Supplement Zeus Infinity Empowered 3

English

Reprocessing

Safety information

Appropriate reprocessing

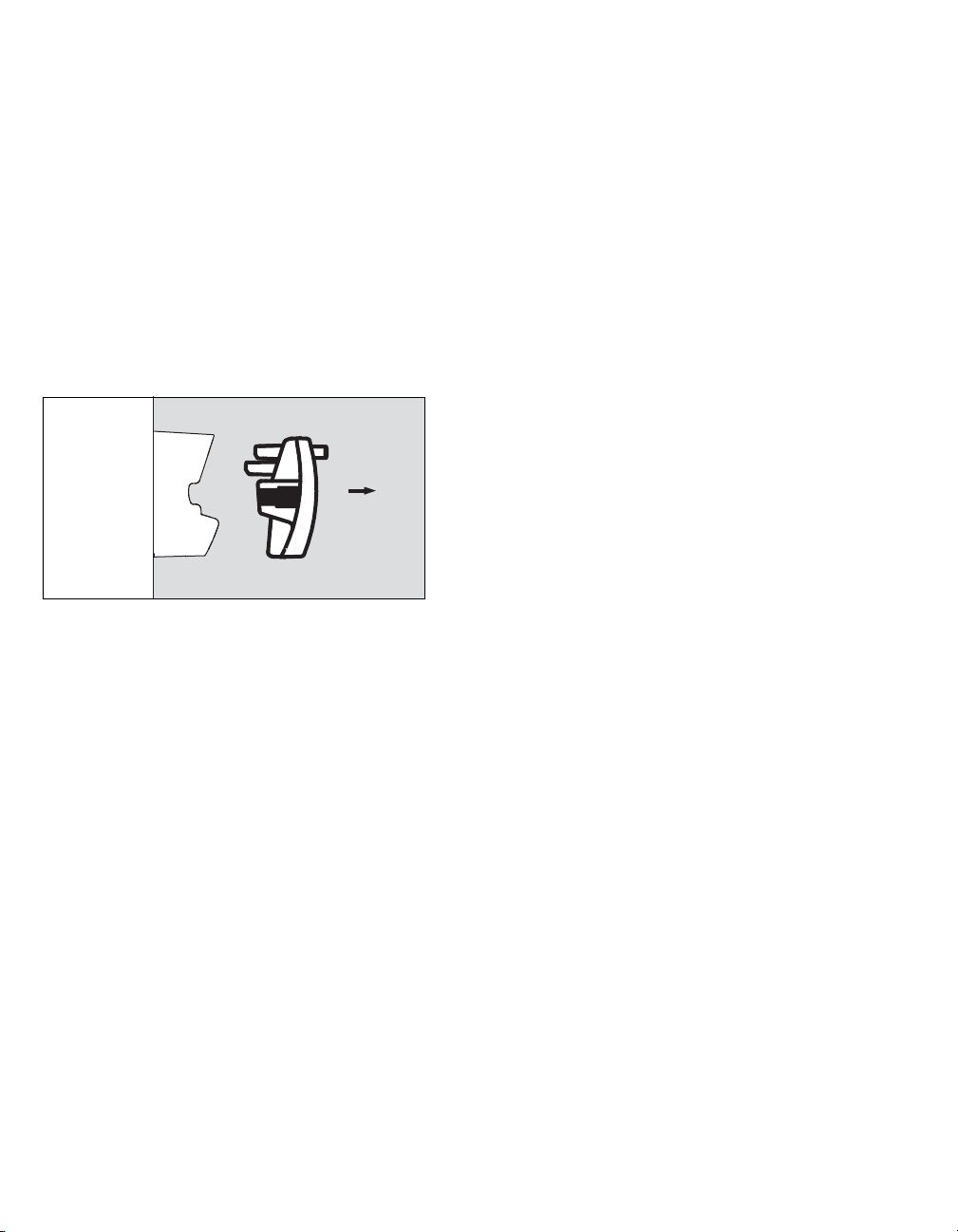

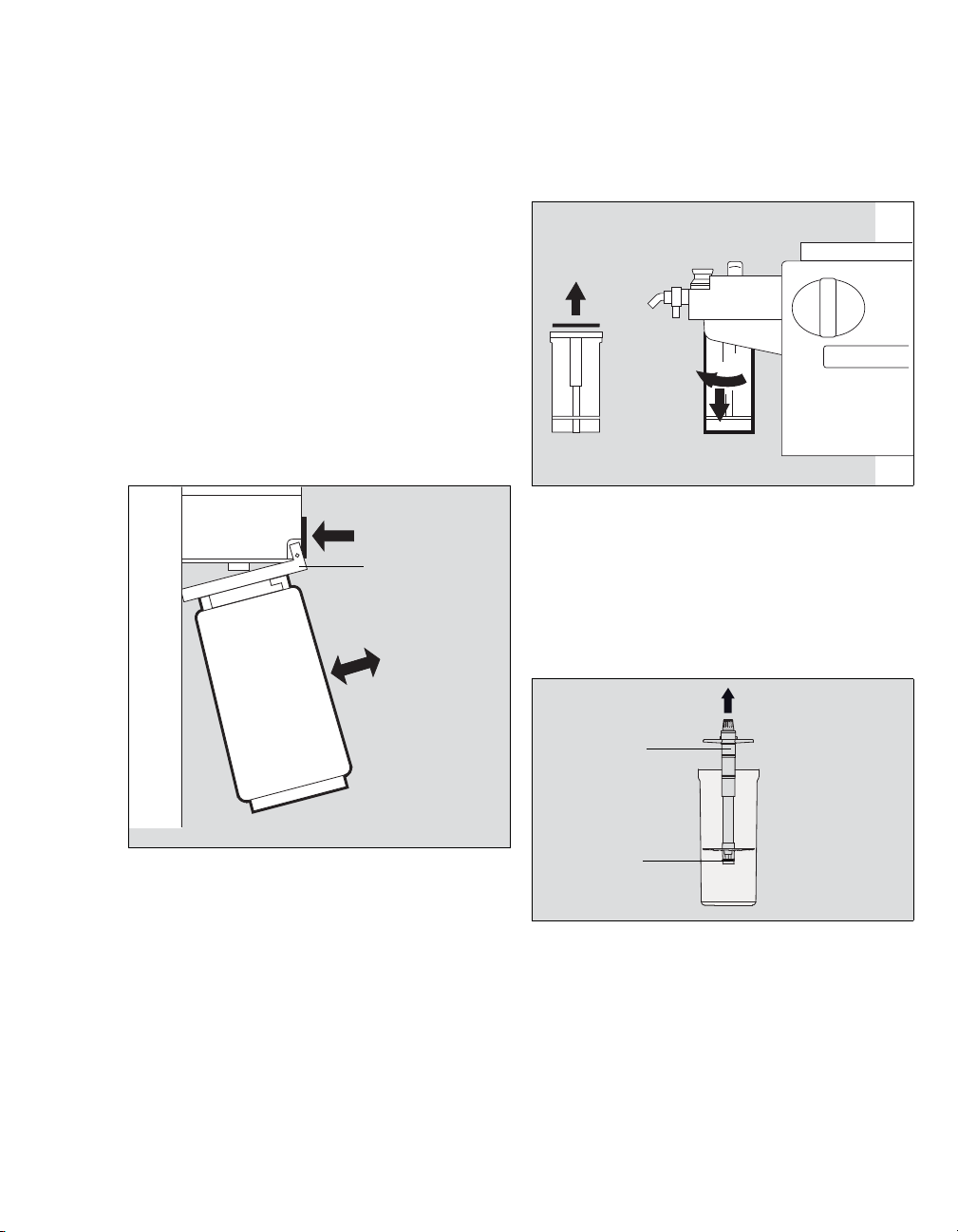

SpiroLife flow sensor

WARNING

Risk due to inappropriately reprocessed prod-

ucts

Reusable products must be reprocessed, oth-

erwise there is an increased risk of infection.

– Follow the infection prevention policies

and reprocessing regulations of the

health-care facility.

– Follow the national infection prevention

policies and reprocessing regulations.

– Use validated procedures for reprocess-

ing.

– Reprocess reusable products after every

use.

– Follow the manufacturer's instructions for

cleaning agents, disinfectants, and repro-

cessing devices.

WARNING

Risk due to faulty products

Signs of wear, e.g., cracks, deformation, dis-

coloration, or peeling, may occur with repro-

cessed products.

Check the products for signs of wear. Replace

them if necessary.

CAUTION

Risk of failure of flow measurement

Improper reprocessing and soiling, such as de-

posits or particles, may damage the flow sensor:

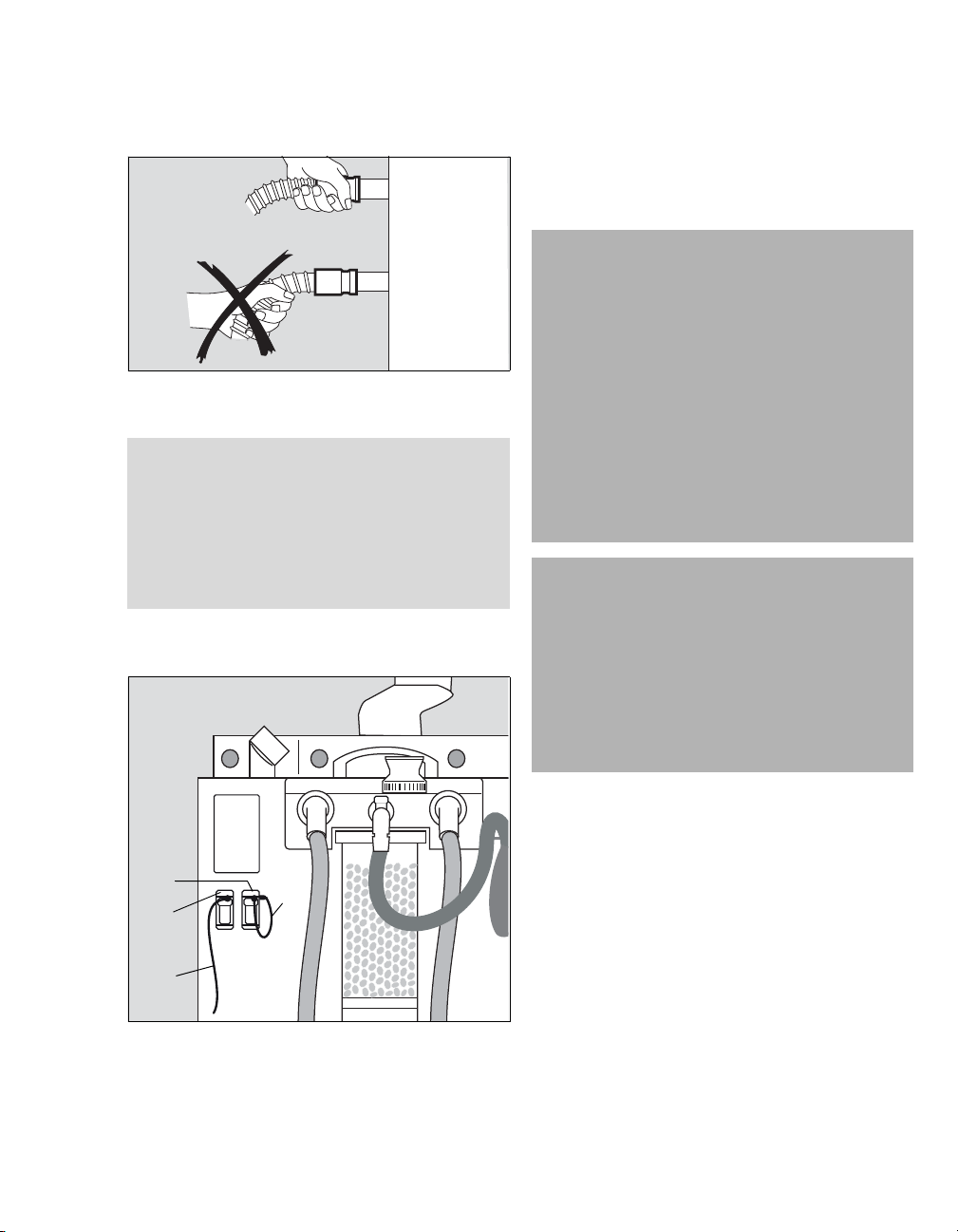

– No machine cleaning or disinfection of the

sensor insert

– No plasma sterilization or radiation steriliza-

tion

– No water jets, compressed air, brushes, or

similar to be used on the sensor insert

– No ultrasonic bath

– Clean and disinfect the flow sensor in accor-

dance with the corresponding instructions for

use.

– For disinfecting the flow sensor use only clean

disinfectant solutions.

WARNING

Risk of fire

Residual vapors of highly flammable disinfec-

tants (e.g., alcohols) and deposits that were

not removed during reprocessing may ignite

when the flow sensor is in use.

– Ensure particle-free cleaning and disinfec-

tion.

– After disinfection, allow the flow sensor to

air for at least 30 minutes.

– Before inserting the flow sensor check for

visible damage and soiling, such as resid-

ual mucus, medication aerosols, and parti-

cles.

– Replace flow sensors when damaged,

soiled, or not particlefree.