Draper 32301 User manual

CONTACTS

– DRAPER TOOLS LIMITED,

Hursley Road, Chandler's Ford,

Eastleigh, Hampshire. SO53 1YF. U.K.

– Helpline: (023) 8049 4344

– Sales Desk: (023) 8049 4333

– Internet: www.drapertools.com

– Sales Fax: (023) 8049 4209

–General Enquiries: (023) 8026 6355

– Service/Warranty Repair Agent

For aftersales servicing or warranty repairs, please

contact the Draper Tools Helpline for details of an

agent in your local area.

YOUR DRAPER STOCKIST

KCCH0217

©Published by Draper Tools Limited.

No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, electronic, mechanical photocopying,

recording or otherwise without prior permission in writing from Draper Tools Ltd.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY TO ENSURE THE

SAFE AND EFFECTIVE USE OF THIS PRODUCT.

INSTRUCTIONS

These instructions accompanying the product are the original instructions. This document is part of the product,

keep it for the life of the product passing it on to any subsequent holder of the product. Read all these

instructions before assembling, operating or maintaining this product.

This manual has been compiled by Draper Tools describing the purpose for which the product has been

designed, and contains all the necessary information to ensure its correct and safe use. By following all the

general safety instructions contained in this manual, it will ensure both product and operator safety, together

with longer life of the product itself.

AlI photographs and drawings in this manual are supplied by Draper Tools to help illustrate the operation of the

product.

Whilst every effort has been made to ensure the accuracy of information contained in this manual, the Draper

Tools policy of continuous improvement determines the right to make modifications without prior warning.

PETROL

BLOWER/

VAC

32301

1. TITLE PAGE

1.1 INTRODUCTION:

USER MANUAL FOR: Petrol Blower Vac

Stock No: 32301

Part No: BVP26

As our user manuals are continually updated, users should make sure that they use

the very latest version.

Downloads are available from: http://www.drapertools.com/manuals

Draper Tools Limited

Hursley Road

Chandler’s Ford

Eastleigh

Hampshire

SO53 1YF

UK

Website: drapertools.com

Product Helpline: +44 (0) 23 8049 4344

General Fax: +44 (0) 23 8026 0784

1.3 UNDERSTANDING THIS MANUALS SAFETY CONTENT:

WARNING! – Information that draws attention to the risk of injury or death.

CAUTION! – Information that draws attention to the risk of damage to the product or

surroundings.

1.4 COPYRIGHT © NOTICE:

Copyright © Draper Tools Limited.

Permission is granted to reproduce this publication for personal and educational use

only. Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any

other form or means without written permission from Draper Tools Limited.

In all cases this copyright notice must remain intact.

1.2 REVISIONS:

Date first published May 2017.

- 23 -

NOTES

2. CONTENTS

1. TITLE PAGE

1.1 INTRODUCTION.......................................................................................................... 2

1.2 REVISION HISTORY .................................................................................................. 2

1.3 UNDERSTANDING THIS MANUAL ............................................................................. 2

1.4 COPYRIGHT NOTICE ................................................................................................. 2

2. CONTENTS

2.1 CONTENTS .................................................................................................................... 3

3. GUARANTEE

3.1 GUARANTEE ...............................................................................................................4

4. INTRODUCTION

4.1 SCOPE......................................................................................................................... 5

4.2 SPECIFICATION .......................................................................................................... 5

4.3 HANDLING AND STORAGE ........................................................................................ 5

5. HEALTH AND SAFETY INFORMATION

5.1 SPECIFIC SAFETY INSTRUCTION FOR PETROL BLOWER/VAC’S ........................ 6

–¬Service..................................................................................................................... 6

5.2 HEALTH AND SAFETY INFORMATION CONCERNING THE USE OF FUELS ........6

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION ......................................................................................................... 8

7. UNPACKING AND CHECKING

7.1 PACKAGING ............................................................................................................... 9

7.2 WHAT’S IN THE BOX.................................................................................................. 9

8. ASSEMBLING THE PETROL BLOWER/VAC

8.1 ASSEMBLING THE BLOWER TUBES ..................................................................... 10

8.2 ASSEMBLING THE VACUUM TUBES....................................................................... 11

8.3 ATTACHING THE COLLECTION BAG ..................................................................... 12

8.4 ATTACHING THE CARRYING STRAP ..................................................................... 12

9. OPERATING INSTRUCTIONS

9.1 FUELLING..................................................................................................................13

9.2 COLD STARTING THE ENGINE................................................................................ 14

9.3 WARM STARTING THE ENGINE .............................................................................. 15

9.4 STOPPING THE ENGINE .......................................................................................... 16

9.5 ADJUSTING THE ENGINE IDLE SPEED..................................................................16

9.6 USING THE BLOWER/VAC ....................................................................................... 17

–¬Blower Operation ................................................................................................. 17

–¬Vacuum Operation................................................................................................ 17

10. MAINTENANCE AND TROUBLESHOOTING

10.1 CLEANING THE AIR FILTER ..................................................................................... 18

10.2 SPARK PLUG MAINTENANCE ................................................................................. 18

10.3 CLEANING THE FUEL FILTER.................................................................................. 19

10.4 TROUBLESHOOTING GUIDE................................................................................... 19

10.5 CLEANING AND MAINTENANCE OVERVIEW.........................................................20

10.6 STORING THE MACHINE FOR AN EXTENDED PERIOD OF TIME ........................ 20

11. EXPLANATION OF SYMBOLS

11.1 EXPLANATION OF SYMBOLS ................................................................................... 21

12. DISPOSAL

12.1 DISPOSAL ................................................................................................................. 22

DECLARATION OF CONFORMITY .............................................................................. ENCLOSED

12.1 DISPOSAL

– At the end of the machine’s working life, or when it can no longer be repaired, ensure that it is

disposed of according to national regulations.

– Contact your local authority for details of collection schemes in your area.

In all circumstances:

•Do not dispose of power tools with domestic waste.

•Do not incinerate.

•Do not abandon in the environment.

•When decommissioning (preparing the machine to be scrapped) drain any remaining fuel

and oil for separate disposal.

- 22 -

12. DISPOSAL

- 3 -

3. GUARANTEE

3.1 GUARANTEE

Draper tools have been carefully tested and inspected before shipment and are guaranteed to be

free from defective materials and workmanship.

Should the tool develop a fault, please return the complete tool to your nearest distributor or

contact:

Draper Tools Limited, Chandler's Ford, Eastleigh, Hampshire, SO53 1YF. England.

Telephone Sales Desk: (023) 8049 4333 or:

Product Helpline (023) 8049 4344.

A proof of purchase must be provided with the tool.

If upon inspection it is found that the fault occurring is due to defective materials or workmanship,

repairs will be carried out free of charge. This guarantee period covering parts/labour is 12 months

from the date of purchase except where tools are hired out when the guarantee period is 90 days

from the date of purchase. The guarantee is extended to 12 months for parts only. This guarantee

does not apply to normal wear and tear, nor does it cover any damage caused by misuse, careless

or unsafe handling, alterations, accidents, or repairs attempted or made by any personnel other

than the authorised Draper warranty repair agent.

Note: If the tool is found not to be within the terms of warranty, repairs and carriage charges will be

quoted and made accordingly.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its

terms are not authorised.

Your Draper guarantee is not effective unless you can produce upon request a dated receipt or

invoice to verify your proof of purchase within the guarantee period.

Please note that this guarantee is an additional benefit and does not affect your statutory rights.

Draper Tools Limited.

- 21 -

11. EXPLANATION OF SYMBOLS

103

Warning!

Keep bystanders away.

Warning!

Risk of danger to wildlife.

Warning!

Hot surface.

Warning!

Wear suitable gloves.

Warning!

Read the instruction manual.

Warning!

Keep out of the reach of children.

Single value noise marking.

(Maximum declared

A-Weighted sound power level

in decibels).

11.1 EXPLANATION OF SYMBOLS

Danger!

Risk of flying debris.

Warning!

Wear suitable foot protection.

Warning!

Wear suitable eye/face mask

protection.

Warning!

Wear suitable ear protection.

Fuel/2-stroke oil mixture ratio.

Strictly no naked flames or

smoking near the appliance.

Choke closed.

Choke open.

Danger from rotating impeller.

- 4 -

4. INTRODUCTION

4.1 SCOPE

This product is designed for blowing fallen leaves and other loose green matter prior to collection.

This product is designed for use in the domestic environment only.

4.2 SPECIFICATION

Stock No: ................................................................................................................................. 32301

Part No: .................................................................................................................................. BVP26

Engine displacement ............................................................................................................... 25.4cc

Maximum revolutions per min. (no load) ........................................................................... 7,000min-1

Maximum revolutions per min. at idle (no load)................................................................. 3,200min-1

Fuel tank capacity ..................................................................................................................... 0.65L

Fuel mixture...............................................................................................................................30:1††

Carburettor ................................................................................... Diaphragm type with primer pump

Spark plug .................................................................................................................................... L7T

Air flow:

Maximum air speed (blowing) ............................................................................. 75m/s (270km/h)

Maximum air speed (vacuuming)................................................................................... 6.3m3/min

Sound pressure level.............................................................................................................86dB(A)

Sound power level...............................................................................................................103dB(A)

Single value noise level (LWA)†...........................................................................................103dB(A)

Vibration level ................................................................................................................. 5.5±1.5m/s2

Dimensions (assembled) (L

×

W

×

H) ................................................................1210

×

520

×

360mm

Weight (dry, with vacuum tubes) ............................................................................................... 5.4kg

†A-weighted sound pressure level in accordance to 2000/14/EC.

††Use semi-synthetic 2 stroke oil.

4.3 HANDLING AND STORAGE

Care must still be taken when handling and lifting. Dropping this machine will have an effect on the

accuracy and may also result in personal injury. This machine is not a toy and must be respected.

The environment will have a negative result on its operation if you are not careful. If the air is

damp, components will rust. If the machine is unprotected from dust and debris; components will

become clogged: And if not cleaned and maintained correctly or regularly the machine will not

perform at its best.

- 5 -- 20 -

10. MAINTENANCE AND TROUBLESHOOTING

10.4 TROUBLESHOOTING GUIDE (continued)

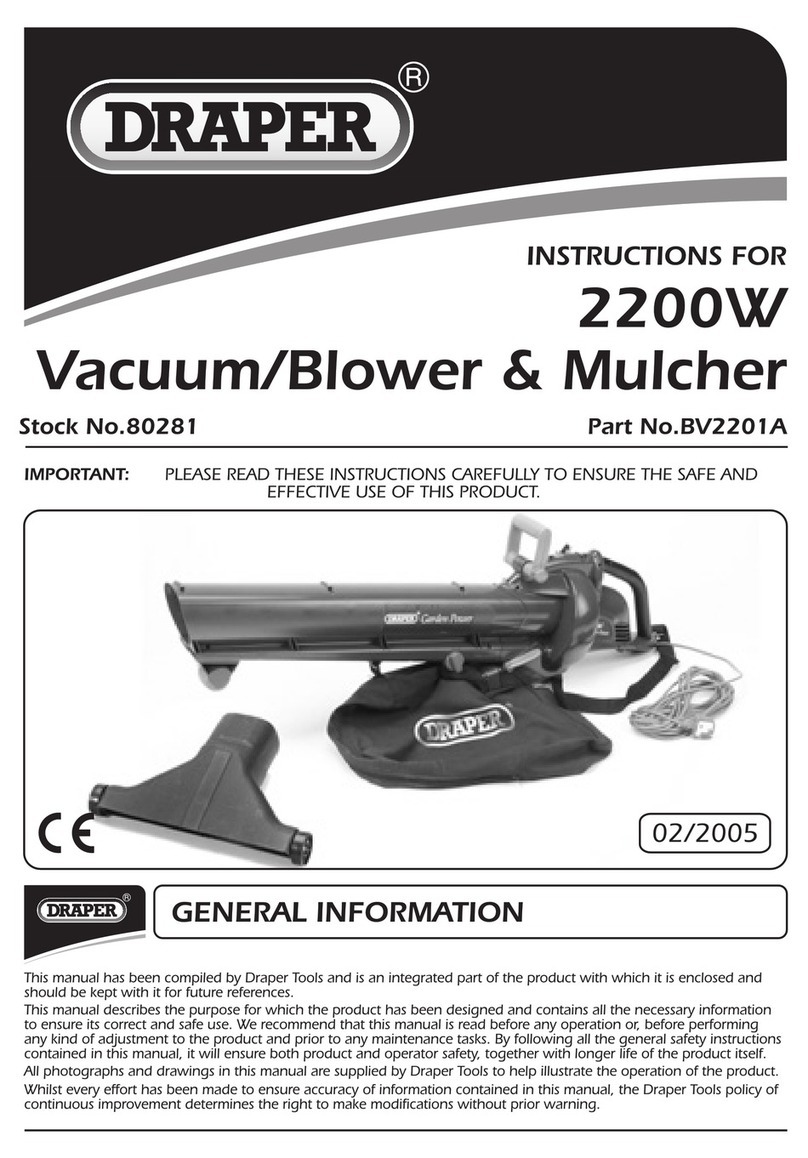

10.5 CLEANING AND MAINTENANCE OVERVIEW

Fault Possible cause Remedy

The motor does not

reach its maximum

speed.

Important: Please note, all repairs/servicing should be carried out by a qualified person.

1. The air filter is dirty.

2. The spark plug is dirty.

3. The distance between

the electrodes of the

spark plug is too large.

4. Wrong fuel.

1. Clean the air filter.

2. Clean the spark plug.

3. Set the gap to 0.6 to 0.7mm.

4. Drain the tank and fill with the

correct fuel.

Prior to every start.

Every 10 operating hours (more frequently in dusty conditions).

Every 10/15 operating hours.

Every 50 operating hours. (more frequently for reduced engine performance).

1. Check/clean/replace air filter element.

2. Check the pull starter for damage to the

starter .

3. Checking threaded connections for

tightness.

4. Remove dirt and debris from the

machine’s exterior

5. Inspect engine cooling fins for

accumulations of dirt and debris, clean as

necessary.

1. Check/clean/replace air filter element.

1. See section 10.1.

2. Visual inspection/testing.

3. Visual inspection/testing.

4. Visual inspection.

5. Visual inspection.

1. Check/clean/replace spark plug. 1. See section 10.2.

1. Inspect the entire machine and tubes for

damage, including loose or missing

components and repair as necessary.

2. Replace spark plug.

3. Inspect/replace fuel filter.

1. Visual inspection.

2. See section 10.2.

3. See section 10.3.

1. See section 10.1.

10.6 STORING THE MACHINE FOR AN EXTENDED PERIOD OF TIME

(3 MONTHS OR LONGER)

Before an extended period of disuse, you must remove the fuel from the machine.

– Drain the fuel tank, then start the engine and let it run until it stops of its own accord.

5. HEALTH AND SAFETY INFORMATION

5.1 SPECIFIC SAFETY INSTRUCTIONS FOR PETROL BLOWER/VAC’S

Warning! For your safety, please read and understand these instructions before assembling,

operating or maintaining this machine.

– Never attempt to modify or operate a modified machine. Fully assemble this machine,

including all relevant guards, before operating.

– Do not operate this machine without being completely familiar with the safety features and how

to operate them.

– Never operate this machine if the stop switch is faulty or not functioning.

– Never operate this machine while tired, ill or under the influence of drugs.

Danger! Keep out of the reach of children.

– Fully read and understand before attempting to assemble, operate or maintain the machine.

– Never allow people unfamiliar with these instructions to operate this machine. Local

regulations may restrict the age of the operator.

– Prior to each use, inspect the machine for signs of damage. Make sure the safety features are

present and functioning and that all visible nuts, bolts and screws remain tight. Vibration from

normal use can cause them to loosen over time.

– Never operate this machine with defective or missing guards.

Warning! Use of this product can pose a danger to wildlife. Before attempting to use this machine,

check the area, particularly long grass and under bushes for signs of life: if necessary relocate.

Note: Not all animals will be deterred by the noise of the product alone.

– Do not point the blower/vac nozzle in the direction of people or pets.

– Check the attachment is correctly fitted to the machine before attempting to start the engine.

Caution! As the user you are responsible for any injury to people or damage to property.

Warning! During use the engine gets very hot. Do not touch it, especially the exhaust.

– Always be aware of your surroundings, staying alert for possible hazards that you may not

hear over the noise of the engine.

– Always hold the blower/vac in your right hand, refer to the operating instructions in the manual.

– To reduce the risk of hearing loss associated with sound level, hearing protection is required.

– Wear suitable gloves to help reduce vibration fatigue.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

5.2 HEALTH AND SAFETY INFORMATION CONCERNING THE

USE OF FUELS

Fuels are inflammable and explosive. Reduce the risk of explosion and fire by:

– Turning off and cooling the motor down before filling the tank with fuel.

– Refraining from smoking and starting open fires when handling fuels.

– Storing and mixing fuels in approved and correspondingly labelled canisters.

10. MAINTENANCE AND TROUBLESHOOTING

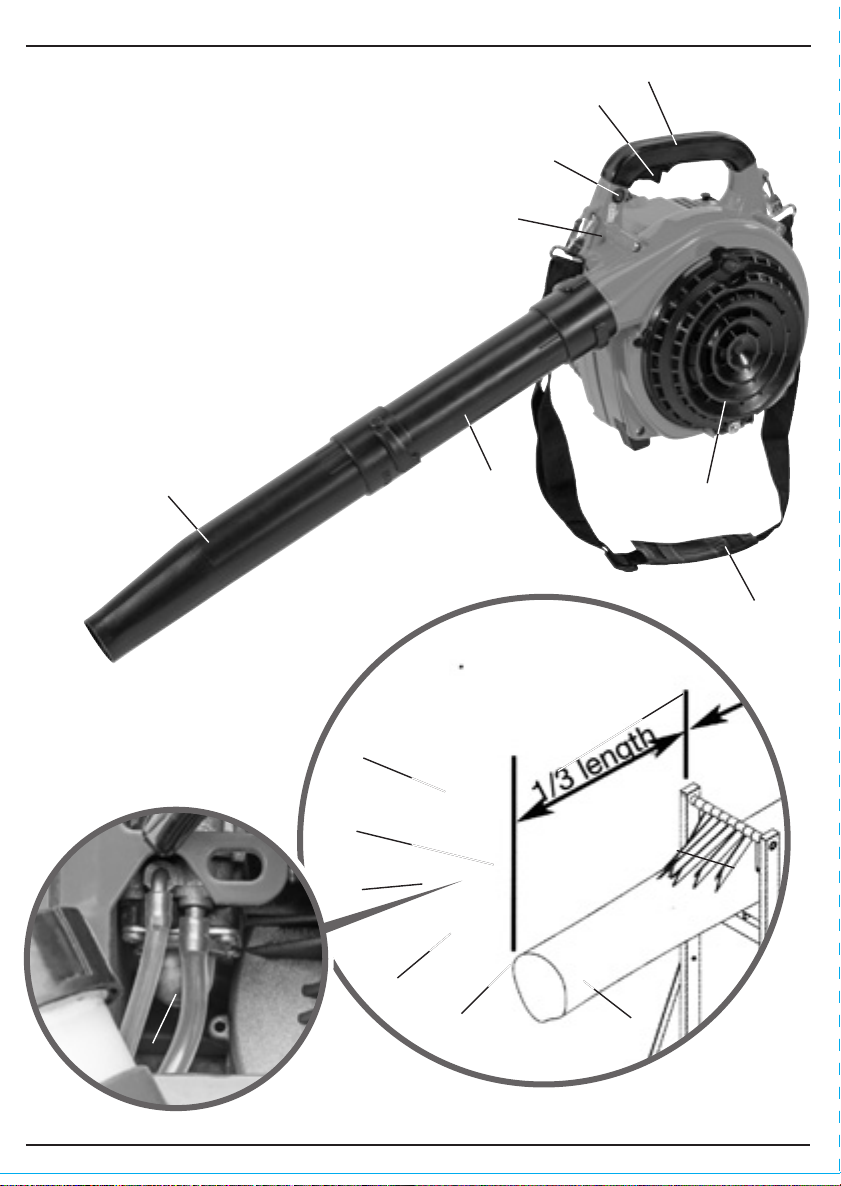

10.3 CLEANING THE FUEL FILTER

The fuel tank is fitted with a filter.

– The filter is situated at the free end of the fuel pipe and can be picked out through the fuel port

with a piece of hooked wire.

– Check the fuel filter periodically. Do not allow dust to enter the fuel tank. Clogged filter will

cause difficulty when starting engine or abnormalities in engine performance.

Replace the filter if dirty.

When the inside of the fuel tank is dirty it can be cleaned by rinsing the tank out with petrol.

- 6 - - 19 -

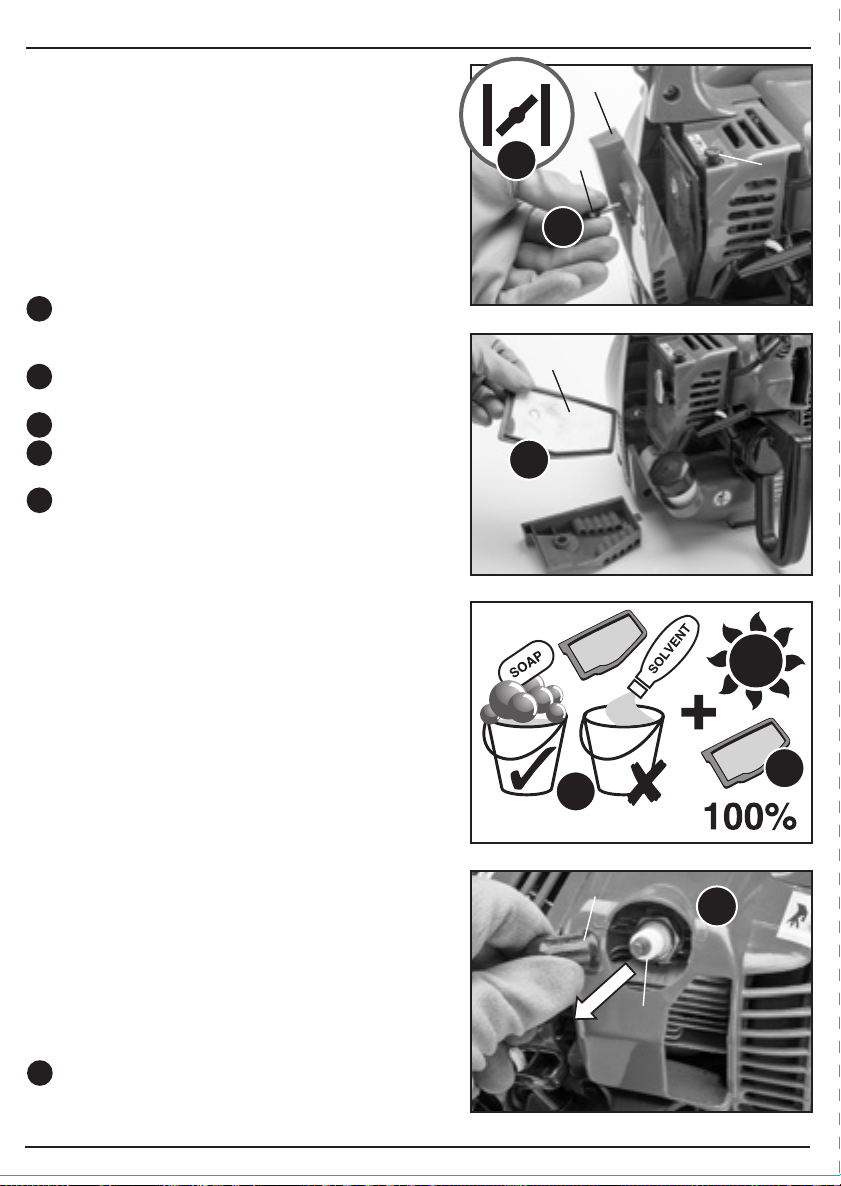

Using the spark plug box spanner supplied

, turn the spark plug anticlockwise to

remove it.

Clean the spark plug and check the electrode

gap. Maintain a gap of 0.6 to 0.7mm.

– If required, replace the spark plug with a L7T

coded plug, or equivalent, gapped to 0.6 –

0.7mm.

Warning! Make sure you correctly seat the spark

plug thread in to the engine before screwing it

clockwise in to the head.

Fig.34

2

3

0.6mm to

0.7mm

2

3

10.4 TROUBLESHOOTING GUIDE

Fault Possible cause Remedy

Engine does not start.

Machine runs but

stutters.

1. No fuel in the tank.

2. The STOP/START switch

is in the STOP position.

3. Ignition cable plug not

firmly attached.

4. Ignition cable plug dirty.

5. Is there fuel inside the

combustion chamber.

6. The spark plug is dirty.

7. The distance between

the electrodes of the

spark plug is too large.

8. Wrong fuel.

9. Spark plug defective.

1. Is the choke set to the off

(closed) position.

1. Refuel tank.

2. Put the switch in the START

position.

3. Push the plug on tightly.

4. Clean the plug.

5. Remove the spark plug, dry off the

electrode and start at full throttle.

6. Clean the spark section.

7. Set the gap to 0.6 to 0.7mm.

8. Drain the tank and fill it with the

correct fuel.

9. Replace the spark plug.

1. Set the choke to the on (open)

position.

5. HEALTH AND SAFETY INFORMATION

Regular maintenance tasks must be carried out at

specific intervals to retain the engine's performance.

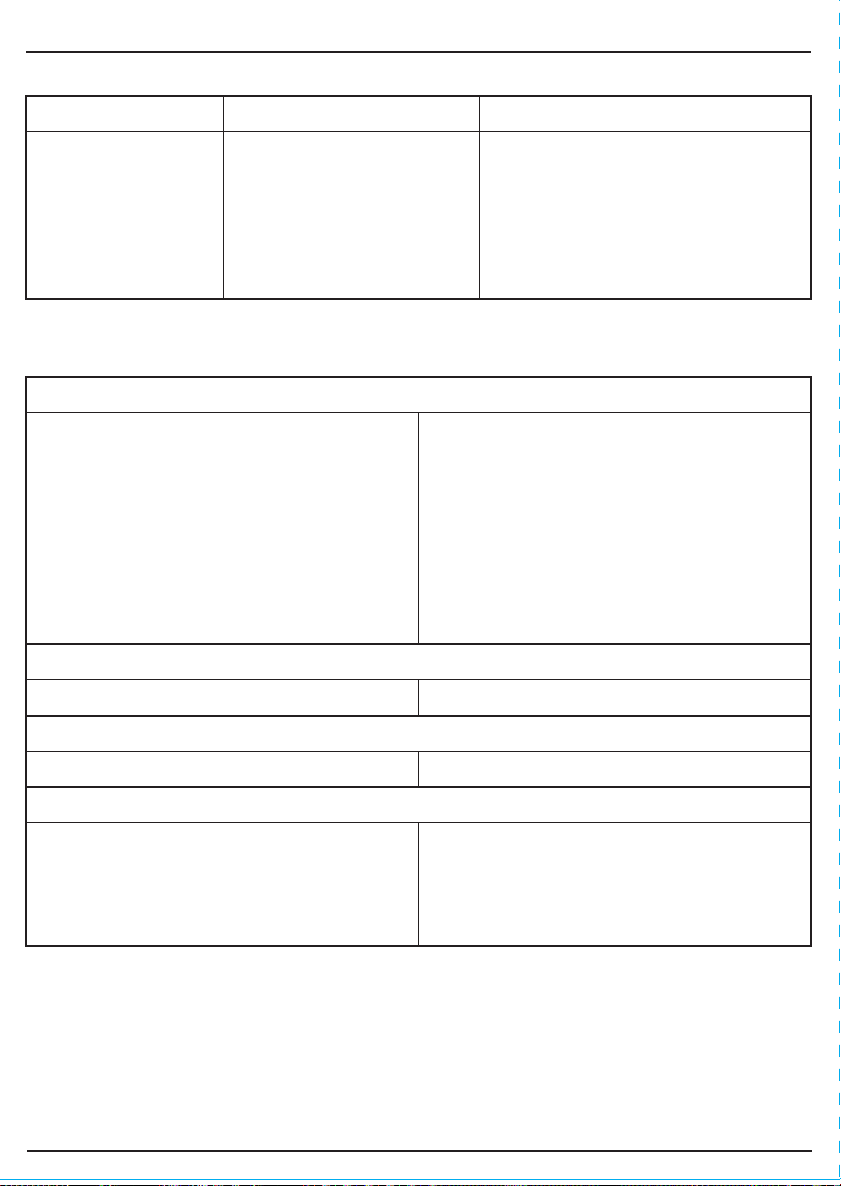

10.1 CLEANING THE AIR FILTER –

FIGS. 30 – 32

A dirty, clogged air filter will restrict the air flow in to

the engine and will cause rough running. It will

increase fuel consumption and may result in starting

problems.

Attention: Stop the engine before removing the air

filter assembly.

Pull the choke lever upwards to the closed

position to prevent any debris entering the

carburettor inlet.

Unscrew the retaining bolt on the air filter

cover to remove it.

Remove the air filter element .

Wash the element in warm soapy water to clean

it. Do not use solvents to clean it.

Allow the filter to dry 100% before refitting it on

to the engine.

– Refit cover .

– Replace the filter if it appears worn or

damaged.

10.2 SPARK PLUG MAINTENANCE –

FIGS. 33 – 34

Over time the spark plug

can become

contaminated.

This can be due to adverse running

conditions such as, working with part throttle for a

prolonged period or a fuel mix containing too much

oil. This contamination can build up causing the

engine to run roughly, reduce the fuel consumption

or create starting problems.

Without using any tools so as to avoid damaging

the H.T. lead, remove the lead from the

back of the spark plug.

Fig.30

Fig.31

2

3

Fig.32

Fig.33

1

1

2

3

4

5

1

1

5

4

– Storing fuels in closed containers. Keeping in mind that fuels may evaporate at room

temperature and collect on the floor of closed rooms (risk of explosion).

– Start the device at least nine metres away from any stored fuels or flammable liquids.

Fuels are toxic, they contain substances that have an immediate toxic effect and may cause

permanent damage to your health. Take all precautionary measures to prevent your body from

absorbing any of these substances:

– Tank and siphon fuels only outdoors or in well-ventilated rooms.

– Do not inhale fuel fumes.

– Avoid contact with eyes and skin.

– Wear gloves when transferring fuel.

– When fuel has come into contact with your clothes, change them immediately. Clean your

clothes before putting them back on.

– Store fuels out of the reach of children.

When handled inappropriately, fuels may cause damage to the environment:

– Transfer fuel carefully. Fuel must never trickle into the ground or the sewage system.

– Dispose of any remaining fuel in an appropriate manner. Never dispose of fuel with regular

household waste.

– Fuels may be stored only for a limited time. Purchase only such quantities that can be used up

within a few months.

- 7 -

10. MAINTENANCE AND TROUBLESHOOTING

- 18 -

- 8 - - 17 -

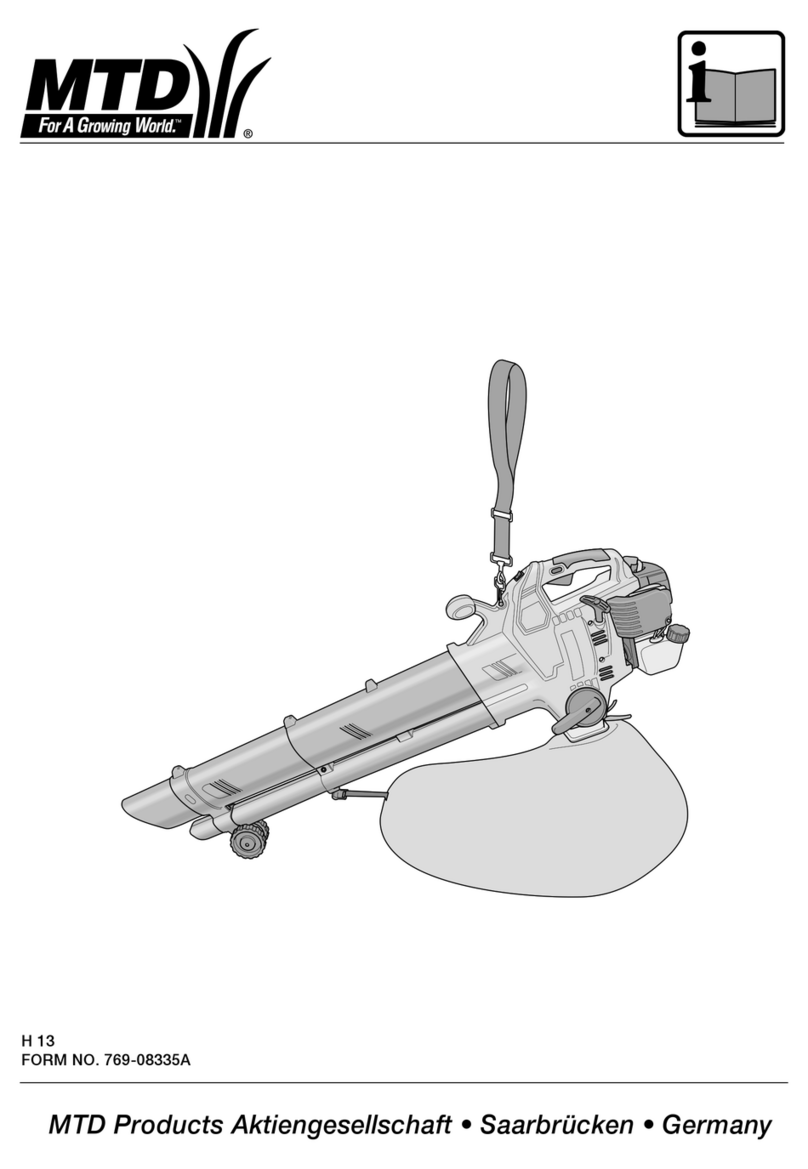

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION

Petrol motor unit.

Carry handle.

Throttle trigger.

ON/OFF/Ignition switch.

Blower nozzle.

Blower tube.

Vacuum air intake.

Carry strap.

Choke lever.

Recoil starter cord.

Air filter cover.

Fuel tank cap.

Fuel tank.

Side handle.

Exhaust.

Spark plug cap.

Fuel primer bulb.

Fig.28

9. OPERATING INSTRUCTIONS

9.6 USING THE BLOWER/VAC – FIGS. 27 – 29

Note: As a general rule, try to operate the machine using the lowest throttle setting necessary for

the task in hand.

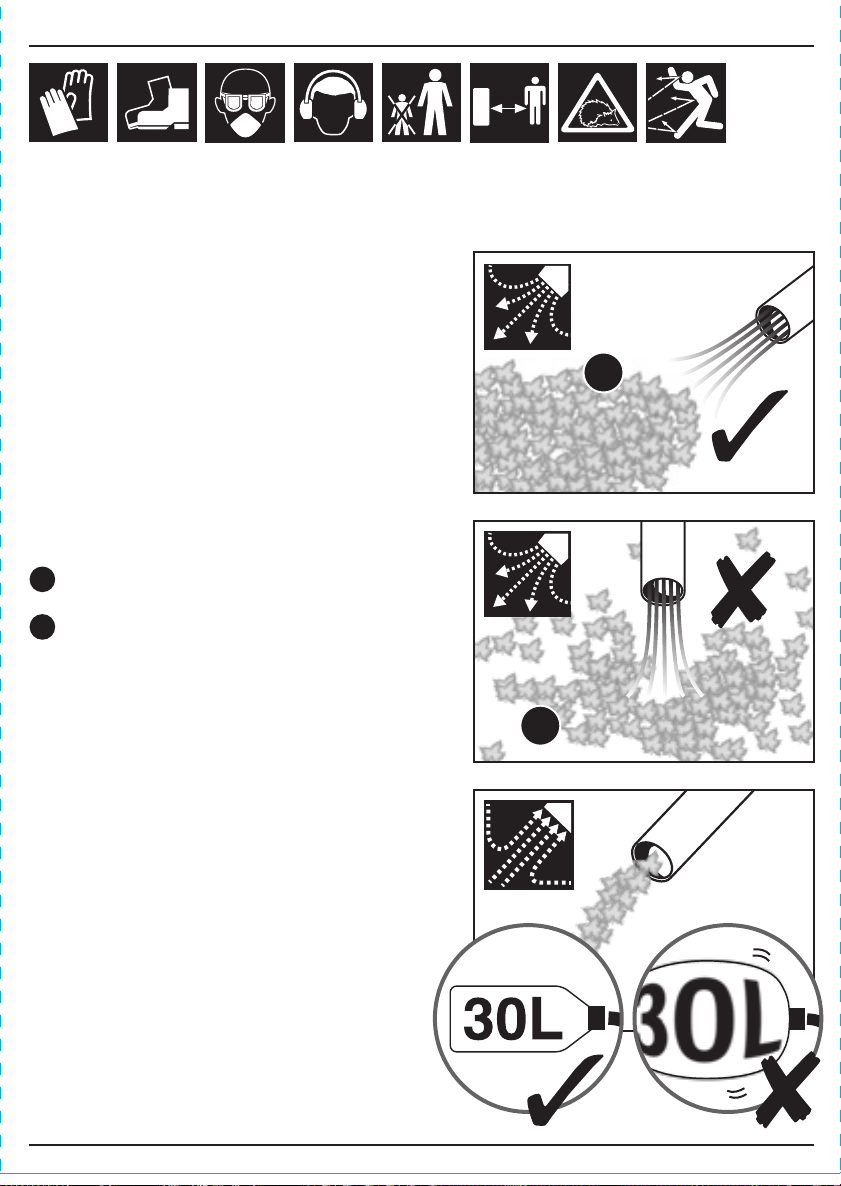

Blower Operation – Figs. 27 – 28

Note: To set up the machine for blowing

applications, refer to Section 8: Assembling The

Petrol Blower/Vac.

– Use low throttle settings when clearing

lightweight materials from around lawns or

shrubbery.

– Use medium to higher throttle settings to move

lightweight grass or leaves from open areas.

– Use full throttle when moving heavy loads such

as dirt or snow.

– Machine noise increases at higher throttle

settings. Always use the lowest possible throttle

setting.

– To keep from scattering debris, blow around the

outer edges of a debris pile.

Never blow directly into the centre of a pile.

– Use rakes and brooms to loosen debris before

blowing.

– In dusty conditions, slightly dampen surface with

water (if available).

Vacuum Operation – Fig.29

Note: To set up the machine for vacuuming

applications, refer to Section 8: Assembling The

Petrol Blower/Vac.

– When using the machine in vacuuming

operation, be sure not to allow the collection

bag to become overfilled.

– Allowing the collection bag to become overfilled

will reduce the appliances effectiveness and

may cause damage to the bag itself or the

appliance.

Fig.27

Fig.29

1

2

1

2

- 16 - - 9 -

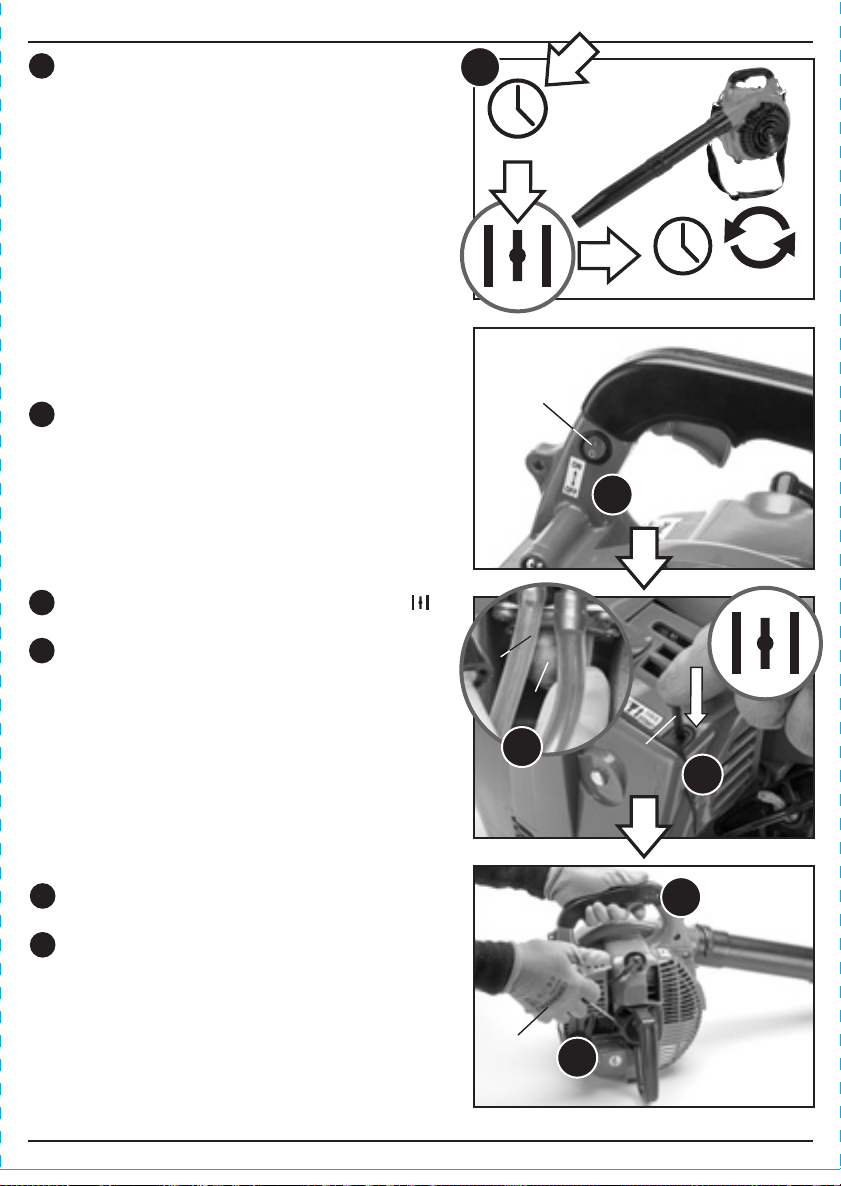

9.4 STOPPING THE ENGINE – FIG. 24

To stop the engine, move the stop switch to

the “stop” position.

Note: If the blower/vac has been running at full

speed for a prolonged period allow the engine to

idle for a few minutes before stopping.

The engine must be stopped while carrying out any

other operation such as:

– Refuelling.

– Making checks or adjustments.

– Cleaning.

9.5 ADJUSTING THE ENGINE IDLE

SPEED – FIGS. 25 – 26

Start the engine by following the steps highlighted in

the previous section: 9.2 Cold Starting the Engine.

Run the engine at idle speed until operating

temperature is reached (2 – 3 minutes).

Use the supplied screwdriver to adjust the

engine idle speed to 2300 – 2500r/min.

Turn the idle screw clockwise to increase

engine idle speed. Turn the idle screw

counterclockwise to decrease engine idle

speed.

Warning! Machine tubes and intake cover must be

installed while adjusting engine idle! Engine idle

speed will also be affected if either the intake cover

or machine tubes are blocked, damaged or

incorrectly installed.

1

1

2

3

2

9. OPERATING INSTRUCTIONS

1

Fig.24

Fig.26

Fig.25

2 – 3 mins

2300 –

2500r/min

2 – 3 mins

2

2

3

7. UNPACKING AND CHECKING

7.1 PACKAGING

Carefully remove the machine from the packaging and examine it for any sign of damage that may

have happened during shipping. Lay the contents out and check them against the parts shown

below. If any part is damaged or missing; please contact the Draper Helpline (the telephone

number appears on the Title page) and do not attempt to use the machine.

The packaging material should be retained at least during the guarantee period: in case the

machine needs to be returned for repair.

Warning! Some of the packaging materials used may be harmful to children. Do not leave any of

these materials in the reach of children.

If any of the packaging is to be thrown away, make sure they are disposed of correctly; according

to local regulations.

7.2 WHAT´S IN THE BOX?

As well as the blower vac, there are several parts not fitted or attached to it.

Petrol motor unit.

Blower nozzle.

Blower tube.

Carry strap.

Collection bag

intake tube.

Vacuum tube.

Vacuum nozzle.

Collection bag.

Fuel mixing bottle.

Screwdriver.

Large hex. key.

Small hex. key.

Box spanner.

M5

×

10 Screw

×

3.

- 10 - - 15 -

8. ASSEMBLING THE PETROL BLOWER/VAC

8.1 ASSEMBLING THE BLOWER

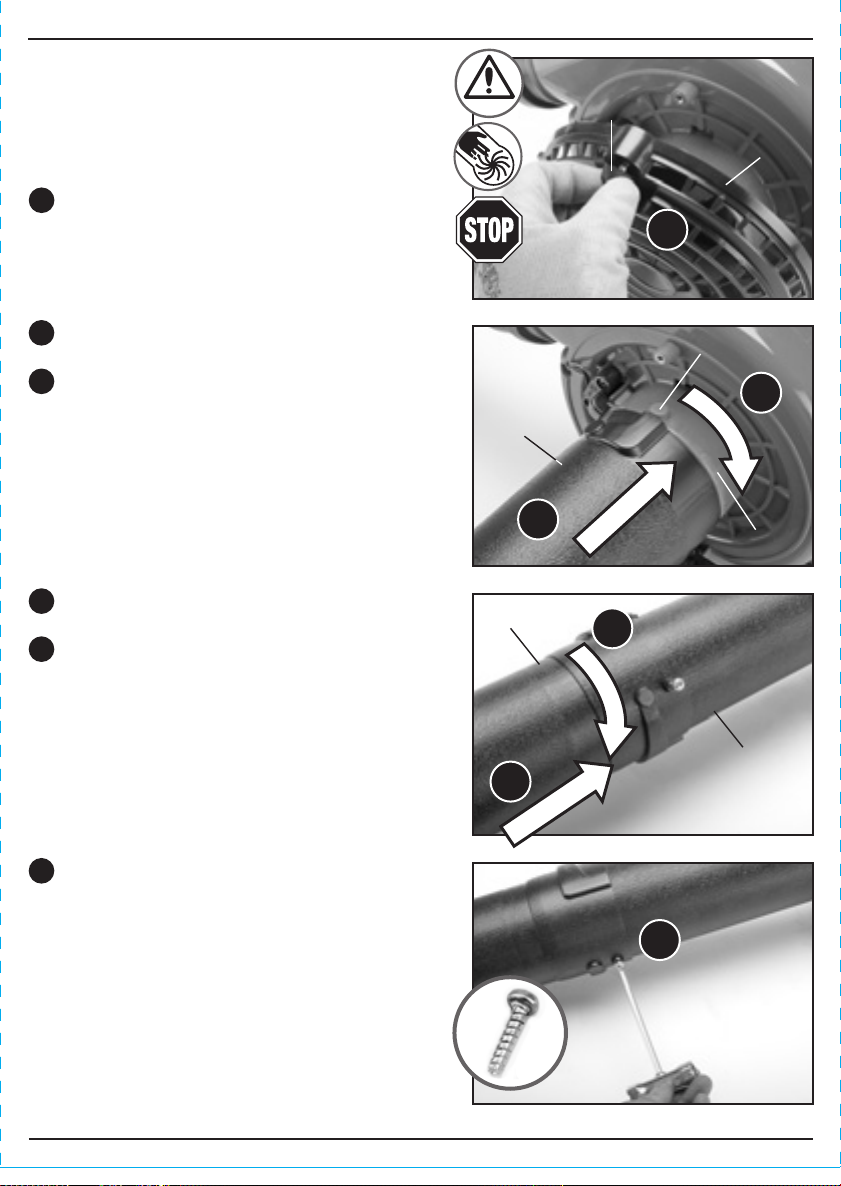

TUBES – FIGS. 1 – 3

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Slide the blower tube over the discharge

port and locking lug .

Rotate the tube clockwise to lock in place.

Secure the blower tube in place using the

supplied M5

×

10 screw and the

screwdriver end of the box spanner .

Slide the blower nozzle on to the blower

tube and locking lug

Rotate the nozzle clockwise to lock in place.

1

2

3

4

5

Fig.1

Fig.2

Fig.3

2

3

4

5

1

Important: This petrol blower vac can switch from blowing to suction functions. This is achieved

by connecting the tubes to the correct mounting.

– For blowing function, the tube is fitted to the front outlet (see section 8.1: assembling the

blower tubes).

– For vacuum function, the collection bag is fitted to the front outlet and the main tube is fitted to

the mounting that is accessed by opening the vented side cover (see section 8.2: assembling

the vacuum tubes).

Once the motor has started, allow the motor to

warm up for a few minutes before commencing

operation.

7

9. OPERATING INSTRUCTIONS

Standing behind the machine, firmly grip the

front handle with your hand.

With your other hand grip the recoil starter cord

. Pull the starter cord using short sharp

movements.

– If the engine does not start, refer to the steps

highlighted in the previous section: 9.2 Cold

Starting the Engine.

4

5

Fig.20

2 – 3 mins

5 sec

7

9.3 WARM STARTING THE ENGINE –

FIGS. 21 – 23

Rest the blower/vac on a stable surface.

Press the ON/OFF/IGNITION switch to the

‘I’ (ON) position.

1

Fig.21

1

Push the choke lever downwards to the

(open) position.

Pump the primer eight times until fuel flows

in and out of the discharge line with no air

bubbles.

2

3

Fig.22

2

3

Fig.23

4

5

- 11 -

9. OPERATING INSTRUCTIONS

- 14 -

8. ASSEMBLING THE PETROL BLOWER/VAC

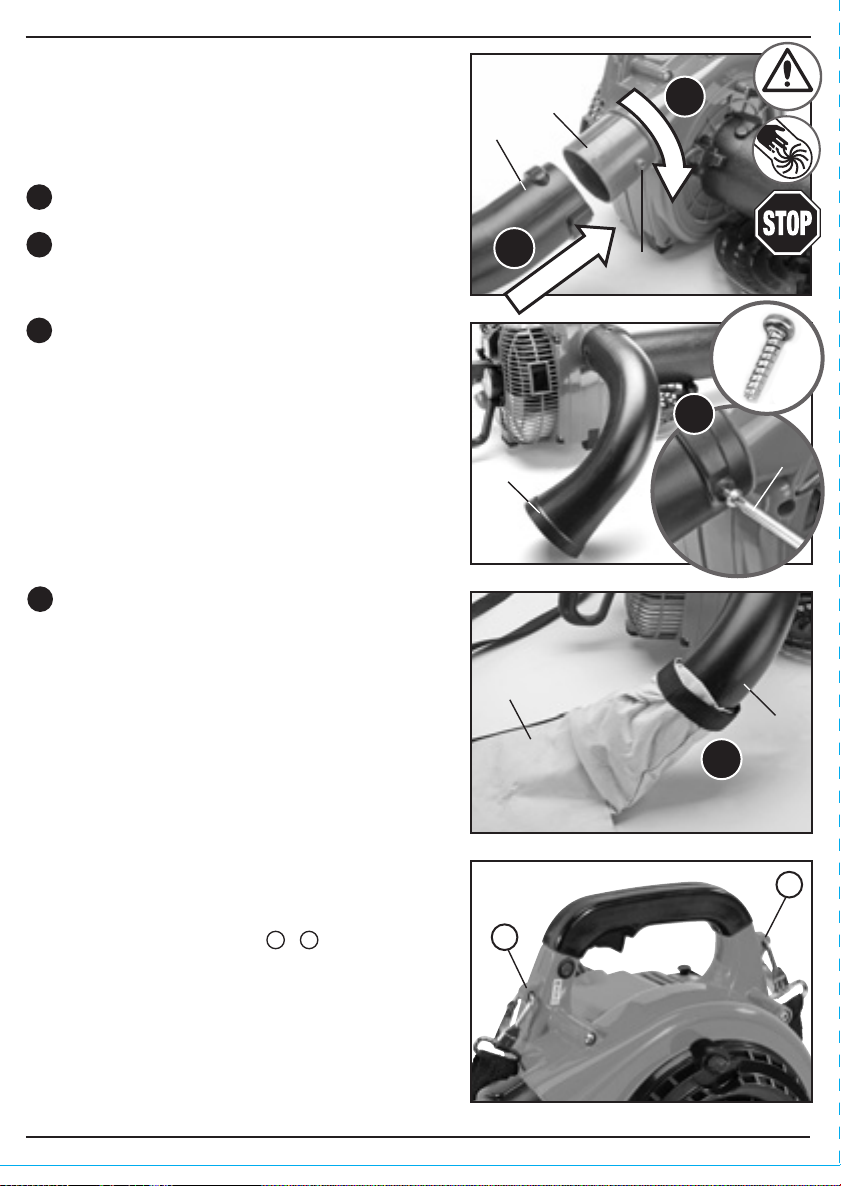

Slide the vacuum nozzle over the vacuum

tube and locking lug.

Rotate the nozzle clockwise to lock in place.

Secure the vacuum nozzle in place using the

supplied M5

×

10 screw and the screwdriver

end of the box spanner .

Slide the vacuum tube over the air intake

port and locking lug .

Rotate the tube clockwise to lock in place.

Fig.5

Fig.6

Fig.7

2

4

3

5

6

2

3

4

5

6

8.2 ASSEMBLING THE VACUUM

TUBES – FIGS. 4 – 7

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Unscrew the retaining knob on the vacuum

intake cover .

1

Fig.4

1

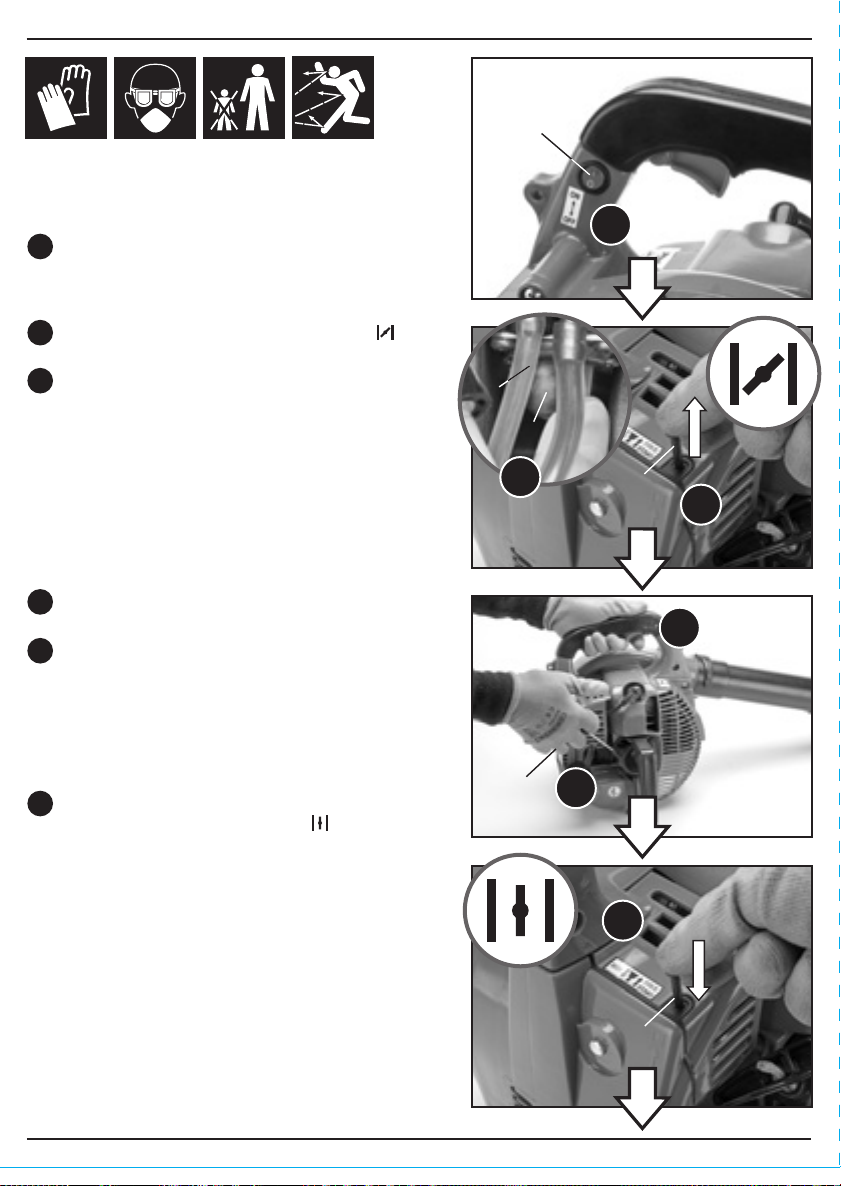

9.2 COLD STARTING THE ENGINE –

FIGS. 16 – 20

Rest the blower/vac on a stable surface.

Press the ON/OFF/IGNITION switch to the

‘I’ (ON) position.

Standing behind the machine, firmly grip the

front handle with your hand.

With your other hand grip the recoil starter cord

. Pull the starter cord using short sharp

movements.

Note: Do not use the full length of the recoil starter

cord as this can cause breakage or premature

failure. Do not release the starter cord to recoil on

its own. Damage will occur to the mechanism.

Once the engine tries to fire, push the choke

lever downwards to the the (open)

position.

Note: If there is a strong smell of fuel this indicates

that the engine may be flooded. Wait a few minutes

before attempting to restart the machine as if the

engine were warm i.e. no choke.

Pull the choke lever upwards to the

(closed) position.

Pump the primer eight times until fuel flows

in and out of the discharge line with no air

bubbles.

1

2

3

4

5

6

Fig.16

Fig.19

Fig.17

Fig.18

1

2

4

5

6

3

- 12 -

8. ASSEMBLING THE PETROL BLOWER/VAC8. ASSEMBLING THE PETROL BLOWER/VAC

Secure the collection bag intake tube in

place using the supplied M5

×

10 screw and

the screwdriver end of the box spanner .

- 13 -

3

Secure the collection bag to the collection

bag intake tube using the fastenings

attached at the opening of the bag.

4

The carry strap is attached by threading each of

the 2 sprung loaded buckles through the

holes in the 2 attachment points .

1

Fig.9

Fig.10

Fig.11

Fig.12

8.4 ATTACHING THE CARRYING

STRAP – FIGS. 11 – 12

The petrol motor unit has 2 fastening points for the

attachment of the carry strap ( & ).

3

4

1

A

AB

B

8.3 ATTACHING THE COLLECTION

BAG – FIGS. 8 – 10

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Slide the collection bag intake tube over

the discharge port and locking lug .

Rotate the tube clockwise to lock in place.

Fig.8

1

2

1

2

9.1 FUELLING – FIGS. 13 – 15

This petrol blower vac is equipped with a 2 stroke

air cooled petrol engine.

This type of engine requires a mixture of fuel and oil

to perform and function. Failure to use the correct

oil, fuel or mixture ratio will cause permanent

damage to the engine. Only use fresh, clean, good

quality unleaded fuel mixed with a high quality 2

stroke oil. Do not use any other types of oil e.g.

engine oil as this will cause damage to the

engine.

For synthetic oil or semi-synthetic a mix ratio of 30:1

must be used. To mix a ratio of 30:1:

Add 166ml of 2 stroke oil into 5 litres of

unleaded fuel (2%).

Attention: Always handle fuel with caution.

Pour the fuel/oil mixture into a specifically

designed mixing receptacle before replacing

the cap and shaking gently.

Remove the fuel tank cap by turning it

anti-clockwise. To prevent identification

problems or accidents the fuel tank cap is

stamped with the symbol .

With the aid of a funnel, if needed, pour the

fuel/oil mixture into the fuel tank before

replacing the cap firmly. Avoid spillage and do

not over fill.

Note: Always mix and refuel in a well ventilated

area away from sources of ignition.

Note: Store fuel for short periods only and avoid

mixing more than is required. Store in a container

specifically designed for petrochemical applications

away from heat and direct sun light.

5L

166ml

Fig.13

Fig.14

Fig.15

1

2

3

4

3

4

1

30 : 1

2

- 12 -

8. ASSEMBLING THE PETROL BLOWER/VAC8. ASSEMBLING THE PETROL BLOWER/VAC

Secure the collection bag intake tube in

place using the supplied M5

×

10 screw and

the screwdriver end of the box spanner .

- 13 -

3

Secure the collection bag to the collection

bag intake tube using the fastenings

attached at the opening of the bag.

4

The carry strap is attached by threading each of

the 2 sprung loaded buckles through the

holes in the 2 attachment points .

1

Fig.9

Fig.10

Fig.11

Fig.12

8.4 ATTACHING THE CARRYING

STRAP – FIGS. 11 – 12

The petrol motor unit has 2 fastening points for the

attachment of the carry strap ( & ).

3

4

1

A

AB

B

8.3 ATTACHING THE COLLECTION

BAG – FIGS. 8 – 10

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Slide the collection bag intake tube over

the discharge port and locking lug .

Rotate the tube clockwise to lock in place.

Fig.8

1

2

1

2

9.1 FUELLING – FIGS. 13 – 15

This petrol blower vac is equipped with a 2 stroke

air cooled petrol engine.

This type of engine requires a mixture of fuel and oil

to perform and function. Failure to use the correct

oil, fuel or mixture ratio will cause permanent

damage to the engine. Only use fresh, clean, good

quality unleaded fuel mixed with a high quality 2

stroke oil. Do not use any other types of oil e.g.

engine oil as this will cause damage to the

engine.

For synthetic oil or semi-synthetic a mix ratio of 30:1

must be used. To mix a ratio of 30:1:

Add 166ml of 2 stroke oil into 5 litres of

unleaded fuel (2%).

Attention: Always handle fuel with caution.

Pour the fuel/oil mixture into a specifically

designed mixing receptacle before replacing

the cap and shaking gently.

Remove the fuel tank cap by turning it

anti-clockwise. To prevent identification

problems or accidents the fuel tank cap is

stamped with the symbol .

With the aid of a funnel, if needed, pour the

fuel/oil mixture into the fuel tank before

replacing the cap firmly. Avoid spillage and do

not over fill.

Note: Always mix and refuel in a well ventilated

area away from sources of ignition.

Note: Store fuel for short periods only and avoid

mixing more than is required. Store in a container

specifically designed for petrochemical applications

away from heat and direct sun light.

5L

166ml

Fig.13

Fig.14

Fig.15

1

2

3

4

3

4

1

30 : 1

2

- 11 -

9. OPERATING INSTRUCTIONS

- 14 -

8. ASSEMBLING THE PETROL BLOWER/VAC

Slide the vacuum nozzle over the vacuum

tube and locking lug.

Rotate the nozzle clockwise to lock in place.

Secure the vacuum nozzle in place using the

supplied M5

×

10 screw and the screwdriver

end of the box spanner .

Slide the vacuum tube over the air intake

port and locking lug .

Rotate the tube clockwise to lock in place.

Fig.5

Fig.6

Fig.7

2

4

3

5

6

2

3

4

5

6

8.2 ASSEMBLING THE VACUUM

TUBES – FIGS. 4 – 7

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Unscrew the retaining knob on the vacuum

intake cover .

1

Fig.4

1

9.2 COLD STARTING THE ENGINE –

FIGS. 16 – 20

Rest the blower/vac on a stable surface.

Press the ON/OFF/IGNITION switch to the

‘I’ (ON) position.

Standing behind the machine, firmly grip the

front handle with your hand.

With your other hand grip the recoil starter cord

. Pull the starter cord using short sharp

movements.

Note: Do not use the full length of the recoil starter

cord as this can cause breakage or premature

failure. Do not release the starter cord to recoil on

its own. Damage will occur to the mechanism.

Once the engine tries to fire, push the choke

lever downwards to the the (open)

position.

Note: If there is a strong smell of fuel this indicates

that the engine may be flooded. Wait a few minutes

before attempting to restart the machine as if the

engine were warm i.e. no choke.

Pull the choke lever upwards to the

(closed) position.

Pump the primer eight times until fuel flows

in and out of the discharge line with no air

bubbles.

1

2

3

4

5

6

Fig.16

Fig.19

Fig.17

Fig.18

1

2

4

5

6

3

- 10 - - 15 -

8. ASSEMBLING THE PETROL BLOWER/VAC

8.1 ASSEMBLING THE BLOWER

TUBES – FIGS. 1 – 3

Warning! Stop the engine and put the switch to

STOP position before installing parts, making

adjustments, cleaning or when not in use. Failure to

do so could result in possible serious injury.

Slide the blower tube over the discharge

port and locking lug .

Rotate the tube clockwise to lock in place.

Secure the blower tube in place using the

supplied M5

×

10 screw and the

screwdriver end of the box spanner .

Slide the blower nozzle on to the blower

tube and locking lug

Rotate the nozzle clockwise to lock in place.

1

2

3

4

5

Fig.1

Fig.2

Fig.3

2

3

4

5

1

Important: This petrol blower vac can switch from blowing to suction functions. This is achieved

by connecting the tubes to the correct mounting.

– For blowing function, the tube is fitted to the front outlet (see section 8.1: assembling the

blower tubes).

– For vacuum function, the collection bag is fitted to the front outlet and the main tube is fitted to

the mounting that is accessed by opening the vented side cover (see section 8.2: assembling

the vacuum tubes).

Once the motor has started, allow the motor to

warm up for a few minutes before commencing

operation.

7

9. OPERATING INSTRUCTIONS

Standing behind the machine, firmly grip the

front handle with your hand.

With your other hand grip the recoil starter cord

. Pull the starter cord using short sharp

movements.

– If the engine does not start, refer to the steps

highlighted in the previous section: 9.2 Cold

Starting the Engine.

4

5

Fig.20

2 – 3 mins

5 sec

7

9.3 WARM STARTING THE ENGINE –

FIGS. 21 – 23

Rest the blower/vac on a stable surface.

Press the ON/OFF/IGNITION switch to the

‘I’ (ON) position.

1

Fig.21

1

Push the choke lever downwards to the

(open) position.

Pump the primer eight times until fuel flows

in and out of the discharge line with no air

bubbles.

2

3

Fig.22

2

3

Fig.23

4

5

- 16 - - 9 -

9.4 STOPPING THE ENGINE – FIG. 24

To stop the engine, move the stop switch to

the “stop” position.

Note: If the blower/vac has been running at full

speed for a prolonged period allow the engine to

idle for a few minutes before stopping.

The engine must be stopped while carrying out any

other operation such as:

– Refuelling.

– Making checks or adjustments.

– Cleaning.

9.5 ADJUSTING THE ENGINE IDLE

SPEED – FIGS. 25 – 26

Start the engine by following the steps highlighted in

the previous section: 9.2 Cold Starting the Engine.

Run the engine at idle speed until operating

temperature is reached (2 – 3 minutes).

Use the supplied screwdriver to adjust the

engine idle speed to 2300 – 2500r/min.

Turn the idle screw clockwise to increase

engine idle speed. Turn the idle screw

counterclockwise to decrease engine idle

speed.

Warning! Machine tubes and intake cover must be

installed while adjusting engine idle! Engine idle

speed will also be affected if either the intake cover

or machine tubes are blocked, damaged or

incorrectly installed.

1

1

2

3

2

9. OPERATING INSTRUCTIONS

1

Fig.24

Fig.26

Fig.25

2 – 3 mins

2300 –

2500r/min

2 – 3 mins

2

2

3

7. UNPACKING AND CHECKING

7.1 PACKAGING

Carefully remove the machine from the packaging and examine it for any sign of damage that may

have happened during shipping. Lay the contents out and check them against the parts shown

below. If any part is damaged or missing; please contact the Draper Helpline (the telephone

number appears on the Title page) and do not attempt to use the machine.

The packaging material should be retained at least during the guarantee period: in case the

machine needs to be returned for repair.

Warning! Some of the packaging materials used may be harmful to children. Do not leave any of

these materials in the reach of children.

If any of the packaging is to be thrown away, make sure they are disposed of correctly; according

to local regulations.

7.2 WHAT´S IN THE BOX?

As well as the blower vac, there are several parts not fitted or attached to it.

Petrol motor unit.

Blower nozzle.

Blower tube.

Carry strap.

Collection bag

intake tube.

Vacuum tube.

Vacuum nozzle.

Collection bag.

Fuel mixing bottle.

Screwdriver.

Large hex. key.

Small hex. key.

Box spanner.

M5

×

10 Screw

×

3.

- 8 - - 17 -

6. TECHNICAL DESCRIPTION

6.1 IDENTIFICATION

Petrol motor unit.

Carry handle.

Throttle trigger.

ON/OFF/Ignition switch.

Blower nozzle.

Blower tube.

Vacuum air intake.

Carry strap.

Choke lever.

Recoil starter cord.

Air filter cover.

Fuel tank cap.

Fuel tank.

Side handle.

Exhaust.

Spark plug cap.

Fuel primer bulb.

Fig.28

9. OPERATING INSTRUCTIONS

9.6 USING THE BLOWER/VAC – FIGS. 27 – 29

Note: As a general rule, try to operate the machine using the lowest throttle setting necessary for

the task in hand.

Blower Operation – Figs. 27 – 28

Note: To set up the machine for blowing

applications, refer to Section 8: Assembling The

Petrol Blower/Vac.

– Use low throttle settings when clearing

lightweight materials from around lawns or

shrubbery.

– Use medium to higher throttle settings to move

lightweight grass or leaves from open areas.

– Use full throttle when moving heavy loads such

as dirt or snow.

– Machine noise increases at higher throttle

settings. Always use the lowest possible throttle

setting.

– To keep from scattering debris, blow around the

outer edges of a debris pile.

Never blow directly into the centre of a pile.

– Use rakes and brooms to loosen debris before

blowing.

– In dusty conditions, slightly dampen surface with

water (if available).

Vacuum Operation – Fig.29

Note: To set up the machine for vacuuming

applications, refer to Section 8: Assembling The

Petrol Blower/Vac.

– When using the machine in vacuuming

operation, be sure not to allow the collection

bag to become overfilled.

– Allowing the collection bag to become overfilled

will reduce the appliances effectiveness and

may cause damage to the bag itself or the

appliance.

Fig.27

Fig.29

1

2

1

2

5. HEALTH AND SAFETY INFORMATION

Regular maintenance tasks must be carried out at

specific intervals to retain the engine's performance.

10.1 CLEANING THE AIR FILTER –

FIGS. 30 – 32

A dirty, clogged air filter will restrict the air flow in to

the engine and will cause rough running. It will

increase fuel consumption and may result in starting

problems.

Attention: Stop the engine before removing the air

filter assembly.

Pull the choke lever upwards to the closed

position to prevent any debris entering the

carburettor inlet.

Unscrew the retaining bolt on the air filter

cover to remove it.

Remove the air filter element .

Wash the element in warm soapy water to clean

it. Do not use solvents to clean it.

Allow the filter to dry 100% before refitting it on

to the engine.

– Refit cover .

– Replace the filter if it appears worn or

damaged.

10.2 SPARK PLUG MAINTENANCE –

FIGS. 33 – 34

Over time the spark plug

can become

contaminated.

This can be due to adverse running

conditions such as, working with part throttle for a

prolonged period or a fuel mix containing too much

oil. This contamination can build up causing the

engine to run roughly, reduce the fuel consumption

or create starting problems.

Without using any tools so as to avoid damaging

the H.T. lead, remove the lead from the

back of the spark plug.

Fig.30

Fig.31

2

3

Fig.32

Fig.33

1

1

2

3

4

5

1

1

5

4

– Storing fuels in closed containers. Keeping in mind that fuels may evaporate at room

temperature and collect on the floor of closed rooms (risk of explosion).

– Start the device at least nine metres away from any stored fuels or flammable liquids.

Fuels are toxic, they contain substances that have an immediate toxic effect and may cause

permanent damage to your health. Take all precautionary measures to prevent your body from

absorbing any of these substances:

– Tank and siphon fuels only outdoors or in well-ventilated rooms.

– Do not inhale fuel fumes.

– Avoid contact with eyes and skin.

– Wear gloves when transferring fuel.

– When fuel has come into contact with your clothes, change them immediately. Clean your

clothes before putting them back on.

– Store fuels out of the reach of children.

When handled inappropriately, fuels may cause damage to the environment:

– Transfer fuel carefully. Fuel must never trickle into the ground or the sewage system.

– Dispose of any remaining fuel in an appropriate manner. Never dispose of fuel with regular

household waste.

– Fuels may be stored only for a limited time. Purchase only such quantities that can be used up

within a few months.

- 7 -

10. MAINTENANCE AND TROUBLESHOOTING

- 18 -

5. HEALTH AND SAFETY INFORMATION

5.1 SPECIFIC SAFETY INSTRUCTIONS FOR PETROL BLOWER/VAC’S

Warning! For your safety, please read and understand these instructions before assembling,

operating or maintaining this machine.

– Never attempt to modify or operate a modified machine. Fully assemble this machine,

including all relevant guards, before operating.

– Do not operate this machine without being completely familiar with the safety features and how

to operate them.

– Never operate this machine if the stop switch is faulty or not functioning.

– Never operate this machine while tired, ill or under the influence of drugs.

Danger! Keep out of the reach of children.

– Fully read and understand before attempting to assemble, operate or maintain the machine.

– Never allow people unfamiliar with these instructions to operate this machine. Local

regulations may restrict the age of the operator.

– Prior to each use, inspect the machine for signs of damage. Make sure the safety features are

present and functioning and that all visible nuts, bolts and screws remain tight. Vibration from

normal use can cause them to loosen over time.

– Never operate this machine with defective or missing guards.

Warning! Use of this product can pose a danger to wildlife. Before attempting to use this machine,

check the area, particularly long grass and under bushes for signs of life: if necessary relocate.

Note: Not all animals will be deterred by the noise of the product alone.

– Do not point the blower/vac nozzle in the direction of people or pets.

– Check the attachment is correctly fitted to the machine before attempting to start the engine.

Caution! As the user you are responsible for any injury to people or damage to property.

Warning! During use the engine gets very hot. Do not touch it, especially the exhaust.

– Always be aware of your surroundings, staying alert for possible hazards that you may not

hear over the noise of the engine.

– Always hold the blower/vac in your right hand, refer to the operating instructions in the manual.

– To reduce the risk of hearing loss associated with sound level, hearing protection is required.

– Wear suitable gloves to help reduce vibration fatigue.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

5.2 HEALTH AND SAFETY INFORMATION CONCERNING THE

USE OF FUELS

Fuels are inflammable and explosive. Reduce the risk of explosion and fire by:

– Turning off and cooling the motor down before filling the tank with fuel.

– Refraining from smoking and starting open fires when handling fuels.

– Storing and mixing fuels in approved and correspondingly labelled canisters.

10. MAINTENANCE AND TROUBLESHOOTING

10.3 CLEANING THE FUEL FILTER

The fuel tank is fitted with a filter.

– The filter is situated at the free end of the fuel pipe and can be picked out through the fuel port

with a piece of hooked wire.

– Check the fuel filter periodically. Do not allow dust to enter the fuel tank. Clogged filter will

cause difficulty when starting engine or abnormalities in engine performance.

Replace the filter if dirty.

When the inside of the fuel tank is dirty it can be cleaned by rinsing the tank out with petrol.

- 6 - - 19 -

Using the spark plug box spanner supplied

, turn the spark plug anticlockwise to

remove it.

Clean the spark plug and check the electrode

gap. Maintain a gap of 0.6 to 0.7mm.

– If required, replace the spark plug with a L7T

coded plug, or equivalent, gapped to 0.6 –

0.7mm.

Warning! Make sure you correctly seat the spark

plug thread in to the engine before screwing it

clockwise in to the head.

Fig.34

2

3

0.6mm to

0.7mm

2

3

10.4 TROUBLESHOOTING GUIDE

Fault Possible cause Remedy

Engine does not start.

Machine runs but

stutters.

1. No fuel in the tank.

2. The STOP/START switch

is in the STOP position.

3. Ignition cable plug not

firmly attached.

4. Ignition cable plug dirty.

5. Is there fuel inside the

combustion chamber.

6. The spark plug is dirty.

7. The distance between

the electrodes of the

spark plug is too large.

8. Wrong fuel.

9. Spark plug defective.

1. Is the choke set to the off

(closed) position.

1. Refuel tank.

2. Put the switch in the START

position.

3. Push the plug on tightly.

4. Clean the plug.

5. Remove the spark plug, dry off the

electrode and start at full throttle.

6. Clean the spark section.

7. Set the gap to 0.6 to 0.7mm.

8. Drain the tank and fill it with the

correct fuel.

9. Replace the spark plug.

1. Set the choke to the on (open)

position.

4. INTRODUCTION

4.1 SCOPE

This product is designed for blowing fallen leaves and other loose green matter prior to collection.

This product is designed for use in the domestic environment only.

4.2 SPECIFICATION

Stock No: ................................................................................................................................. 32301

Part No: .................................................................................................................................. BVP26

Engine displacement ............................................................................................................... 25.4cc

Maximum revolutions per min. (no load) ........................................................................... 7,000min-1

Maximum revolutions per min. at idle (no load)................................................................. 3,200min-1

Fuel tank capacity ..................................................................................................................... 0.65L

Fuel mixture...............................................................................................................................30:1††

Carburettor ................................................................................... Diaphragm type with primer pump

Spark plug .................................................................................................................................... L7T

Air flow:

Maximum air speed (blowing) ............................................................................. 75m/s (270km/h)

Maximum air speed (vacuuming)................................................................................... 6.3m3/min

Sound pressure level.............................................................................................................86dB(A)

Sound power level...............................................................................................................103dB(A)

Single value noise level (LWA)†...........................................................................................103dB(A)

Vibration level ................................................................................................................. 5.5±1.5m/s2

Dimensions (assembled) (L

×

W

×

H) ................................................................1210

×

520

×

360mm

Weight (dry, with vacuum tubes) ............................................................................................... 5.4kg

†A-weighted sound pressure level in accordance to 2000/14/EC.

††Use semi-synthetic 2 stroke oil.

4.3 HANDLING AND STORAGE

Care must still be taken when handling and lifting. Dropping this machine will have an effect on the

accuracy and may also result in personal injury. This machine is not a toy and must be respected.

The environment will have a negative result on its operation if you are not careful. If the air is

damp, components will rust. If the machine is unprotected from dust and debris; components will

become clogged: And if not cleaned and maintained correctly or regularly the machine will not

perform at its best.

- 5 -- 20 -

10. MAINTENANCE AND TROUBLESHOOTING

10.4 TROUBLESHOOTING GUIDE (continued)

10.5 CLEANING AND MAINTENANCE OVERVIEW

Fault Possible cause Remedy

The motor does not

reach its maximum

speed.

Important: Please note, all repairs/servicing should be carried out by a qualified person.

1. The air filter is dirty.

2. The spark plug is dirty.

3. The distance between

the electrodes of the

spark plug is too large.

4. Wrong fuel.

1. Clean the air filter.

2. Clean the spark plug.

3. Set the gap to 0.6 to 0.7mm.

4. Drain the tank and fill with the

correct fuel.

Prior to every start.

Every 10 operating hours (more frequently in dusty conditions).

Every 10/15 operating hours.

Every 50 operating hours. (more frequently for reduced engine performance).

1. Check/clean/replace air filter element.

2. Check the pull starter for damage to the

starter .

3. Checking threaded connections for

tightness.

4. Remove dirt and debris from the

machine’s exterior

5. Inspect engine cooling fins for

accumulations of dirt and debris, clean as

necessary.

1. Check/clean/replace air filter element.

1. See section 10.1.

2. Visual inspection/testing.

3. Visual inspection/testing.

4. Visual inspection.

5. Visual inspection.

1. Check/clean/replace spark plug. 1. See section 10.2.

1. Inspect the entire machine and tubes for

damage, including loose or missing

components and repair as necessary.

2. Replace spark plug.

3. Inspect/replace fuel filter.

1. Visual inspection.

2. See section 10.2.

3. See section 10.3.

1. See section 10.1.

10.6 STORING THE MACHINE FOR AN EXTENDED PERIOD OF TIME

(3 MONTHS OR LONGER)

Before an extended period of disuse, you must remove the fuel from the machine.

– Drain the fuel tank, then start the engine and let it run until it stops of its own accord.

This manual suits for next models

1

Table of contents

Other Draper Blower manuals

Draper

Draper BV2201A User manual

Draper

Draper BP30A User manual

Draper

Draper BV2000 User manual

Draper

Draper BP25A User manual

Draper

Draper 70526 User manual

Draper

Draper BV3000 User manual

Draper

Draper 230V 2200W Garden Blower/Vacuum User manual

Draper

Draper BV3000 User manual

Draper

Draper BP25 User manual

Draper

Draper BP33 User manual