-VI-

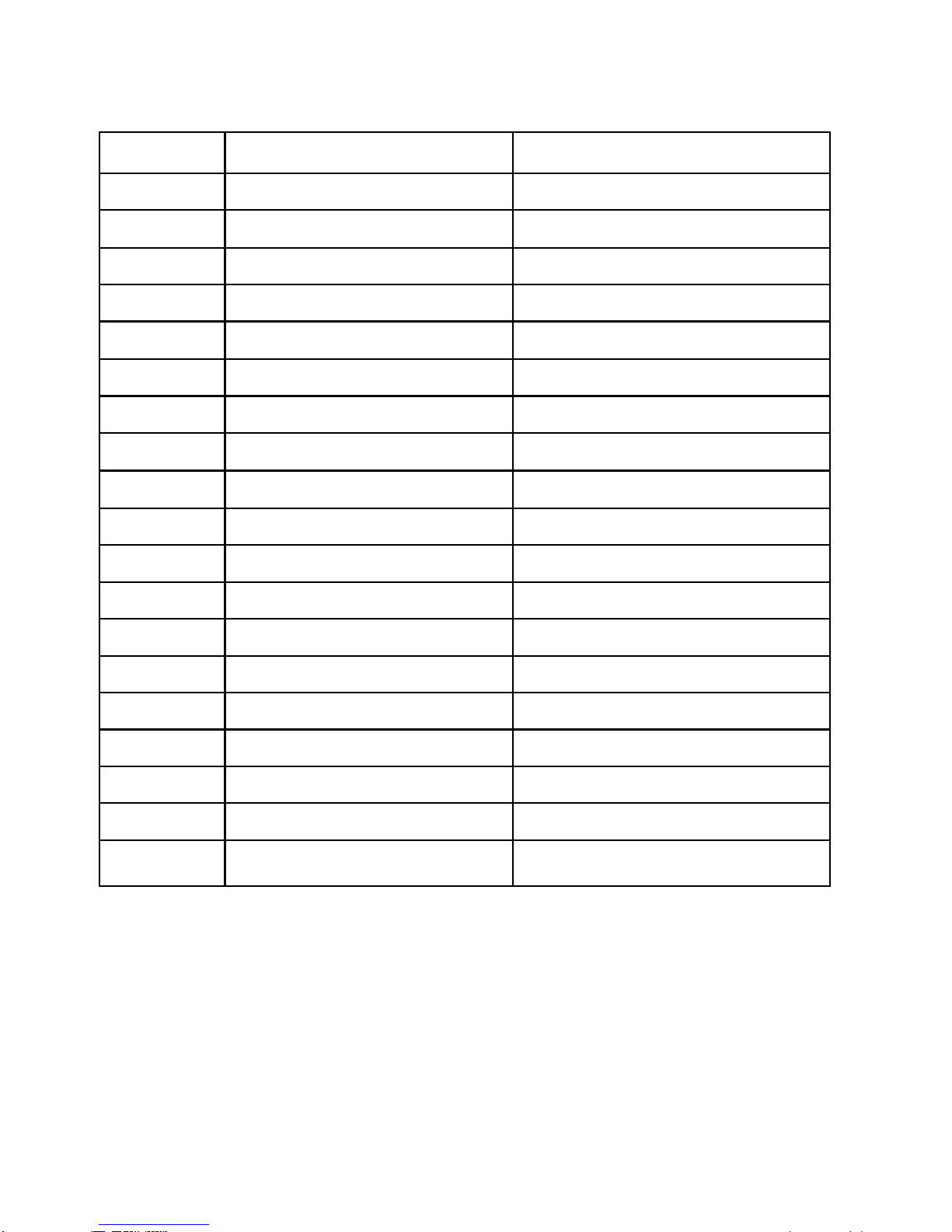

3) SET-UP ( F-FUNCTION AND SETTING )

F-Function FUNCTION CONTENTS

F00 S & C MODE CHANGE-OVER

F01 DECIMAL POINT POSITION

SETTING-UP

0, 1, 2, 3, LESS THAN(0, 0.0, 0.00,

0.000) THE DECIMAL POINT

F02 WEIGHT BACK-UP Normal, Back - UP

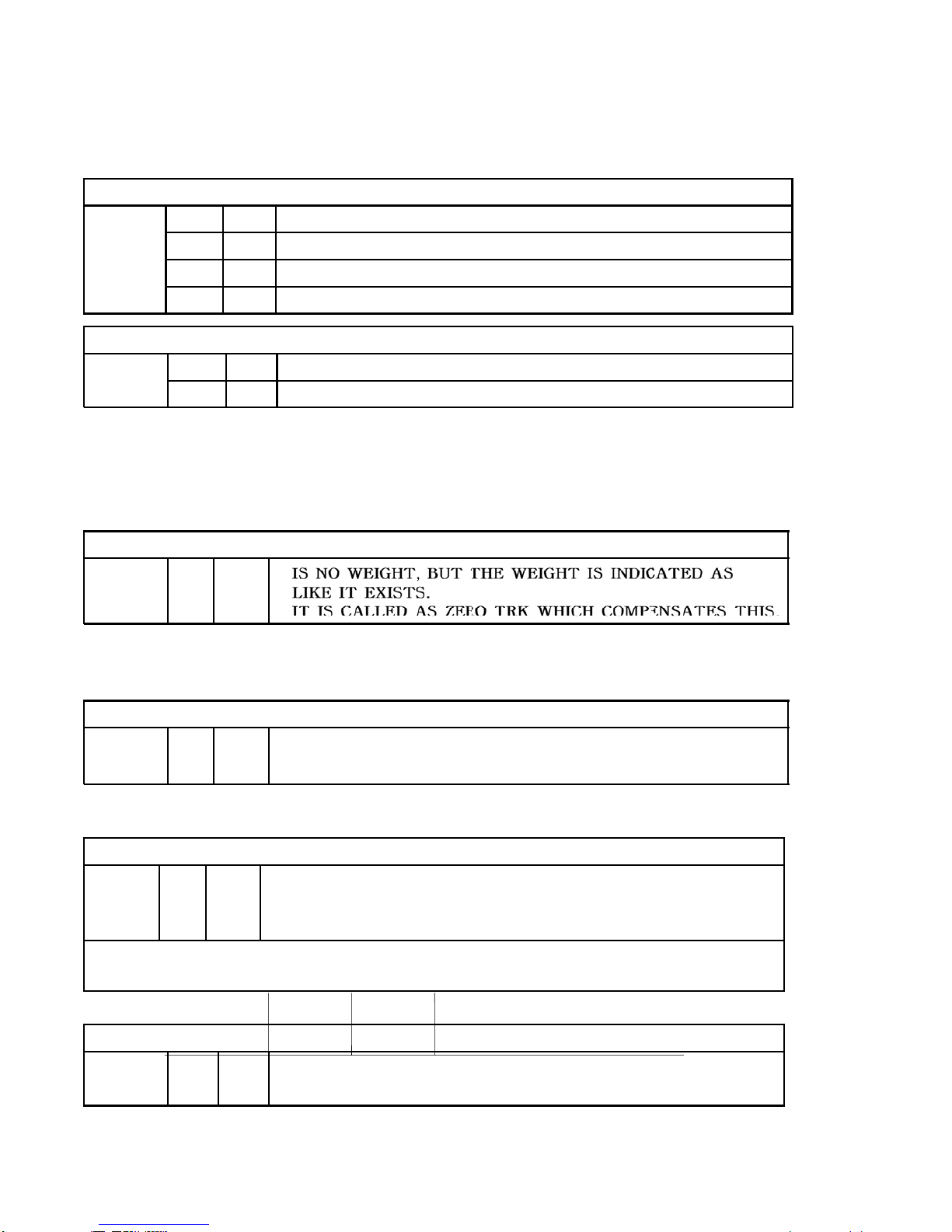

F03 ZERO TRK, SCOPE SETTING-UP 0 3~

F04 MOTION AND SCOPE SETTING-UP COMPENSATING THE MOMENT

MOTION OF 2, 5, 10 DIGIT

F05 AUTO-ZERO (AUTOMATIC ZERO) 00 99(AUTOMATIC ZERO SCOPE)~

F06 DIGITAL FILTER 0-9 (MOTION REDUCTING)

F07 VESSEL KEY OPERATION MODE STABLE & NON-STABLE

OPERATION MODE

F08 ZERO KEY OPERATION MODE STABLE & NON-STABLE

OPERATION MODE

F16 HOLD MODE PEAK, SAMPLE MODE

F17 HOLD INPUT MODE PULSE, LEVEL

F18 SAMPLE HOLD MODE MANUAL & AUTOMATIC

F20 PARITY MODE EVEN, ODD, NO PARITY BIT

F21 TRANSMISSION MODE STREAM, AUTO PRINT, PRINTKEY

F22 STABLE & NON-STABLE MODE STABLE & NON-STABLE DATA OUT

F23 TRANSMISSION METHOD RS232C, COMMAND MODE

F24 ID NUMBER NAME OF DEVICE (1-99)

F25 TRANSMISSION SPEED 300-9600 BPS

F99 WEIGHT-ADJUSTING CONSTANT

AMENDING MODE