10 DR® LEAF and LAWN VACUUM

Assembly Parts Identification

Compare the contents of the Parts Boxes and Hardware Packages with the Parts Supplied lists and Figures 3 thru 8 below. If there

are any questions contact us at www.DRpower.com or call 1-800-DR-OWNER (376-9637).

There may be hardware left over when assembly is finished. This is sometimes expected in the process of filling hardware bags at

the factory.

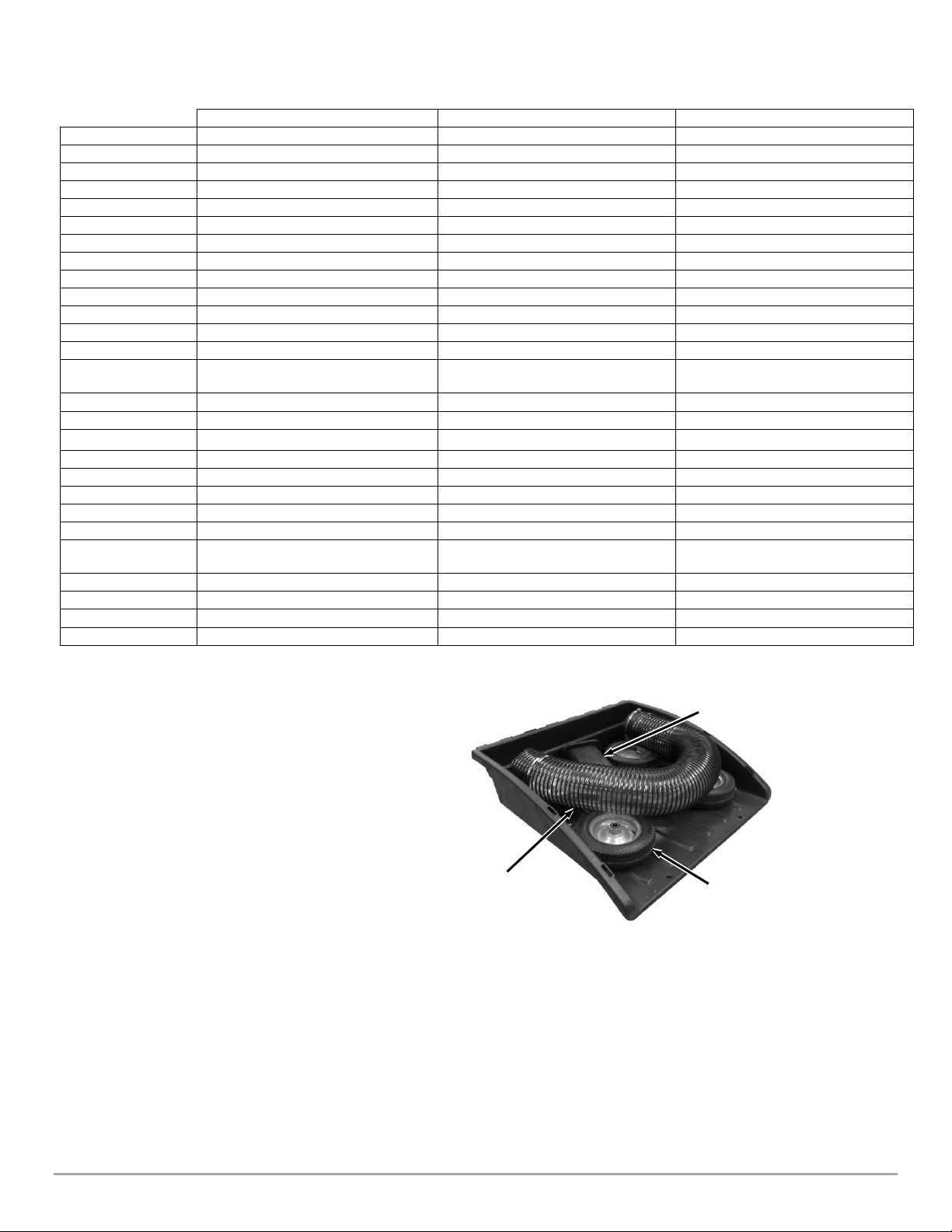

Product Package Hardware (Figure 3):

Item # Part # Description Qty

1 .............A0000253563....... Pin, Clevis, 1/2" X 4.5", ZP ....................... 1

2 .............211541 ................. Pin, Clevis, 1/2" X 3.5", ZP ....................... 2

3 .............350371 ................. Bolt, Hex, 7/16-20, Impeller Tool ............. 1

4 .............350291 ................. Knob Set, 5/16-18 W/Lock, 17 Pack ......... 1

5 .............350271 ................. Bolt, C-Head, 5/16-18 X 1.75″, ZP ............ 2

6 .............112411 ................. Washer-Flat 5/16 USS............................... 2

7 .............110761 ................. Nut-Lock Nylon 5/16-18 ........................... 2

8 .............337871 ................. Pin, Cotter, Hair, 1/4-3/8.......................... 4

9 .............160031 ................. Pin, Hitch Clip 1/2"................................... 3

10 ...........189671 ................. Washer, Flat, 1/2", Rubber ....................... 1

11 ...........350331 ................. Bolt, C-Head, 5/16-18 X 1.75”, ZP............ 2

12 ...........106681 ................. Nut, Flange 5/16-18.................................. 2

*11, 12 only included in PRO/ PRO XL models*

Large Parts Box Contents (Figure 4):

Item # Description Qty

1 .............Tube Frame Assembly, LH……………………………….................. 1

2 .............Tube Frame Assembly, RH……………………………….................. 1

3 .............Small Parts Box……………………………………………….................. 1

4 .............Enclosure, Fabric ………………………………. ............................... 1

5 .............Rod, Support, Hose…………………………………………................. 1

6 .............Hinge, Split, Frame Collector, RH……………………… ............... 1

7 .............Hinge, Split, Frame Collector, LH……………...………................ 1

8* ...........Bracket, Foot Assist……………………………...…………................. 1

9 .............Gas Spring, 500-300 mm, 150 lb………………………... .............. 2

10 ...........Batten, FRP…………………….…………...……. ............................... 1

11 ...........Pin, Hinge……………….……….……….……… ................................ 1

12 ...........Handle, Tube Frame ………………….………................................ 1

13 ...........Hinge Tube Assembly…………….…………. ................................ 1

14 ...........Outer Link Assembly, Bottom Rear ……... .............................. 1

15 ...........Inner Link Assembly, Top Rear ……………………………………... . 1

16 ...........Retainer, Enclosure LH…………………………………….................. 1

17 ...........Retainer, Enclosure RH……………………………………... .............. 1

*8, only included in PRO/PRO XL models*