Draper EC2000/PRO User manual

INSTRUCTIONS FOR

2 Tonne Folding

Hydraulic Engine Crane

Stock No.43924 Part No.EC2000/PRO

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY TO ENSURE THE SAFE AND

EFFECTIVE USE OF THIS PRODUCT.

GENERAL INFORMATION

Read all these instructions before operating this product and save these instructions.

This manual has been compiled by Draper Tools and is an integrated part of the product with which it is enclosed and

should be kept with it for future references.

This manual describes the purpose for which the product has been designed and contains all the necessary information

to ensure its correct and safe use. We recommend that this manual is read before any operation or, before performing

any kind of adjustment to the product and prior to any maintenance tasks. By following all the general safety instructions

contained in this manual, it will ensure both product and operator safety, together with longer life of the product itself.

All photographs and drawings in this manual are supplied by Draper Tools to help illustrate the operation of the product.

Whilst every effort has been made to ensure accuracy of information contained in this manual, the Draper Tools policy of

continuous improvement determines the right to make modifications without prior warning.

DECLARATION OF CONFORMITY

We :

Draper Tools Ltd., Hursley Road, Chandler’s Ford,

Eastleigh, Hampshire. SO53 1YF. England.

Declare under our sole responsibility that the product:

Stock No:- 43924.

Part No:- EC2000/PRO.

Description:- 2 TON ENGINE CRANE.

To which this declaration relates is in conformity with the following directive(s) 2006/42/EC.

J.N. Draper

Chairman 19/09/2007

INTRODUCTION

- Read these safety instructions carefully in addition to the instructions for use, operation and maintenance. Keep them in a

safe place for later consultation.

This crane has been designed for use as a hoist with extensive use in industry and garages, particularly in the handling of

engines. Any other application beyond the conditions established for use of this crane will be considered inappropriate.

Handle the crane correctly and ensure that all parts and components are in good condition and that no parts are missing.

Take special care with the elevation accessories used with the crane, such as slings, supports, compensators etc.

The crane should only be used by authorised persons, having read carefully and understood the contents of this manual.

Do not modify the crane in any way.

Non-compliance with these instructions may result in injury or damage to the user, the crane or the load to be lifted.

The manufacturer accepts no responsibility for the improper use of the crane.

SAFETY INSTRUCTIONS

- The load to be lifted should never exceed the rated capacity of the crane in each of the

positions of the hoisting arm.

- Ensure the element to be lifted against any type of slipping. Do not apply any lateral pressure

to the elevated or suspended load.

- The crane should be supported on a solid, level and horizontal, non-slip surface. It should be

well illuminated and free of unnecessary obstacles.

- The capacity of the crane is reduced as the arm is extended. For this, make sure that the load

capacity is never exceeded in each of the positions of the slide, as indicated on the adhesive

label.

- Both children and unauthorised persons should be kept away from the work area. During the

work, ensure that there is nobody in its path.

- Prior to proceeding to work with the crane, make sure that the slide is perfectly fitted to the

screw limit (1). The crane arm should be located in the nearest possible position to the load to

be elevated. Make sure that there are no elements in the vicinity which hinder the elevation of

the load or obstacles which prevent its lowering. When securing the load to the hook, always

use appropriate elevation elements with a capacity superior to that of the load to be elevated.

Check that the safety trigger functions correctly.

- To lift the load in a stable and balanced way, suspend it from the hook and bear in mind that

its centre of gravity should always be within the crane support base.

- Never allow the load to sway or lower it brusquely as this may prove to be dangerous (2 )

- Do not place any part of the body under the elevated load (3), and do not climb on top of the crane.

- The crane is not a transportation element but in the event that it is necessary to move the load a short distance, position

the arm of the crane in the lowest possible position. Once the movement has been completed, place the load on the

ground. The crane is not a device to maintain the load elevated for an unlimited period.

- As a safety measure against overload, the crane is fitted with an overload valve, set at its maximum working pressure at

the factory. This valve should not be tampered with under any circumstances.

FIG.18

ASSEMBLY, USE AND OPERATION

As we are handling heavy elements, it is essential to carry out the following assembly processes with the help of other

people.

- To assemble the legs (10 and 11) of foldable cranes, it is necessary to position the crane on the ground with the wheels in

the position indicated in Figure 18. Start by extracting the rivet (9) turning it until its fixed limit (C) which coincides with

the window. With the legs on the ground, introduce the rivet (9) in the outlets (A and B), making the fixed limit coincide

(C) with the outlet window. Turn the rivet slightly in order to prevent it from falling out, hence securing the legs to the

base of the crane. Perform the reverse operation to fold the legs.

- Prior to using the crane, the hydraulic circuit needs to be drained in order to eliminate any air from the valve system of the

hydraulic unit. From behind the crane, turn the handle 90º whilst pumping the hydraulic unit several times. By releasing

the handle (5), the crane is ready for use. Turn the hydraulic unit to activate the pump from the most comfortable work

position.

- To lift the load, activate the lever (2) which enables you to choose a comfortable position due to the fact it is revolving. If

lifting an engine, secure it at the points recommended by the manufacturer.

- If it is necessary to use the crane in other positions, the slide should be perfectly fitted to the limiting screw.

- To lower the load, turn the handle (5). This system enables the lowering to be regulated and controlled manually and

precisely. As another safety element, the crane is fitted with an LCS system to avoid brusque lowering resulting from a

possible incorrect manoeuvre. The crane will stop the lowering process when the handle is not activated.

- Following use of the crane, the piston of the hydraulic unit should be fully retracted. First move the slide to its initial

position (4).

- IMPORTANT: Both the maintenance and repair of this crane may only be carried out by qualified and authorized

personnel, who as a result of their training and experience are familiar with the hydraulic systems used in these devices.

- Clean and lubricate the axes of the moving parts of the crane (5) at regular intervals. The crane should be kept clean and

protected from aggressive conditions at all times.

- Only original spare parts should be used.

- Withdraw the crane from service if it is suspected that it has been subjected to abnormal loads or has suffered any type of

knock until the problem has been resolved.

- If the oil level needs to be checked or refilled, dismantle the hydraulic unit and with the piston fully retracted, remove the

filler plug and drain its contents into a container. With the hydraulic in a horizontal position, proceed to introduce the

necessary volume (avoid the entrance of any dirt with the new oil).

- IMPORTANT: An excess of oil over the volume required may affect the operation of the crane.

Only use hydraulic oil, HL or HM type, with an ISO grade of cinematic viscosity of 30cSt at 40ºC or of an Engler viscosity of

3 at 50ºC.

Extremely important: Never use brake fluid.

- When the crane is not in use, it should be fully retracted in the lowest position so as to minimize piston corrosion (4). It is

recommendable to apply an anti-corrosion product to the main piston and to the pump.

- Store the crane in a dry, clean place, out of the reach of children.

- At the end of the useful life of the crane, drain off the oil and hand it over to an authorised agent and dispose of the

remaining parts in accordance with local regulations.

- Both the repair kit, which exclusively contains the retainers and joints and the spare part sets must be ordered together.

ASSEMBLY, USE AND OPERATION

MAINTENANCE

12345

CONTACTS

- DRAPER TOOLS LIMITED,

Hursley Road, Chandler's Ford,

Eastleigh, Hampshire. SO53 1YF. U.K.

- Helpline: (023) 8049 4344

- Sales Desk: (023) 8049 4333

- General Enquiries: (023) 8026 6355

- Fax: (023) 8026 0784

- Internet: www.draper.co.uk

- Service/Warranty Repair Agent

For aftersales servicing or warranty repairs, please

contact the Draper Tools Helpline for details of an

agent in your local area.

YOUR DRAPER STOCKIST

OAKC021007

©Published by Draper Tools Limited.

No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, electronic, mechanical photocopying,

recording or otherwise without prior permission in writing from Draper Tools Ltd.

This manual suits for next models

1

Table of contents

Other Draper Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Upright

Upright SB-80 Service & parts manual

Knauf PFT

Knauf PFT SILOMAT trans plus 105 operating manual

Fayat Group

Fayat Group DYNAPAC CC1300C instruction manual

Underground Magnetics

Underground Magnetics Mag 8S manual

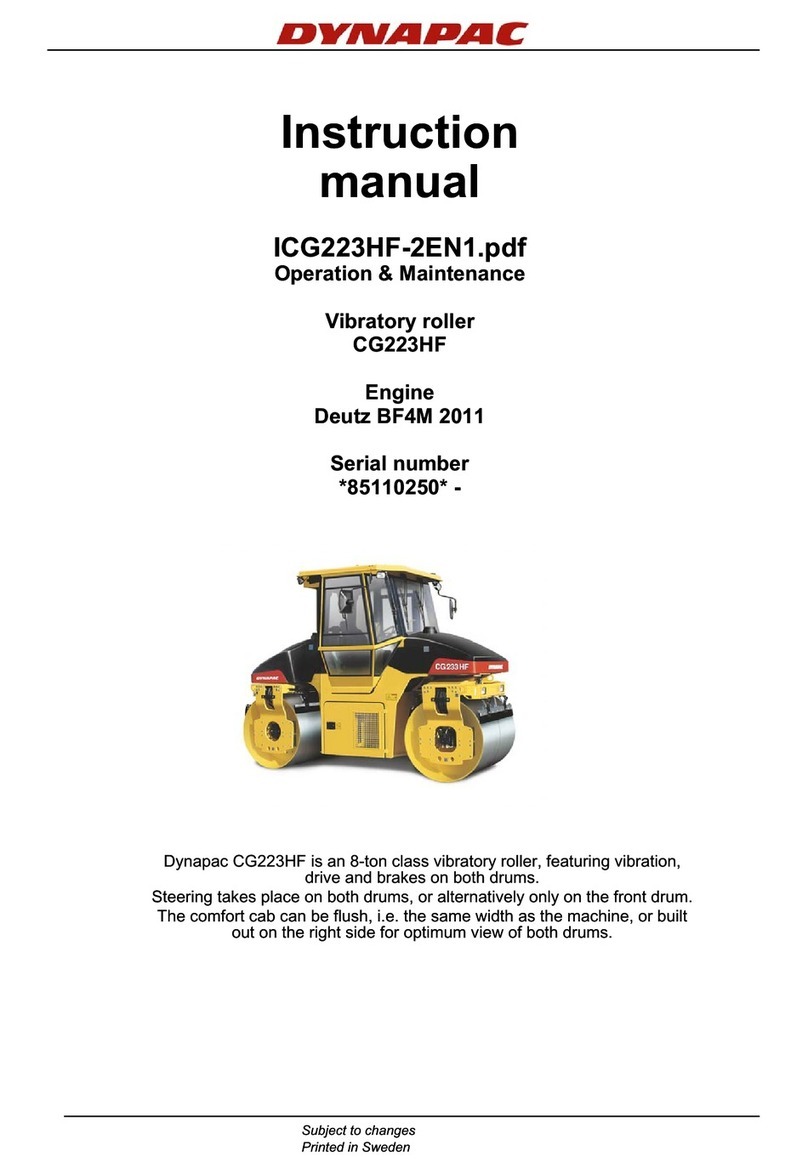

Dynapac

Dynapac CG223HF instruction manual

Altrad

Altrad BELLE RPC 60/80 Operator's manual