5

Intended use

Intended Use

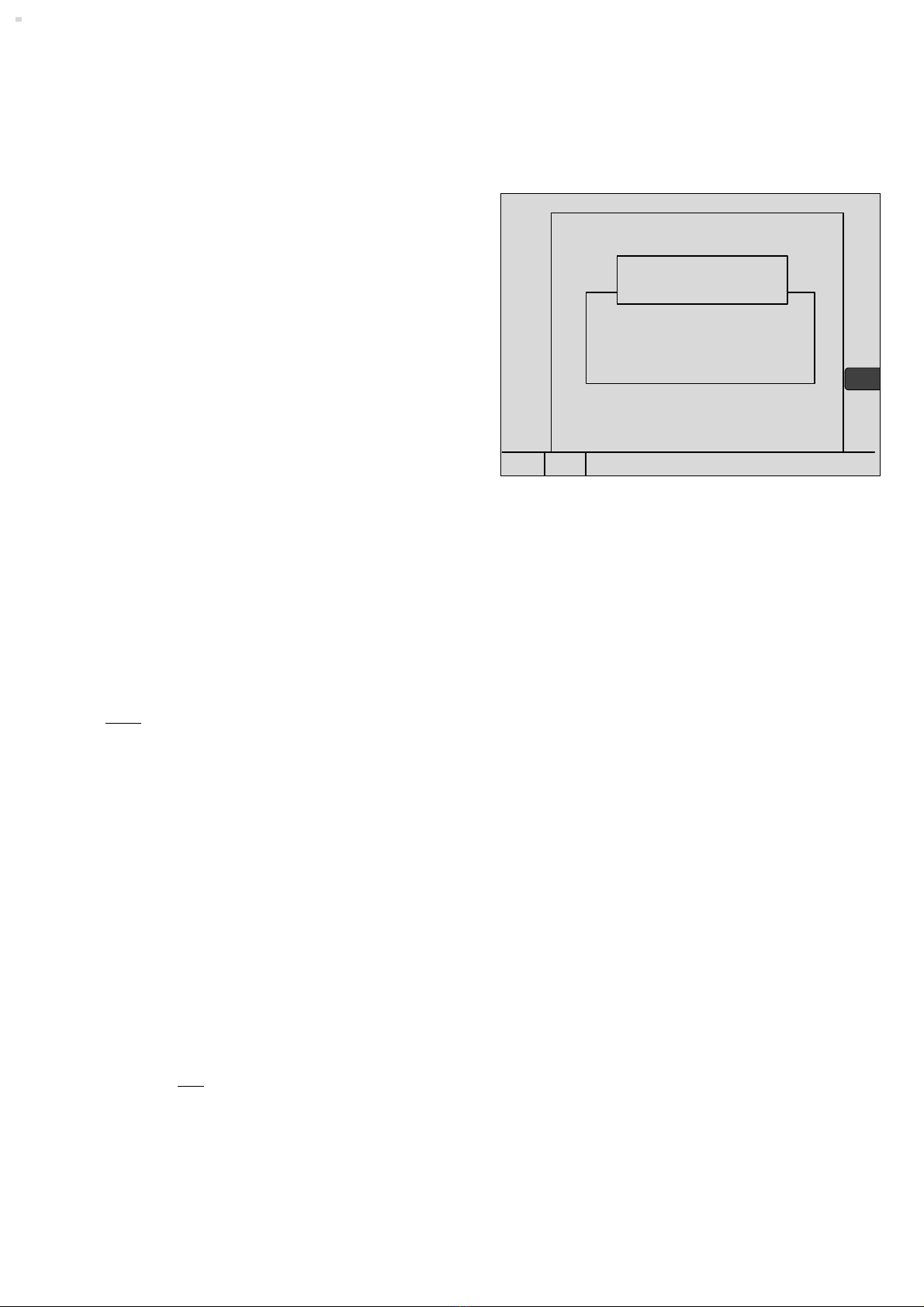

Integrated anaesthetic workstation

»Cicero EM« with system monitor

Universally applicable, integrated anaesthetic workstation

for

– Inhalation anaesthesia for adults, children and

neonates.

– Inhalation anaesthesia in semi-closed to virtually

closed systems with »low flow« and »minimal flow«

techniques (for minimum gas and anaesthetic

consumption).

– Automatic ventilation (IPPV).

– Synchronized intermittent mandatory ventilation

(SIMV).

– Pressure-controlled breathing (PCV) in the PCV

ventilator.

– Manual ventilation (MAN).

– Spontaneous breathing (SPONT).

– Automatic anaesthetic agent recognition.

The following information is displayed in colour on the

system monitor:

– Airway pressure and temperature

– Inspiratory O2concentration

– Expiratory tidal volume

– Patient compliance

–CO2and anaesthetic concentration at the Y-piece

– Fresh gas balance

together with the main haemodynamic parameters

monitored with the parameter box:

– ECG curve with heart rate and ST segment analysis.

– The real-time curve of the invasive blood pressure

(iBP) in two channels, with the systolic, diastolic and

mean pressure values.

– The values of the non-invasive blood pressure (NiBP)

with the systolic, diastolic and mean pressure values.

– The body temperature in two channels.

– The functional O2saturation (SpO2) with the pulse

rate.

– The plethysmogram.

Other accessories (optional)

Vapor*)

Anaesthetic vaporizer for enflurane, isoflurane, halothane

and sevoflurane.

Connection for two Vapor vaporisers*)

Devapor*)

Anaesthetic vaporizer for desflurane.

Anaesthetic gas scavenging system*)

Uninterruptible power supply*)

Passive air conditioning*)

Heated breathing hoses.

pEEG*)

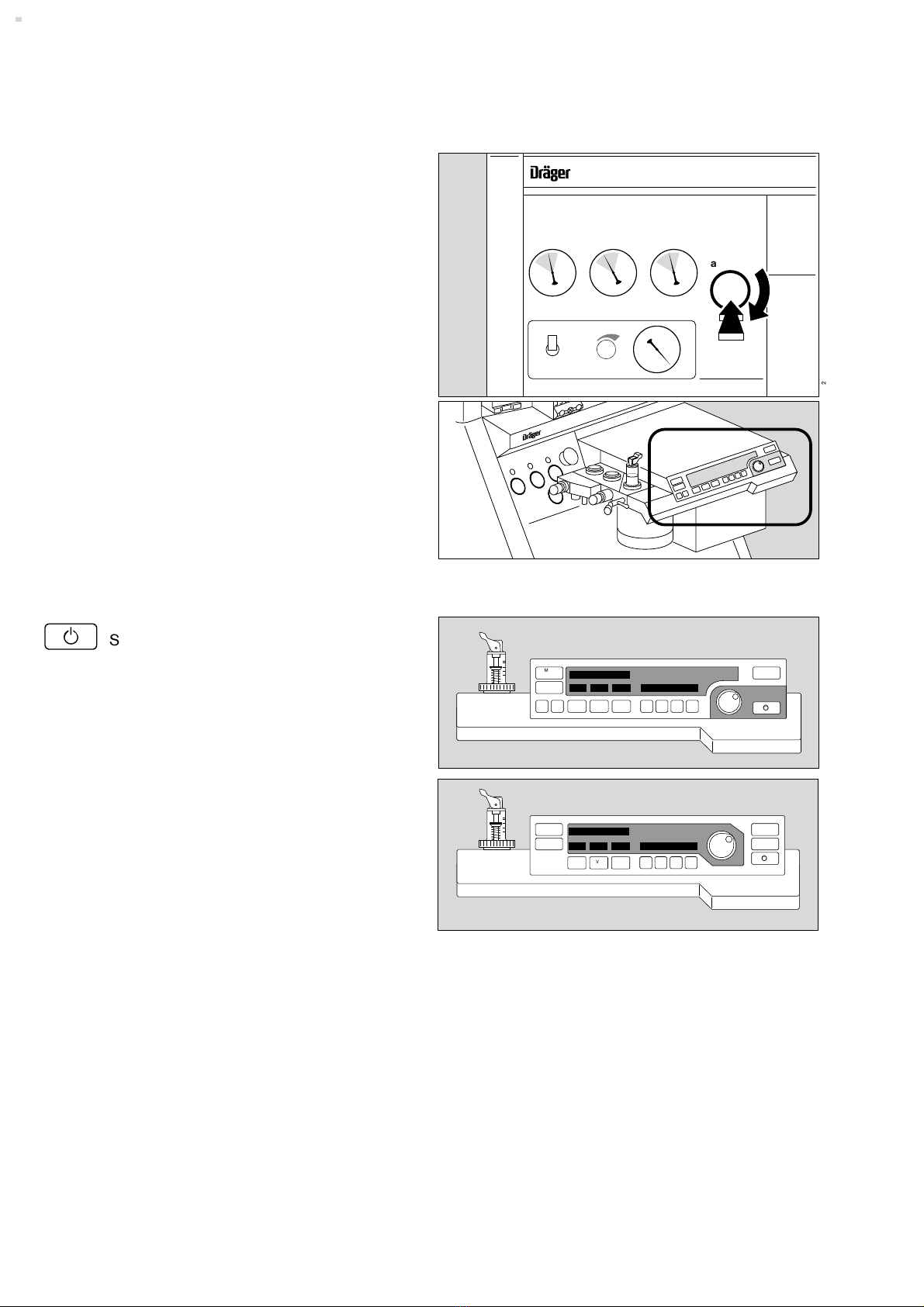

Notes on operation

Only non-flammable anaesthetic agents conforming to

EN 740 may be used. Risk of fire!

Since this apparatus is not approved for use with

inflammable anaesthetics (ether, cyclopropane, etc.),

it is not necessary to use antistatic (conductive) breathing

hoses or face masks.

Conductive breathing hoses and face masks may cause

burns during high-frequency surgery and are therefore

not recommended for this apparatus.

Any additional electrical equipment which is latched

onto the top of the workstation must also be con-

nected to the base unit by means of an equipotential

bonding conductor!

Electromagnetic fields exceeding the limits specified

in EN 60601-1-2 may interfere with the operation of

the device and therefore put patients at risk.

Mobile radio telephones must not be used within

10 metres of the workstation!

Cicero EM must not be used with magnetic resonance

tomography (MRT, NMR, NMI).

The workstation should only be moved by the handles!

Always operate the device under the supervision of

qualified medical personnel in order to obtain prompt

assistance in the event of malfunction.

Retrofitting in different devices

The software described in these Instructions for Use, in

combination with the »Cicero EM«, has passed a conformity

evaluation procedure conforming to 93/42/EEC (medical

appliances); the corresponding conversion kits therefore

bear the

C

mark of conformity.

The conversion kit can also be installed in the »Cicero EM

color« even if the unit itself does not bear the

C

symbol,

because the conformity evaluation procedure has confirmed

the suitability of the product for this type of device.

*) Refer to the separate Instructions for Use for this equipment.