Contatto

ModDALI

The specified value, at each variation, will be transferred to

the DALI output AO2:1). At the releasing of each pushbut-

ton, the value is always set to 0x0080 no operation, but

needed to inform the module about the releasing of the

buttons).

A similar example is true to send command to a group of

ballasts:

V1 = !(I1.1 | I1.2 | I1.3)

AO2:1 = P(0x0080)V1 & \

P(0x817D)I1.1 & P(0x817E)I1.2 & \

P(0x8132)I1.3

The specified value, at each variation, will be transferred to

the DALI devices assigned to group 1 on the channel

AO2:1). At the releasing of each pushbutton, the value is

always set to 0x0080 no operation, but needed to inform

the module about the releasing of the buttons).

Of course the commands to DALI devices can be also sent

by MCP through the using of the Scripts.

Commands rom the ront panel

Four pushbuttons on the front panel, related to each DALI

line, allow the following functions: a short pulse will cause

the complete switching ON and OFF, while holding down

the button the brightness increases or decreases depend-

ing on previous action every next continuous pressing will

invert the previous one). These pushbuttons are useful dur-

ing the installation procedure.

Meaning o the LEDs on the ront panel

For each DALI line, the related LED continuously flashes

during normal operation. Since the four lines are sequen-

tially polled, thus the LEDs flash in the same way, even if

MCP controller is not connected.

The LEDs on the front panel will be fixed lighted when

these one or more of the following events will occur on the

related DALI line:

•Lamp failure

•Dali line broken or no ballast connected

•Short circuit on DALI line

In the case of short circuit, an automatic procedure will try

to restore the fault line, thus allowing to module to return to

to the normal operation with a maximum 15 sec delay after

the short circuit condition has been removed.

All the LEDs will be instead switched off if the DALI section

of the module is not supplied terminals 19-20) or if the

polling has been disabled.

In any case, the occurred problem can be discriminated by

MCP Visio or by a supervisor or video-terminal connected

to MCP reading input channel as described in the related

paragraph).

Note:

In lamp failure condition, it is not possible to know on which

DALI device this event occurred: it is only possible to know on

which of the 4 lines of ModDALI the failure is present.

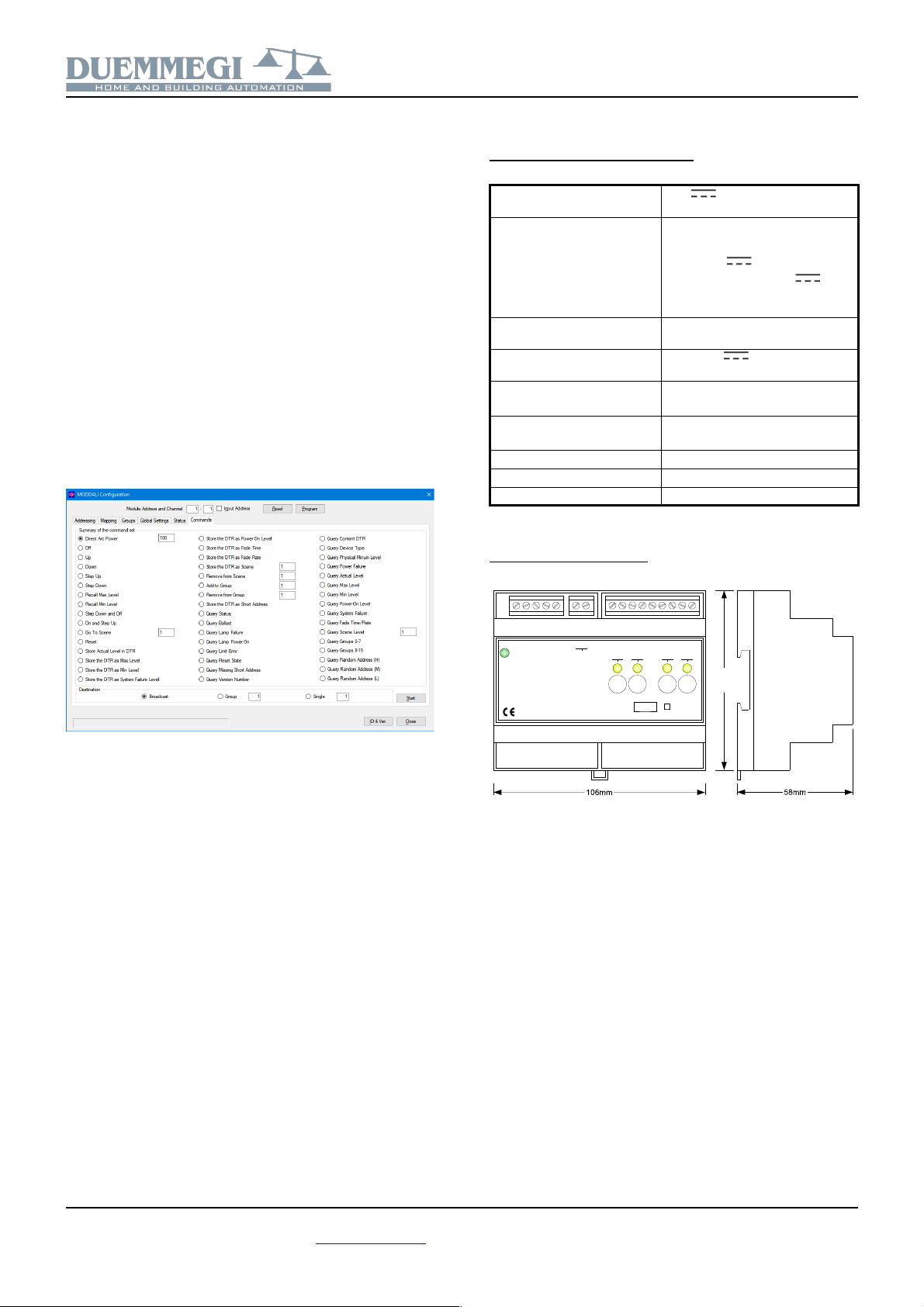

Setting the operating parameters

MCP IDE allows to set the operating parameters of each

DALI channel and to perform some diagnostic functions.

The setting up is performed via the Contatto bus and MCP

through a specific configuration panel which can be opened

selecting, from the menu of MCP IDE, “Configuration”,

“Lighting Gateway” and then “MODDALI”. The window in

Figure 3 will be shown. The following refers to the standard

version, but the procedures for the special version are

similar.

This configuration panel allows to set the main parameters

and some other options as described in the following of this

paragraph. Before to proceed with any other action, the

communication with MCP has to be enabled.

The top side of the DALITools window reports the section

for the addresses management. After having entered the

address of the ModDALI to be managed, it is possible to

enable the input address of the module through the check

box named “Input Address” and then clicking on the button

Program; by the button Read it is instead possible to check

the current setting, after having specified the desired mod-

ule address and the channel.

Six tabs in the window allow some well defined functions as

described in the following.

The button ID & Ver. on the lower side allows to read the

firmware version of the selected ModDALI module.

Addressing

3 mutually exclusive functions are available::

Set the address. In the first case, an address will be as-

signed to all the connected ballasts, and the starting ad-

dress can be chosen the typical value is 1). This type of

addressing assigns consecutive values, in the range 1 to

32, to the ballasts in a random order.

If some ballasts on the selected channel have been previ-

ously addressed and some other ballasts have to be

added, the addressing procedure can be performed without

any modification to the previously assigned addresses. A

timer icon will inform that the operation is running.

At the end of the procedure, the normal mouse icon will be

restored.

The time required for this procedure is about:

T = 5sec + 5sec x “nr. of ballasts”)

Remove the address. If some addressing or reconfiguration

errors occurred, it can be useful removing the address of all

the ballasts on the line or of a well specified ballast.

Restore the factory setting. The DALI ballasts are factory

set without any address and with a basic configuration for

the main parameters; the following table shows a typical

default configuration:

Parameter Value

Minimum brightness level 1%

Maximum brightness level 100%

Brightness level in failure condi-

tions

100%

Ramp value 0 seconds

Preset None

DUEMMEGI s.r.l. - Via Longhena, 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 2.4 October 2017 Page 5 of 9