Draper 60981 User manual

Other Draper Power Tools manuals

Draper

Draper MR1350K User manual

Draper

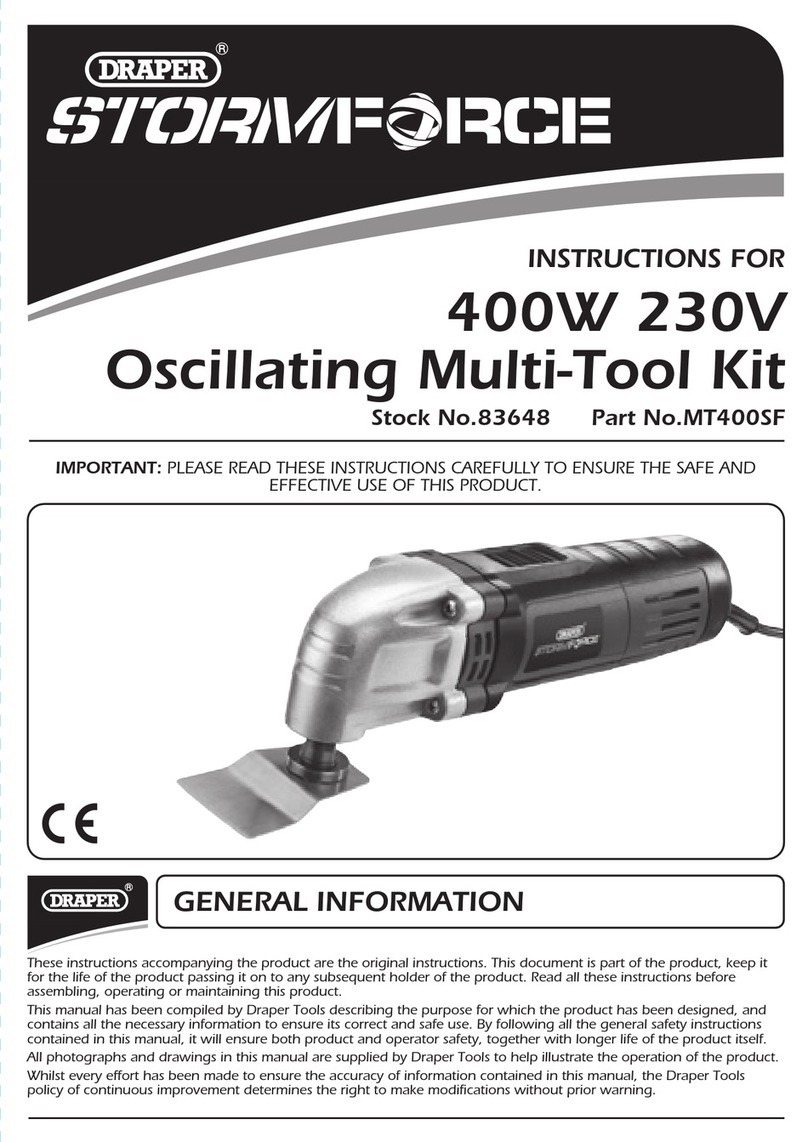

Draper Storm Force 83648 User manual

Draper

Draper PT141K Firmware update

Draper

Draper 3004A User manual

Draper

Draper STORMFORCE PT142KSF User manual

Draper

Draper 13274 User manual

Draper

Draper 70276 User manual

Draper

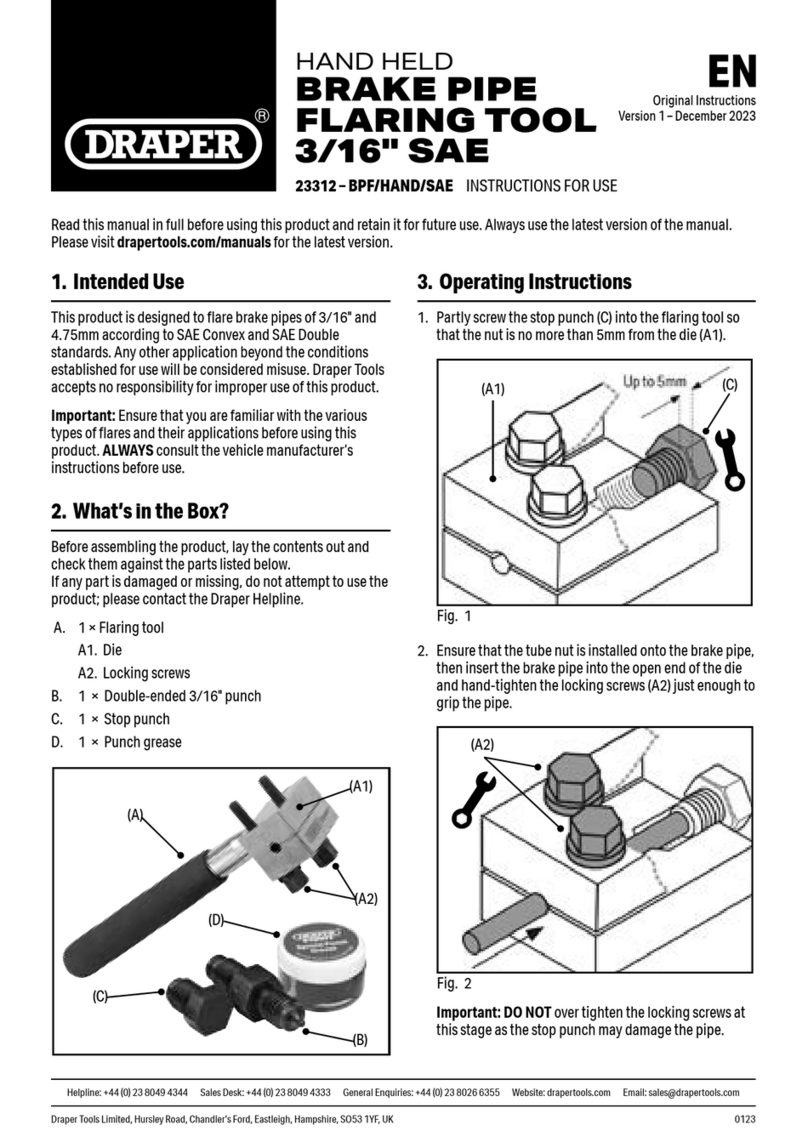

Draper 23312 User manual

Draper

Draper Storm Force SFASK1025 User manual

Draper

Draper Storm Force PT8100SF User manual

Draper

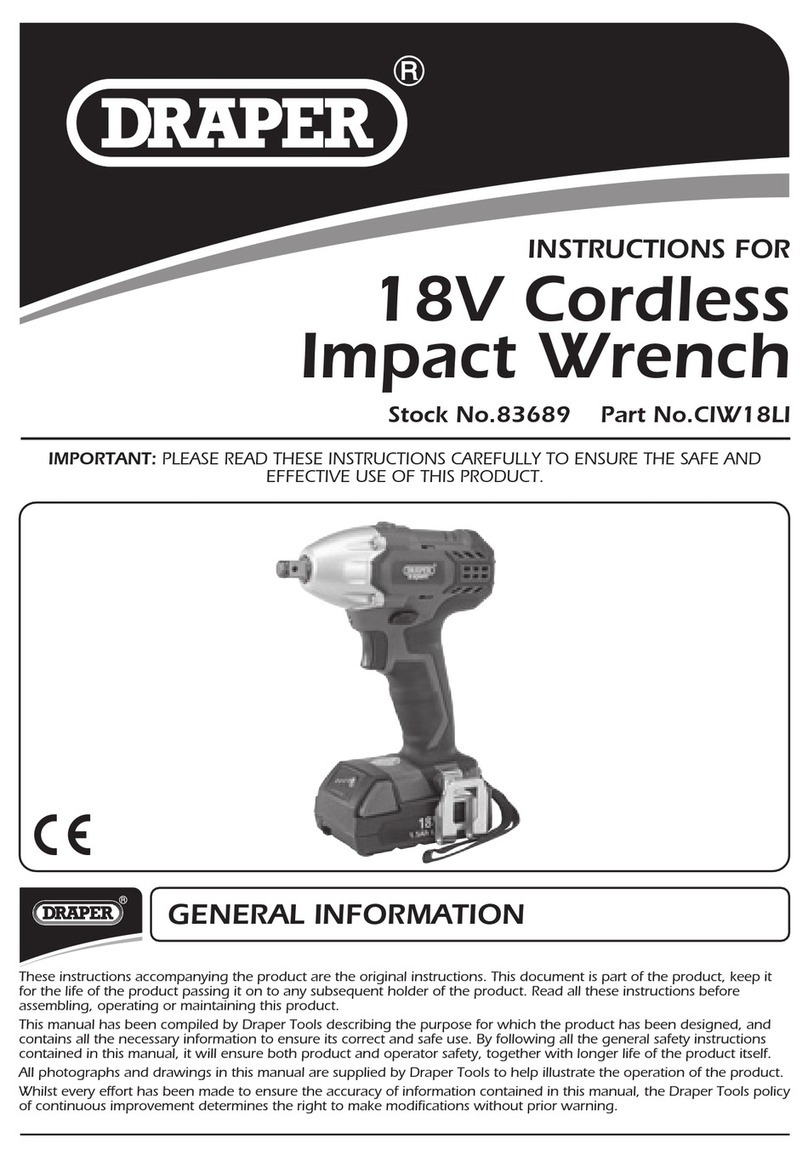

Draper CIW18LI User manual

Draper

Draper D20 User manual

Draper

Draper PHD1050MAX User manual

Draper

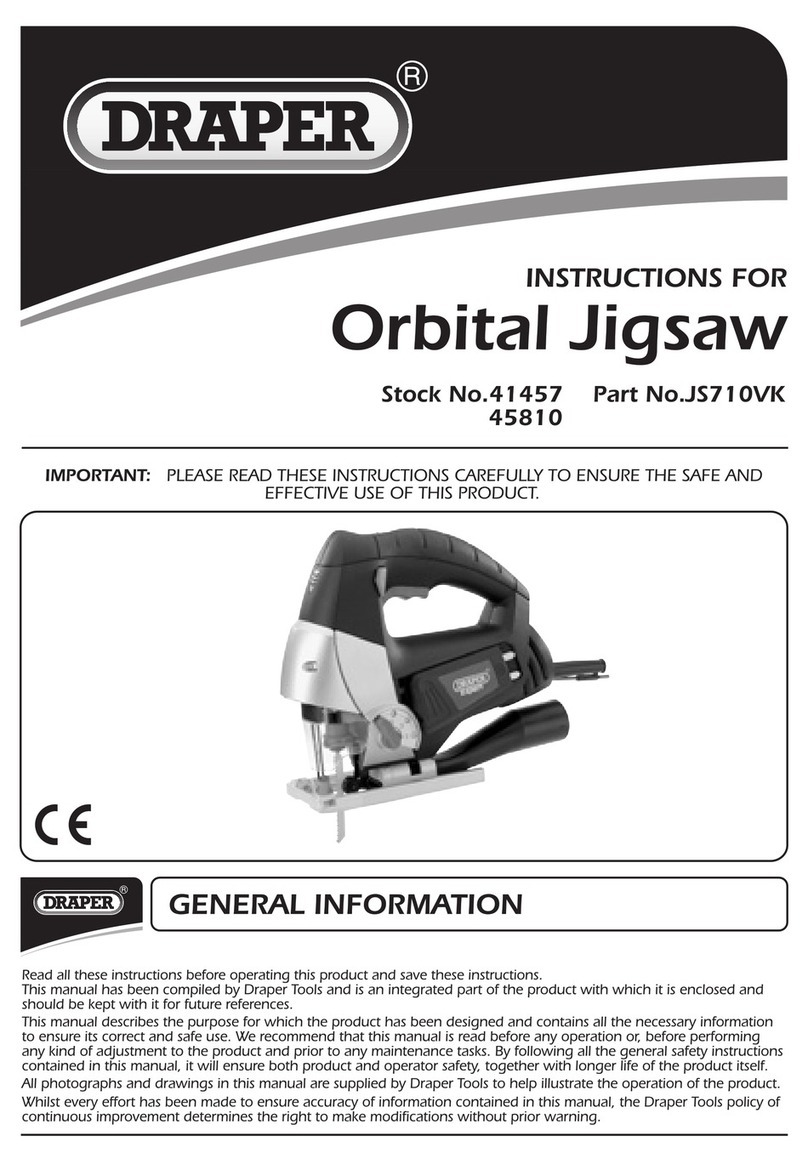

Draper JS710VK User manual

Draper

Draper HG2004A User manual

Draper

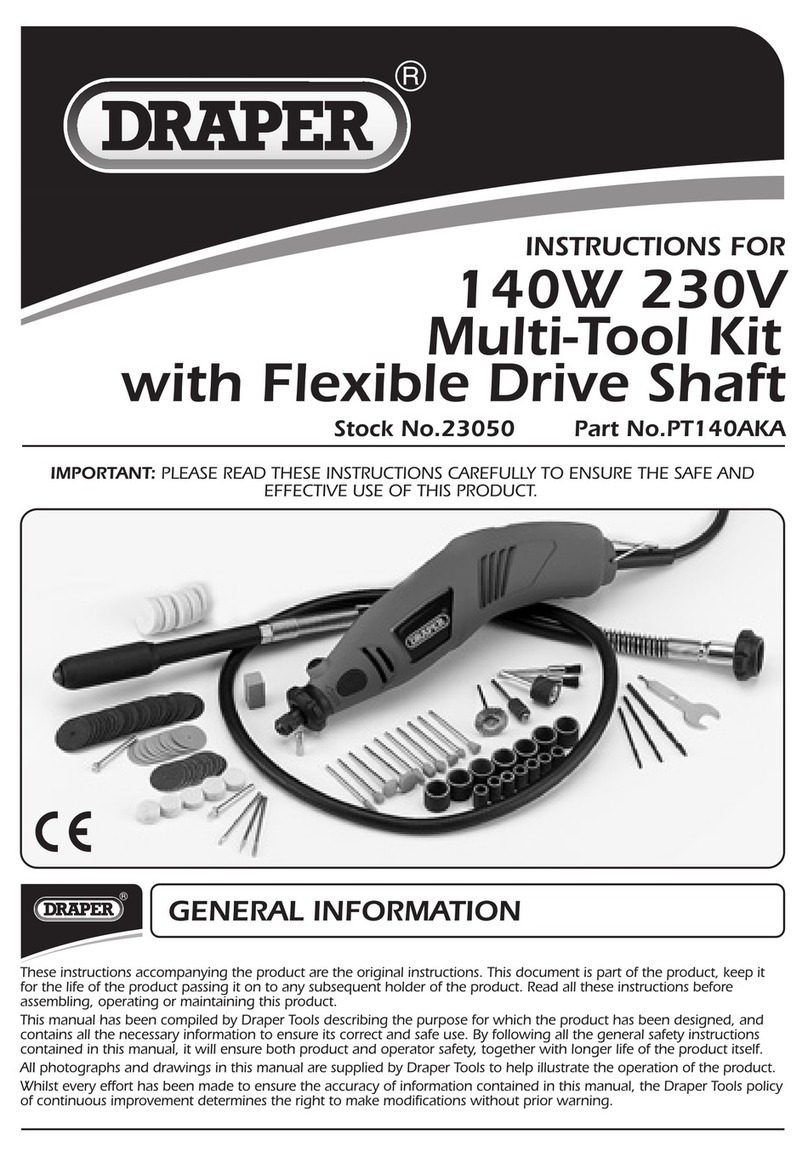

Draper PT140AKA User manual

Draper

Draper BR15A User manual

Draper

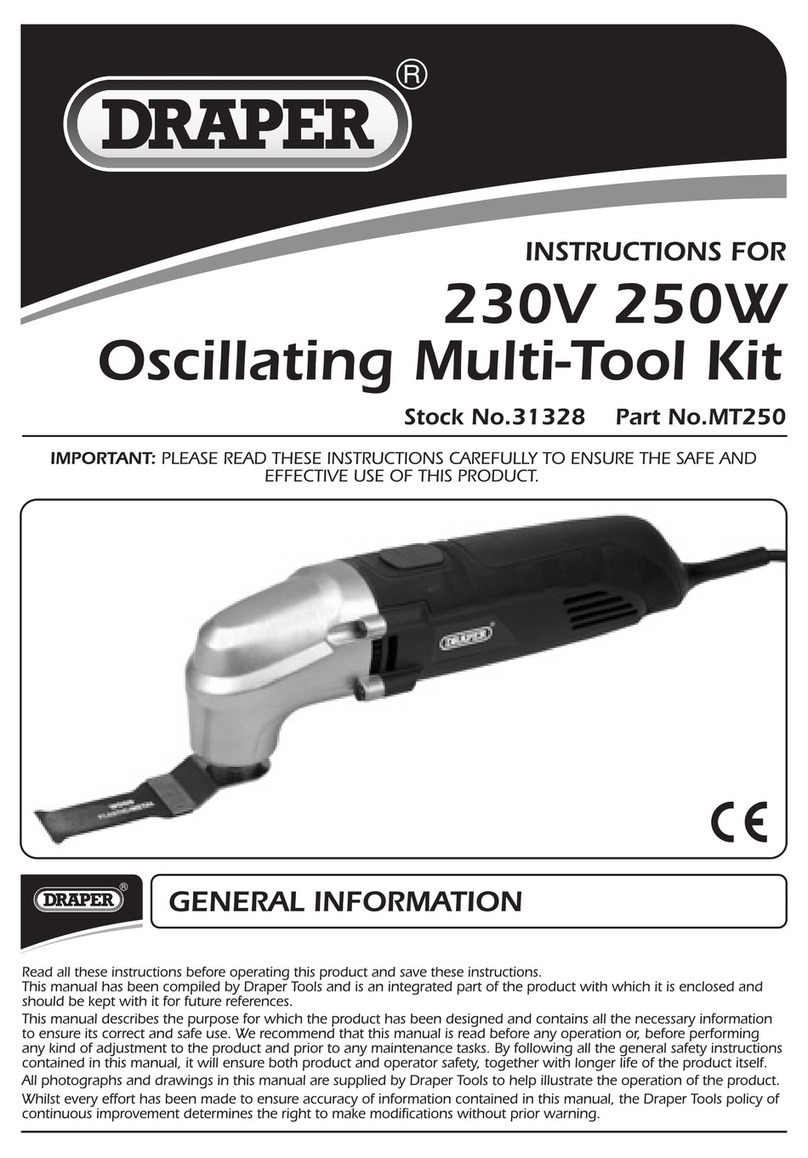

Draper MT250 User manual

Draper

Draper FS16VA User manual

Draper

Draper ETW6-30 User manual

Popular Power Tools manuals by other brands

Central Machinery

Central Machinery 90589 Assembly and operating instructions

Stanley

Stanley FATMAX SFMCHT855 Original instructions

Eaton

Eaton MBS-I2 Instruction leaflet

Dremel

Dremel 8220 Operating/safety instructions

Stanley

Stanley 150703XSTN Instruction manual for owner's use

Grad-M

Grad-M DA-18N-PDK user manual

Bosch

Bosch Professional GSR 12V- 15 FC Original instructions

Everwin

Everwin FS9240BC Operation and maintenance manual

Gearwrench

Gearwrench 85076 operating instructions

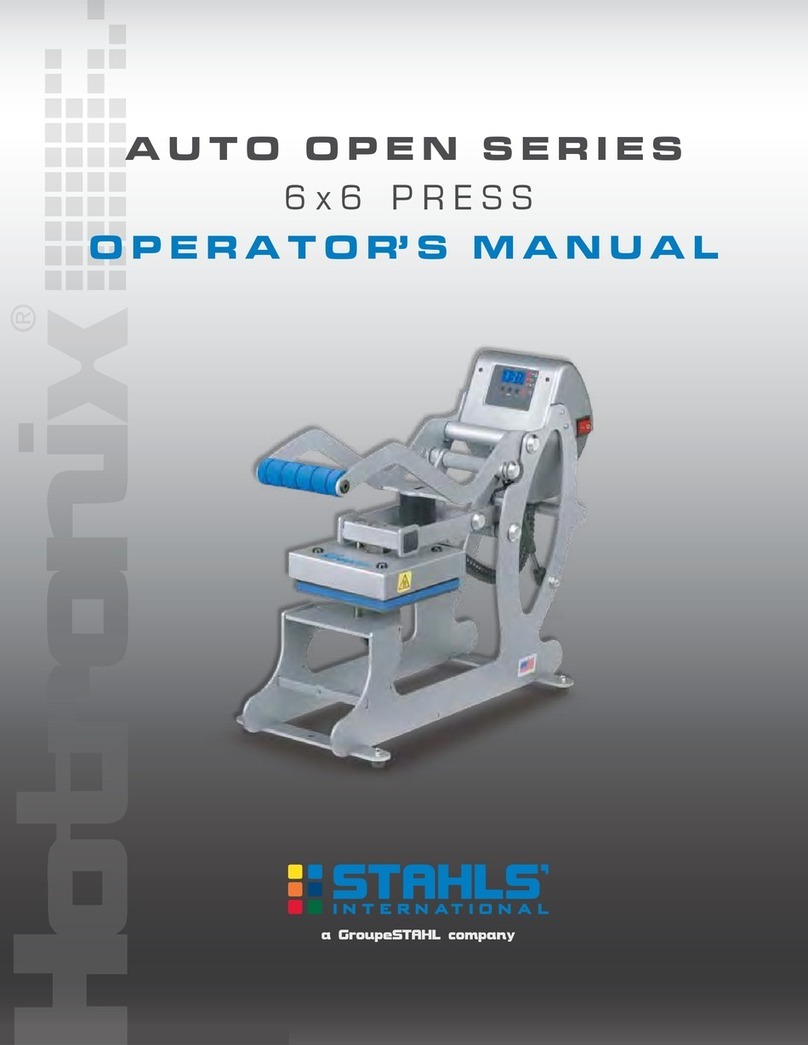

Hotronix

Hotronix Auto Open 6x6 Operator's manual

Jet

Jet JWS-20CS Operating instructions and parts manual

Atlas Copco

Atlas Copco ETV ST81-50-10 manual

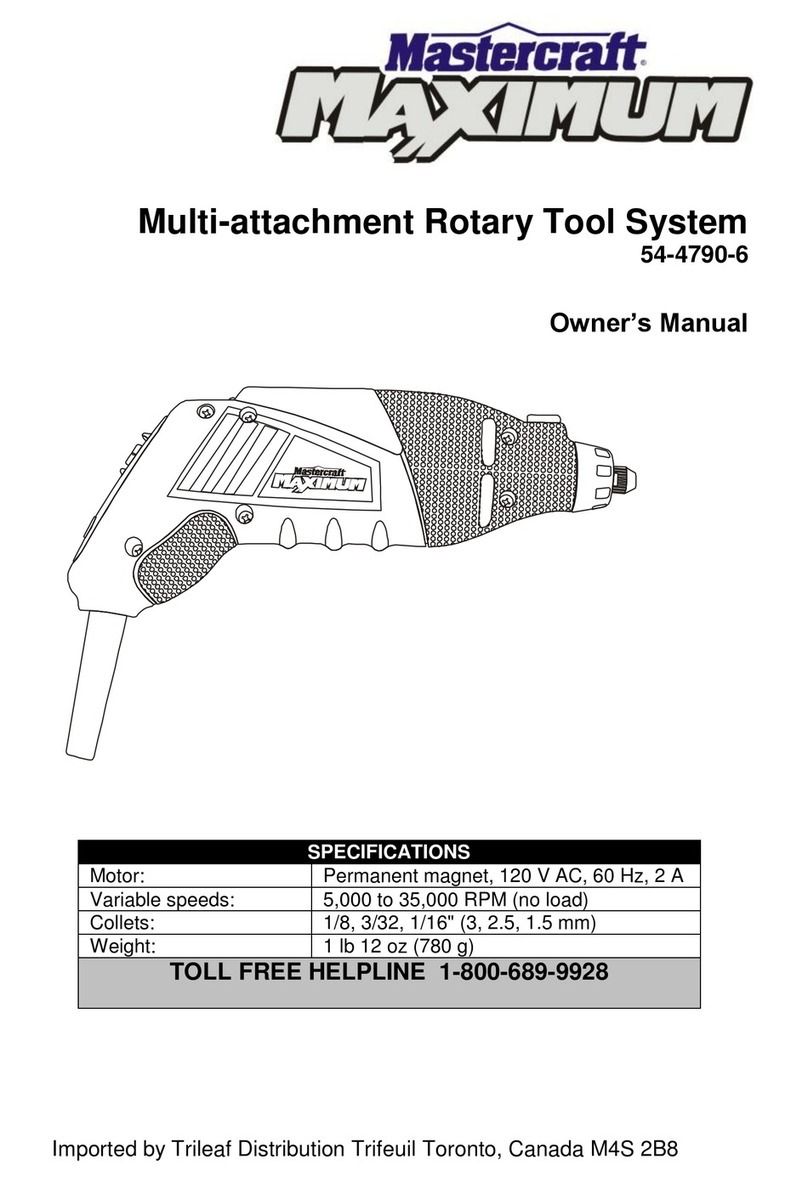

MasterCraft

MasterCraft 54-4790-6 owner's manual

Hilti

Hilti WSJ 750 manual

Wassermann Dental-Maschinen

Wassermann Dental-Maschinen HSM-500 user manual

Chicago Electric

Chicago Electric 33710 Assembly & operating instructions

NARGESA

NARGESA MC400 Instruction book

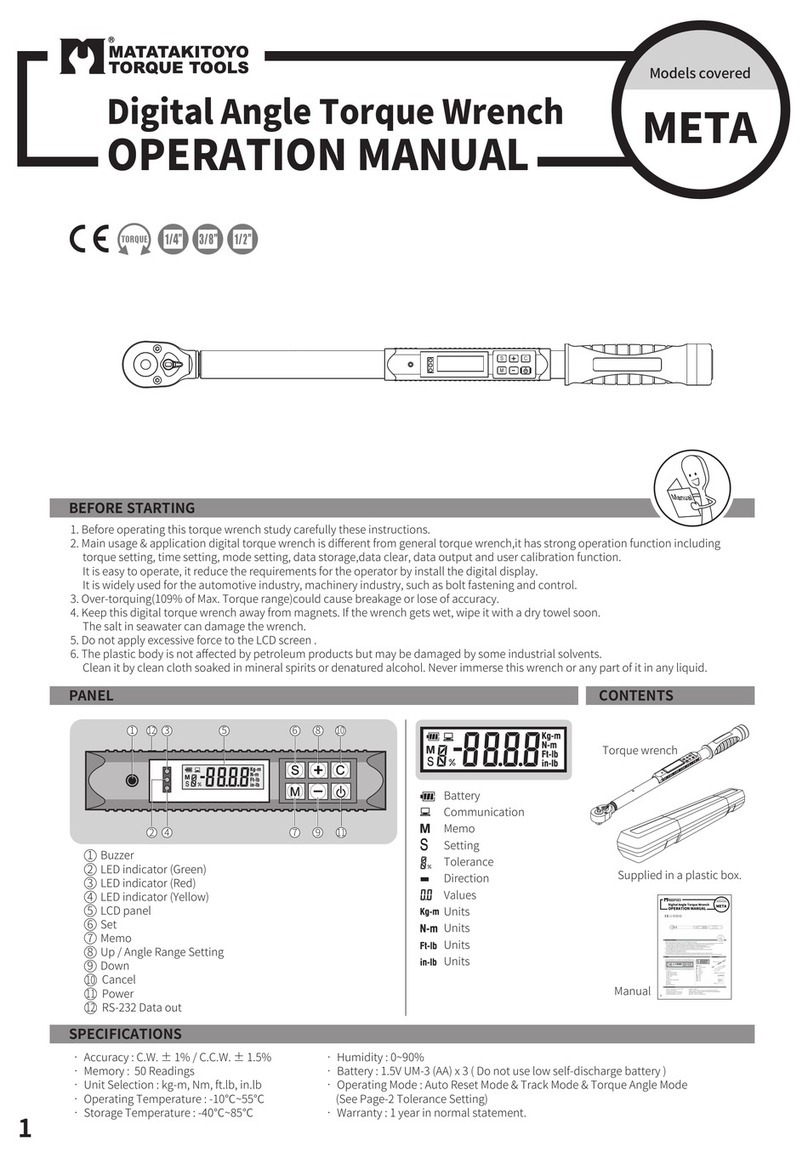

Matatakitoyo Torque Tools

Matatakitoyo Torque Tools META Operation manual