Page 2

Contents

Introduction

Assembly

Fixing

Rolling code remote

control

Power adjustment

1. Contents of kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3

2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3

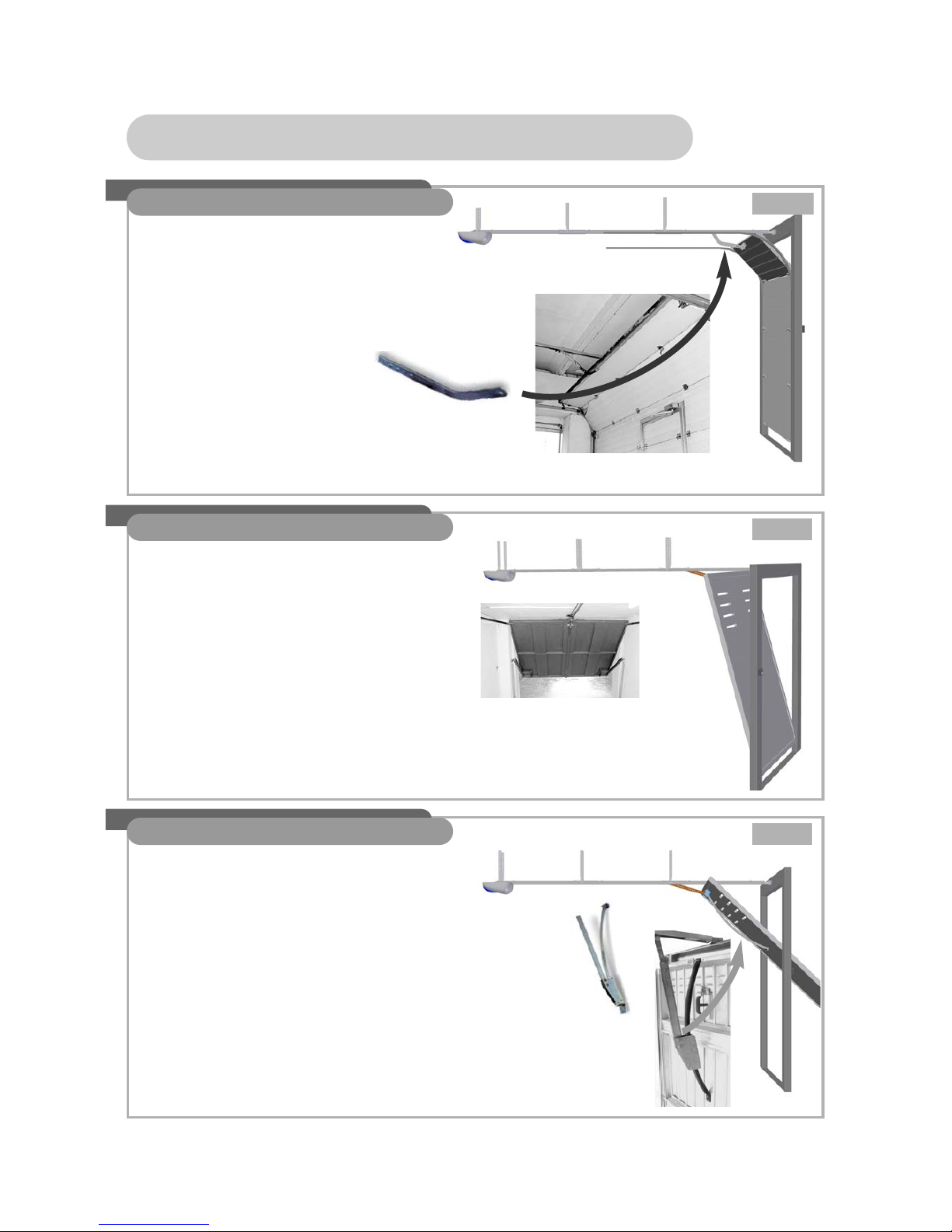

3. Types of door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4

4. Installation criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 5

5. Installation diagram . . . . . . . . . . . . . . . . . . . . . . . . . .page 6-7

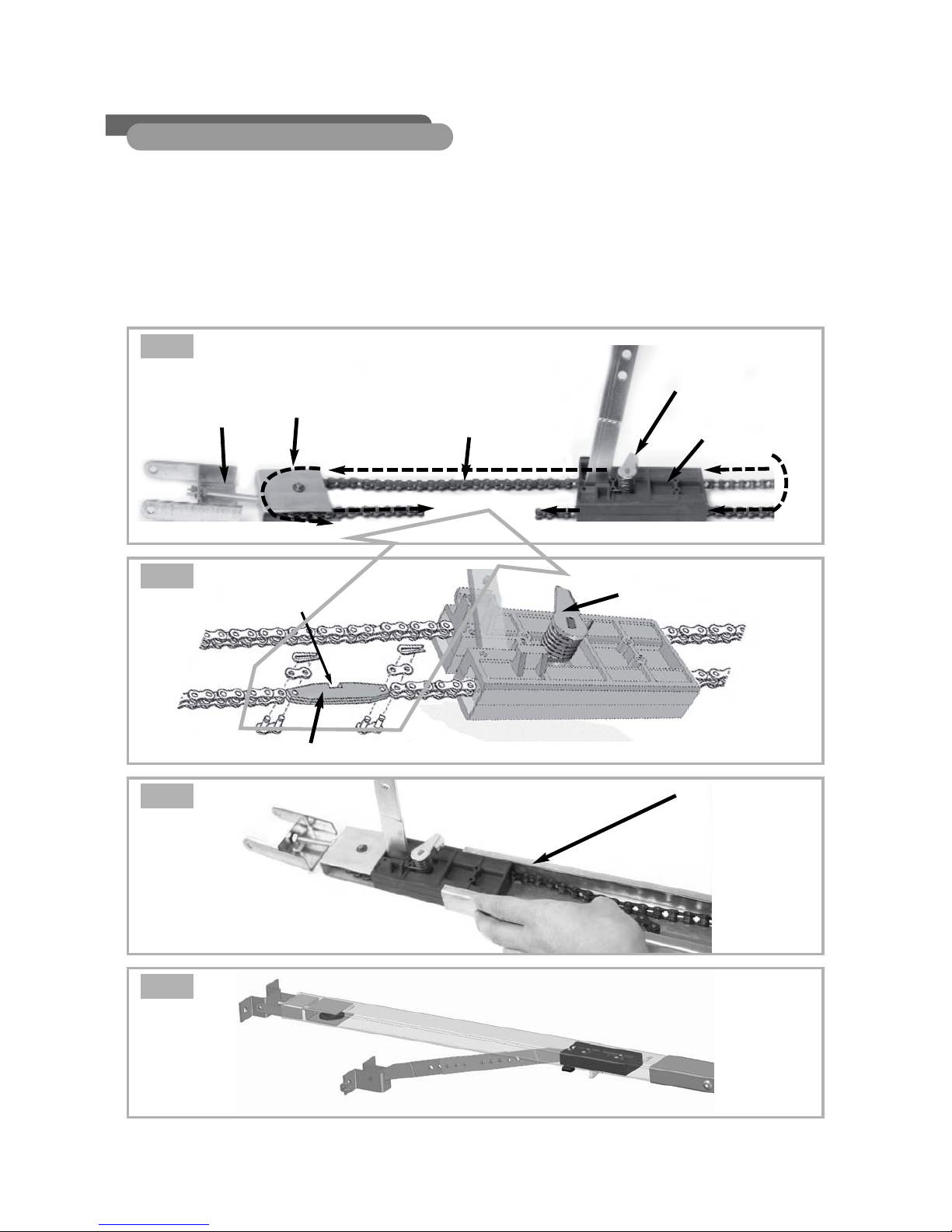

6.1 Assembly of the “U” channel rail . . . . . . . . . . . . . . . . . .page 8

6.2 Return pulley and preassembled accessories . . . . . . .page 8

6.3 Assembly of the chain . . . . . . . . . . . . . . . . . . . . . . . . .page 9

6.4 Assembly of the drive plate . . . . . . . . . . . . . . . . . . . .page 10

7.1 Fixing to the door lintel. . . . . . . . . . . . . . . . . . . . . . . . page 11

7.2 Fixing the drive head . . . . . . . . . . . . . . . . . . . . . . . . . page 11

7.3 Fixing to the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

7.4 Chain tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Release 8. Manual release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 13

End of travel 9. Adjusting the mechanical end-of-travel stop . . . . . . . .page 14

Power supply

connection

10. 230V power supply connection . . . . . . . . . . . . . . . . . .page 14

11. CTH29E circuit board . . . . . . . . . . . . . . . . . . . . . . . . .page 15

12. A) Storing the transmission code . . . . . . . . . . . . . . . .page 16

12. B) Erasing codes from memory . . . . . . . . . . . . . . . . .page 16

13. Power adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 16

Accessoires 14. Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . .page 17

Troubleshooting 16. Quick troubleshooting: . . . . . . . . . . . . . . . . . . . . . . . .page 17

CE Conformity 17. Declaration of conformity . . . . . . . . . . . . . . . . . . . . . .page 18

Guarantee and

After-Sales Service

18. Guarantee and After-Sales Service . . . . . . . . . . . . . .page 19

Spare parts Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 19