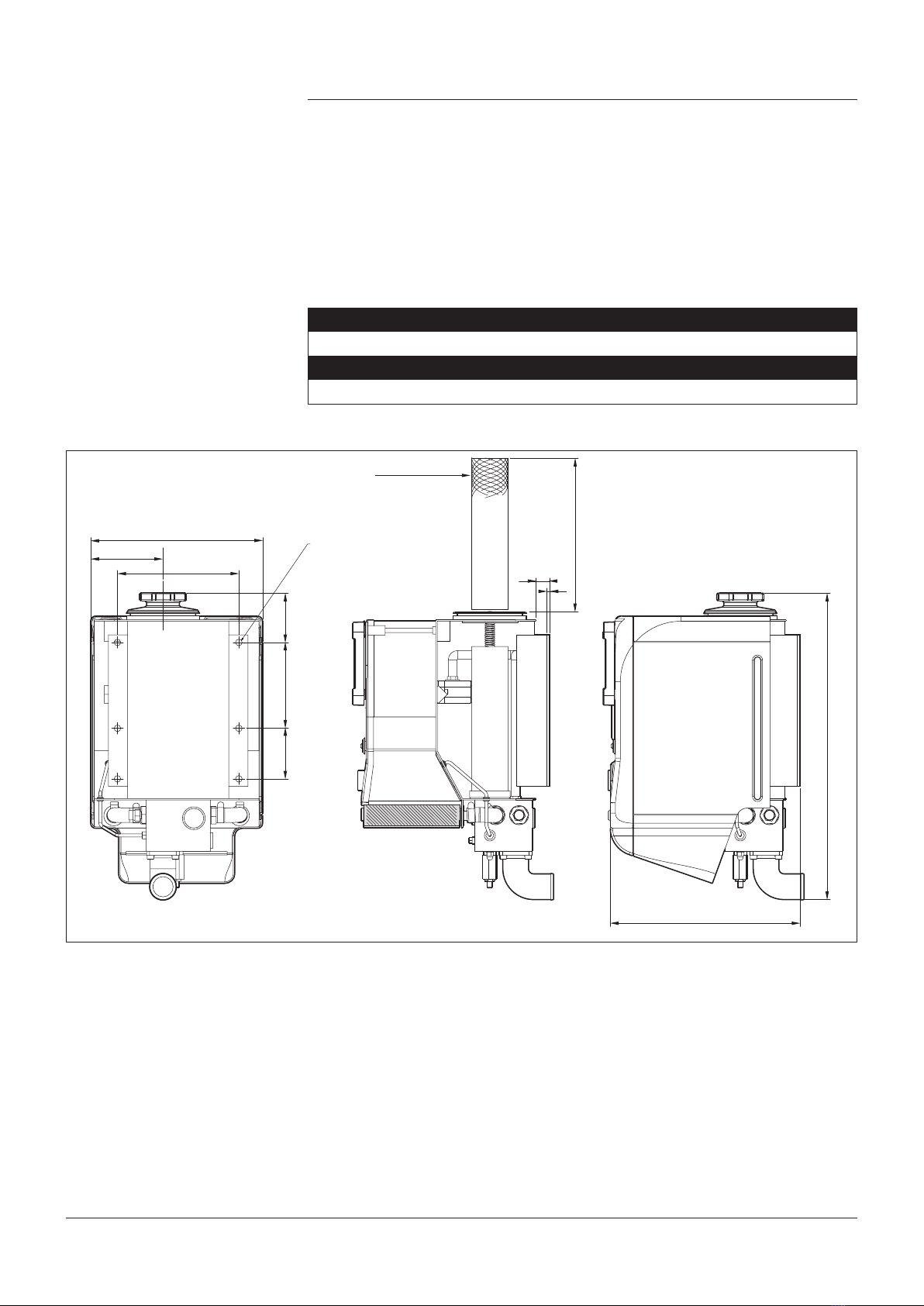

1. Allow a minimum space of 280 mm above the Hydrapak ller cap to

allow removal of the lter element when servicing.

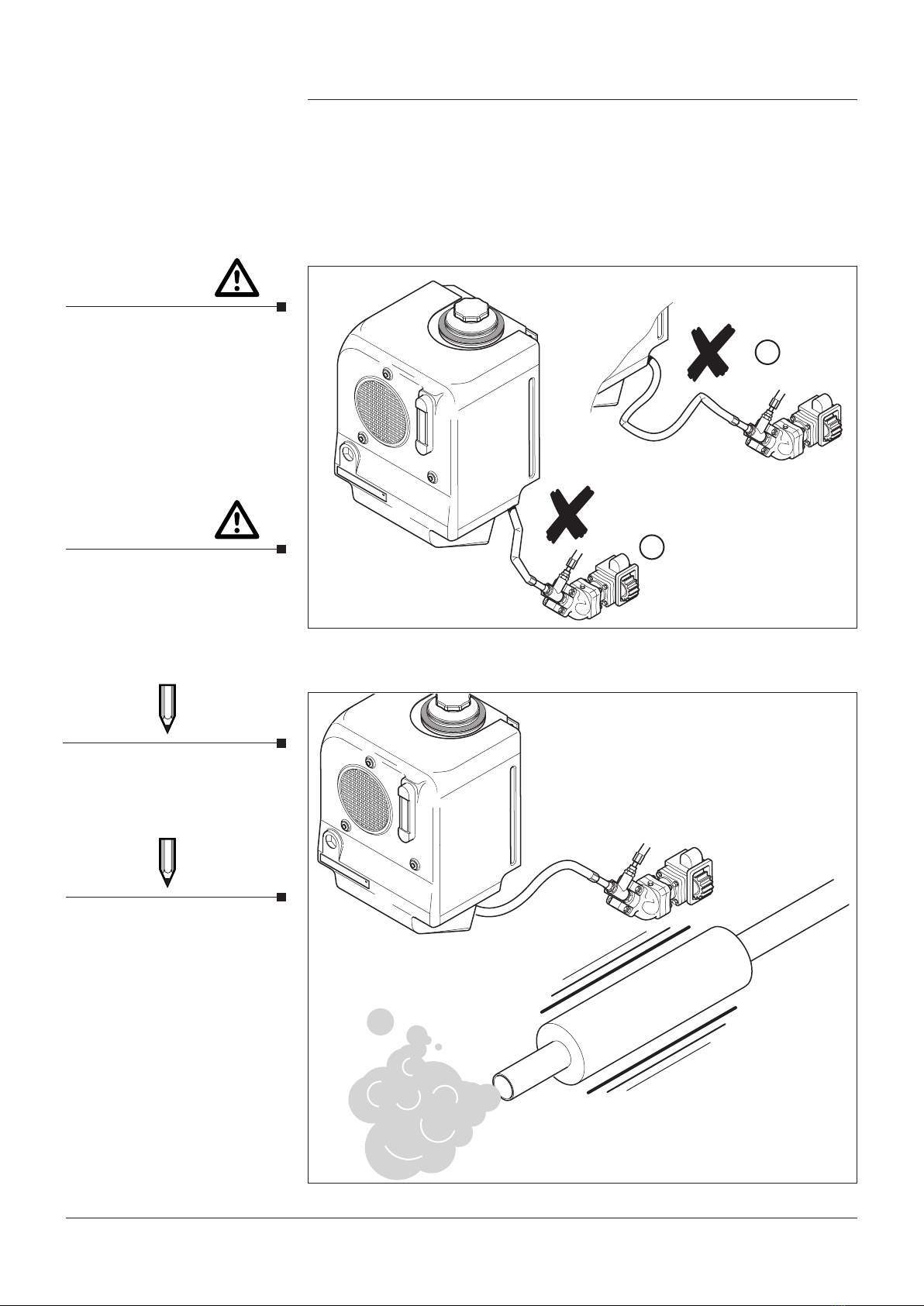

2. When retting ller cap, only tighten by hand. Do not use excessive

force as this will cause the tank to distort.

3. During installation it is important to make sure that the air inlet and

outlet ducts (shown below Fig 2) are not obstructed,

allowing a free ow of air for maximum cooling.

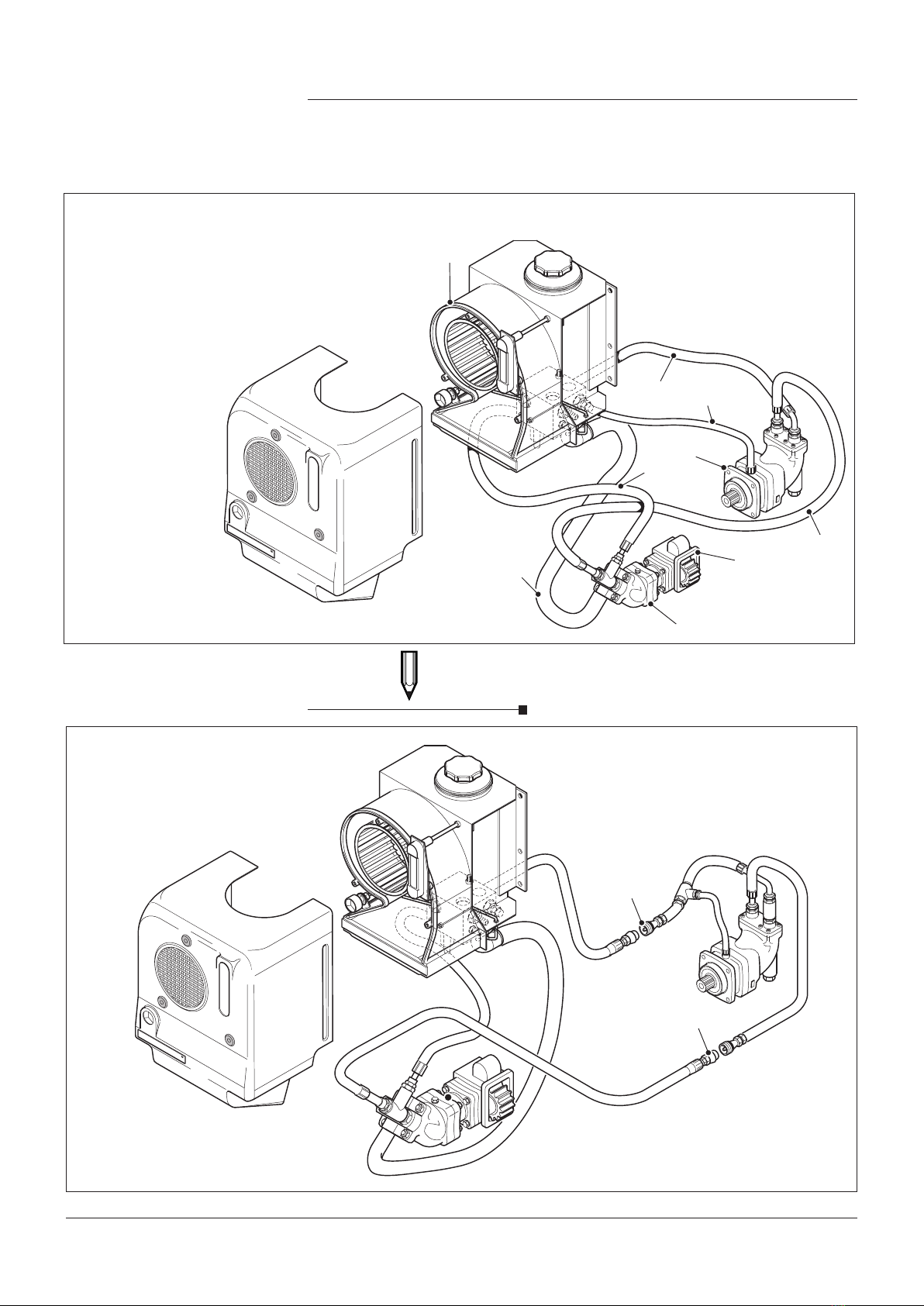

4. Typically ISO VG46 hydraulic oil will be suitable but the correct

viscosity for the hydraulic pump and motor (see manufacturers

instructions) will also suce for the Hydrapak. Ensure that the oil

level coincides approximately with the mid point of the sight glass.

Run the unit for 1 minute then top up the oil level if necessary.

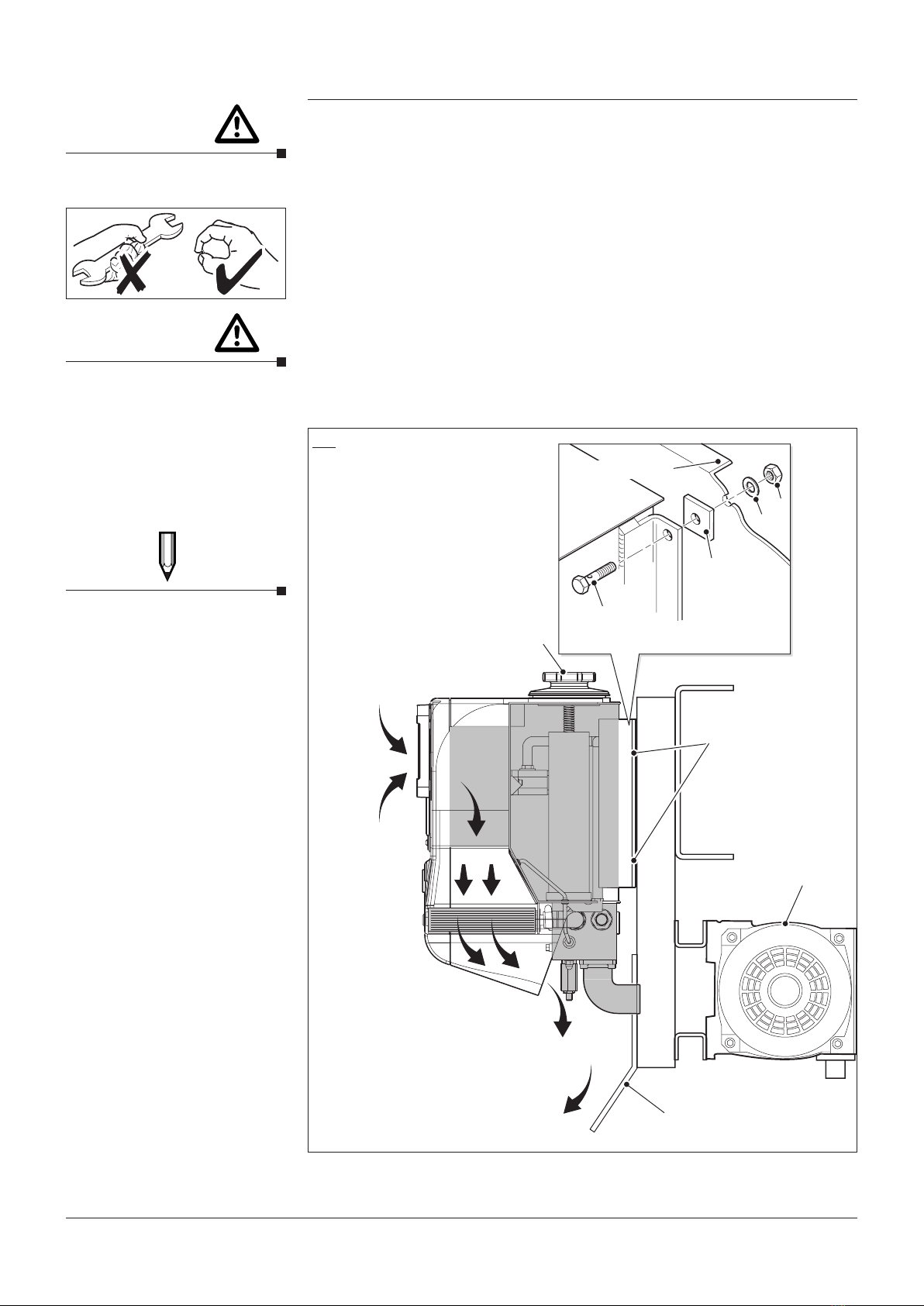

5. When the Hydrapak is sharing the same mounting uprights with a

compressor it is recommended that a deector plate is installed to

divert the hot air discharged away from the compressor. See Fig 2.

Installation

KEY

1. Chassis Frame

2. M12 Bolt

3. Anti-vibration Pad

4. M12 Washer

5. M12 Nut

6. Filler Cap

7. Typical Compressor Installation

8. Deector Plate

Fig. 2 Airow direction incorporating typical compressor installation.

1

AIR INLET

6

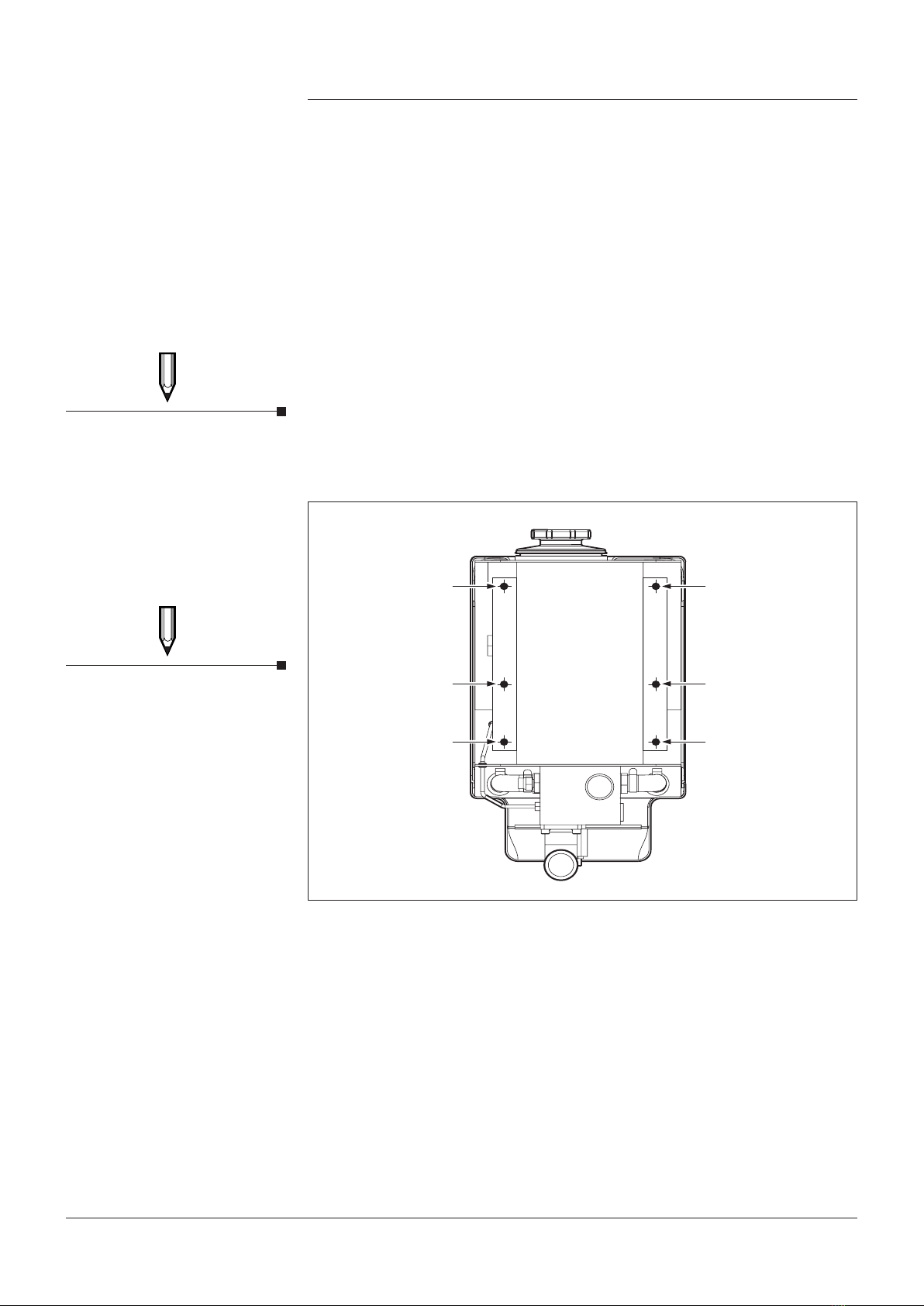

Mounting Points

7

8

HOT AIR OUT

2

3

4

5

Do not use excessive force

when tightening the Filler Cap.

CAUTION

Do not distort tank when

tting, ensuring tank is

secured using Anti-Vibration

pads as illustrated.

NOTE

When the Hydrapak is to be

used on cryogenic’s, specialist

hydraulic oils are used. The

Motor supply hose should be

changed accordingly.

See page 19 & 20 for correct

part number.

CAUTION

Page 7

4991015005 Date:02/18 Hydrapak Installation, Operating & Maintenance Manual