Draper TJ2/GD Manual

OPTIONAL ACCESSORIES

IMPORTANT SAFETY TIPS cont’d

2. CORRECT POSITIONING:

The jack should be positioned (normally

under the suspension near appropriate

front or rear wheels). Since these points

may vary with each vehicle, it is important

to consult the vehicle manufacturer’s

handbook.

- 4 -

3. TERRAIN:

The jack should be operated on a hard

and level surface as the location will

permit.

4. NEVER EXCEED THE JACK’S RATED

CAPACITY.

5. WORKING UNDER THE VEHICLE:

It is extremely important, when working

under the vehicle, to ensure axle stands

are always used.

DRAPER TOOLS LIMITED,

Hursley Road, Chandler's Ford,

Eastleigh, Hants. SO53 1YF. England.

Tel: (01703) 266355.

Fax: (01703) 260784.

©Published by Draper Tools Ltd.

No part of this publication may be reproduced,

stored in a retrieval system or transmitted in

any form or by any means, electronic, mechanical

photocopying, recording or otherwise without prior

permission in writing from Draper Tools Ltd.

TROUBLE PROBABLE CAUSE REMEDY

TROUBLE SHOOTING

Jack will not hold load.

Jack will not lift load.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Dirt on valve seats.

Air block.

The reservoir could be overfilled.

Low hydraulic oil level.

The pump cup seal could be worn

out.

Air block.

Unit needs lubrication.

(1) Lower the lifting arm, close

the release valve and remove

oil filler plug.

(2) Place one foot on a front

wheel and pull up the lifting

arm to its full height by hand.

(3) Open the release valve to

lower the lifting arm.

(4) Worn seals.

(1) Open the release valve and

remove oil filler plug.

(2) Pump handle a couple of full

strokes and close the release

valve.

Check the oil level.

Remove the filler plug. Top up oil

to correct level.

Replace the cup seal with a new

one.

Release air by removing filler

plug.

Oil external moving parts.

- 5 -

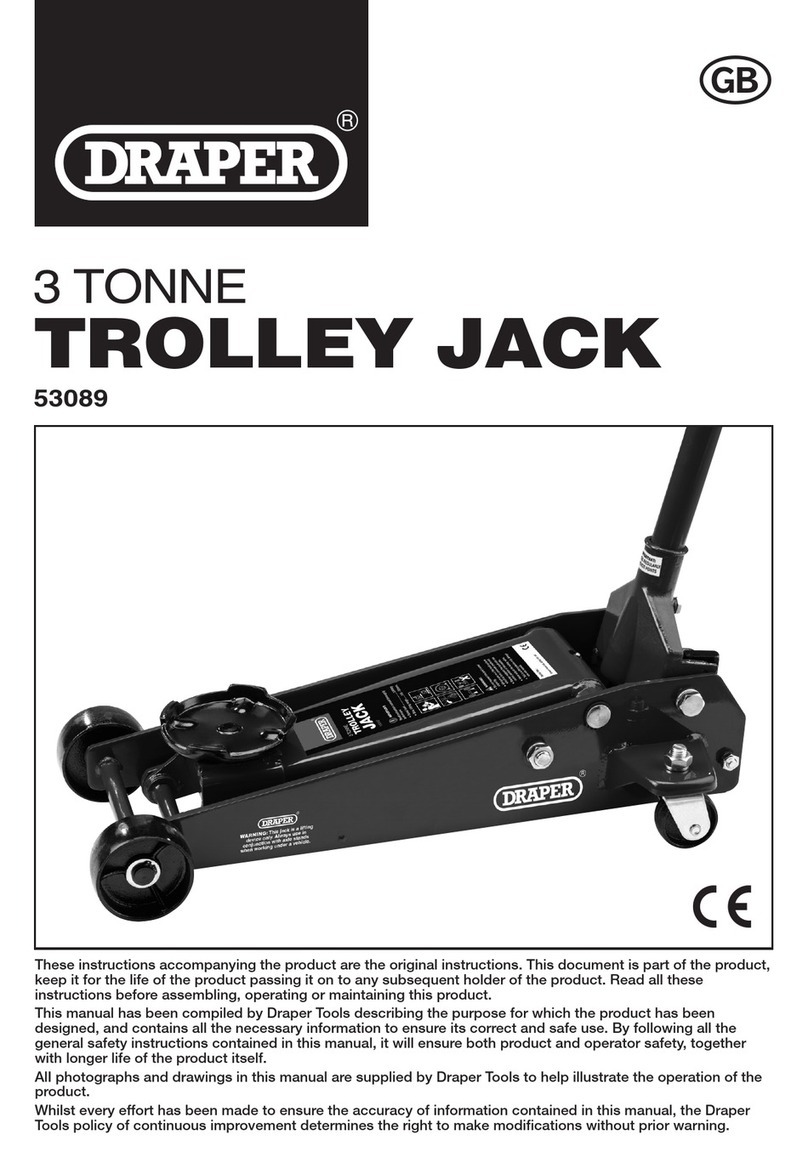

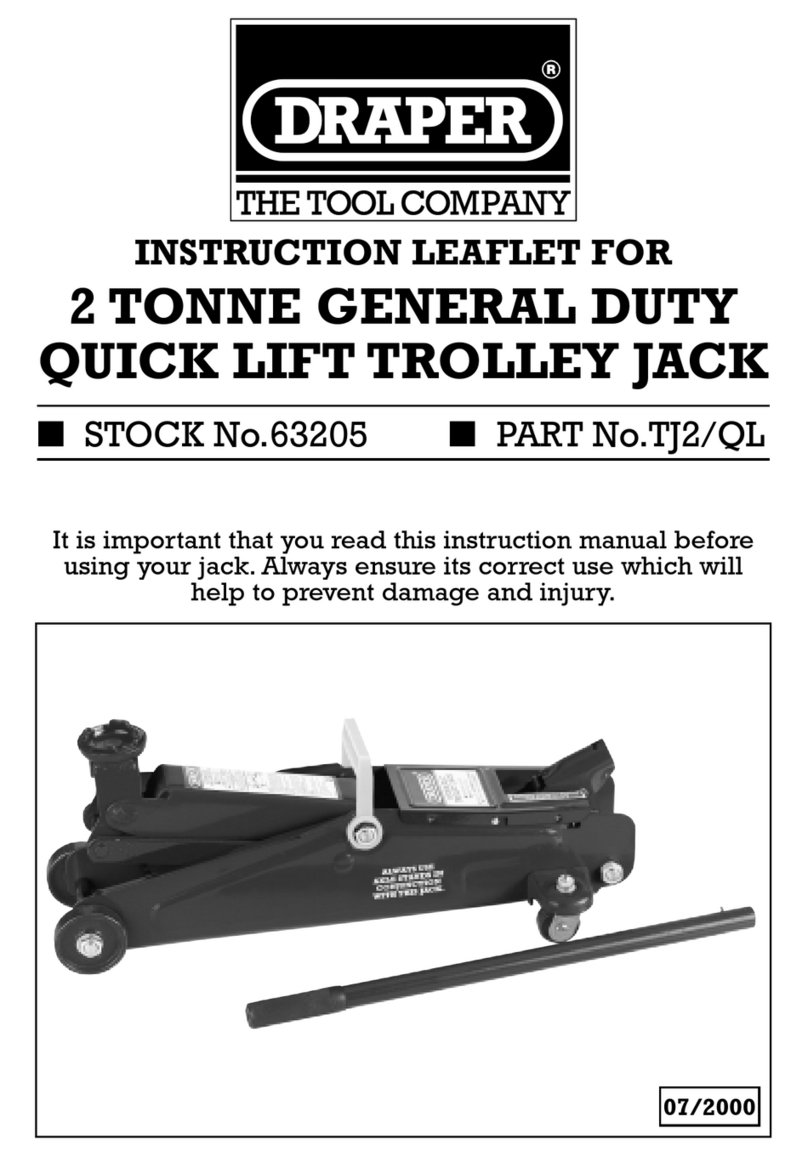

INSTRUCTION LEAFLET FOR

2 TONNE TROLLEY JACK

GENERAL DUTY

■STOCK No.37173 ■PART No.TJ2/GD

04/98

It is important that you read this instruction manual before

using your jack. Always ensure its correct use which will

help to prevent damage and injury.

FOLDING AXLE STANDS

PART No.FAS18

STOCK No.36524

FRONT

WHEELS

REAR

WHEELS

SUGGESTED

JACKING

POINTS

- 1 -

CAUTION:

• Use only on a firm, level surface.

• Do not exceed the rated capacity of this jack.

• This is a lifting device only...do not work under the vehicle without proper support

devices, such as axle stands.

• Make sure that the lifting point is stable and correctly centred on the jack saddle.

• Familiarize yourself thoroughly with this manual before operating to prevent damage

to the jack, property, or personal injury.

CAUTION

SPECIFICATION FOR: Hydraulic Trolley Jack.

Capacity ..............................................................................................................2,000kg

Lifting range ................................................................................................100 x 390mm

Overall size ........................................................................................630 x 250 x 140mm

Weight ..............................................................................................................9.5kg nett

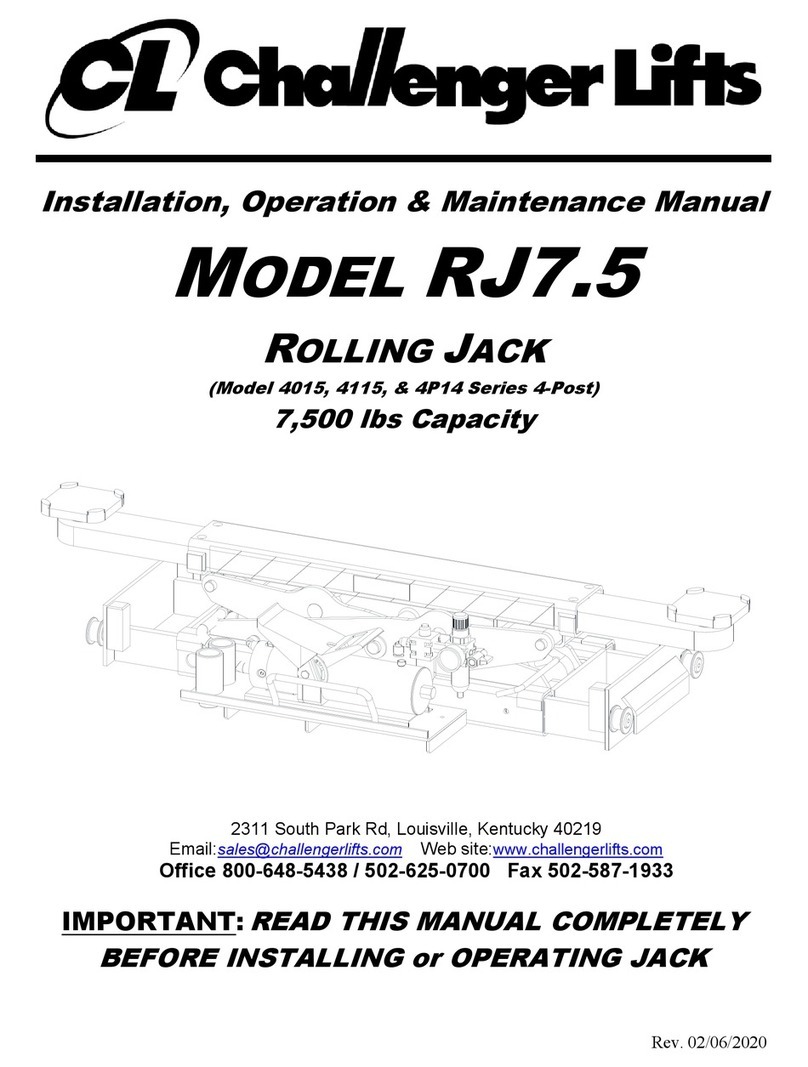

KNOW YOUR TROLLEY JACK

1. Cylinder Pump.

2. Release Valve.

3. Base.

4. Castor.

5. Oil Filler Plug.

6. Reservoir.

7. Middle Spindle.

8. Frame.

9. Front Wheel.

10. Radius Link.

11. Saddle.

12. Lifting Arm.

13. Handle Sleeve.

14. Jack Handle.

BEFORE USE

1. If oil spillage is noted, check oil level, refer to maintenance section, paragraphs 3

and 4, on page 3.

2. Check to see that the release valve is opened. (Never more than two full turns), then

insert the handle into handle sleeve and pump a couple of full strokes to purge any

air from the system and evenly distribute the hydraulic oil.

- 2 -

1. Firmly lock release valve in a clockwise

direction with the end of the jack handle.

2. Place the handle in the sleeve to position

the jack under the lifting point. Check that

the saddle is correctly positioned.

To prevent damage to the jack, or the

vehicle, NEVER MOVE THE JACK WITH THE

HANDLE ON THE RELEASE VALVE.

3. To raise load, insert handle into handle

sleeve and pump up and down fully, until

the desired height is reached.

4. ALWAYS USE AXLE STANDS.

5. To lower load, slowly turn the release valve

anticlockwise two full turns with the end of

the jack handle.

OPERATING INSTRUCTIONS

CARE AND MAINTENANCE

1. When the jack is not in use, the lifting arm and handle sleeve should be kept in the

fully down position.

2. Keep the jack clean and lubricated. Oil the points indicated on the diagram below

on a regular basis.

3. To check oil level, fully lower jack on level

ground and remove cover plate (Item 13).

Remove filler plug . The correct level is 5mm

below filler plug hole. If low, add oil as

needed.YOUR JACK WAS FILLED AT THE

FACTORY WITH HIGH GRADE HYDRAULIC

OIL. ONLY USE APPROVED JACK OIL*.

4. After extensive use, the oil supply should be

replaced to ensure longer equipment life. To

drain, remove filler plug and release valve.

Ensure that no dirt gets into the system. Refill

with approved jack oil, as paragraph 3.

5. Check pump piston rod periodically for signs of rust or corrosion. Clean exposed

area with a clean oiled cloth.

* We recommend Shell Telus 22.

- 3-

1. BEFORE POSITIONING THE JACK,YOU SHOULD ENSURE THE FOLLOWING:

IMPORTANT SAFETY TIPS

A. Vehicle should be clear of all

passengers. Transmission should be

in gear (or ‘Park’ for automatic

transmissions) and the handbrake

applied.

B. To prevent vehicle from movement,

wheels should be securely blocked

with wheel chocks.

250mm

20mm

630mm

66mm

100mm

390mm

14mm

40mm

6.

7. 8.

9.

10. 11.

12.

5. 4.

3.

2.

1.

14.

13.

OIL FILLER PLUG

HANDLE SLEEVE

OPEN RELEASE VALVE

ANTICLOCKWISE

CLOSING RELEASE

VALVE CLOCKWISE

TO RAISE:

TURN RELEASE

VALVE

CLOCKWISE

TO LOWER:

TURN RELEASE

VALVE

ANTICLOCKWISE

LUBRICATION

POINTS

➦

➦

❖

- 1 -

CAUTION:

• Use only on a firm, level surface.

• Do not exceed the rated capacity of this jack.

• This is a lifting device only...do not work under the vehicle without proper support

devices, such as axle stands.

• Make sure that the lifting point is stable and correctly centred on the jack saddle.

• Familiarize yourself thoroughly with this manual before operating to prevent damage

to the jack, property, or personal injury.

CAUTION

SPECIFICATION FOR: Hydraulic Trolley Jack.

Capacity ..............................................................................................................2,000kg

Lifting range ................................................................................................100 x 390mm

Overall size ........................................................................................630 x 250 x 140mm

Weight ..............................................................................................................9.5kg nett

KNOW YOUR TROLLEY JACK

1. Cylinder Pump.

2. Release Valve.

3. Base.

4. Castor.

5. Oil Filler Plug.

6. Reservoir.

7. Middle Spindle.

8. Frame.

9. Front Wheel.

10. Radius Link.

11. Saddle.

12. Lifting Arm.

13. Handle Sleeve.

14. Jack Handle.

BEFORE USE

1. If oil spillage is noted, check oil level, refer to maintenance section, paragraphs 3

and 4, on page 3.

2. Check to see that the release valve is opened. (Never more than two full turns), then

insert the handle into handle sleeve and pump a couple of full strokes to purge any

air from the system and evenly distribute the hydraulic oil.

- 2 -

1. Firmly lock release valve in a clockwise

direction with the end of the jack handle.

2. Place the handle in the sleeve to position

the jack under the lifting point. Check that

the saddle is correctly positioned.

To prevent damage to the jack, or the

vehicle, NEVER MOVE THE JACK WITH THE

HANDLE ON THE RELEASE VALVE.

3. To raise load, insert handle into handle

sleeve and pump up and down fully, until

the desired height is reached.

4. ALWAYS USE AXLE STANDS.

5. To lower load, slowly turn the release valve

anticlockwise two full turns with the end of

the jack handle.

OPERATING INSTRUCTIONS

CARE AND MAINTENANCE

1. When the jack is not in use, the lifting arm and handle sleeve should be kept in the

fully down position.

2. Keep the jack clean and lubricated. Oil the points indicated on the diagram below

on a regular basis.

3. To check oil level, fully lower jack on level

ground and remove cover plate (Item 13).

Remove filler plug . The correct level is 5mm

below filler plug hole. If low, add oil as

needed.YOUR JACK WAS FILLED AT THE

FACTORY WITH HIGH GRADE HYDRAULIC

OIL. ONLY USE APPROVED JACK OIL*.

4. After extensive use, the oil supply should be

replaced to ensure longer equipment life. To

drain, remove filler plug and release valve.

Ensure that no dirt gets into the system. Refill

with approved jack oil, as paragraph 3.

5. Check pump piston rod periodically for signs of rust or corrosion. Clean exposed

area with a clean oiled cloth.

* We recommend Shell Telus 22.

- 3-

1. BEFORE POSITIONING THE JACK,YOU SHOULD ENSURE THE FOLLOWING:

IMPORTANT SAFETY TIPS

A. Vehicle should be clear of all

passengers. Transmission should be

in gear (or ‘Park’ for automatic

transmissions) and the handbrake

applied.

B. To prevent vehicle from movement,

wheels should be securely blocked

with wheel chocks.

250mm

20mm

630mm

66mm

100mm

390mm

14mm

40mm

6.

7. 8.

9.

10. 11.

12.

5. 4.

3.

2.

1.

14.

13.

OIL FILLER PLUG

HANDLE SLEEVE

OPEN RELEASE VALVE

ANTICLOCKWISE

CLOSING RELEASE

VALVE CLOCKWISE

TO RAISE:

TURN RELEASE

VALVE

CLOCKWISE

TO LOWER:

TURN RELEASE

VALVE

ANTICLOCKWISE

LUBRICATION

POINTS

➦

➦

❖

- 1 -

CAUTION:

• Use only on a firm, level surface.

• Do not exceed the rated capacity of this jack.

• This is a lifting device only...do not work under the vehicle without proper support

devices, such as axle stands.

• Make sure that the lifting point is stable and correctly centred on the jack saddle.

• Familiarize yourself thoroughly with this manual before operating to prevent damage

to the jack, property, or personal injury.

CAUTION

SPECIFICATION FOR: Hydraulic Trolley Jack.

Capacity ..............................................................................................................2,000kg

Lifting range ................................................................................................100 x 390mm

Overall size ........................................................................................630 x 250 x 140mm

Weight ..............................................................................................................9.5kg nett

KNOW YOUR TROLLEY JACK

1. Cylinder Pump.

2. Release Valve.

3. Base.

4. Castor.

5. Oil Filler Plug.

6. Reservoir.

7. Middle Spindle.

8. Frame.

9. Front Wheel.

10. Radius Link.

11. Saddle.

12. Lifting Arm.

13. Handle Sleeve.

14. Jack Handle.

BEFORE USE

1. If oil spillage is noted, check oil level, refer to maintenance section, paragraphs 3

and 4, on page 3.

2. Check to see that the release valve is opened. (Never more than two full turns), then

insert the handle into handle sleeve and pump a couple of full strokes to purge any

air from the system and evenly distribute the hydraulic oil.

- 2 -

1. Firmly lock release valve in a clockwise

direction with the end of the jack handle.

2. Place the handle in the sleeve to position

the jack under the lifting point. Check that

the saddle is correctly positioned.

To prevent damage to the jack, or the

vehicle, NEVER MOVE THE JACK WITH THE

HANDLE ON THE RELEASE VALVE.

3. To raise load, insert handle into handle

sleeve and pump up and down fully, until

the desired height is reached.

4. ALWAYS USE AXLE STANDS.

5. To lower load, slowly turn the release valve

anticlockwise two full turns with the end of

the jack handle.

OPERATING INSTRUCTIONS

CARE AND MAINTENANCE

1. When the jack is not in use, the lifting arm and handle sleeve should be kept in the

fully down position.

2. Keep the jack clean and lubricated. Oil the points indicated on the diagram below

on a regular basis.

3. To check oil level, fully lower jack on level

ground and remove cover plate (Item 13).

Remove filler plug . The correct level is 5mm

below filler plug hole. If low, add oil as

needed.YOUR JACK WAS FILLED AT THE

FACTORY WITH HIGH GRADE HYDRAULIC

OIL. ONLY USE APPROVED JACK OIL*.

4. After extensive use, the oil supply should be

replaced to ensure longer equipment life. To

drain, remove filler plug and release valve.

Ensure that no dirt gets into the system. Refill

with approved jack oil, as paragraph 3.

5. Check pump piston rod periodically for signs of rust or corrosion. Clean exposed

area with a clean oiled cloth.

* We recommend Shell Telus 22.

- 3-

1. BEFORE POSITIONING THE JACK,YOU SHOULD ENSURE THE FOLLOWING:

IMPORTANT SAFETY TIPS

A. Vehicle should be clear of all

passengers. Transmission should be

in gear (or ‘Park’ for automatic

transmissions) and the handbrake

applied.

B. To prevent vehicle from movement,

wheels should be securely blocked

with wheel chocks.

250mm

20mm

630mm

66mm

100mm

390mm

14mm

40mm

6.

7. 8.

9.

10. 11.

12.

5. 4.

3.

2.

1.

14.

13.

OIL FILLER PLUG

HANDLE SLEEVE

OPEN RELEASE VALVE

ANTICLOCKWISE

CLOSING RELEASE

VALVE CLOCKWISE

TO RAISE:

TURN RELEASE

VALVE

CLOCKWISE

TO LOWER:

TURN RELEASE

VALVE

ANTICLOCKWISE

LUBRICATION

POINTS

➦

➦

❖

OPTIONAL ACCESSORIES

IMPORTANT SAFETY TIPS cont’d

2. CORRECT POSITIONING:

The jack should be positioned (normally

under the suspension near appropriate

front or rear wheels). Since these points

may vary with each vehicle, it is important

to consult the vehicle manufacturer’s

handbook.

- 4 -

3. TERRAIN:

The jack should be operated on a hard

and level surface as the location will

permit.

4. NEVER EXCEED THE JACK’S RATED

CAPACITY.

5. WORKING UNDER THE VEHICLE:

It is extremely important, when working

under the vehicle, to ensure axle stands

are always used.

DRAPER TOOLS LIMITED,

Hursley Road, Chandler's Ford,

Eastleigh, Hants. SO53 1YF. England.

Tel: (01703) 266355.

Fax: (01703) 260784.

©Published by Draper Tools Ltd.

No part of this publication may be reproduced,

stored in a retrieval system or transmitted in

any form or by any means, electronic, mechanical

photocopying, recording or otherwise without prior

permission in writing from Draper Tools Ltd.

TROUBLE PROBABLE CAUSE REMEDY

TROUBLE SHOOTING

Jack will not hold load.

Jack will not lift load.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Dirt on valve seats.

Air block.

The reservoir could be overfilled.

Low hydraulic oil level.

The pump cup seal could be worn

out.

Air block.

Unit needs lubrication.

(1) Lower the lifting arm, close

the release valve and remove

oil filler plug.

(2) Place one foot on a front

wheel and pull up the lifting

arm to its full height by hand.

(3) Open the release valve to

lower the lifting arm.

(4) Worn seals.

(1) Open the release valve and

remove oil filler plug.

(2) Pump handle a couple of full

strokes and close the release

valve.

Check the oil level.

Remove the filler plug. Top up oil

to correct level.

Replace the cup seal with a new

one.

Release air by removing filler

plug.

Oil external moving parts.

- 5 -

INSTRUCTION LEAFLET FOR

2 TONNE TROLLEY JACK

GENERAL DUTY

■STOCK No.37173 ■PART No.TJ2/GD

04/98

It is important that you read this instruction manual before

using your jack. Always ensure its correct use which will

help to prevent damage and injury.

FOLDING AXLE STANDS

PART No.FAS18

STOCK No.36524

FRONT

WHEELS

REAR

WHEELS

SUGGESTED

JACKING

POINTS

OPTIONAL ACCESSORIES

IMPORTANT SAFETY TIPS cont’d

2. CORRECT POSITIONING:

The jack should be positioned (normally

under the suspension near appropriate

front or rear wheels). Since these points

may vary with each vehicle, it is important

to consult the vehicle manufacturer’s

handbook.

- 4 -

3. TERRAIN:

The jack should be operated on a hard

and level surface as the location will

permit.

4. NEVER EXCEED THE JACK’S RATED

CAPACITY.

5. WORKING UNDER THE VEHICLE:

It is extremely important, when working

under the vehicle, to ensure axle stands

are always used.

DRAPER TOOLS LIMITED,

Hursley Road, Chandler's Ford,

Eastleigh, Hants. SO53 1YF. England.

Tel: (01703) 266355.

Fax: (01703) 260784.

©Published by Draper Tools Ltd.

No part of this publication may be reproduced,

stored in a retrieval system or transmitted in

any form or by any means, electronic, mechanical

photocopying, recording or otherwise without prior

permission in writing from Draper Tools Ltd.

TROUBLE PROBABLE CAUSE REMEDY

TROUBLE SHOOTING

Jack will not hold load.

Jack will not lift load.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Jack will not lift to its full height.

Jack pump feels unsteady under

load.

Jack pump feels unsteady under

load.

Jack will not lower completely.

Dirt on valve seats.

Air block.

The reservoir could be overfilled.

Low hydraulic oil level.

The pump cup seal could be worn

out.

Air block.

Unit needs lubrication.

(1) Lower the lifting arm, close

the release valve and remove

oil filler plug.

(2) Place one foot on a front

wheel and pull up the lifting

arm to its full height by hand.

(3) Open the release valve to

lower the lifting arm.

(4) Worn seals.

(1) Open the release valve and

remove oil filler plug.

(2) Pump handle a couple of full

strokes and close the release

valve.

Check the oil level.

Remove the filler plug. Top up oil

to correct level.

Replace the cup seal with a new

one.

Release air by removing filler

plug.

Oil external moving parts.

- 5 -

INSTRUCTION LEAFLET FOR

2 TONNE TROLLEY JACK

GENERAL DUTY

■STOCK No.37173 ■PART No.TJ2/GD

04/98

It is important that you read this instruction manual before

using your jack. Always ensure its correct use which will

help to prevent damage and injury.

FOLDING AXLE STANDS

PART No.FAS18

STOCK No.36524

FRONT

WHEELS

REAR

WHEELS

SUGGESTED

JACKING

POINTS

Table of contents

Other Draper Jack manuals

Draper

Draper 53089 User manual

Draper

Draper 16407 User manual

Draper

Draper 02078 User manual

Draper

Draper 13064 User manual

Draper

Draper TJ2250B User manual

Draper

Draper 24276 User manual

Draper

Draper 78611 User manual

Draper

Draper TJ2LD-LE User manual

Draper

Draper TJ100B User manual

Draper

Draper TJ2/QL Manual