Tennant 3640E User manual

Other Tennant Blower manuals

Tennant

Tennant 800 User manual

Tennant

Tennant 6200 Training manual

Tennant

Tennant SweepSmart S20 ELECTRIC Training manual

Tennant

Tennant 6400 User manual

Tennant

Tennant 6600 User manual

Tennant

Tennant 340429 Training manual

Tennant

Tennant S6 User manual

Tennant

Tennant M17 Series Training manual

Tennant

Tennant S10 Operating and installation instructions

Tennant

Tennant 6500 User manual

Tennant

Tennant 800 User manual

Tennant

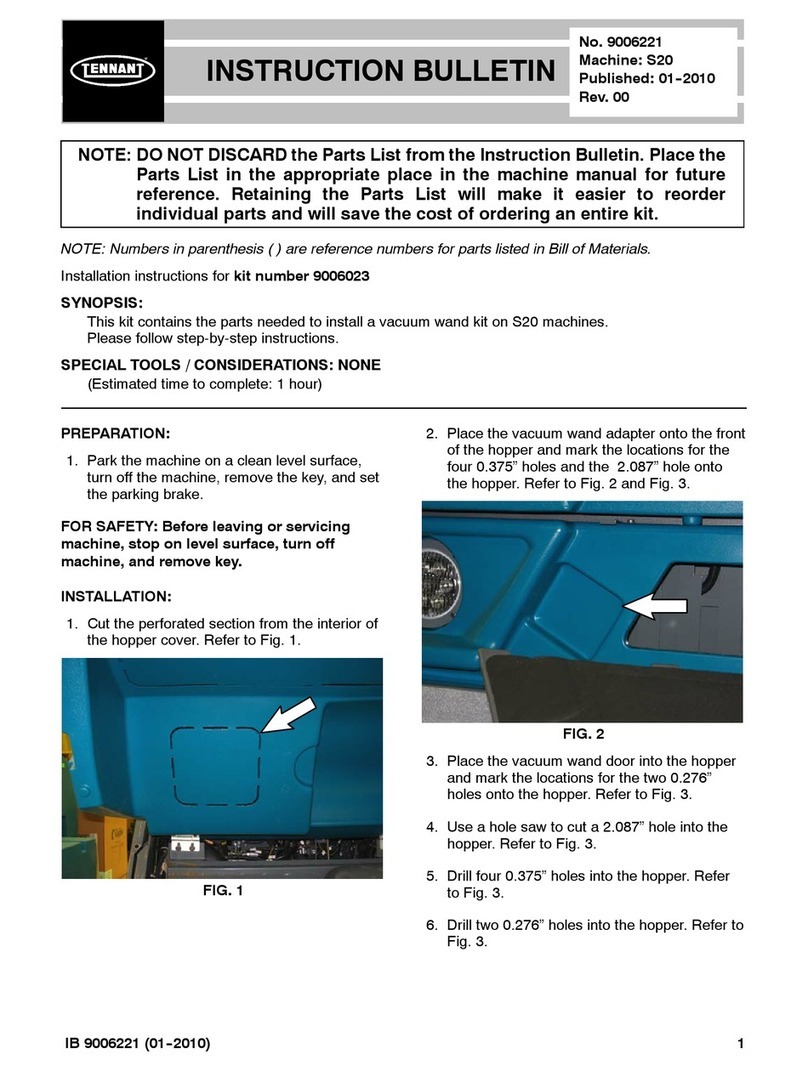

Tennant SweepSmart S20 ELECTRIC Operating and installation instructions

Tennant

Tennant 6100 Training manual

Tennant

Tennant S20 Gas User manual

Tennant

Tennant CENTURION User manual

Tennant

Tennant 6200 User manual

Tennant

Tennant ATLV 4300 Training manual

Tennant

Tennant SweepSmart S20 ELECTRIC User manual

Tennant

Tennant 614214-Tennant 3610 Product manual

Tennant

Tennant 800 User manual