1 SAFETY PRECAUTIONS

In addition to normal safety rules which should be observed with

stationary air compressors and equipment, the following safety

directions and precautions are of special importance.

When operating this unit, the operator must employ safe working

practices and observe all related local work safety requirements

and ordinances.

The owner is responsible for maintaining the unit in a safe

operating condition. Parts and accessories shall be replaced if

unsuitable for safe operation.

Installation, operation, maintenance and repair shall only be

performed by authorised, trained, competent personnel.

Never remove or tamper with the safety devices, guards or

insulations fitted on the unit.

4.2 SITING

Position the compressor on firm, level ground.

Site in a well-ventilated area well away from any source of

hazardous gas, dust or vapour so that any contamination created

by the work to be undertaken does not drift towards the

compressor.

WARNING: The breathing-air filtration will not remove carbon

monoxide or carbon dioxide, therefore position the compressor

well away from any potential vehicle exhaust contamination.

4.3 PRE-OPERATION CHECKS

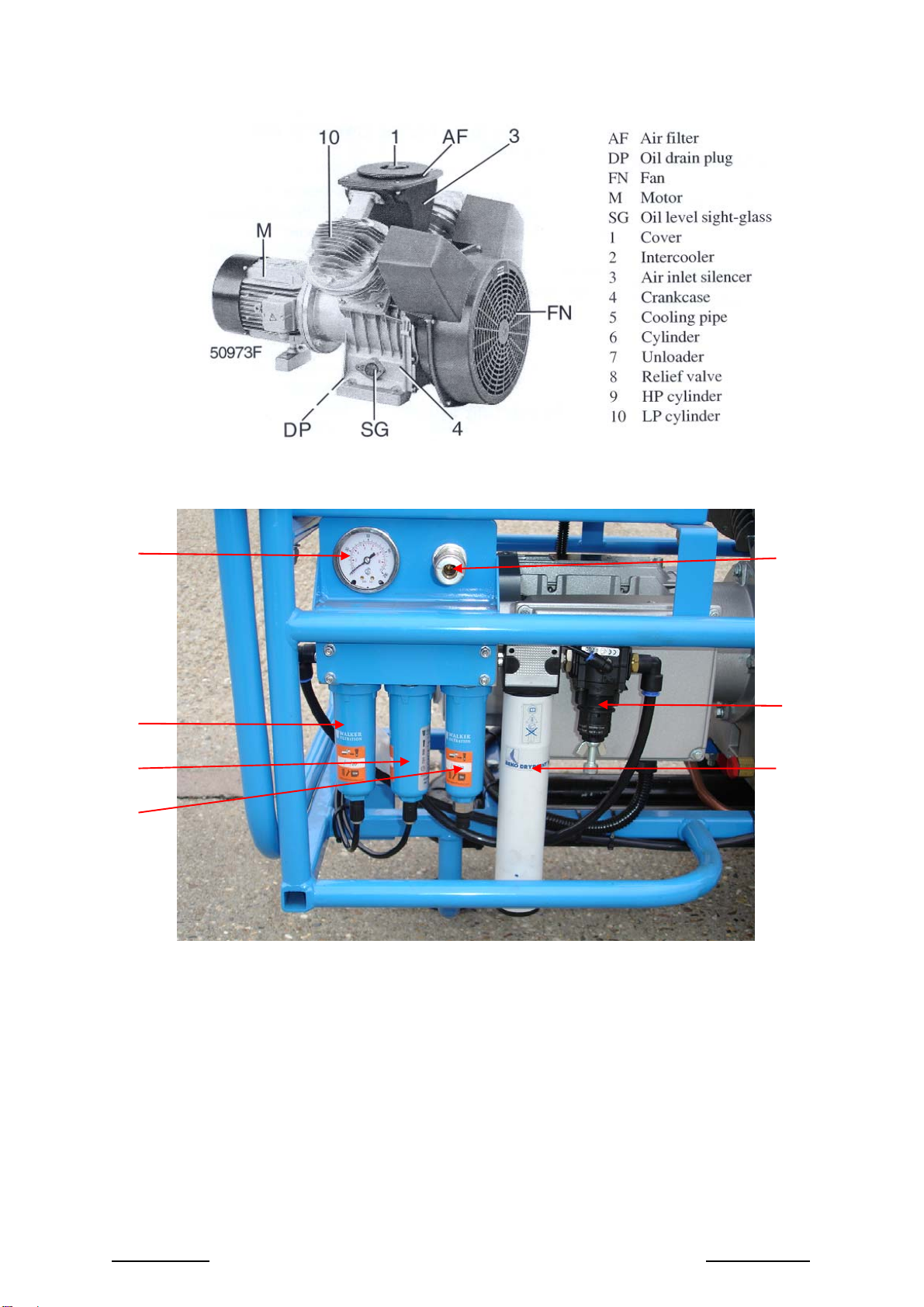

Check the compressor’s oil level which must be near the top of the

red circle of the sight glass. The minimum level is the lower part of

the red circle.

Top up, if necessary, by slowly unscrewing the filler cap. If there is

any escape of oil/air DO NOT CONTINUE REMOVING THE CAP

UNTIL ALL PRESSURE IS RELEASED. (The filler cap is located

between the cylinders on top of the compressor casing.)