Domino

DFDALI

✗The code 128 is required onl to inform DFDALI when interrupt

a running function. For instance, to perform an Up function, the

code 125 must be sent: the brightness will increase until the

sending of code 128.

✗The code 139 saves, in the non volatile memor of the bal-

lasts, the brightness level which will be automaticall recalled

when a DALI or Domino bus failure occurs.

✗The change from a brightness level to another one will be ex-

ecuted according to a ramp that can be set as desired b the

codes 140 to 173. The ramp value will be stored in the non

volatile memor of the ballasts, therefore a power failure does

not affect it.

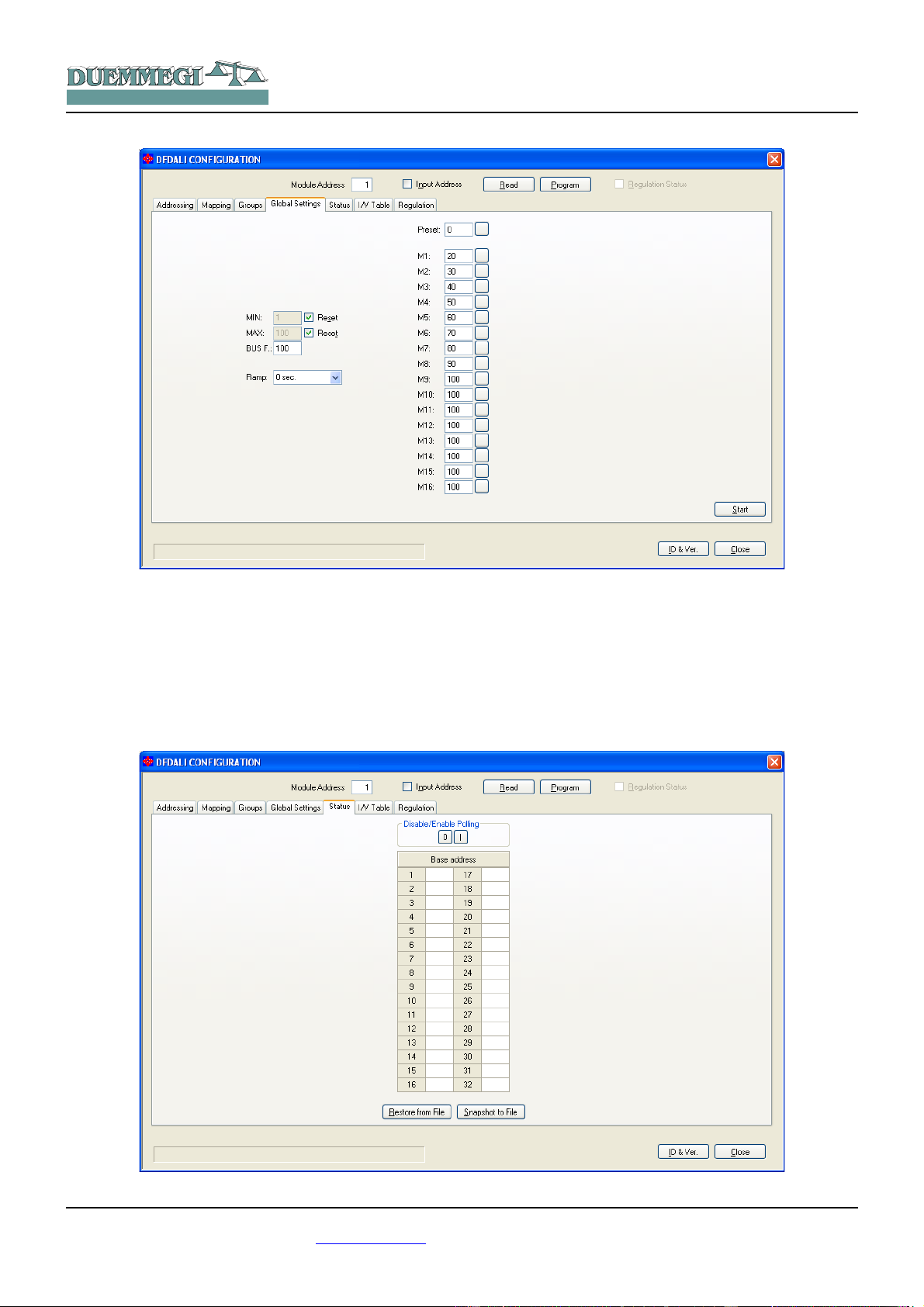

Management by DF P or by I/V table

The sending of commands or values to DALI devices can

be performed through a supervisor simpl writing the

memor locations of DFCP related to the output of the in-

stalled DFDALI modules.

As option, or in addition, it is possible to send commands or

value from DFCP to the DALI module through proper equa-

tions as in the following example:

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(128)V1 & \

P(125)I1.1 & P(126)I1.2 & \

P(50)I1.3

where I1.1 and I1.2 are, for instance, the Up and Down

inputs and AO2 is DFDALI module with address 2; I1.3

will set the brightness to 50%. The specified value, at each

variation, will be transferred to the DALI output (AO2). At

the releasing of each pushbutton, the value is alwa s set to

128 (no operation, but needed to inform the module about

the releasing of the buttons). In this case the described Up,

Down and Preset functions acts on all connected ballasts

(broadcast commands).

To get the same result on a ballast individuall addressed,

it is easiest (even if not mandator ) to use the hexadecimal

format to write the equations, because the address of the

ballast has to be specified in the high b te of the channel:

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(0x0180)V1 & \

P(0x017D)I1.1 & P(0x017E)I1.2 & \

P(0x0132)I1.3

where I1.1 and I1.2 are the Up and Down inputs and

AO2 is DFDALI with address 2; I1.3 will set the brightness

to 50%. The specified value, at each variation, will be trans-

ferred to the DALI ballast addressed 1. At the releasing of

each pushbutton, the value is alwa s set to 0x0180 (no

operation, but needed to inform the module about the re-

leasing of the buttons).

A similar example follows to send command to a group of

ballasts:

V1 = !(I1.1 | I1.2 | I1.3)

AO2 = P(0x8180)V1 & \

P(0x817D)I1.1 & P(0x817E)I1.2 & \

P(0x8132)I1.3

The specified value, at each variation, will be transferred to

the DALI devices assigned to group 1. At the releasing of

each pushbutton, the value is alwa s set to 0x8180 (no

operation, but needed to inform the module about the re-

leasing of the buttons).

Of course the commands to DALI devices can be also sent

b DFCP through the using of the Scripts.

DFDALI module can however work without DFCP control-

ler, simpl linking the desired commands to bus input

points (both real and virtual ones); for details about this

possibilit , refer to the paragraph I/V Table.

Manual commands by the module

pushbutton

Near to the terminal block of DALI line, a pushbutton allows

the following functions: a short pulse will cause the com-

plete switching ON and OFF, while holding down the button

the brightness increases or decreases depending on previ-

ous action (ever next continuous pressing will invert the

previous one).

This pushbutton is useful during the setting up of the plant.

Diagnostic of DALI line by yellow LED

The ellow LED, located near the just described pushbut-

ton, continuousl flashes during normal operation. Since

the DALI line is continuousl polled in a sequential wa ,

thus the LED flashes in the same wa , even if DFCP con-

troller is not connected.

The ellow LED will be fixed lighted when one or more of

the following events will occur on the DALI line:

•Lamp failure

•DALI line broken or no ballast connected

•Short circuit on DALI line

In the case of short circuit, an automatic procedure will tr

to restore the line, thus allowing to module to return to to

the normal operation with a maximum 15 sec dela after

the short circuit condition has been removed.

The LED will be instead switched off if the DALI section of

the module is not supplied or if the polling has been dis-

abled. In an case, the occurred problem can be discrimin-

ated b the map of DCP IDE or BDTools or b a supervisor

or video-terminal connected to DFCP (reading input chan-

nel as described in the related paragraph).

Note:

✗In lamp failure condition, it is not possible to know on which

DALI device this event occurred.

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.1 Ma 2013 Page 4 of 11

HOME AND BUILDING AUTOMATION