PAS:MAC4000 - 1 - MAY 2010

1.0 INTRODUCTION

Draegerprovides a rangeofbreathing-airsystems which are completely

self-contained, fully mobile and specially designed to deliver breathing

quality compressed air to operatives wearing air-fed respiratory

equipment when working in hazardous atmospheres such as occur in

the nuclear, petrochemical, pharmaceutical and other industries. The

systems provide breathable air conforming EN 12021.

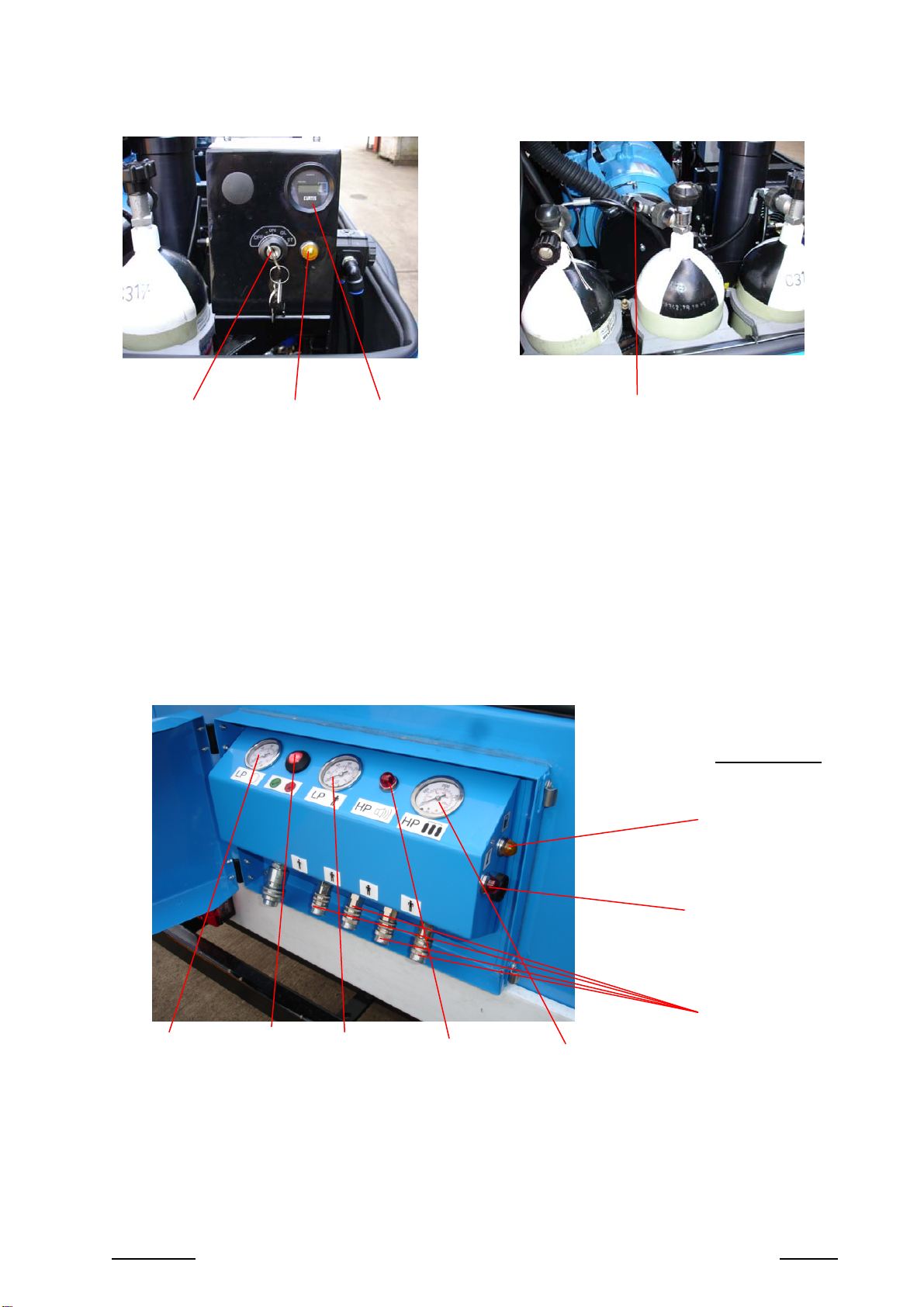

The MAC4000 is a fast towing unit with a three-cylinder, water-cooled

diesel engine, driving a rotary vane compressor mounted on a

subframe. A fully automatic back-up system is incorporated which

maintains the air supply from reserves stored in three 9-litre cylinders.

When the air reserve in the cylinders falls below a permissible level,

audible and visible alarms sound/flash at which time all breathing-air

apparatus wearers should immediately evacuate to a safe area.

The unit has a centrally-mounted lifting eye and is enclosed within a

steel canopy which allows the correct air flow and access to all

necessary parts for both running and service. The unit is also sound

attenuated to ensure that the noise level is within the European

regulations of <97LWA.

Ahinged high-level airintakeisprovided which,intheoperationalmode,

is pivoted to the vertical. Off site the intake tube is lowered to the

horizontal position. The unit should be operated on reasonably level

groundand sited topreventthere-entrainment of exhaustgasesintothe

inlet. It should also be kept well away from other polluted or toxic

atmospheres.

Simple precautions and attention to the operation and maintenance

instructionsensurethat the unitprovideshigh-qualityairandtrouble-free

operation over a long period.

IMPORTANT

A qualified attendant should be in charge of the equipment during operation and

ensure that it is operated only, and strictly, in accordance with these instructions.

The attendant should check that all hoses are laid out without kinks or tangles, are

safe from interference or damage, and orifices of all couplings are clear of dirt.

If the unit switches over to cylinder supply, the attendant should immediately

instruct the operatives to leave the hazardous area.