Ducar DR40 User manual

carer / Lawn dethatcher

eratr ana

de

Before using your scarifier, please read this

manual carefully to understand the proper use of

your unit. Keep this manual handy.

Contents

1. Know your scarifier ........................................................... 3

2. Symbols marked on the product ............................................. 3

3. General safety information ................................................. 4

3.1 Training....... ........................................................................ 4

3.2 Preparation ......................................................................... 4

3.3 Operation......................... .................................................... 5

4. Layout and items supplied ................................................. 9

4.1 Layout .............................................................................. 9

4.2 Items supplied .................................................................. 9

5. Proper use .......................................................................... 9

6. Technical data ................................................................... 10

7. Before starting the equipment .............................................. 10

8. Operation ........................................................................... 11

8.1 Starting the equipment (Fig.6-7) ....................................... 11

8.2 Adjusting the working depth (Fig.8) .................................... 11

8.3 Stopping ............................................................................... 11

9. Cleaning, maintenance, storage, transport and ordering of

spare parts ........................................................................ 12

9.1 Cleaning ......................................................................... 12

9.2 Servicing ....................................................................... 13

9.3 Preparing the equipment for storage ................................ 14

9.4 Preparing the device for transport .................................... 15

9.5 Ordering replacement parts ............................................. 15

10.

Cleaning, maintenance and ordering of spare parts .......... 15

11.

Troubleshooting guide ..................................................... 15

12.

Warranty......................................................................... 15

2

3.4 Maintenance and storage .................................................... 5

1.Knowyourscarifier

Readthismanualcarefully,observingtherecommendedsafetyinstructionsbefore,during

andafterusingyourlawnmower.Followingthesesimpleinstructionswillalsomaintainyou

lawnmoweringoodworkingorder.Familiarizeyourselfwiththecontrolsonyourmower

beforeattemptingtooperateit,butaboveall,besureyouknowhowtostopyourmowerin

anemergency.

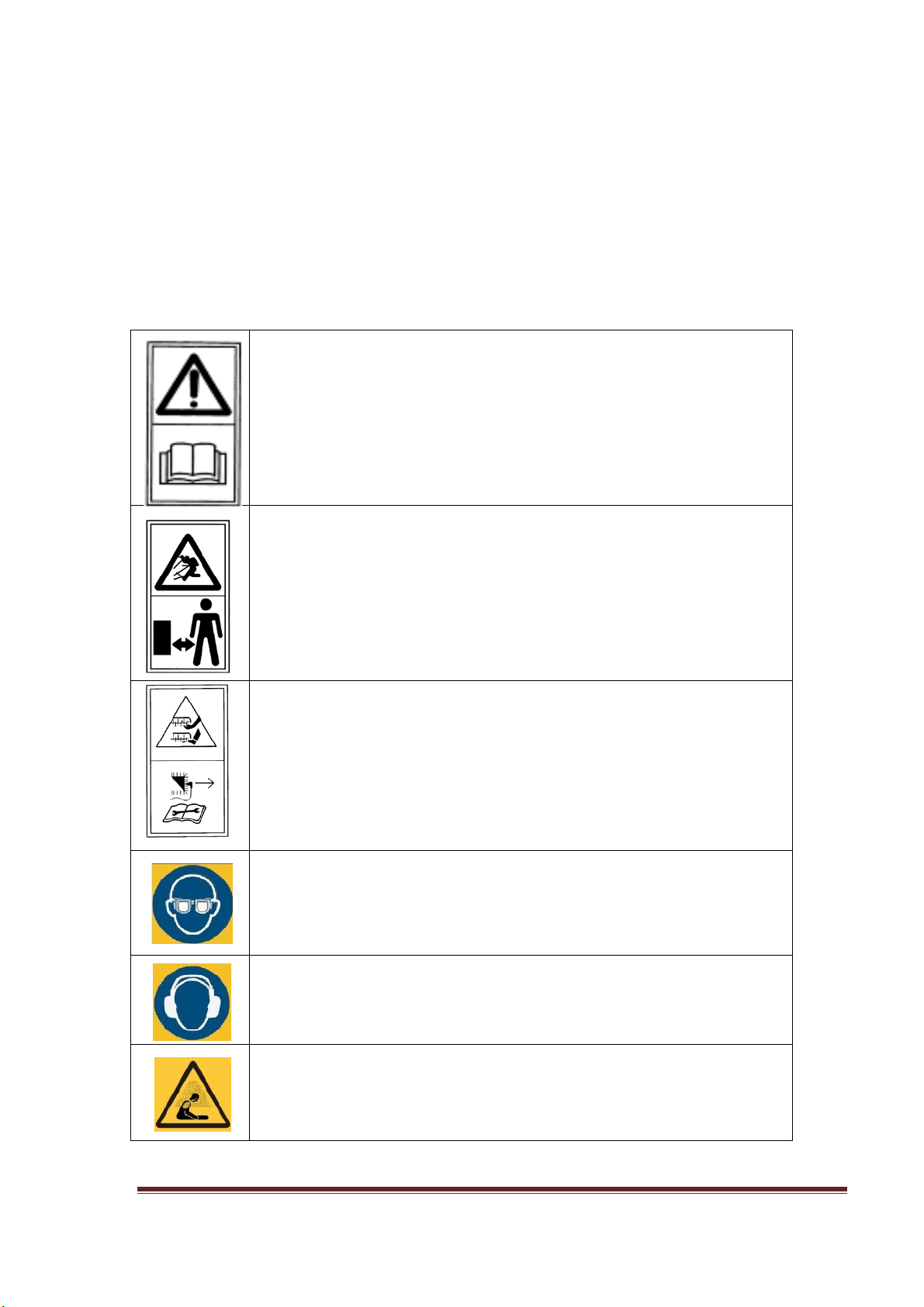

2.Symbolsmarkedontheproduct

Readthisinstructionbookcarefullybeforeusingthelawnmower

andkeepitinasafeplaceforfuturereference

Keepbystandersaway.

Sharptines‐Bewareofcuttingfingersortoes

Removesparkplug leadbeforemaintenance

Wear eye protection

Wear ear protection

Carbonmonoxide (CO)danger

3

4

3. General safety information

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

Read the operating instructions carefully. Be familiar with the controls and the proper use of

the machine. Local regulations can restrict the age of the operator.

3.1 Training

a) Read the instructions carefully. Be familiar with the controls and the proper use of the machine.

3.2 Preparation

a) Never allow people unfamiliar with these instructions or children to use the machine. Local

regulations can restrict the age of the operator;

b) never operate the machine while people, especially children, or pets are nearby;

c) operators should take care to prevent accidents to themselves or other people and damage to

property;

d) wear ear protection and safety glasses at all times while operating the machine;

e) while operating the machine, always wear substantial footwear and long trousers. Do not operate the

machine when barefoot or wearing open sandals;

f) thoroughly inspect the area where the machine is to be used and remove all stones, sticks, wires,

bones and other foreign objects;

g) WARNING — Petrol is highly flammable;

h) store fuel in containers specifically designed for this purpose;

i) refuel outdoors only and do not smoke while refuelling;

j) add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol while the

engine is running or when the engine is hot;

k) if petrol is spilled, do not attempt to start the engine but move the machine away from the area of

spillage and avoid creating any source of ignition until petrol vapours have dissipated;

l) replace all fuel tanks and container caps securely;

m) replace faulty silencers;

n) before using, always visually inspect to see that the tines, bolts are not worn or damaged. Replace

worn or damaged tines and bolts in sets to preserve balance;

o) for rear discharge appliances with exposed rear rollers, when used without a catcher, full eye

protection shall be worn.

5

b) operate the machine only in daylight or in good artificial light;

c) avoid operating the machine in wet grass or take additional precautions to avoid slipping;

d) always be sure of your footing on slopes;

e) walk, never run;

f) always work across the face of slopes, never up and down;

g) exercise extreme caution when changing direction on slopes;

h) do not operate the machine on steep slopes;

i) use extreme caution when reversing or pulling the machine towards you;

j) stop the tines if the machine has to be tilted for transportation. Do not operate the tines when crossing

surfaces other than grass, and when transporting the machine to and from the working area;

k) never operate the machine with defective guards, or without safety devices, for example deflectors

and/or catchers, in place;

l) do not change the engine governor settings or over-speed the engine;

m) disengage all tine and drive clutches before starting the engine;

n) start the engine carefully according to instructions and with feet well away from the tine(s);

o) do not tilt the machine when starting the engine, except if the machine has to be tilted for starting. In

this case, do not tilt it more than absolutely necessary and lift only the part which is away from the

operator;

p) do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all times;

q) never pick up or carry a machine while the engine is running;

r) avoid operating the machine in bad weather conditions especially when there is a risk of lightning;

s) stop the engine, disconnect the spark plug wire and for battery start machines remove the

ignition key:

1) before clearing blockages or unclogging chute;

2) before checking, cleaning or working on the machine;

3) after striking a foreign object. Inspect the machine for damage and make repairs before restarting

and operating the machine;

4) if the machine starts to vibrate abnormally (check immediately);

t) stop the engine, disconnect the spark plug wire and for battery start machines remove the

ignition key:

1) whenever you leave the machine;

2) before refuelling;

u) reduce the throttle setting during engine shut down and, if the engine is provided with a shut-off

valve, turn the fuel off at the conclusion of aerating or scarifying.

3.4 Maintenance and storage

a) Keep all nuts, bolts and screws tight to be sure the machine is in a safe working condition;

b) never store the machine with petrol in the tank inside a building where fumes can reach an open

flame or spark;

c) allow the engine to cool before storing in any enclosure;

d) to reduce the fire hazard, keep the engine, silencer, battery compartment and petrol storage area

free of grass, thatch, moss, leaves or excessive grease;

e) check the catcher frequently for wear or deterioration;

f) examine the machine regularly and replace worn or damaged parts for safety;

3.3 Operation

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions